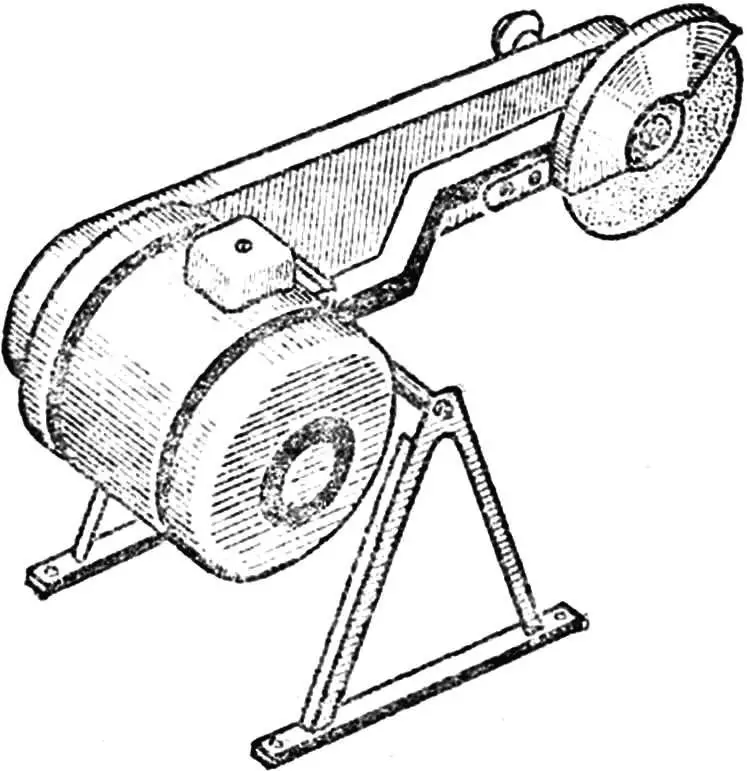

It’s useful to supplement the arsenal of metal-cutting machines in a home workshop with a pendulum saw. It can be mounted on a workbench, next to bench vises, in which the workpiece to be processed is clamped. The working tool of the saw is an abrasive disc. It can handle steel bars, angles, pipes, sheets hardened to any hardness, and even encaustic tiles, porcelain, and glass, with the cut surface being quite clear. If you replace the disc with a saw with fine teeth, you can cut wood, plywood, or plastic, while a diamond disc will allow you to process stones.

For clamping the workpiece, it’s convenient to use swivel vises; in this case, cutting can be done at an angle, which is very convenient when preparing parts for welding.

Various attachments to the saw allow you to make shallow cuts and grooves and even turn it into a regular “circular saw.”

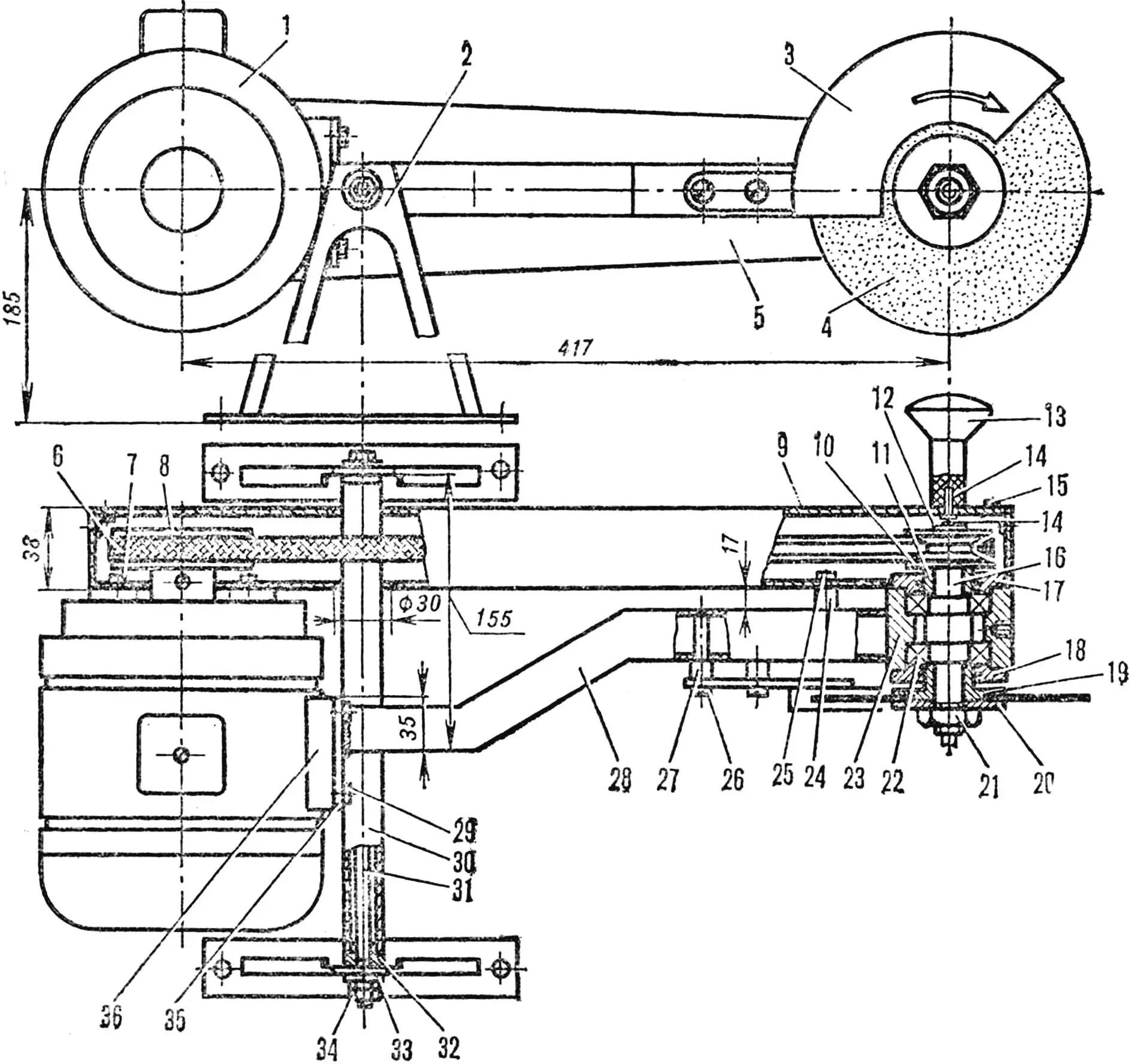

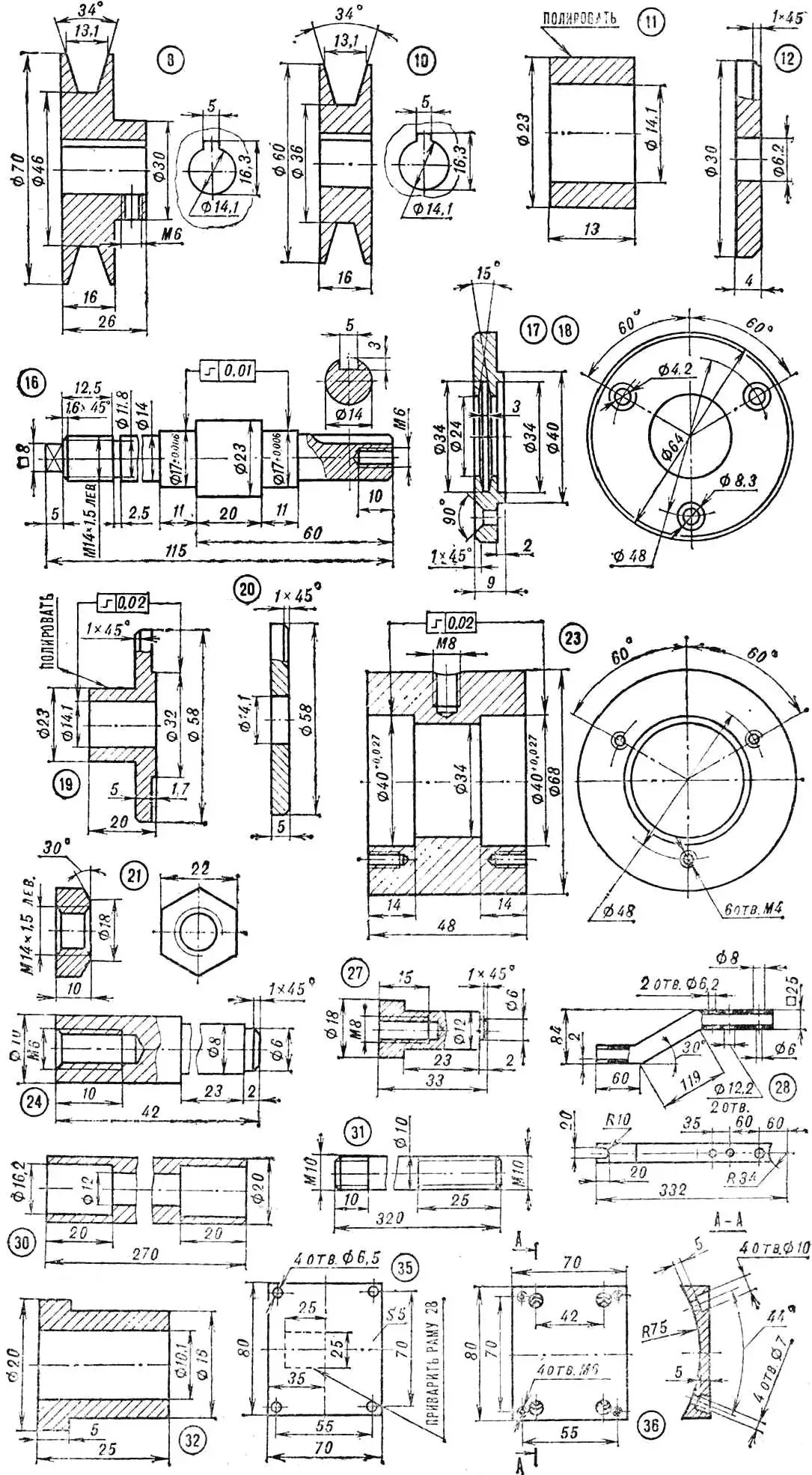

1 — electric motor, 2 — support, 3 — tool protective guard, 4 — tool (abrasive disc), 5 — belt protective guard, 6 — V-belt A-1018, 7 — screw M8X14 mm, 8 — drive pulley (D 16), 9 — belt guard cover (steel), 10 — driven pulley (D 16), 11 — spacer bushing (steel), 12 — washer (steel), 13 — pendulum feed handle, 14 — bolt M6X12 mm, 15 — screw M5X10 mm, 16 — shaft (steel), 17 — cover (D 16), 18 — cover (D 16), 19 — bushing (steel), 20 — washer (steel), 21 — nut (steel), 22 — ball bearing No. 203, 23 — housing (steel), 24 — boss (steel), 25 — screw M6X8 mm, 26 — screw M8X16 mm, 27 — boss (steel), 28 — frame (steel), 29 — bolt M6X16 mm, 30 — pipe 1/2″ (steel), 31 — axis (steel), 32 — bushing (steel), 33 — washer, 34 — nut M10, 35 — plate (steel), 36 — intermediate housing (D 16). Main saw parts see p. 20.

For such a saw, you will need a single-phase electric motor with a power of 340 W (from an electric grinder) or a three-phase type AOL 21-2 with a power of 400 W and a rotation speed of 2800 rpm. The rotation transmission to the machine spindle is by a V-belt type A-1018 from a GAZ-24 car.

The base of the saw is a backbone frame of square cross-section, to which the spindle housing is welded on one side, and a plate for mounting the motor on the other. A 1/2″ pipe is passed through a slot in the frame—it is the housing of the saw’s oscillation axis. When performing welding work, make sure that the motor shaft axis, the spindle shaft, and the saw’s oscillation axis are strictly parallel. After welding, be sure to straighten the frame, clean the welds, and paint with nitro enamel with preliminary priming.

The belt guard and abrasive disc guard are made of 2 mm thick sheet steel. It’s best to weld the blanks from the inside with a fillet weld. The belt guard is fastened with screws directly to the motor and frame, to which the abrasive disc guard is also screwed. The drive handle is located on the removable belt guard cover.

Before assembly, pack the spindle bearings with CIATIM-221 grease. Insert felt rings soaked in liquid grease into the bearing grooves.

In the assembled saw, the motor should outweigh the spindle and be located at the bottom, between the supports; otherwise, when the saw is turned on, the abrasive may hit the workpiece and crumble.

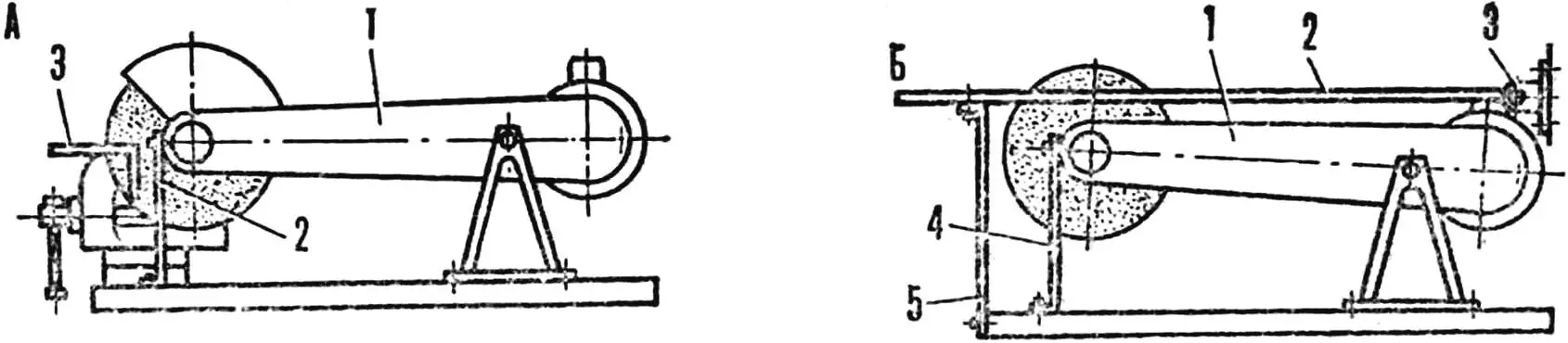

A — for cutting grooves:

1 — belt drive guard, 2 — bracket, 3 — work table, secured in vises;

B — for cutting sheet material:

1 — belt drive guard, 2 — folding table, 3 — hinge, 4, 5 — brackets.

When working on a pendulum saw, it is necessary to strictly observe safety rules. The power cable must be protected from mechanical damage by a steel flexible hose, which can be taken from a shower hose. The electric motor, as well as the saw itself, must be reliably grounded. Fasten the working tool on the shaft only with a nut with left-hand thread. Working with the saw without safety glasses is dangerous.

If during operation of the device the drive belt loosens, it must be tightened, for which it is sufficient to place a plate of the required thickness between the frame plate and the motor.

«Modelist-Konstruktor» No. 12’85, V. ZAYTSEV, design engineer