When there is no permanent gazebo on a summer cottage for rest on a hot summer day, the only salvation from the scorching sun is a large “beach” umbrella. The undeniable advantage is that the umbrella can be installed anywhere you want to organize a rest area, where a table with chairs or just a sun lounger has been brought out.

On the beach, installing such an umbrella is simple: stick its pole deeper into the sand — and even in the wind, no additional reinforcements or guy lines will be needed. But on a summer cottage, this won’t work, especially if the area is specially prepared — covered with gravel, laid with tiles, or asphalted.

Therefore, for a large sunshade umbrella, a portable metal or concrete base is usually made — a massive plinth with a bushing for the pole. For the umbrella not to be blown over by the wind and to be stable, such a base must be heavy enough. However, this makes it difficult to carry. It would seem that with such a contradiction, it is difficult to find any optimal solution. Nevertheless, there is one.

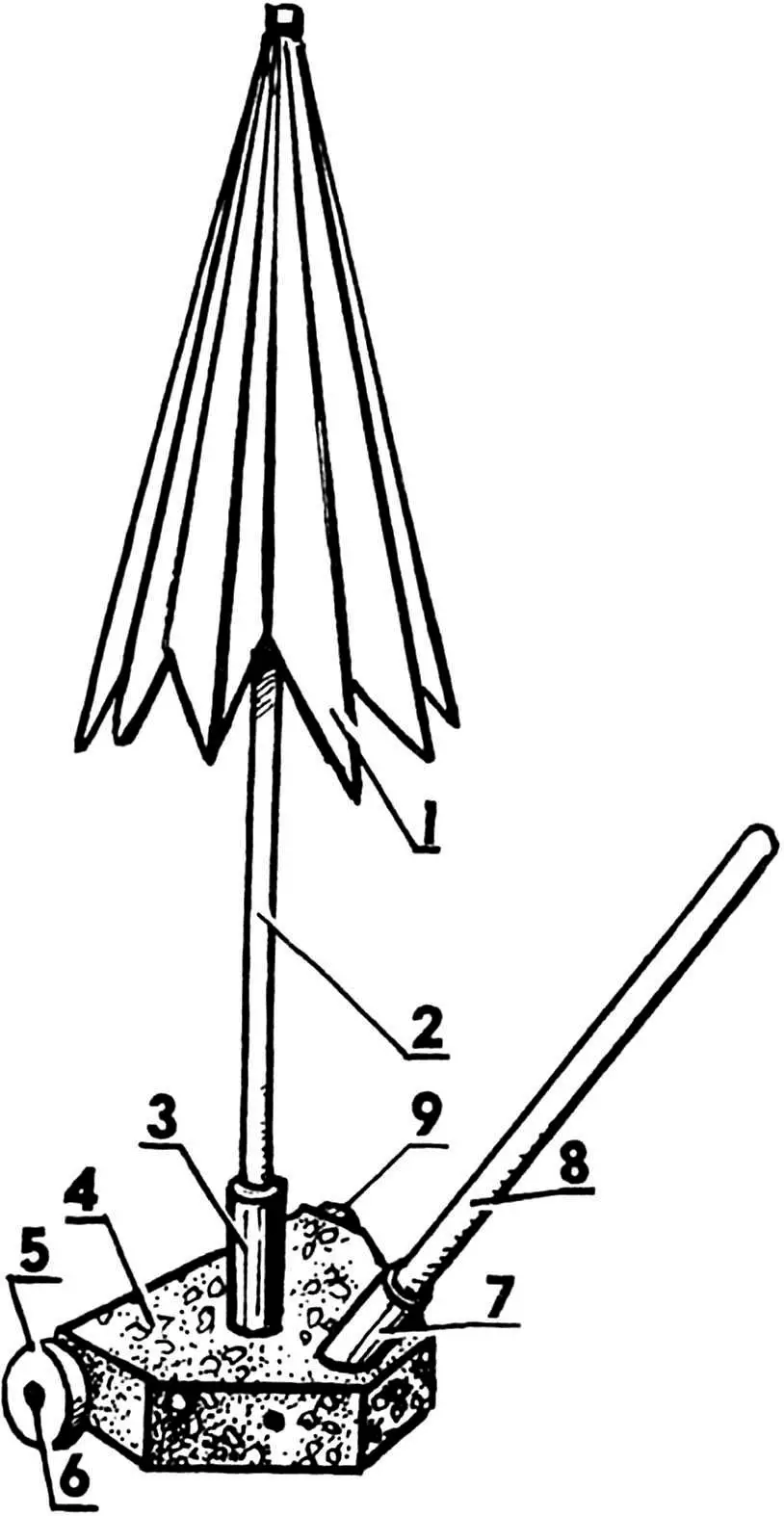

1 — canopy; 2 — pole; 3 — umbrella bushing; 4 — plinth; 5,9 — wheels; 6 — axle; 7 — handle bushing; 8 — handle for transport

The German magazine “Praktik” suggests making the plinth not portable, but… mobile, with small wheels. Of course, they can be installed on an existing plinth, but it is still better to make an improved version by casting it from concrete.

What is needed for this? Some cement, half a bucket of sand, the same amount of gravel or any small stones, as well as two wheels from an old hand cart, a metal rod for the axle, and two pieces of pipe with an internal diameter suitable for the umbrella pole.

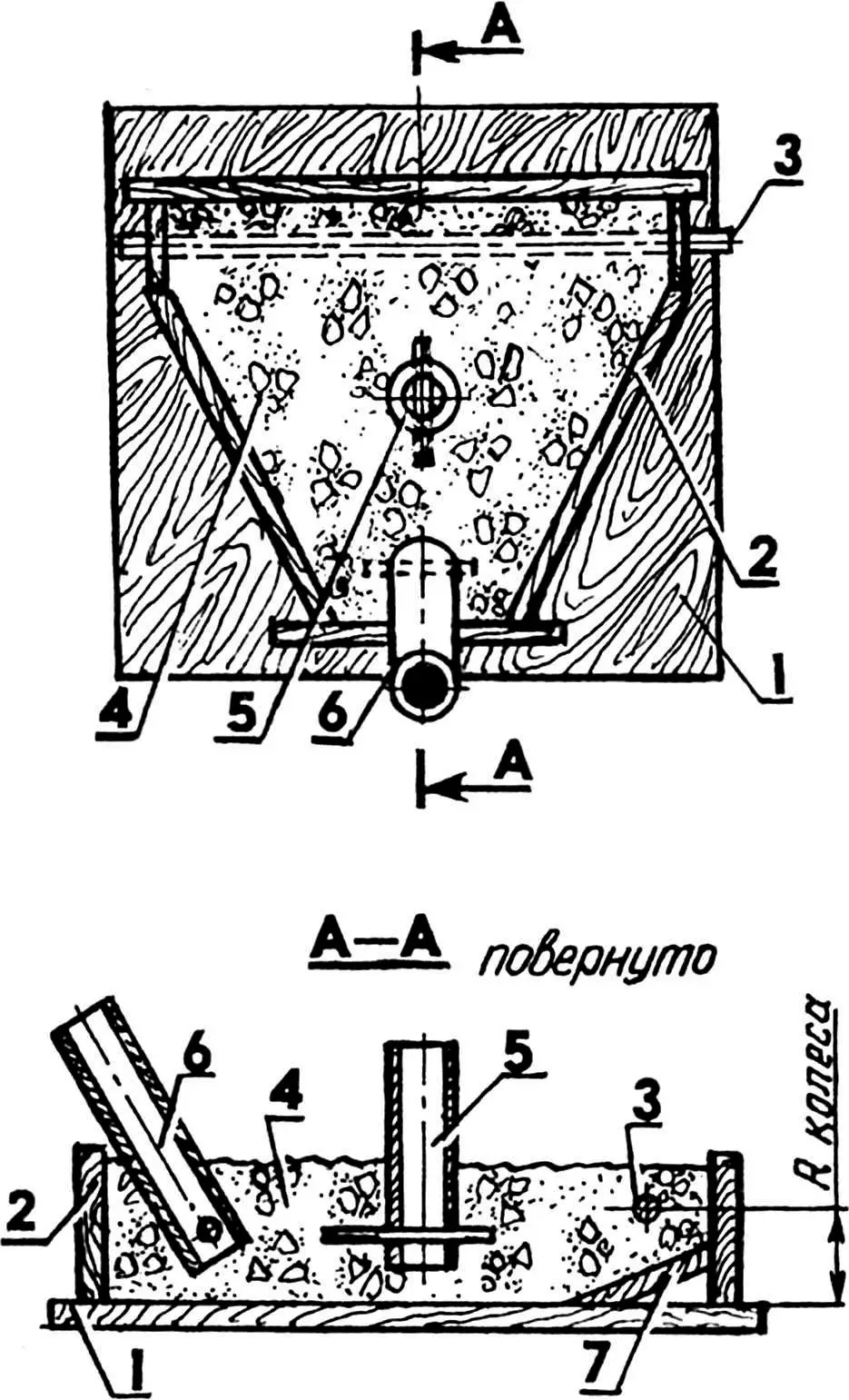

1 — base; 2 — formwork; 3 — wheel axle; 4 — mortar; 5 — pole bushing; 6 — handle bushing; 7 — embedded board for plinth bevel

A formwork is assembled from boards. A board is placed in it at a certain angle, thanks to which the future plinth will have a bevel. Here, a rod-axle is inserted into the formwork so that the height of its position equals the wheel radius. This completes the preparation of the form for pouring concrete.

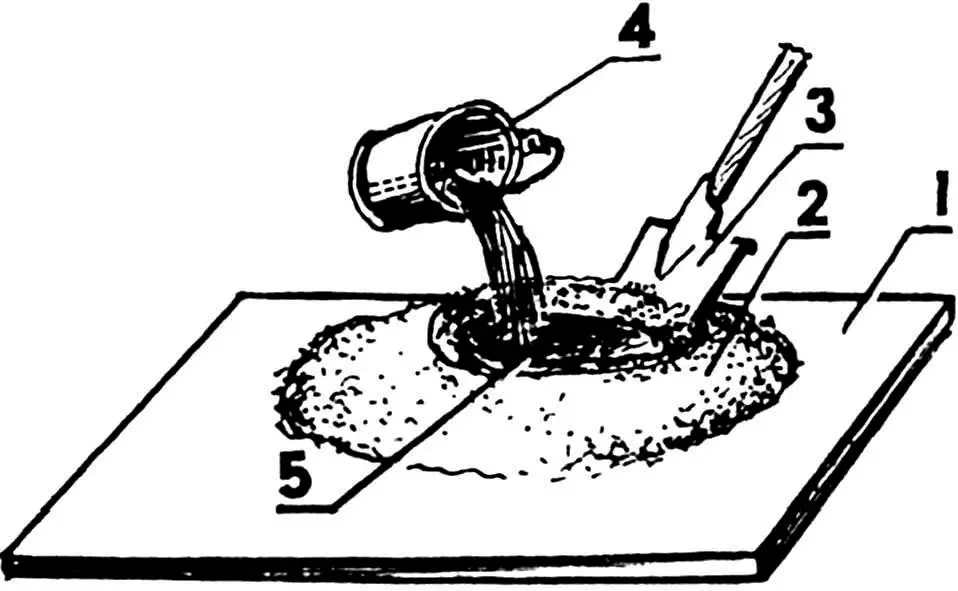

On a sheet of plywood or sheet metal, sand and cement are poured in layers. Both in a ratio of: 1 part cement to 3—5 parts sand. Everything is thoroughly mixed until a homogeneous mass is obtained and formed into a mound with a large depression in the middle. Water is added to the depression with constant stirring, and a thick, viscous mortar is prepared. The formwork is filled two-thirds with it, and a small amount of gravel or small stones is embedded in the mortar.

1 — sheet of plywood or sheet metal; 2 — sand and cement mixture; 3 — shovel: 4 — bucket with water; 5 — mortar

At the same time, bushings made from pipe sections are installed in the mortar: one vertically — for the umbrella pole, the other at an angle — for the handle to transport the plinth. After two or three days, when the mortar has hardened, the plinth can be freed from the formwork and the wheels can be attached.

Thanks to the design features, the plinth in a stationary position is immobile, as it rests on the platform with its entire bottom plane. Moving it, however, is not difficult: a handle is inserted into the angled bushing, with its help the plinth is lifted, thanks to which the support transfers to the wheels — and the plinth can be rolled to a new location.