Needless to say, it’s nice to warm up in chilly or cold weather at home (whether Dutch or European fireplace), and even admire them, if it is done skillfully. And good Russian stove — the heat capacity, multifunction. But it requires a lot of space, and to fold her, like a fireplace, under force, perhaps, only an experienced professional. But the farm — cottage, garden or rural — can not do without ovens simpler to manage in addition to space heating, and many everyday tasks: cooking for the household and fodder for domestic animals, water heating, drying of berries and fruits, as well as clothing and shoes.

To help out in this case, the oven even without grace, but the universal set, of course, not in the living room, and in any utility room or freestanding construction: the bath, summer kitchen, shed or even under a canopy.

Design of two such welded steel furnaces are given in the published material. The disadvantages of metal (steel) furnace include their low thermal inertia, i.e., poor accumulation of heat. And this is true for the heating of furnaces, when required of them a considerable accumulation of heat in the furnace, and then a gradual long-term heat needed in homes with a permanent residence.

But this deficiency has resulted in many cases of advantage when, for example, the desired rapid heating of the premises during firing and short-lived cooling after the furnace. This quality furnace preferably in the cottage and garden homes, where the owners are in the cold season are only short-term visits. A long slow warm up is economical furnace in “gas” mode.

We offer furnaces, at first glance similar to each other, as it is made from the same materials, are composed of homogeneous interconnected functional units: a boiler, a drying rack, water tank and chimney, the dimensions of which vary slightly.

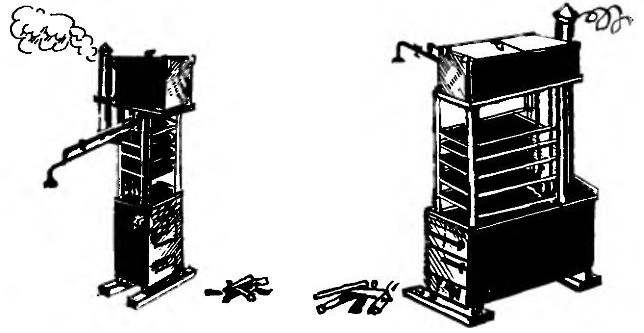

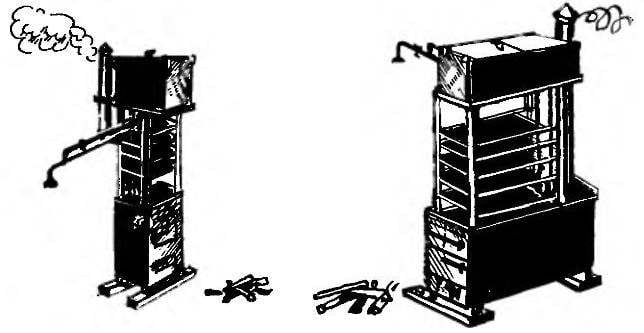

Steel universal ovens (a — country b — with heater):

1 — leg (angle steel 50×50); 2 — ash; 3 — furnace; 4 — plate (in option “a” — removable, in the embodiment b — stationary); 5 — barbecue (supports for skewers); 6 — Dutch oven; 7 — oven; 8 — water tank; 9 — guides for protine (steel angle 25×25); 10 — water tank (steel sheet s2); 11 — cap of the chimney (plate s0.8); 12 — flue (plate s1); 13 — mounting brackets (steel angle 50×50); 14 — supporting rack (angle steel 50×50); 15 — gate valve; 16 — bolt; 17 — a cover of tank (steel sheet s2); 18 — piece (1/2″); 19 — valves (1/2″); 20 — cold water riser (pipe 1/2″); 21 — risers hot water (pipe 1/2″); 22 — tray; 23 — coupling (1/2n); 24 — fasteners (bracket, bolt); 25—groundsel (timber concrete); 26 — ash door; 27 — furnace door; 28 — dverki ovens; 29 — drain valve; 30 — bolt; 31 — handshower; 32 — hopper for stones; 33 — door of the heater; 34 — grate. ( The flat parts of the boiler are made of steel sheet s4).

The main differences in the construction of the heating units (boilers), which we will start the description of the devices of both furnaces. The first of them (Fig. a) the boiler is welded from steel sheet 4 mm thick and consists of the following components, and more specifically, cameras: ash (he’s ash pit) furnace with a grate at the bottom and removable oven with hob top, oven with supports for grills and skewers, and hot water tank.

Cover plates and slide gate valve to regulate the direction and flow of the flame of combustible gases of the combusted fuel or the heat of the burning coals. Draft in the furnace is regulated by opening the ash door (the size of the throat blew).

The base of the chimney passes through the water tank, which provides a more rapid heating of the water and increases the efficiency of the furnace.

The walls of the furnace lined with refractory bricks, which protects them from rapid “burn-out” and slightly increases the thermal inertia.

Heating block of the second furnace a bit lower, but “deeper”. It has the same set of nodes (cameras), and the boiler in the first furnace, and even the bunker with stones. The last node allows the use of this variant of the heating unit

tion as a heater in the bath or sauna. An array of stones besides greatly increases the thermal inertia of the furnace.

Outside the bunker there is a door. Through it is the initial load of stones in the bunker, and the main water supply to generate steam. In the partition separating the hopper from the other cameras of the boiler has two holes for the passage of combustible gases: the first from the oven, second from the furnace. The last hole if necessary (do not require heating of the array of stones) block valve, do not forget to open the burner in the stove of the oven to pass from the furnace into the pipe of hot air.

Drying racks ovens, as well as the top of the water tank, similar in construction and differ only in size depending on the basic units — boilers.

Rack shelving is made of steel angle 50×50 mm. Such a large cross section taken because struts serve as supports for heavy containers with water. Are welded thereto a lateral horizontal guides, on which are prot-blame. Racks are mounted on the cover of the water tank and attached by bolts to the ribs (protrusions of the walls) the heating block. Top rack wrapped frame from the same area, which serves as a platform for capacity. For heating water in the tank connected to the hot water tank cold and hot risers, forming a water circulation system. For quick hot water in the lower tank of the system overlaps two valves on the risers.

For the device the soul of the risers hot and cold water taps made with their valves. The taps are connected to the mixing head.

For heating greenhouses or buildings with hot-water heating system connected to the riser pipe of the system, which circulates heated water.

Chimneys at both kilns are made of tin and is made in shell form (without a separate base).

The proposed design of the stoves tested for the prototype for multi-year operation.

V. HORT, Kiev

Recommend to read FROM THE CLOUD — IN FAUCET Almost every rural or suburban home on the corner, under the gutters is a barrel for collecting rainwater. This, of course, the easiest option, but if m only! Remember: around this place... DECORATIVE CANDLES These elegant candles will easily fit into any modern interior. Their Golden lights create a home atmosphere of coziness and warmth, give a special charm to Christmas night. About the...