Oven-stove for baths, which will be discussed below, the list was designed and built by me. Prior to this was construction of a camp bath, “badger valley” with a simple stove type samovar and another bath Villa with a pretty good stove, which served as a prototype for this, which I call “the dream of the bathers”.

Oven-stove for baths, which will be discussed below, the list was designed and built by me. Prior to this was construction of a camp bath, “badger valley” with a simple stove type samovar and another bath Villa with a pretty good stove, which served as a prototype for this, which I call “the dream of the bathers”.

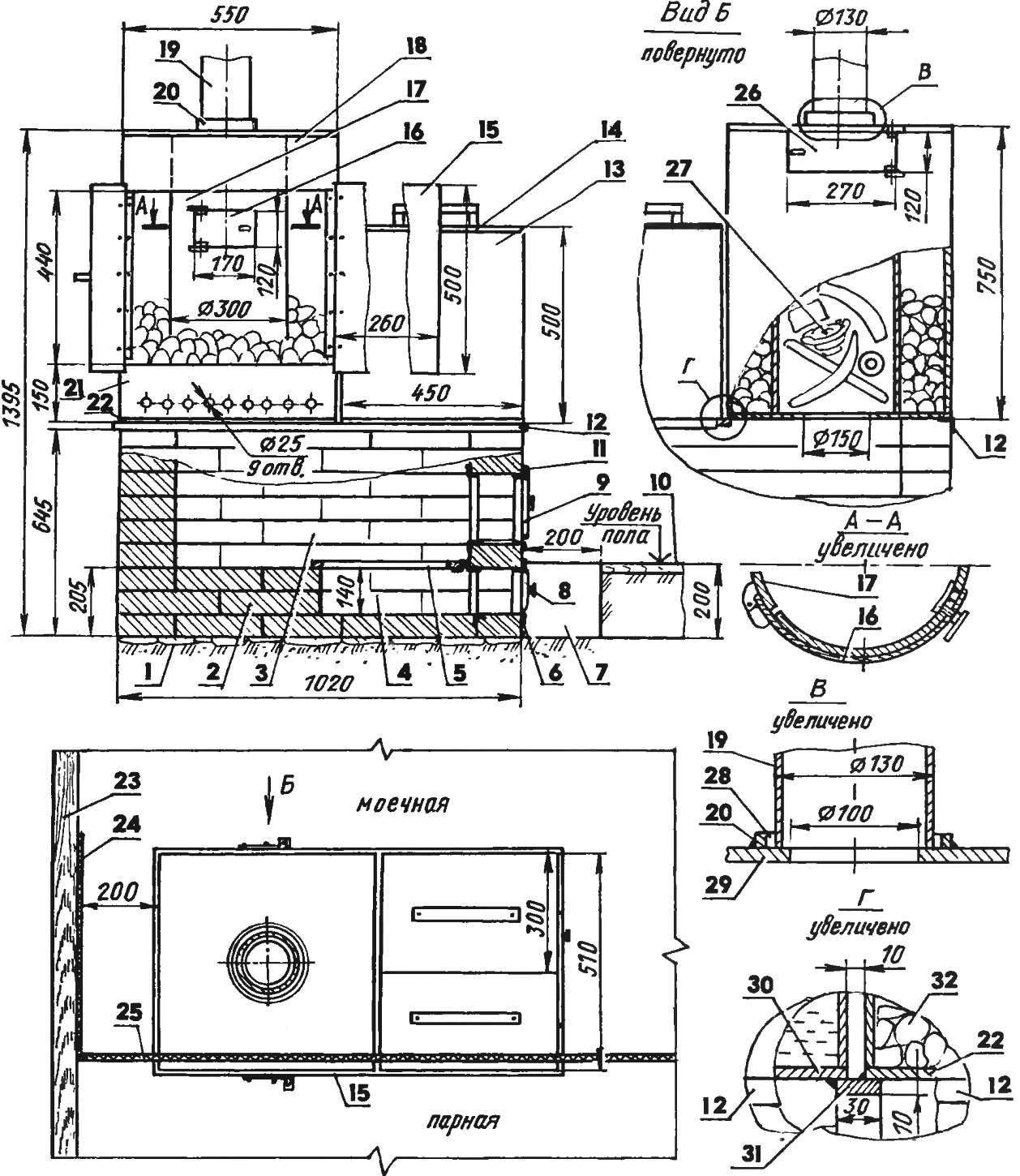

The dimensions of the stove-the heater is a small — length x width x height (without pipe) approx 1030x520x1400 mm. But such a size in my estimation (and the operation is confirmed), was the most optimal for baths with the overall dimensions of the steam room and washing 3,3×2,3×2,0 m (length x width x height).

In terms of (geographically) the stove is located in the washing compartment and only one side with wing doors for the heater through a fireproof partition asbotsementnye placed in a steam room. In addition, between the stove and the wall leaving a gap (otstupku). The wall in this place is covered with asbestos sheet.

The furnace design combined: burner brick, and other metal items from steel sheet of different thicknesses. Flues: Converter the spark arrester and chimney — circular cross-section, made of steel pipes.

The oven stands on the subgrade from which lifted the top vegetative layer. On the ground laid the flake (flat) quarry stone. The gaps between the stones filled with gravel mixed with clean river sand, and the surface is planned horizontally.

The firebox of the furnace is made of ceramic (burnt clay) brick dimensions 250x125x65 mm, on clay-sandy-asbestos solution. Of course, this oven is heated longer than metal, but has a higher thermal inertia (stay hot).

Under the firebox of the furnace in front it is arranged in the ash pit. By area, it is two times less than the furnace, but this is quite enough to ensure good traction even in the summer. Oven buried in the ground to the grate, covering the ash pit.

Furnace and podduvalom equipped with doors with frames industrial manufacturing. In the doorways installed in the masonry box welded out of steel angle corner № 2,5 with ties from strips of 3-mm steel. From the same area and made the top rail of the masonry of the furnace (harness only made from the outside of the masonry).

On the rear part of the furnace (viewed from the side doors) stacked steel 10 mm sheet width 550 mm and a length of the entire width of the furnace. This sheet serves as the ceiling of the furnace and the bottom of the heater.

In the center of the overlying sheet cut a hole with a diameter of 150 mm (but there is a hole to make a square with the same dimensions of the sides) for the release of combustible gases and smoke from the furnace.

The post-combustion of gases occurs in the afterburner, which is a hollow cylinder with a height of 735 mm, made from thick-walled steel pipe with outer diameter of 300 mm. Pipe installed by the end of the overlapping sheet over the hole. Inside of the cylinder through a special hole with a door laid various iron and steel items and pig so that they samosatenus and not to fall into the hole. This steel-cast-iron filler performs several functions. First, it delays the entry into the tube of combustible gases, thereby contributing to more complete combustion in the afterburner directly. Secondly, it (the filler) serves as a spark arrester. Thirdly, the details of pig and accumulate heat, which is then passed into the heater. On top of the afterburner is closed in common with a heater cover made of 5 mm steel sheet.

The heater was a closet, inside of which is the “silencer” (as for brevity, I call the afterburner-spark arrester-heat accumulator). The heater is about a third the height of laid stones-“savages” and porcelain insulators. The purpose of me even uncomfortable to explain to those who like to sweat, but still let me remind you is the main dagadarthi the storage tank to generate steam. Moreover, after the end of the bath procedures, allocating the remaining heat together with the bricks of the furnace, it also promotes faster drying of flooring in the bathroom.

Oven-stove for baths (on main form wall 23, the panel 24 and the partition 25 is not shown):

1 — base (quarry stone stone, river sand); 2 — furnace (ceramic brick 250x125x65); 3—furnace; 4 — ash pit; 5 — grate (cast iron); 6 — box door-blower (area and 25×25 steel strip s3); 7 — pit; 8 — the door blew; 9 — fire door; 10 — half bath (Board s30); 11 — box of fire doors (area and 25×25 steel strip s3); 12 — tying furnace (25×25 area); 13 — water tank capacity 100 litres (steel sheet s4); 14 — tank cover (aluminum sheet s2) with handle (aspen); 15 — fold doors of the heater from the steam bath (steel sheet s2, 2); 16 — the door of the Converter; 17 — Converter (steel pipe Ø300); 18 — the lintel of the heater (steel sheet s4); 19 — steel flue pipe Ø130); 20 — pipe (steel pipe Øвн.150); 21 —a nut of the heater (steel sheet s4); 22 — the bottom of the heater (steel sheet s10); 23 — the wall (logs); 24 — fire panel (asbestos sheet); 25 — the partition between two compartments (ambientcolor); 26 — the door of the heater from the washing compartment (sheet s2); 27 filler Converter (steel and cast iron scrap); 28 — sealant (solution); 29 — a cover of the sauna heater (steel sheet s5); 30 — the bottom of the water tank (steel sheet s10); 31 —smoke constipation (steel strip 30×10); 32 filler Kamenka (stone-“savage”, porcelain electrical insulators)

The stove has two doors: one is relatively small — on the part of the washing compartment and the second hinged double — side steam. From the wall of the heater from this side only the bottom part is the nut and the upper part of the lintel. The nut serves to retain in the oven sprinkled on a hill of stones. In the nut for the best way out of steam, generated from evaporation of water, to get to the bottom, drilled a series of holes with a diameter of 25 mm. Using the same holes with closed wings in the steam room and open the door to the washing compartment in the stove into the cold air. Pairs of the same “mined” in the traditional way by splashing from the ladle portion of hot water on the hot stones and insulators.

The lintel is to produce a “superheated” steam, when the latter, rising from the rocks up, heats up even more from the hot walls of the silencer and then EXITS from the Cabinet to the steam room. In addition, when both doors open (in the steam room and washing) lintel contributes to the direction of the heated air through the small door in the washing Department.

In the lid of the Cabinet, along the axis of the afterburner cut a hole with a diameter of 100 mm for smoke. Above the hole is welded a short pipe with an internal diameter slightly larger than the outer tube. Inserted in the outlet of a chimney, which, through the fireproof cutting in the ceiling and the roof comes out. Chimney — steel, with a diameter of 130 mm. the pipes Have no view, but on top it is covered from rain by a hood. Thrust is governed by the opening of a door or blew the furnace. The gap between the pipe and the pipe be filled with mortar or sealed by means of any inflammable material to the exclusion of the way of smoke.

On the remaining free surface of the furnace near the heater mounted welded steel hot water tank with a capacity of about 100 l. Tank has the shape of a “Quadra-power generation” — of a rectangular parallelepiped. The bottom of the tank is made of steel sheet 10 mm thick, and the walls — 4 mm. Two pot covers are made of 2 mm duralumin sheet, and their handles are carved from an aspen Board. The bottom of the tank and the bottom of the heater are connected welded to the steel strip, which serves as smoke constipation. The ends of the strip are welded with the parts of the strapping chamber.

The main modes heating furnace two:

1 — open the ash-pit door, there is a rapid (within 1 — 1.5 hours) warm baths even in cold weather;

2 — if the door is covered with a furnace in the warm season and maintained the heat in the cold.

You can use one of four different ways of heating individual rooms baths:

1 — open the sash-door of the heater in the steam room and opened the door of the heater in the washing compartment is made simultaneous uniform heating of both premises;

2 — sash door of the heater in the steam room closed and the door to the washing compartment is open — there is priority heating of the washing compartment;

3 — sash doors of the heater in the steam room open and the door to the washing compartment closed, implemented rapid heating the pair separation;

4 — all doors closed — the heat accumulation stones in the heater (this option is used only when the second mode of the furnace furnace cover door blower).

To warm baths use wood of various species of trees: both deciduous and coniferous, and in the course of going even nedosushennye. You can use of course, and gas, and coal, but the spirit in the bath is not the same. Smoke during ignition inside the bath is not discarded wood requires relatively little. Hot steam lightweight, it is a lot and for long enough, and the water in the tank is heated to 90°C.

In short, I bath my Pets happy.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.