A gardener, vegetable grower, or builder cannot easily do without such a vehicle as a wheelbarrow. When moving a wide variety of loads, it significantly lightens hard work—saves strength, time, and possibly health when transport volumes are substantial.

Construction material markets and hardware stores sell wheelbarrows of various designs. But at prices incomparable to their efficiency. Moreover, they are made like utility carts—with a wheel in front of the cargo platform (or body).

As is known from school physics, such a system forms a second-class lever. Therefore, almost half of the load’s mass falls on the hands of the person pushing it. If one tries to transfer most of this weight to the support point (wheel) by raising the handles higher, pushing the cart becomes much more difficult.

Unloading such a wheelbarrow by tipping it forward is also not easy, since the entire mass must be tipped over the support point (wheel). Dumping the load to the side creates such bending (torsional) moments in the cart’s frame that it is not designed for.

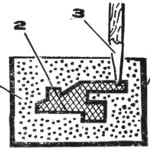

1 — wheel; 2 — fork with axle; 3 — body (steel stamped tub); 4 — support post (2 pcs.); 5 — handle (steel pipe 1″, 2 pcs.); 6 — frame cross member; 7 — frame; 8 — cradle; 9 — brace;

units 1,2 — from “Elektron” scooter; parts 4,6,7,8,9 — from steel pipe 1/2″

I made the frame of my wheelbarrow together with the handles, bending it in the shape of the letter U from half-inch water and gas pipe (its outer diameter is 21.3 mm). From segments of the same pipe—all other parts: cross member, support posts, braces, cradle.

I bent large radii of parts “cold,” small ones—with local heating using a blowtorch. I performed all connections of elements by electric arc welding.

As a body, I used an old factory-made steel stamped tub. I determined the dimensions of the wheelbarrow frame based on it, since the tub is inserted into it. I widened the handles for a comfortable grip. I put and welded handles on their ends—segments of one-inch pipe.

The body is removable and attached to the frame with four M4 bolts through corresponding holes in the tub’s flanging and in the frame pipe. Under the middle of the body, I welded a cradle bracket to the frame.

For the running gear, I used a wheel with axle and fork from the “Elektron” scooter. I welded the wheel fork to the cradle. I reinforced the mounting of this unit with two braces. I secured the lower ends of the braces in the standard lugs of the fork blades, and welded the upper ones to the front part of the frame.

So that the body would be horizontal when loading and the wheelbarrow itself would not tip to the side, I welded support posts to the handles near the cross member. So they would not sink into the ground, I welded base plates to them from below.

The chassis construction—running gear and frame—turned out very rigid. It allows unloading the body on three sides: forward, left, and right. At the same time, the wide-profile pneumatic tire of fairly large diameter provides the wheelbarrow with good cross-country ability and smooth ride.

Thanks to the fact that the center of gravity falls on the wheel axle, it is easy to transport loads weighing 50—60 kg on the wheelbarrow even for an untrained person. Dumping materials transported in bulk also does not require much effort.

And one more thing. For convenience when moving loads down an inclined surface, I plan to install a brake lever with cable on the wheelbarrow, since the brake in the wheel is already present.

A. NARVATOV