The timber and lumber must be stored so that they were not only protected from moisture, but dried would be in storage, especially if purchased wood is high humidity. For this material it is better to put in a stack aligned on a horizontal platform provided with a drainage system. First, on the ground, stepping back from the ends of the stack of 200-300 mm, is placed through a 1.2—1.5 m sleepers with a height of 200-250 mm, having spread under them, strips of roofing felt (roofing material, plastic film), and on them — a number of boards with between 30-50 mm. In this range over the ledge put the crossmember thickness is also 30-50 mm, and to them, the Board of the next row so that they overlap the spaces between the lower boards (staggered, like bandaging the joints in masonry). On the last row are laid over long cross, and on them — without pads and with releases at the ends of the several layers of the edging, defective boards or slabs, overlapping the underlying longitudinal joints and reducing by half the Board overlying a number with each edge that they are on top of the stack formed saddle surface. Such warehousing will provide a good blowing each Board in the pile. In the rain, the pile is covered with tape at the top and at the edges of the pressed slabs or pieces of boards. For storage of round timber (tree, logs, podtovarnikom) to sills and cross members need to cut down a small Cup or fasten the logs together with the cross braces. Each row of logs in the pile are placed opposite ends (after thick thin, and Vice versa).

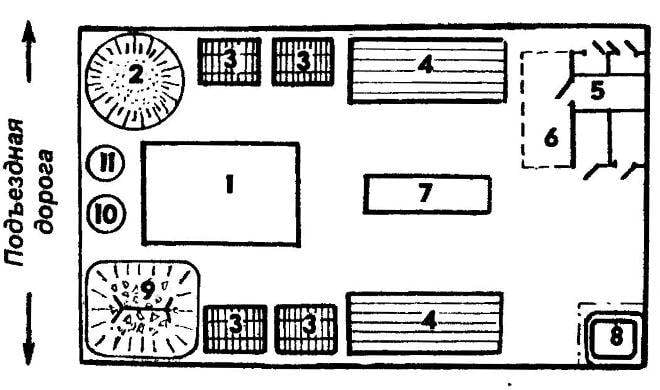

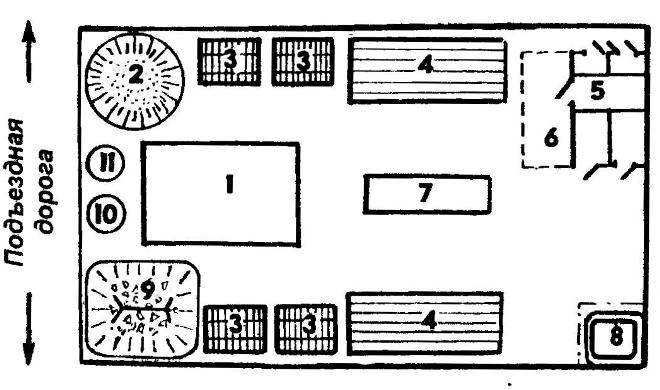

The estimated storage of materials and constructions on the construction site:

1 — area under house; 2 — sand; 3 — pallets with bricks or blocks; 4 — stacks of timber and lumber; 5 — hozblok; 6 — cover; 7 — workbench; 8 — tvorenia pit 9 — a lot of crushed stone or gravel, 10 — betonomeshalka; 11 — water tank

Pile timber h sawn timber:

1 —sleepers (h200…250 bar) for waterproofing; 2 – strip (plank h30…50); 3 — timber and lumber; 4 — elongated transverse strip; 5 — gorbalenya unedged Board; 6—plastic film: 7 — clamping Board

Pallets with bricks or blocks:

1 — support (bar 100×100); 2 — the bottom (Board s25…50); 3 — backup (triangular brusok 100×100); 4 — brick; 5 —blocks

Warehousing of precast concrete and concrete structures:

1 —ingredients (bar 150×150); 2 — strip (bars 100×80); 3 — mounting tabs; 4 — Foundation blocks; 5 — floor slab

The width of the stacks should be measured against its height and last not exceed 2 m.

When storing, we must remember that the lumber will dry faster than logs, edged boards — faster than unedged, planed faster than the unplaned, and remember that wood is hygroscopic, that is able to absorb moisture even from the air, and the dry wood after a long stay in a damp location will again become wet.

The wood on the content of moisture is divided into three categories: 10 percent — dry (for furniture), from 10 to 15 percent room humidity (DPJ internal structures) and from 15 to 23 per cent air humidity (external structures). More raw wood in construction, as a rule, is not used.

Bulk inert materials (sand, rubble, gravel), mostly used for Foundation designs and start up in business in the first place. Therefore, they can be stored in heaps, even on the outskirts of the development area. Protection from the elements, these materials do not require, but to exclude their introduction into the soil layer, it would be nice before the store put him on the ground steel plate or a concrete slab: inert materials, are mixed with the soil used for construction is impossible. And processing of the earth mixed with gravel or crushed stone, the owners (growers, gardeners, cottagers) will not bring joy, but cleaning the soil from these contaminants will require a lot of time.

The area that will take a bunch of inert materials, it is easy to calculate by the known geometrical formulas, knowing the required volume and having an average natural slope slopes slept in a pile of material is equal to 45°.

If the construction of brick, block or monolithic homes used precast concrete or reinforced concrete structure (Foundation blocks, floor slabs), then harvest them for the future is impractical, because for their installation in the same way as for unloading, required a crane. It would be more rational to prepare a scope of work (to dig a pit for the Foundation, to build a Foundation or load-bearing walls under the floor), order the product at the same time with a crane and mount them with “wheels”. If this organization of work is impossible, store design should be on such distance from plot development to get them without reinstalling the faucet. Lining and pads for storage set across the structures at a distance of 250-300 mm from their ends, and the spacers shall be of such height that are not damaged (not jammed) installation, Pepi products.

Single-piece wall materials — brick, stones or blocks laid on the pallets of brick in the “tree”, with a slope inside, and the stones and blocks — series with cross-dressing. Pallets represent the plank shields with transverse bars and side bars of the triangular profile. If the pallet of stacked sand-lime bricks (blocks), then they need to cover from rain with a tarp or plastic. Between packages it is necessary to leave the passages with a width of 0.5 m. When space is restricted packages (pallets of bricks) can be installed in two tiers, increasing the passage to 0.8 m.

Some building materials (binders) and millwork must be stored in closed rooms and even in a sealed package (for example, plaster or hardwood planks).

Here without pre-construction of auxiliary facilities that could be used for storage, will not do: time (barns, bins with canopies) or capital (barns, cabins, baths) — it’s up to the developer.

Tvorilnuyu pit :

1 film; 2 — clay shaft; 3 – wooden flooring; 4 – cover

Temporary warehouse (shed) with carport

Possible design step temporary warehouse:

a — wooden single; b— dosta double insulated; in—frame with the outer skin; 1 – the ground or floor; 2 – hydro, 3 — sleepers (the bars lower trim); 4 – borders (bar 40×40); 5 — SGSN (Board S35…50); 6 — bars top binding: 7 — nastavni bar; 8 – outer St, Jena (Board s25); 9 — insulation (s30…40); 10 —inner wall (Board s15); And pillar frame; 12 — exterior sheathing (slate); 13 – — the lintel of the doorway

Major outbuildings are usually built of the same materials as the main building (to provide a unified architectural appearance), simplified design: reducing the thickness and the height of the walls and, respectively, the depth and cross-section of foundations, as well as simplifying other elements. The construction of these structures at the same time gives the necessary skills that will be useful in the construction of houses.

Temporary warehouses and sheds are satisfied with the most simple design schemes, even using substandard materials. However, this should not affect the stability and durability of the construction.

Such constructions can be done without a Foundation, sleepers laid through a layer of waterproofing material directly on the dirt ground, slightly elevated above the surface of the earth, providing her drainage. Ingredients are used in construction as the lower harness frame. Base can serve as a mud floor, facing 100-200 mm beyond the area of the barn. For a device of this floor removed the humus and underlying soil additionally stamp on it and laid crumpled fat clay with additives straw cleavers or fires in two layers with thickness up to 100 mm each. Having laid a layer of clay rams, align, and allow it to dry. Top floor cover lime, clay or cement mortar with a thickness of 2Q—30 mm. Coating can be made of a layer of gravel or crushed stone, and it is better to use a local flat stone, buried it in the floor tamper.

For the preparation of crushed clay and lime slaking in the “far corner” of the construction site tvorilnuyu need to dig a hole, put it with a thick plastic film. If the walls of the pit crumble, it is necessary to make the formwork. At the bottom of the stack the boardwalk, and the pit cover.

The walls of the barn (warehouse), often do frame with single or double plating of flat slate or other slab materials, outside — water-resistant. Intermediate stands in this case, the set according to the material width of the hull.

The plank walls do without intermediate posts connecting the Board in the longitudinal joints with pins. Using boards with a thickness of 30-50 mm with a quarter or grooved with no pins, collect windproof hard walling without gaps. If necessary do and double wooden walls with an air gap or a layer of insulation. Use Board thinner than the thickness of 20-25 mm.

When deciding on the design of walls, the most acceptable it is necessary to consider the one that will be easier to disassemble without damaging the material.

The roof of the shed are usually fine lean-to with a slate roof or a coating of rolled materials (roofing felt, asphalt), but the latter requires a solid crate. The back wall of the shed should not be below 2 m.

Inside the shed doing several compartments, mounting the partition to the full height of the building. The fact that some binding materials, e.g., cement, gypsum, lime, require separate storage. Doors, it is desirable to make each compartment opening to the outside.

To the barn it is advisable to attach the canopy. Materials it will require a bit, and the need for it will always be. If you allow the height of the lower wall, the canopy can be mounted behind a barn under common roof. But even if the canopy is mounted to the front of its roof, as a rule, satisfied by the type of roof of the shed. The frame of the canopy is usually harvested without bottom trim (sills), and the ends of the struts, previously protected from rotting, bury into the soil to 800-1000 mm. the Pits around the b-pillars covered with gravel or gravel and tamped.

And the last: almost all binding materials during prolonged storage lose its activity. Cement per year could lose 50 percent of its astringent properties. Gypsum will lose the same percentage of its activity in just three months, and quicklime for a month. So, procuring these materials must be located a reasonable volume.

A. POLIBIN

Recommend to read DIESEL BUS ELECTRIC The development of industry in our country in the mid 30-ies of the last century entailed the growth of cities, and in these conditions all the more urgent became the problem of their... “VENTILATOR” AT THE SAMOVAR The samovar is again becoming popular, and in suburban areas preferred not electrical, and "wood", with exotic incitement with the old boot and the invariable pipe, providing the...  How to build a house for half price? To do it yourself! This conclusion comes developers, considering estimates for projects of individual houses under articles of expenses, from which it is clear that only one half of the costs goes directly towards the materials and their transportation and the other for payment of construction services. But when the developer — man artisan, in addition to the difficult time he has the ability to summon helpers from among relatives and friends, to build a home of your own becomes a downright matter of honor.

How to build a house for half price? To do it yourself! This conclusion comes developers, considering estimates for projects of individual houses under articles of expenses, from which it is clear that only one half of the costs goes directly towards the materials and their transportation and the other for payment of construction services. But when the developer — man artisan, in addition to the difficult time he has the ability to summon helpers from among relatives and friends, to build a home of your own becomes a downright matter of honor.