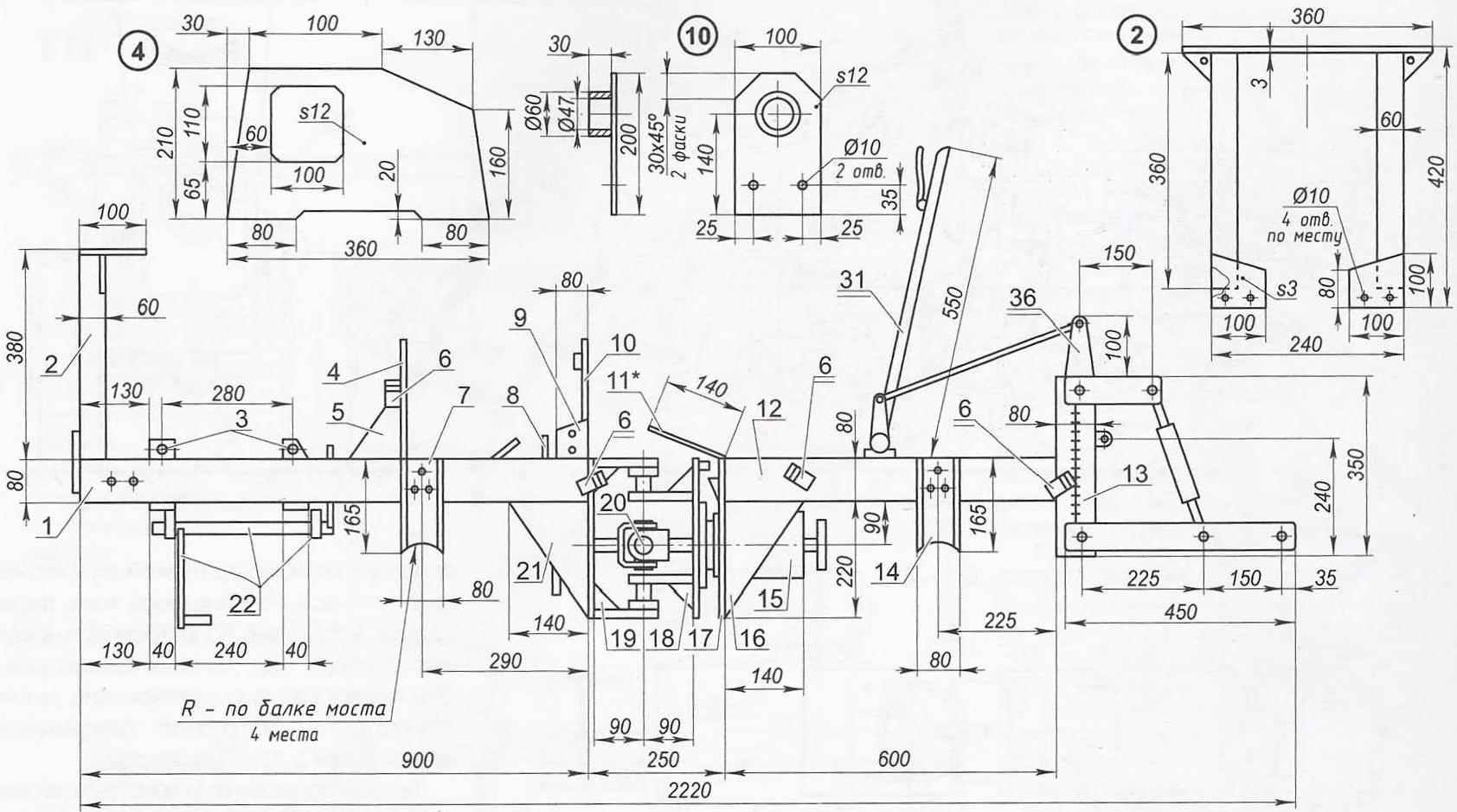

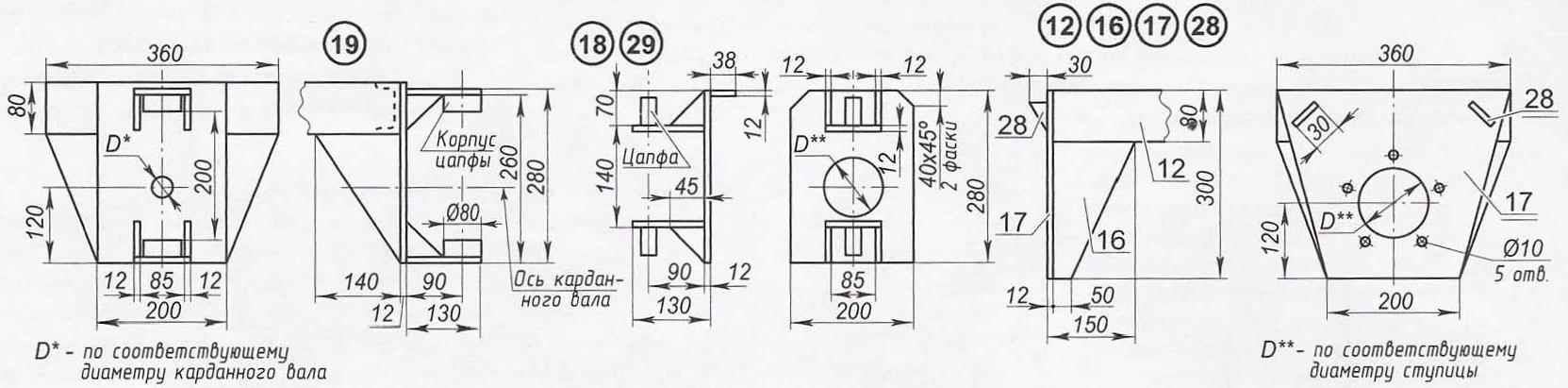

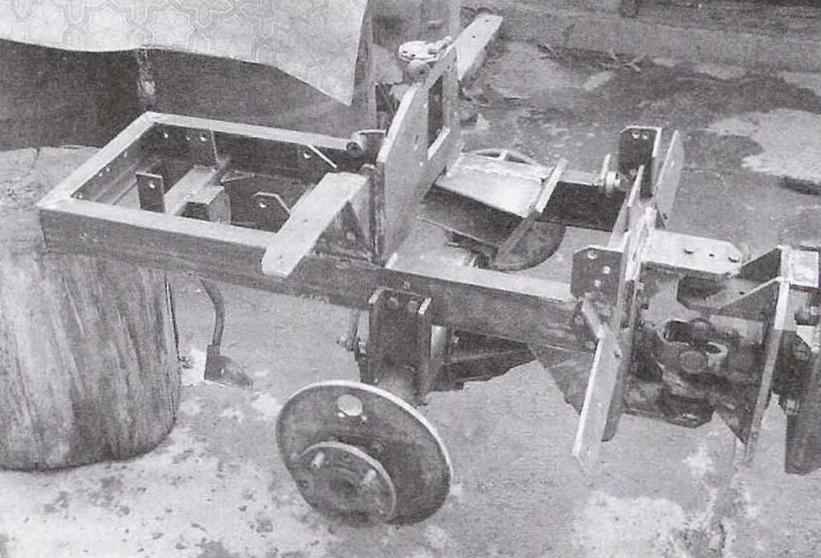

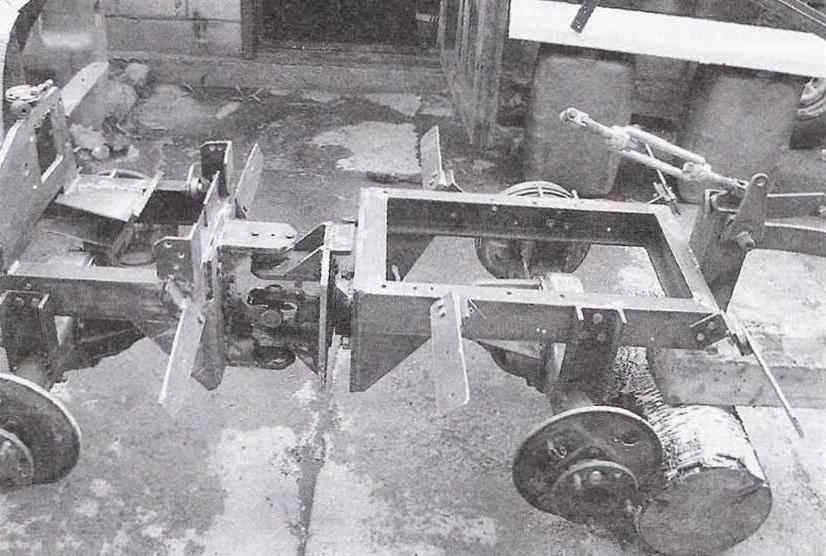

Now more about the design of the mini-tractor. The basis of it — two half-frames are a simple rectangular shape: the front size in terms of 900×360 mm and rear — 600×360 mm. Although they are made at different times, but both are welded from steel channel number 8 (the wall — of a height of 80 mm and a thickness of 4.5 mm, flange width 40 mm with variable thickness). The ends of the lines of channels for connection “on a mustache” cut at a 45°angle.

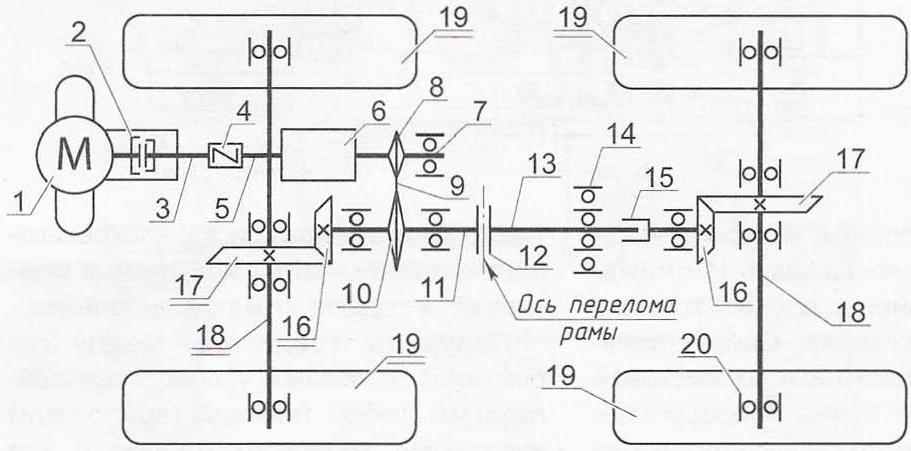

Kinematics mini-tractor:

1 —engine;

2 — gear box and clutch;

3 — output shaft of the power unit;

4—elastic (elastic) coupling (from a motorcycle “Ural”);

5 — primary (splined) shaft transmission (from a motorcycle “Ural”);

6—CAT (from the car “Moskvich”);

7 — secondary (output) shaft of the transmission;

8—small sprocket of the chain transmission (z= 17);

9—rung (t = 22,225);

10—the big sprocket driven chain transmission (z = 68);

11 —front prop shaft;

12 — universal joint (KAMAZ);

13—rear propeller shaft;

14—swivel;

15—spline connection parts rear drive shaft (from the car “Moskvich”);

16 — pinion main gear (from the car “Moskvich”,2);

17 is the driven gear (from the car “Moskvich”, 2);

18—the side shaft (from the car “Moskvich-412”, 4 PCs.);

19—the wheel (from the car “Moskvich-412”, 4 PCs.)

The front frame has two cross cuts from a rectangular tube 50×30 mm (flatted), the subframe power unit. And she also installed a wall of steel sheet with a thickness of 12 mm and welded on a few sites and brackets for mounting units, mechanisms and assemblies.

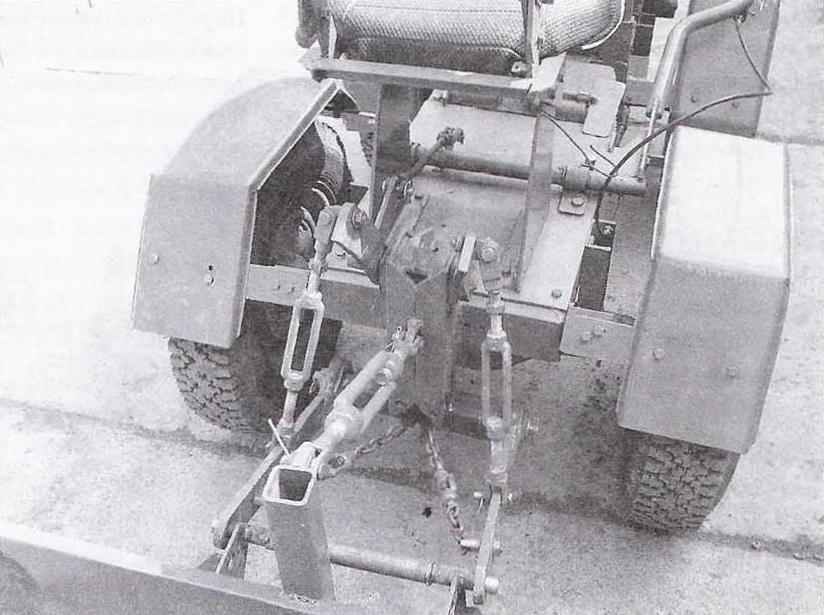

To rear frame rear welded stand made of rectangular tubes 80×80 mm (welded from two segments of channels No. 8, the stacked edges of flanges) for mounting the hinge to which podcasts tillage and other agricultural tools. And the front vertical plate for swivel node (mentioned later), backed on both sides with a scarf. And strut, and plate made from the same 12mm sheet steel. On top of the frame is covered with a flooring of sheet steel 3 mm thick. Front is attached subsequently another area of the same steel sheet, covering the “tipping” site. On it are mounted the pedal “gas” and clutch.

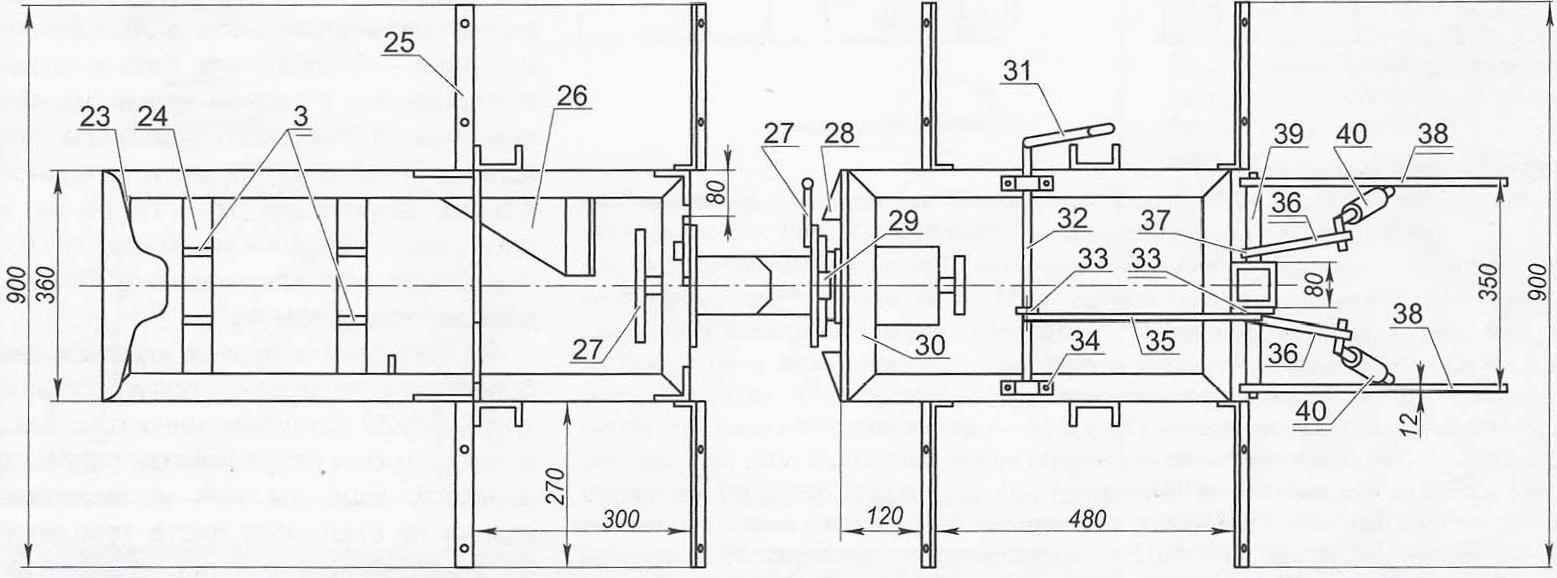

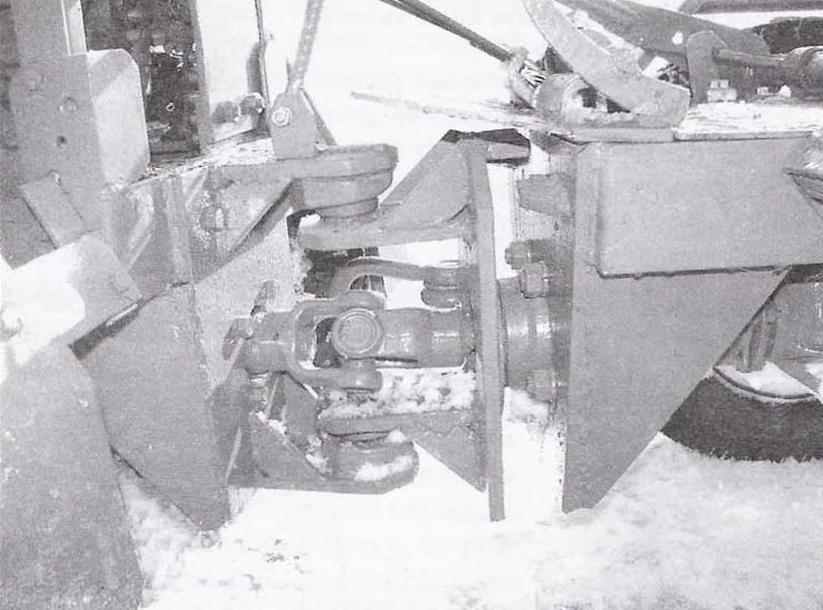

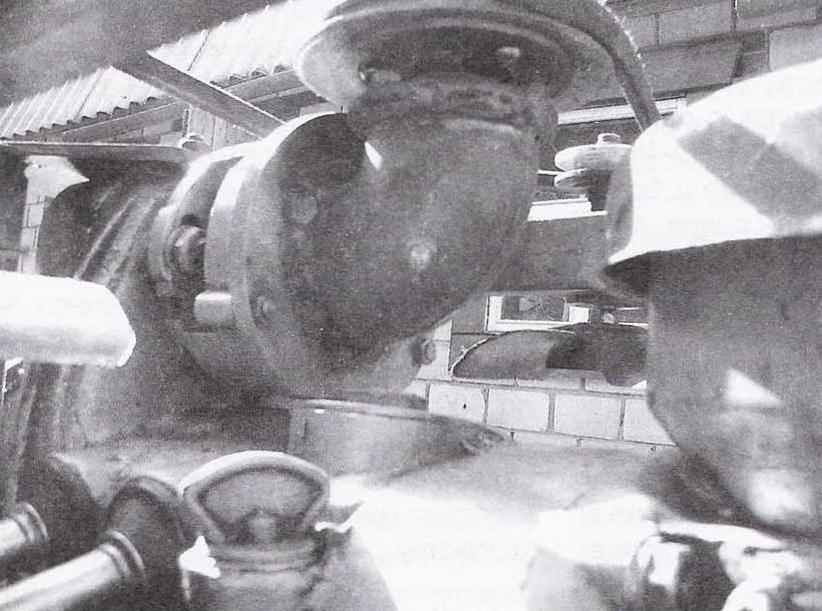

Half frames are connected by a “critical” node, which is a flat (single-axis) gimbal mechanism (hinge). His plugs are welded from steel 12 mm sheet. And the wall of the front forks welded directly to the rear traverse front half frames and reinforced gussets. The horns are reinforced forks too small gussets of the same steel sheet. Axle housings and bearing supports for the hinge cut off and used together with the bearings and lock washers from the respective nodes cardan shaft of KAMAZ.

Suspension of all wheels-dependent and hard. And to wheels of any of the bridges did not get stuck during movement of the tractor through the hillocks and pits, half frames still have the opportunity to “spin”, but rather to deviate at an angle of about 15° clockwise or counterclockwise from mid-position relative to one another. This happens due to the applied in the coupling of the two half-frames of swivel, made from the hub of the front wheel of the UAZ and set in front of the rear articulated. And to prevent too much rotation of the articulated one relative to the other, on the plate of the hinge is welded to the tooth size 38x10x12 mm, and the rear plate articulated welded two of the same stops.

Suspension of all wheels-dependent and hard. And to wheels of any of the bridges did not get stuck during movement of the tractor through the hillocks and pits, half frames still have the opportunity to “spin”, but rather to deviate at an angle of about 15° clockwise or counterclockwise from mid-position relative to one another. This happens due to the applied in the coupling of the two half-frames of swivel, made from the hub of the front wheel of the UAZ and set in front of the rear articulated. And to prevent too much rotation of the articulated one relative to the other, on the plate of the hinge is welded to the tooth size 38x10x12 mm, and the rear plate articulated welded two of the same stops.

The engine is mounted on the crossbars of the front articulated and enshrined here through the eyelets two long bolts. From the motor rotation through the soft connection (coupling) of the motorcycle “Ural” is transmitted on the primary (input) shaft transmission from the “Moskvich-412”. The transaxle is bolted to the frame via welded a plate thickness of 12 mm with four bolts. Far protruding end of secondary

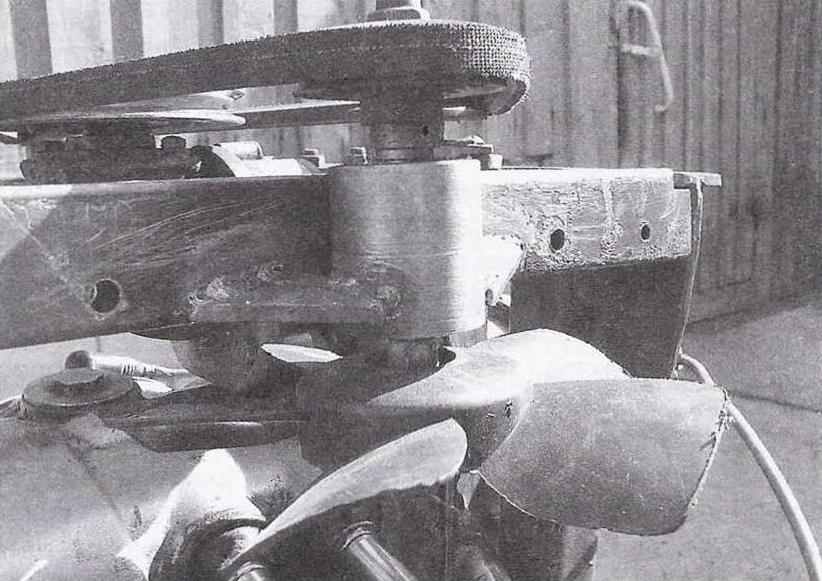

The engine is mounted on the crossbars of the front articulated and enshrined here through the eyelets two long bolts. From the motor rotation through the soft connection (coupling) of the motorcycle “Ural” is transmitted on the primary (input) shaft transmission from the “Moskvich-412”. The transaxle is bolted to the frame via welded a plate thickness of 12 mm with four bolts. Far protruding end of secondary  (output) shaft of the main shaft rests on the bearing installed in the bulkhead. At this end of the secondary shaft is fitted with hub 17-bevel sprocket — drive sprocket chain reducer. The other (driven) sprocket, 68 teeth planted in the front driveshaft. Sprocket connected by a chain with a pitch 22,225 mm. the Gear ratio (reduction in angular velocity or torque multiplication) chain reducer is 1:4. On the main transmission front axle rotation is transmitted directly from the shaft, and the rear axle via the propeller mechanism of the “turning point” node and then through the rear drive shaft. The rear propeller shaft consists of two parts slotted in them. For the first link was used was-zeway the end, cut off from the output shaft “moskovichevskoe” CAT, which is welded to the driveshaft. The second link is borrowed from “moskovichevskoe” propeller shaft. Due to the spline connection of the units with bends will be lengthening the rear shaft.

(output) shaft of the main shaft rests on the bearing installed in the bulkhead. At this end of the secondary shaft is fitted with hub 17-bevel sprocket — drive sprocket chain reducer. The other (driven) sprocket, 68 teeth planted in the front driveshaft. Sprocket connected by a chain with a pitch 22,225 mm. the Gear ratio (reduction in angular velocity or torque multiplication) chain reducer is 1:4. On the main transmission front axle rotation is transmitted directly from the shaft, and the rear axle via the propeller mechanism of the “turning point” node and then through the rear drive shaft. The rear propeller shaft consists of two parts slotted in them. For the first link was used was-zeway the end, cut off from the output shaft “moskovichevskoe” CAT, which is welded to the driveshaft. The second link is borrowed from “moskovichevskoe” propeller shaft. Due to the spline connection of the units with bends will be lengthening the rear shaft.

Bridges from the “Moskvich-412” (front and rear), tapered to the width of the wheels 700 mm. each, on both sides of the crankcase main gear cut the end part of the side casings (motorists often call them “stockings”), and flange limit switches (extreme parts of bridges with bearing seats and threaded holes in the ends) re-welded to the remaining parts of casings. But not immediately. It was accordingly shortened and axles (they cut out the middle pieces). Then to the outer flanged ends of the rod tack-welded weld splined inner ends, and after the mutual alignment of the two parts are welded completely. Next, prepare a shortened axle was bolted to the cut trailer axle regular screws and their inner ends inserted in the slotted hole of the differential gears. And only after the alignment of the trailer and the remaining part of the casing with the housing part have been welded.

Bridges from the “Moskvich-412” (front and rear), tapered to the width of the wheels 700 mm. each, on both sides of the crankcase main gear cut the end part of the side casings (motorists often call them “stockings”), and flange limit switches (extreme parts of bridges with bearing seats and threaded holes in the ends) re-welded to the remaining parts of casings. But not immediately. It was accordingly shortened and axles (they cut out the middle pieces). Then to the outer flanged ends of the rod tack-welded weld splined inner ends, and after the mutual alignment of the two parts are welded completely. Next, prepare a shortened axle was bolted to the cut trailer axle regular screws and their inner ends inserted in the slotted hole of the differential gears. And only after the alignment of the trailer and the remaining part of the casing with the housing part have been welded.

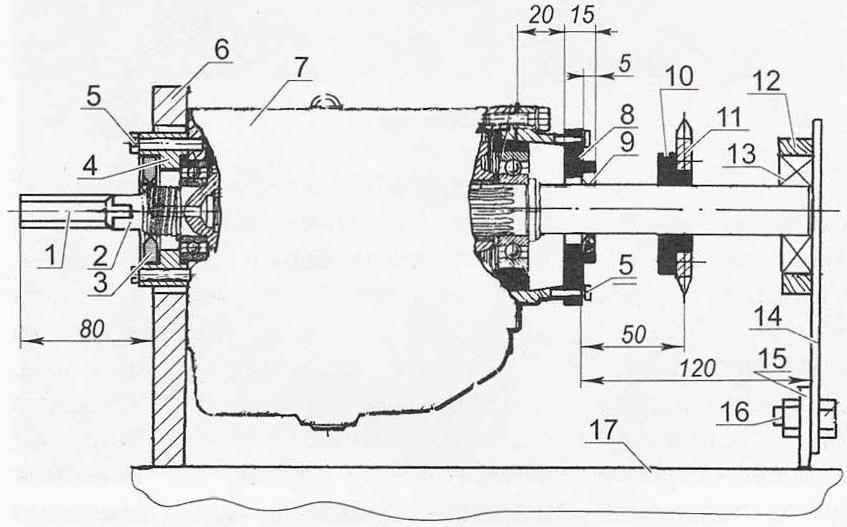

At the transmission from the “Moskvich-412” to the protruding end of the shaft to connect it to the power unit is welded the splined end of the propeller shaft of the motorcycle “Ural”. The length of the docked input shaft is 80 mm. But before that abutting ends of the shafts are being finalized. Runs on one spike, and the other is cut a corresponding groove. The hole in the crankcase of the box is covered with a makeshift lid with a seal, screwed to the crankcase with four screws M6.

At the transmission from the “Moskvich-412” to the protruding end of the shaft to connect it to the power unit is welded the splined end of the propeller shaft of the motorcycle “Ural”. The length of the docked input shaft is 80 mm. But before that abutting ends of the shafts are being finalized. Runs on one spike, and the other is cut a corresponding groove. The hole in the crankcase of the box is covered with a makeshift lid with a seal, screwed to the crankcase with four screws M6.

On the other hand PPC extension (casing) output shaft clipped at a distance of 20 mm from the body of the carton, and the end (exit) is blocked by a makeshift lid with a hole for the output end of the shaft, and machined in its wall an annular groove for the seal. The cover is bolted to the trimmed extension cable four screws M6 in the corresponding preset in the walls of the threaded holes.

The steering column is attached to a plate welded to the frame with three bolts M10. To give the plate rigidity thereto welded two scarves made of sheet steel with a thickness of 5 mm.

To rotation of the steering wheel coincides with the rotation of the tractor, changed the direction of the worm of the steering mechanism on the opposite (worm mounted on a shaft at the other end). This had to machined the slot in the adjusting nut bearing on the bottom of the crankcase and the hole in the lid. When turning the steering wheel always stays in front of the driver, although “donut” is on the front frame and the driver’s seat at the rear.

Modification of the input and output ends of the input shaft from the car “Moskvich-412” under the transmission mini tractor:

1 —slotted tip (from driveshaft of the motorcycle “Ural”;

2—the transaxle input shaft;

3 — seal;

4—front cover (steel);

5 — screw M6 (4 PCs.);

6—the partition frame;

7—the transaxle case;

8—back cover (steel);

9—packing gland;

10—hub sprocket (steel);

11—sprocket chain transmission;

12 — the bearing housing;

13 — the bearing;

14—stand;

15—bracket frame;

16 — bolt;

17—spar frame

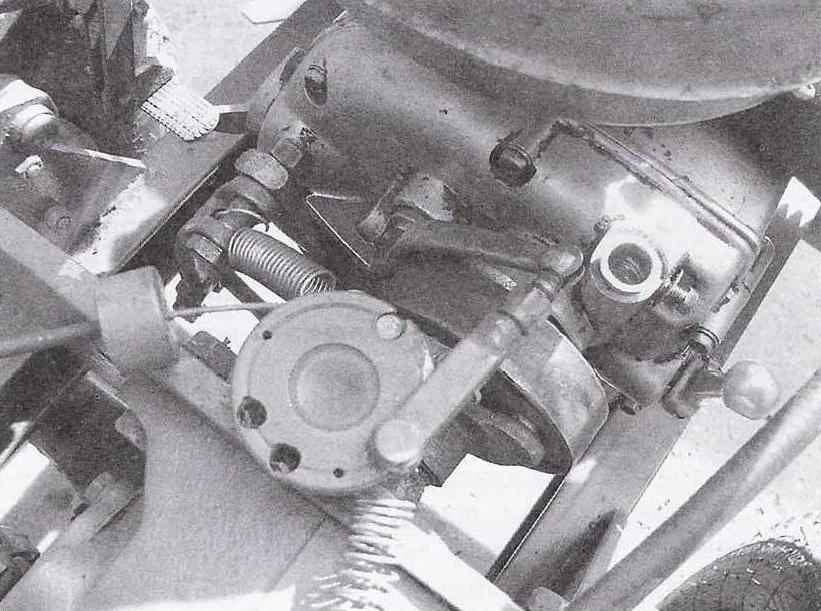

Since the engine was situated quite high above the ground, the launch motor is produced via an intermediate shaft mounted below the power unit in sleeves welded to the frame. At one end of the fixed shaft shortened to 140 mm, lever kick starter, the other pull a length of 140 mm.

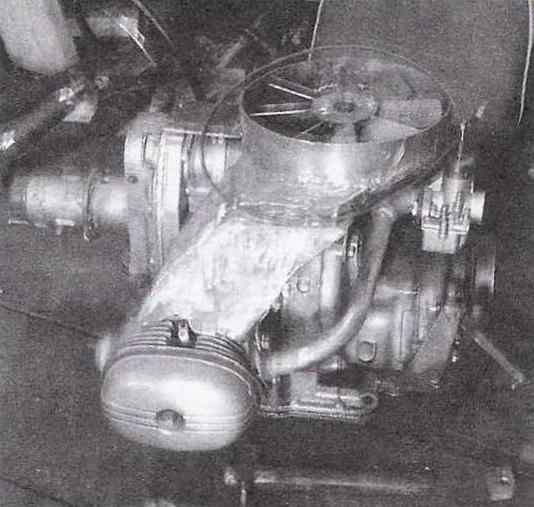

Cylinders equipped with forced air cooling. At first it was carried out from one Central (common) fan, but was not so effective. But because it was upgraded by equipping each cylinder with its impeller. The fan drive shaft made from converted regular “Orlovskogo” generator via the angular gear, the body of which served as a water container two-inch square. Gear for angle gearbox is taken from the corresponding node chainsaw “Friendship 4”. From one gear-shaft cut off the end, drilled and bored through in it a hole under the diameter of the rotor shaft of the generator, planted and welded. The other pinion shaft Assembly with bearings and a holder mounted in the housing of the angular gear with the other hand. On the output shaft of the reducer mounted pulley, which rotation through V-belt transmission is transmitted to the pulleys of the two fans on top of each cylinder. The cage of the bearings of the fans are welded to the frame of the hood. Pulleys from washing machines and fans from the heater core of the car UAZ-469.

Alteration (shortening) the casings and axles of the rear axle of the car “Moskvich-412” under suspension mini tractor:

1 —the axle flange;

2 — pin part of the axle shaft;

3—end-bell of the axle beam;

4—core (the middle part) of the driveshaft;

5—the guard (“stocking”);

6 spline (inner) end of the axle shaft;

7—Carter, the main transmission;

8—large differential bevel gear

Because the staff “Orlowski” generator used in the system of forced air cooling to ensure operation of the engine (ignition of the combustible mixture) applied magneto pumps. The drive of the magneto is supplied from the camshaft to which it podtykova front drum via a homemade adapter.

Fuel tank capacity of 8 litres, with a reworked wiring — now on two the carb used on the walking tractor.

![Diagram of angular gear system forced air cooling]()

Diagram of angular gear system forced air cooling:

1 — body alternator (from a motorcycle “Ural”);

2—the rotary shaft of the generator without winding (from a motorcycle “Ural”);

3 — flange bearing;

4 — flange (steel);

5 — washer (steel);

6—bracket reducer (plumbing fitting elbow 2″);

7, the leading bevel gear (gear-chainsaw “Friendship 4”);

8—dowel (steel);

9—driven gear shaft;

10—bearing-gear shaft (2 PCs.);

11—housing bearing shaft-gear (steel);

12—pulley belt transmission system forced air cooling;

13—mount the pulley (nut with spring washer);

14—mount the flange to the housing (screw. 3 PCs.)

The main gearbox is “Moskvichka”. The switch arm is fixed to the upper horn front fork articulated a “turning point” of the hinge. Shifting “Orlovskogo” the power unit is carried out by means of a handle located to the left of the steering wheel on the instrument panel, by thrust.

The main gearbox is “Moskvichka”. The switch arm is fixed to the upper horn front fork articulated a “turning point” of the hinge. Shifting “Orlovskogo” the power unit is carried out by means of a handle located to the left of the steering wheel on the instrument panel, by thrust.

The tractor is made from sheet strips (12-mm) steel, the length of the lower linkage hitch 450 mm upper 180 mm. the Lifting and lowering of the linkage when the operation produced by the lever located to the right of the driver’s seat. The length of the lever is equal to 550 mm, which allows without much effort to lift any suitable for mini tractor attachments agricultural tool.

As the suspension mini tractor hard, the seat is made of soft. Set it on a pedestal of two pairs of triangular plates held together by bolts. Due to the mutual displacement of the plates you can change the seat height, its distance to the steering wheel. There is also the possibility of adjusting the backrest angle.

The engine management system (“gas”) and traction is made with the help of standard motorcycle wires, but not from the handles, and using the pedal located on the platform covering the “tipping” site and attached to the rear frame.

The engine management system (“gas”) and traction is made with the help of standard motorcycle wires, but not from the handles, and using the pedal located on the platform covering the “tipping” site and attached to the rear frame.

Wheel tractors are all the same, size 6,15×13 inches, used from the car “Moskvich-412”. From him and hydraulic brake system, its wiring on frame — copper pipes and flexible hoses.

Mini tractor has about the same running characteristics as its predecessor with the engine of the motorcycle IZH Planeta-4, but the first is much more powerful and more reliable. Thanks to the two transaxle (the power unit and from the “Moskvich-412), established one after another, turned out a wide variety of speed modes, the tractor has 16 forward gears and 4 back. Quickly on both axles, the tractor began to overcome without any problems, seemingly insurmountable obstacles for him, even with trailer and load.

Someone seems that the construction of a mini-tractor too heavy. The way it is. But it is rather a plus than a disadvantage. First, this ensured the strength of the loaded nodes, and secondly — increases the grip of the wheels with the ground, which is important when using a tractor for plowing, and even more as a bulldozer shoveling the snow drifts in the winter.

Mini tractor operated on the land transport of goods up to 900 kg on the tow truck, hauling a horse-drawn mower in the hay, in the winter clean snow from the tracks and doing other things that you need around the house.

E. SHISHKIN, PGT Kil’mez’, Kirov.

Recommend to read

“Troll” – a business velomobile

“Troll” – a business velomobile

A modern city dweller cannot be intimidated by long trips: all types of public transport are at his service. Another thing is short everyday routes: to a kindergarten, a store, a workshop,... “WATER WITH A SIEVE”

“WATER WITH A SIEVE”

A good housewife in addition to mandatory colander in your kitchen Arsenal is still a spoon with holes, which helps when you need from pans or cans, for example, to extract something,...

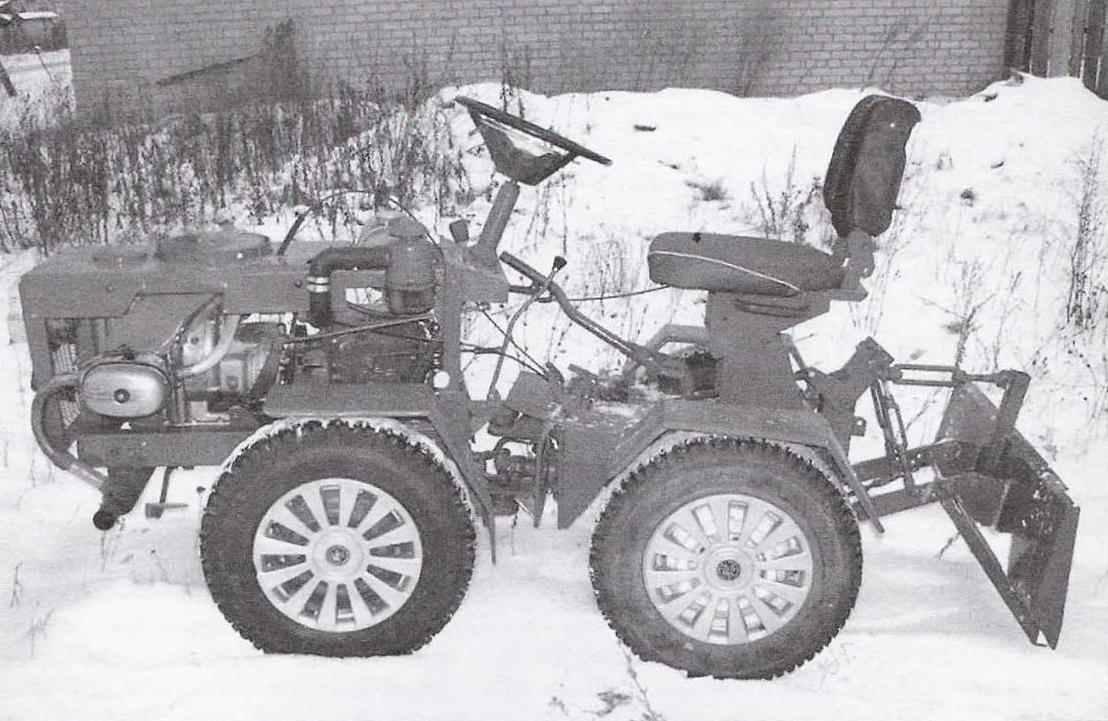

A mini-tractor, which will be the story for the third modification of my DIY construction, originally designed as walk-behind and built by me in 1985. It was the car with the power unit of the motorcycle “IZH-Planeta-4”, equipped with air cooling system and is equipped with an intermediate chain reduction gear. Tillers were intended mainly for the cultivation of the earth. For the transport of works behind him was poicephalus single axle truck with the seat and the body. Truck wheel was, of course, not leading. Reverse tillers also had and with it I felt it is not easy to handle, and realized that he largely loses the tractor.

A mini-tractor, which will be the story for the third modification of my DIY construction, originally designed as walk-behind and built by me in 1985. It was the car with the power unit of the motorcycle “IZH-Planeta-4”, equipped with air cooling system and is equipped with an intermediate chain reduction gear. Tillers were intended mainly for the cultivation of the earth. For the transport of works behind him was poicephalus single axle truck with the seat and the body. Truck wheel was, of course, not leading. Reverse tillers also had and with it I felt it is not easy to handle, and realized that he largely loses the tractor. Mini-tractor had a small size, small turning radius, good traction and maneuverability on the road. And on the way he could reach the speed of 40 km/h Track front and rear wheels was 700 mm, and the wheelbase (distance between axles) is 1 m and the vehicle could pass the gate with a width of only 90 cm, i.e., at the gate.

Mini-tractor had a small size, small turning radius, good traction and maneuverability on the road. And on the way he could reach the speed of 40 km/h Track front and rear wheels was 700 mm, and the wheelbase (distance between axles) is 1 m and the vehicle could pass the gate with a width of only 90 cm, i.e., at the gate.