The propulsion system of this snowmobile consists of a rubber-fabric track made from a 300 mm wide conveyor belt and joined into a ring using a hinged loop. On its outer surface, cleats made of duralumin channels are installed, and on the inner surface – brackets that allow the track to be driven by the drive sprocket. The brackets, shaped like the letter “П” with threads on the legs, are bent from 6 mm steel rod. For marking holes on the track for the brackets, it is advisable to use a jig – a duralumin plate with pairs of holes 6.1 mm in diameter. After tightening the nuts on the brackets, they must be locked.

The track is mounted on a pivoting carriage, the front part of which is fixed to the frame with a hinge, and the rear is connected through a pair of spring-hydraulic shock absorbers from an “Izh-Jupiter” motorcycle. The drive sprocket, as well as large and small support rollers, are attached to the carriage. For small rollers, moped wheel hubs with improvised “tires” stretched over them (rubber rings cut from a motorcycle inner tube) are suitable. Large rollers are made using the same hubs, discs, and tires from a children’s bicycle. The drive sprocket is cut from thick (20 mm) textolite, vinyl plastic, or capron.

The track is driven by the TG-200M engine via a bushed roller chain. The main drive sprocket is located on the outer (right) side of the drive sprocket shaft. Symmetrically to the main drive sprocket, on the opposite side of the shaft, a brake disc is fixed. For braking, a standard “Zhiguli” brake unit is used.

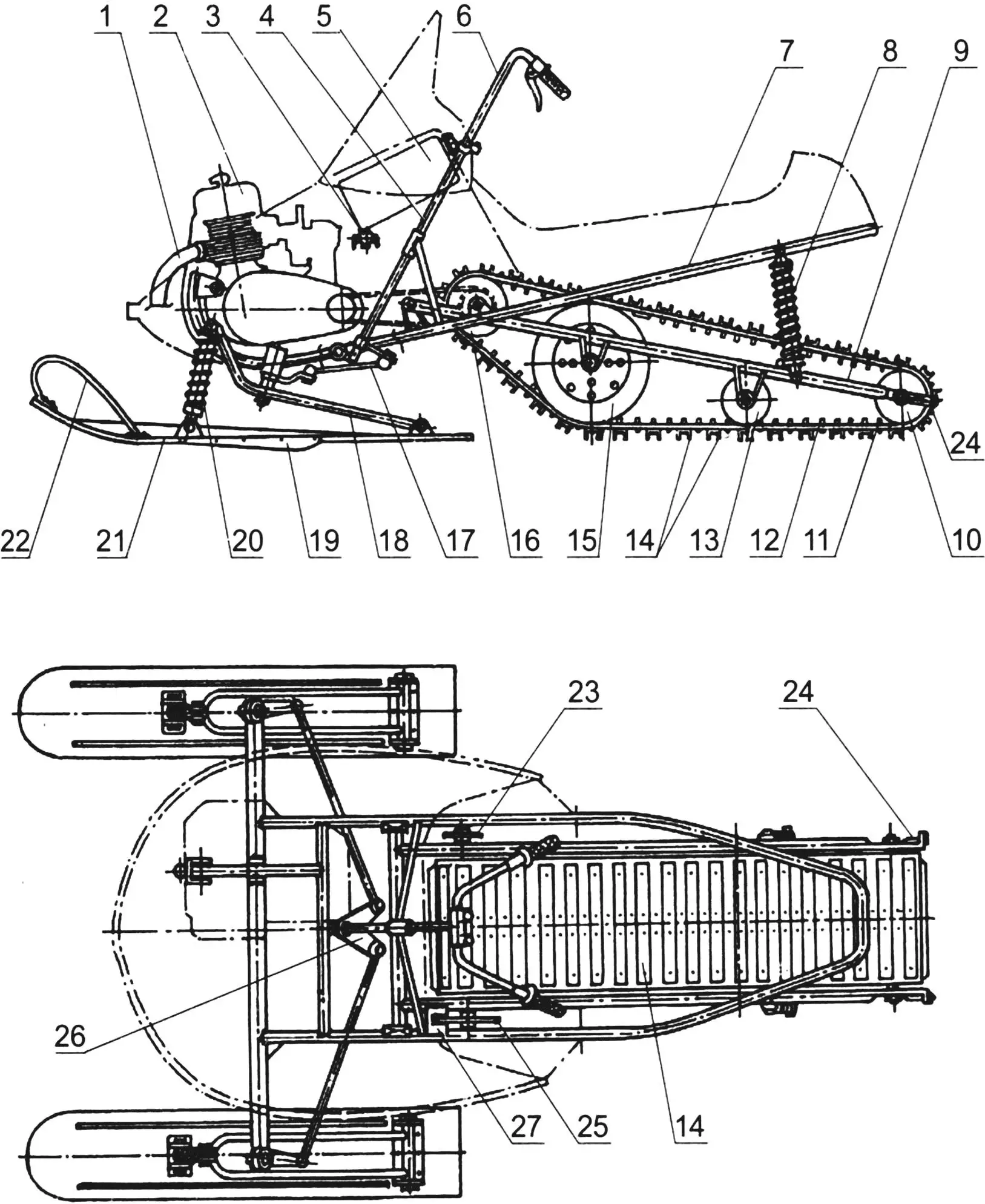

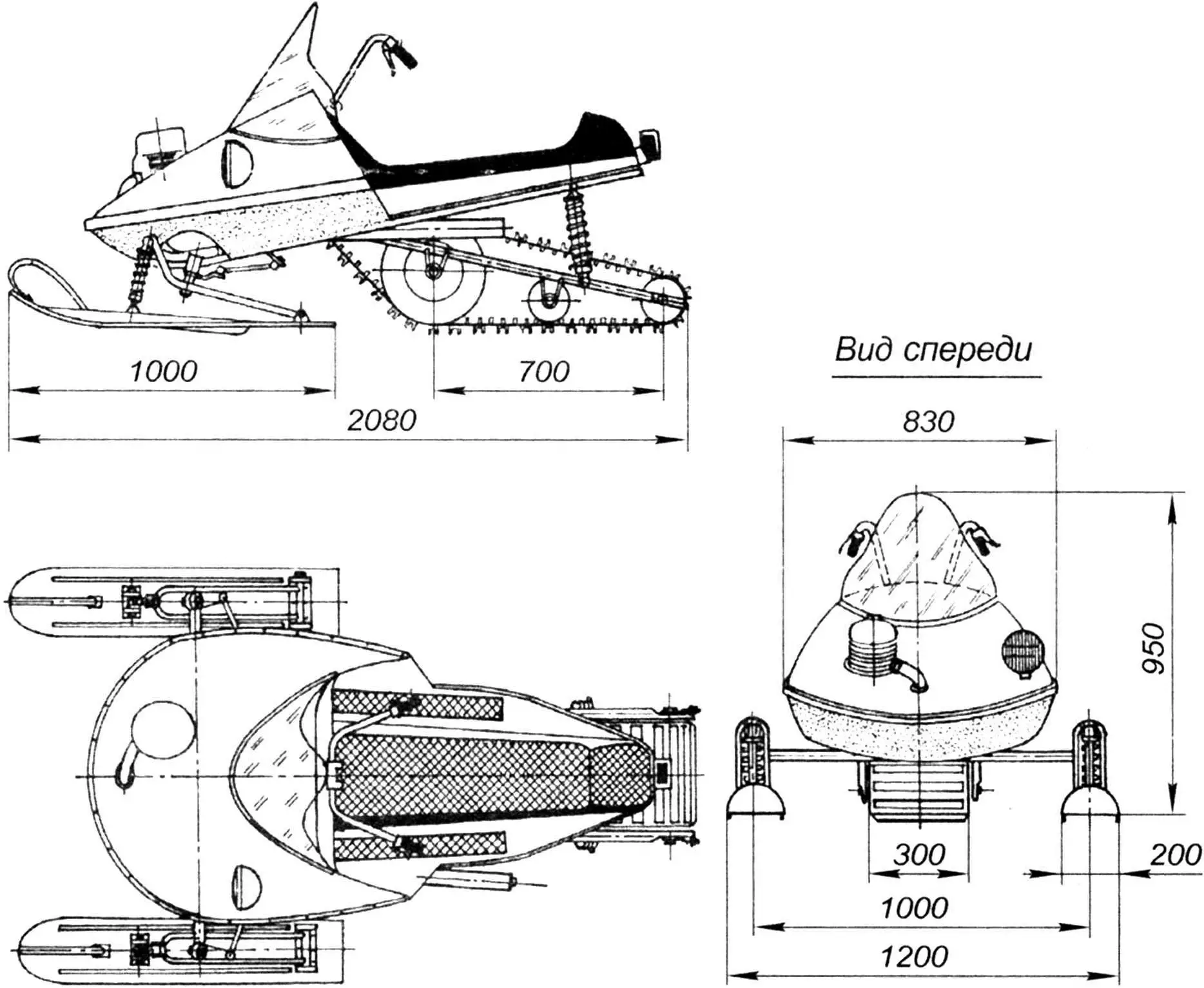

1 – exhaust pipe; 2 – TG-200M engine (199 cm3, power 14 hp); 3 – fuel tap-sediment bowl; 4 – steering column; 5 – tank (10 l); 6 – handlebar; 7 – frame (steel, Ø40×2 mm and Ø30×2.5 mm); 8 – rear shock absorber (“Izh”); 9 – drive carriage (steel, Ø30×2.5 mm and Ø22×2 mm); 10, 13, 15, 16 – track rollers; 11 – bracket; 12 – track; 14 – cleats (duralumin, channel 20x10x2 mm); 17 – steering rod; 18 – rocker bracket (steel, Ø22×2 mm); 19 – runner (steel, sheet 3 mm); 20 – front shock absorber (“Voskhod”); 21 – ski; 22 – arch; 23 – drive sprocket; 24 – tensioning device

(from “Izh” motorcycle); 25 – brake disc; 26 – double-arm rocker of steering mechanism; 27 – brake caliper

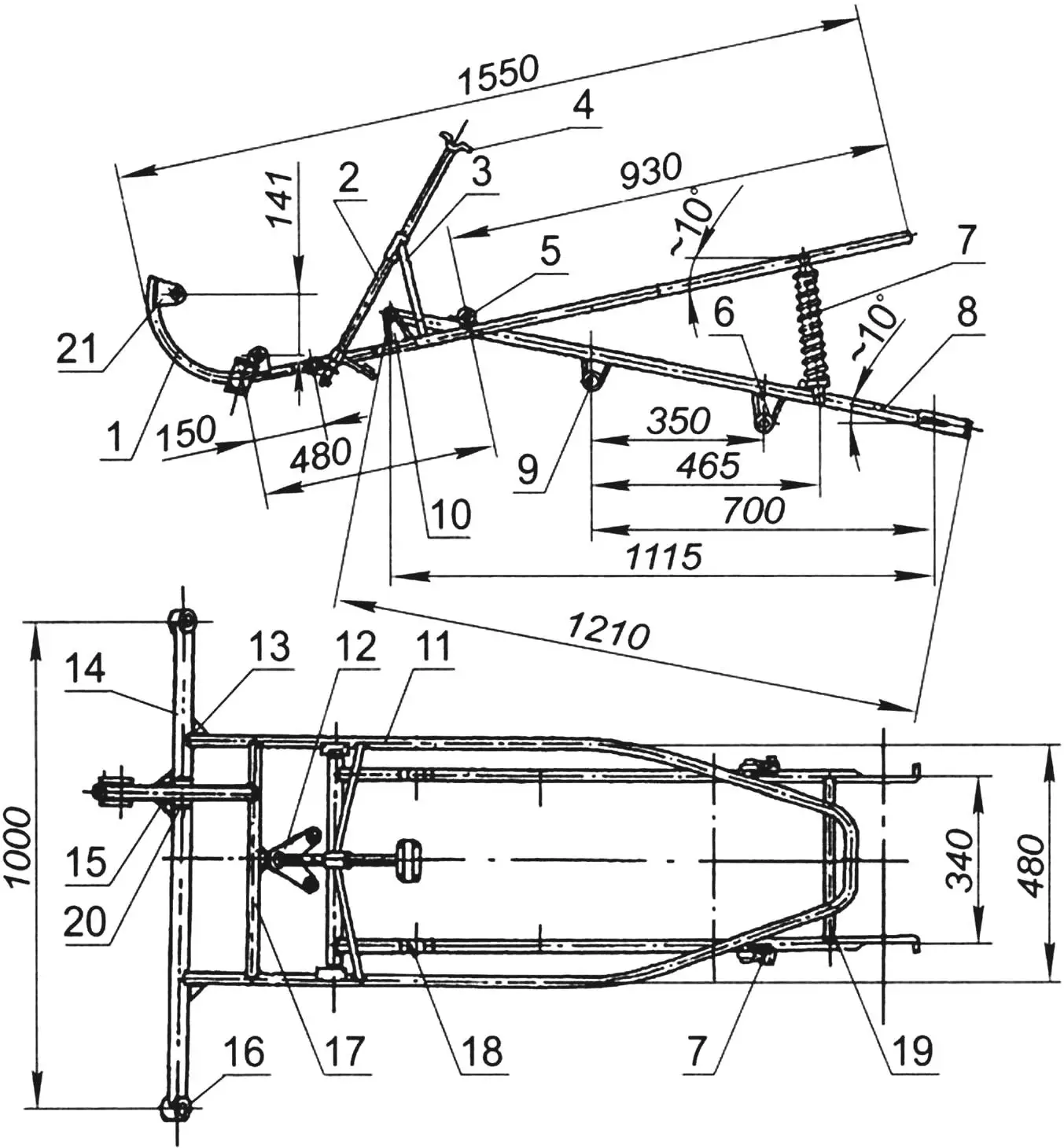

The snowmobile frame is welded from steel thin-walled tubes Ø40 mm (front cross beam) and Ø30 mm – all other parts. It is advisable to assemble the frame on a jig – for example, on a large workbench. Parts are clamped to it, and connected to each other with soft wire. Welding is carried out in several stages: tacking, inspection, straightening, and only then – final welding. Moreover, alternately on the right and left, to avoid thermal warping.

The engine is attached to the engine mount – an arch bent from Ø30 mm tube. A front mounting unit – a U-shaped bracket with a hole for a bolt – is welded to it. A similar U-shaped bracket is fixed by welding on the front tube of the frame.

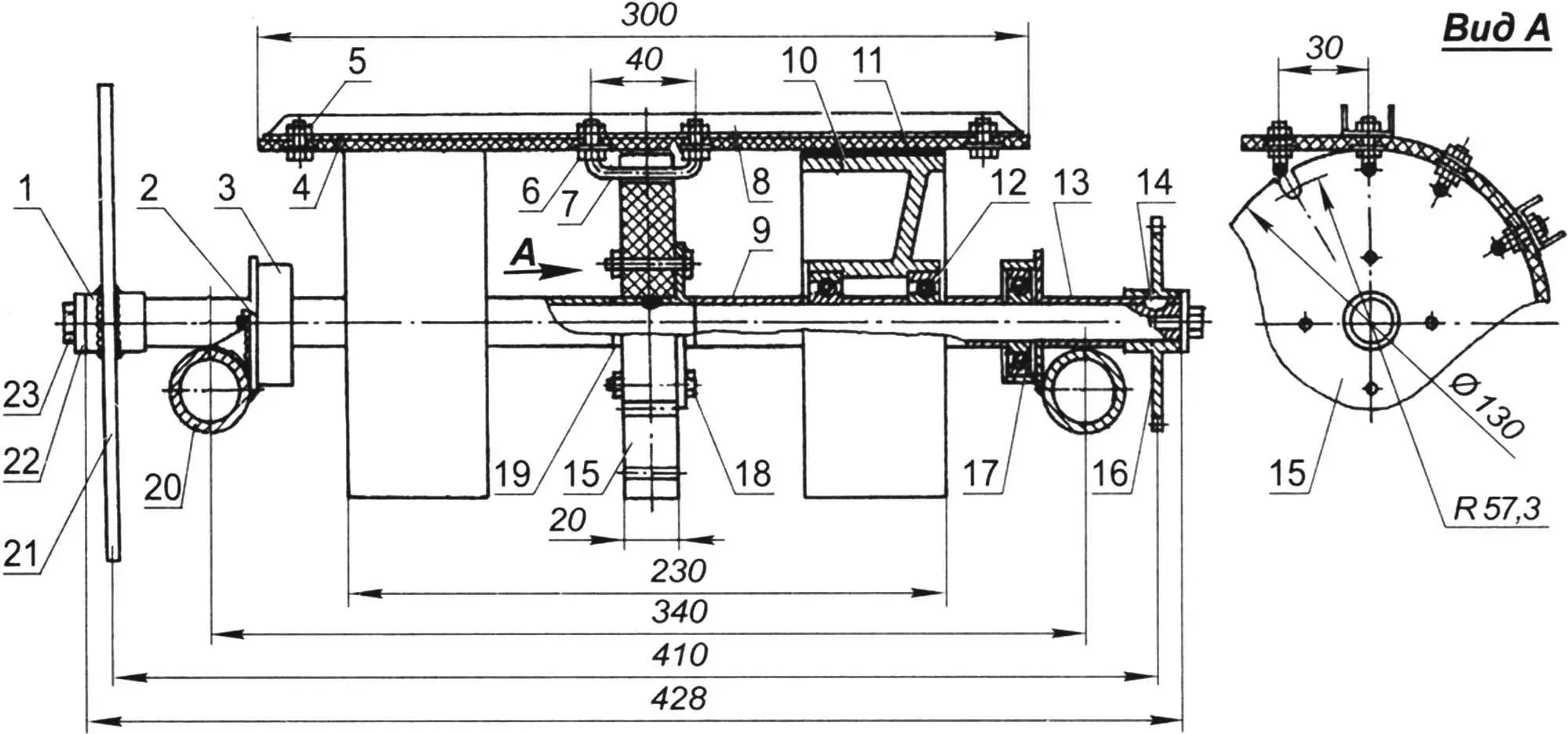

1 – brake disc hub; 2 – bearing housing bracket; 3 – bearing housing; 4 – track belt; 5 – cleat mounting; 6 – bracket mounting; 7 – bracket (steel, Ø6 mm); 8 – cleat (duralumin, 20x10x2 mm); 9, 13 – spacer sleeves (steel, Ø22×2 mm); 10 – roller (moped wheel hub); 11 – roller tire (rubber ring); 12, 17 – bearings 203;

14 – segment key; 15 – drive sprocket (textolite 20 mm); 16 – drive

The pivoting carriage is also tubular, welded. The front rollers, drive and driven sprockets, as well as the brake disc are installed on the front shaft of the carriage, which rotates on two 203 bearings. The drive sprocket is fastened with bolts and nuts on the hub, and it, in turn, is fixed on the shaft using a pair of electric rivets (a connection of parts formed by welding a hole in one of them). The rear roller axle resembles a rear motorcycle axle – it can be moved along elongated slots at the ends of the carriage side members to adjust track tension.

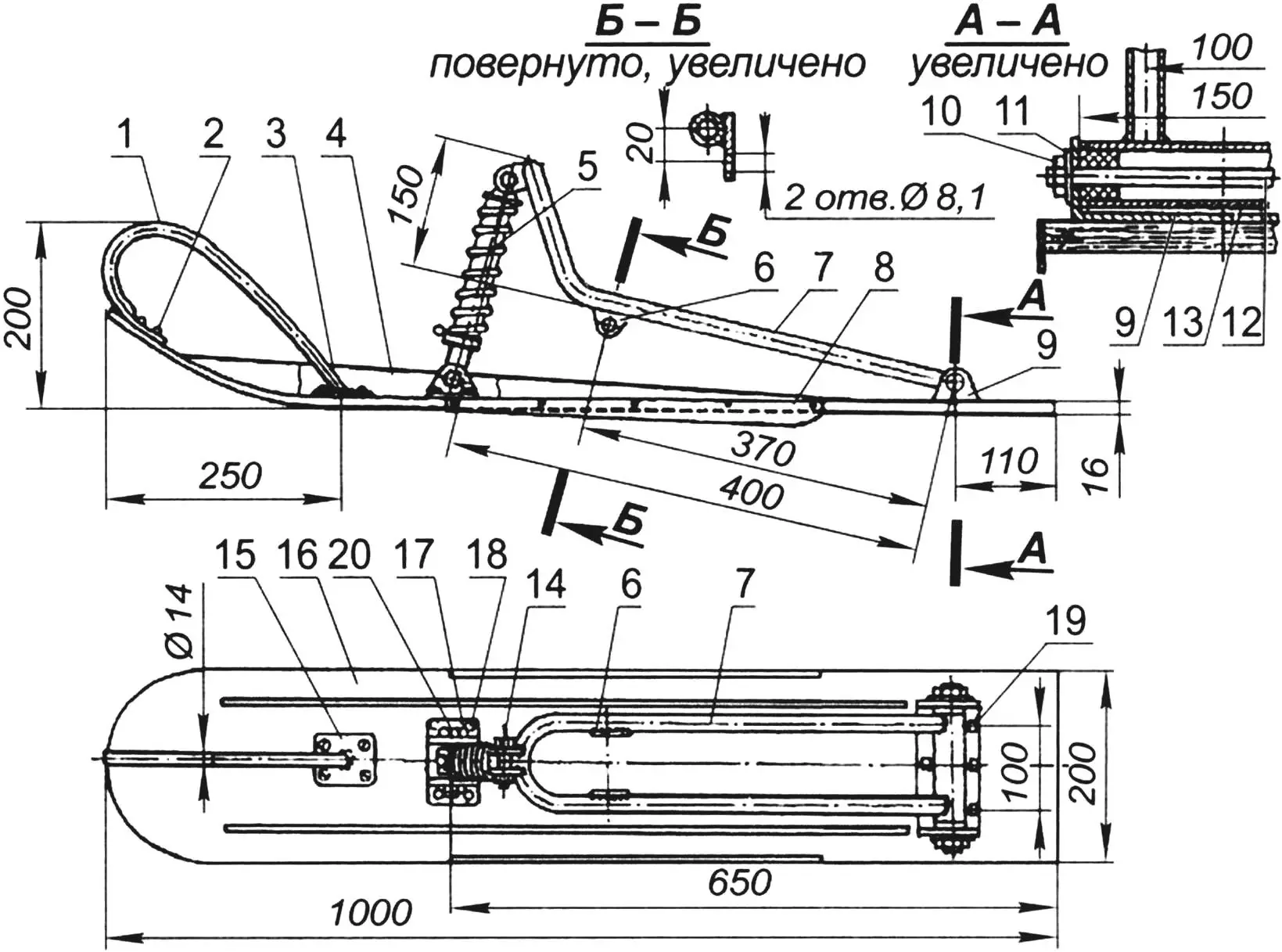

The skis are laminated from plywood blanks – three 5 mm plates are required for each. The ski sole is made of laminated plastic. Lamination is performed on a simple jig – a thick board with blocks nailed to its front part. Each ski is equipped with two runners – steel plates 3 mm thick. The shock-absorbing devices consist of a rocker bracket and a motorcycle shock absorber (from “Voskhod”). A tubular safety arch is installed at the front of the skis.

1 – safety arch (steel, Ø14×1.5 mm); 2, 3 – safety arch mounting; 4 – stiffening rib (10 mm batten); 5 – shock absorber (“Voskhod”); 6 – steering shaft bracket (steel 4 mm); 7 – rocker bracket (steel, Ø22×2 mm); 8 – runner (steel 3 mm); 9 – rocker bracket base (steel, channel 150x50x4 mm); 10 – M10 nut; 11 – washer; 12 – axle (M10 stud); 13 – joint housing (steel, Ø30×2.5mm); 14, 20 – shock absorber mounting; 15 – safety arch flange (steel 2 mm); 16 – ski (laminated); 17 – lower shock absorber support; 18 – support mounting; 19 – rocker bracket base mounting

The snowmobile steering mechanism consists of a motorcycle-type handlebar, a steering column with a double-arm lever, and a pair of rods with “Zhiguli” ball joints connecting the lever to the steering knuckles of the right and left columns. When designing the steering kinematics, it is reasonable to use simple models in a convenient scale made of plywood or cardboard to more accurately select the geometric parameters of the parts.

The fuel tank is a 10-liter aluminum canister into which a motorcycle fuel tap-sediment bowl is installed. For this, a threaded sleeve must be welded into the canister using argon arc welding.

The snowmobile body, consisting of a base and a hood, is laminated from fiberglass and epoxy resin over a mold made of plywood, boards, and plaster using traditional homebuilder technology. After removing the parts from the mold, if necessary, they are reinforced from the inside with stringers made of battens. Holes for the engine cylinder and front cross beam are cut in the hood and base. Finishing of body parts is performed using putty and cold-drying automotive enamels. Flanges are finished with decorative molding.

1 – engine mount (steel, Ø30×2.5 mm); 2 – steering column (steel, Ø25×2.5 mm); 3 – brace (steel, Ø18×2 mm); 4 – half-clamp (steel 3 mm); 5 – bearing housing bracket; 6, 9 – support roller axle brackets (steel 3 mm); 7 – shock absorber (“Izh”); 8 – pivoting carriage side member (steel, Ø30×2.5 mm); 10 – carriage axle bracket (steel 3 mm); 11 – frame base (steel, Ø30×2.5 mm);

12 – steering lever (steel 6 mm); 13, 15 – gussets (steel 3 mm); 14 – front frame beam (steel, Ø40×2 mm); 16 – steering column; 17, 19 – cross member (steel, Ø30×2.5 mm); 18 – bearing housing bracket (steel 3 mm); 20, 21 – engine mounting units

A floor made of 10 mm plywood impregnated with hot linseed oil is installed on the snowmobile frame. Strips of ribbed rubber are glued under the driver’s and passenger’s feet.

The snowmobile is controlled by a motorcycle-type handlebar, with a throttle grip and clutch release lever on the handlebar, and with brake and gear shift pedals. Electrical equipment includes a headlight and taillight.

The seat is a plywood box secured to the floor. A cushion made of rigid foam is glued on top of the box, and the entire unit is covered with artificial leather. The windshield is made of plexiglass. For its precise fitting to the hood, it is worth using a cardboard template.

Technical specifications:

Length, mm … 2080

Width, mm … 1200

Track, mm … 1000

Height, mm … 950

Engine, type … TG-200M

Displacement, cm3 … 199

Power, hp … 14

Maximum speed, km/h … 60

Igor GALKIN, engineer