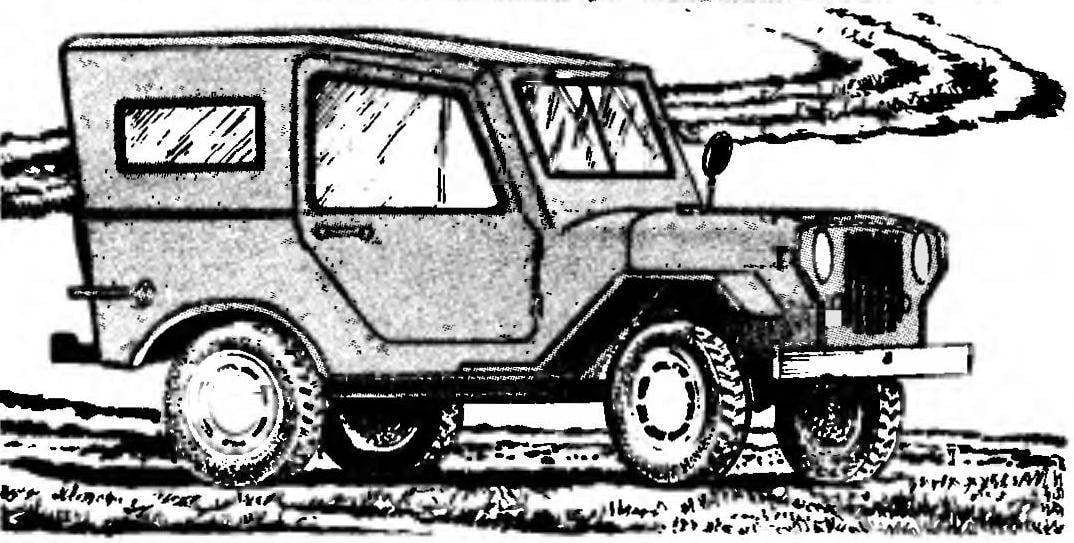

The vehicles of the “jeep” has always attracted Amateur by automakers its pronounced functionality: as they say, a jeep is a machine “advantage.” And, of course, the plainness of the external forms and the complete absence of surfaces with double curvature — and therefore, easy manufacturing of the body from any sheet material, ample inner space. In short, the machine with the appearance of the jeep will always be preferable for those who starts creating his very first vehicle. It was decided to develop a car like the jeep. However, the portrayal of the machine was that the plainness of its external forms is only apparent, and create a truly original body is very, very difficult. All of my “designer” refinements led eventually to the appearance of the paper machine is clearly artisanal. In the end had to turn to classical models by taking as a basis the famous “jeep” of the forties. In fact, I do, in General, a layman in design, to compete with the professionals who created a kind of reference appearance of this vehicle.

Your car I intended to design with the extensive use of components and assemblies motorized FDD. Mapping its track and the track of the station wagon revealed a conversion factor of size, then on the drawing Board appeared the outline of my car, almost repeating an appropriate scale and contours of the prototype. However, to my great regret, to make a mini-jeep scale copy of the “jeep” failed: size of wheels, anthropometric parameters of the driver and passengers, the location on the car engine and other units — all forced to make new adjustments to the design. The result was a car made, in essence, “based on” the legendary jeep, which got (maybe somewhat strange for such a machine) the name “Elf-TX”. It’s something I want to present to the readers of the journal “modelist-Konstruktor”.

A few words about the technical data of my replicar (the so-called machine, copying the outward signs of vintage cars). “Elf-kind” is a four seater two-door car. Structural diagram — front-wheel drive car frame design with a rear engine forced air cooling working volume of 350 CC. the car Body is a combined wood-metal. The front and rear axles of the mini-jeep is almost the same — both made with the front axle of the sidecar FDD. The front axle of the jeep, however, has changed considerably in order to organize the front-wheel drive. How it happened is shown in the drawings of my car.