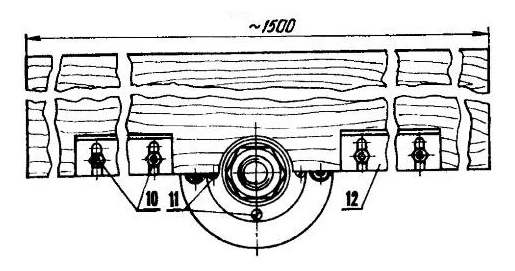

Fixture for milling blanks on a drill press:

1 — machine table; 2 — bearing 80203; 3 — shaft-mandrel (steel 45); 4 — M6 special bolt fastening the bearing housing (2); 5 — the bearing housing (steel 45); 6 — cover housing bearing (STZ); 7 — M20 nut; 8 — a felt seal; 9 — working Board (s35); 10 — a bolt M5 mounting rails (4 PCs); 11 — M4 screws securing the cover (4 PCs); 12 — guide rail (aluminum, area 25×25, 2); And — the position of the cutter

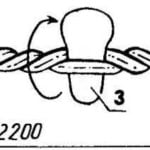

Adapter sleeve for mounting on the mandrel of the cutting tool with a bore diameter of 32 or 27 mm

Bearing with dust shields on both sides mounted in the housing and closed cover with a felt seal. The case itself is fastened to the machine table with two bolts MB so that the axis of the mandrel was strictly vertical and coincides with the axis of the spindle. To reconcile this position the upper end of mandrel clamped in the Chuck, the machine turns at a low speed and by defining the exact place

the body on the table, tighten the nuts to his bolts.

Just above the location of the bearing on the shaft (axle) has a lip which serves as a limiter when installing the cutting tool and additional protection to the bearing from excessive ingress of sawdust and wood dust.

Cutting tool with rings and washers installed at the correct height above the flange and put it on top of another ring or washer, tighten parts nut M20. To obtain the desired surface of the workpiece using different milling cutters: circular, cylindrical, shapes. Below the mandrel to install the cutting tool with a bore diameter of 27 or 32 mm, it is necessary to carve the linking sleeve.

For easy processing of long workpieces on the table of the drilling machine is mounted a working Board with a length of about 1500 and a width of 300 mm. Board Thickness selected such that its top is slightly towered above the protective rib. In our case the size was 35 mm. In the middle of the Board with one of its sides made of semicircular sample under the bearing housing and a shoulder on the mandrel. On the machine table Board is secured with two bolts MB sunken into her head.

On the Board, on both sides of the mandrel, are mounted two guides (inlet and outlet) aluminum corner 25×25 mm. Each guide is attached to the Board with two M5 bolts or screws. To guides can be moved on the Board in the transverse direction in the lower shelves of the parts is the mounting holes are made oblong slots. With their help adjustable cutting depth.

Since the workpiece is processed on the machine at maximum spindle speed, i.e., at an accelerated rate, due to insufficient engine power necessary to follow the heating and, if necessary, to work with breaks.

It is better to Polish with emery sandpaper mounted on a wooden cylinder with a height of 70-80 mm with an inner diameter 22 and an outer 40 to 50 mm.

WISEMAN A., senior teacher of labor training, Donetsk, Ukraine

Recommend to read

STRANDED, A HOMEMADE

STRANDED, A HOMEMADE

Stranded microcable widely used in modern equipment, in particular for the connection of input devices of a type well-known joysticks and other peripherals to computers. With all the... PIPE — HAMMER

PIPE — HAMMER

There are cases when after oblique impact arm break in two next to the hammer, resulting in not only loss of the tool or of the workpiece, but also serious injury. To avoid this...