Having a stove ( coal or wood), it is possible to provide hot water sink in the kitchen and even the shower using the heater device, allowing the use of the heat of the hot gases that are removed through the chimney plate.

Having a stove ( coal or wood), it is possible to provide hot water sink in the kitchen and even the shower using the heater device, allowing the use of the heat of the hot gases that are removed through the chimney plate.

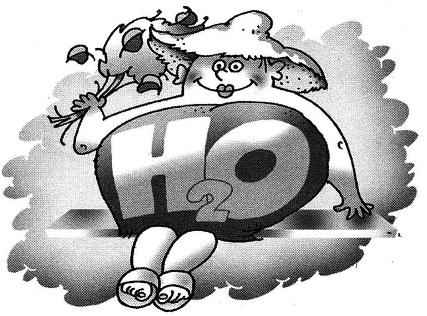

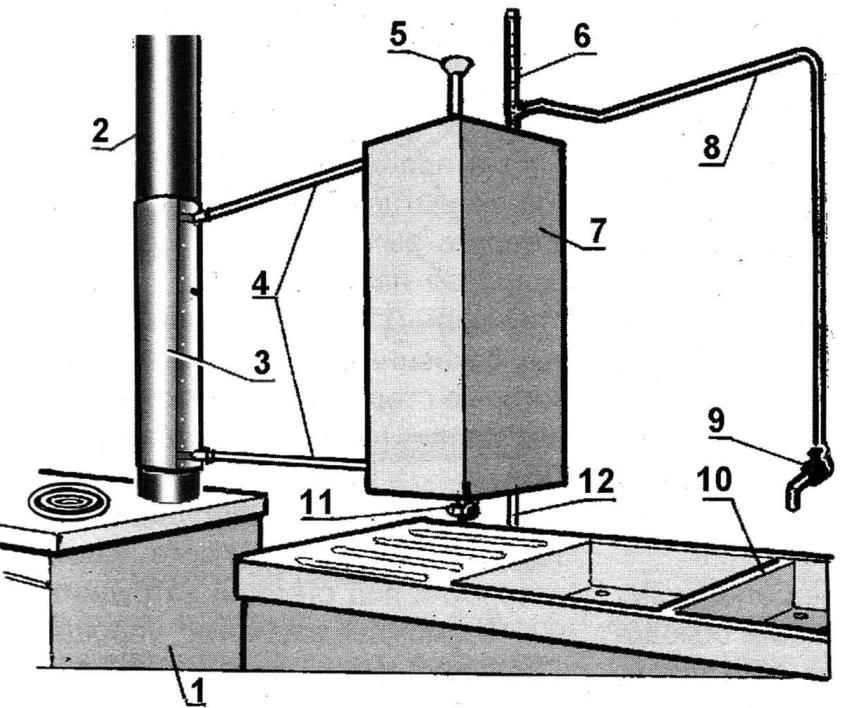

Design and operation of the device is the following (Fig.1,2). Tube heater built into the chimney as close as possible to the stove. The hot water from it flows through pipes in a metal cylinder (e.g. from fire extinguisher) that has a coil and is connected to the water network and tap over the sink. The water filling the tank, is heated by the boiling water coming into the heater coil.

Manufacturer of heater

Knee water pipes in the chimney (Fig.2) has a length of approximately 700 mm . It is the main element of the heating device, is threaded on both ends for tube connections to the coil. This knee is welded on two strips of sheet metal which is shaped of a spiral with several turns around the pipe. To facilitate the bending of the spiral, you can make it cross cuts with scissors on metal. The connection tubes and the spiral must be sufficiently dense to achieve maximum thermal conductivity (in accordance with this requirement must be met continuously welded seam). This part of the heater closes the tin casing in the form of a pipe connected to the outlet of the furnace plate and the component of the bottom element of the chimney. For ease of cleaning part of the housing is removable.

Fig. 1. Hot water system in the country:

1 —furnace; 2—flue pipe; 3—a casing of a heater; 4—pipe to the coil; 5 – filler; 6—thermometer; 7—box-thermos; 8—pipe to flow to the faucet; 9—supply valve; 10—washer; 11—drain valve coil; 12 — water supply

The coil of the heater is separate from and is embedded in the container so as to enable the pipe connections to the heater in the chimney. The cylinder is connected to the water pipe and the branch pipe with a thermometer and control valve (Fig.2). In the upper part of the coil is the pipe with funnel for water filling in case of lack of water replenishment.

Fig. 2. Schematic diagram of the hot water installation:

1 —casing of the heater; 2—knee of the heater; 3—plate gain of tube heating; 4—cylinder-heat accumulator; 5—coil; 6—insulator;7—heated water; 8—drain valve coil; 9—supply valve; 10—water

The cylinder is filled with water at the bottom of the water (or from water containers in the absence of Central water supply). Another section of pipe (top) connects the tank with the domestic water supply to the sink or the soul. Consumable tap on the end supplies the sink with hot water.

The installation and use of

Cylinder in a thermal insulation box mounted on the kitchen wall as close as possible to the sink and the stove. It is important to make the connecting pipe as short as possible to avoid unnecessary heat loss. Two pipes from the knee of the heater are connected to the container with the help of standard tees. If possible, it is desirable to position the pipe horizontally to ensure proper water circulation in the system.