A mini-electro-calorifier (MEC) type heater is unlikely to surprise anyone these days. These compact and quite convenient household appliances can be purchased to suit any taste.

However, it’s not at all necessary to spend money on industrial products, let alone imported ones. I, for example, have long been using a homemade MEC that, by unanimous agreement of my household, is quite aesthetically pleasing. Its basis consists of a nichrome spiral from a hotplate, a record player motor (henceforth referred to as an “electric motor” for respectability) and a tin can from paint.

As in most industrial analogs, the air flow in this calorifier is created by a homemade multi-blade propeller. Rigidly fixed on the electric motor shaft, it drives air through a red-hot nichrome spiral, secured on spacers made of heat-resistant electrically insulating material. This is in the mode of heating a room or drying clothes. With the heater turned off, the homemade MEC works as an ordinary fan.

That is, idleness does not threaten such an electrical appliance. There’s no reason to doubt its reliability either. The only thing required of users is not to forget about fire safety rules.

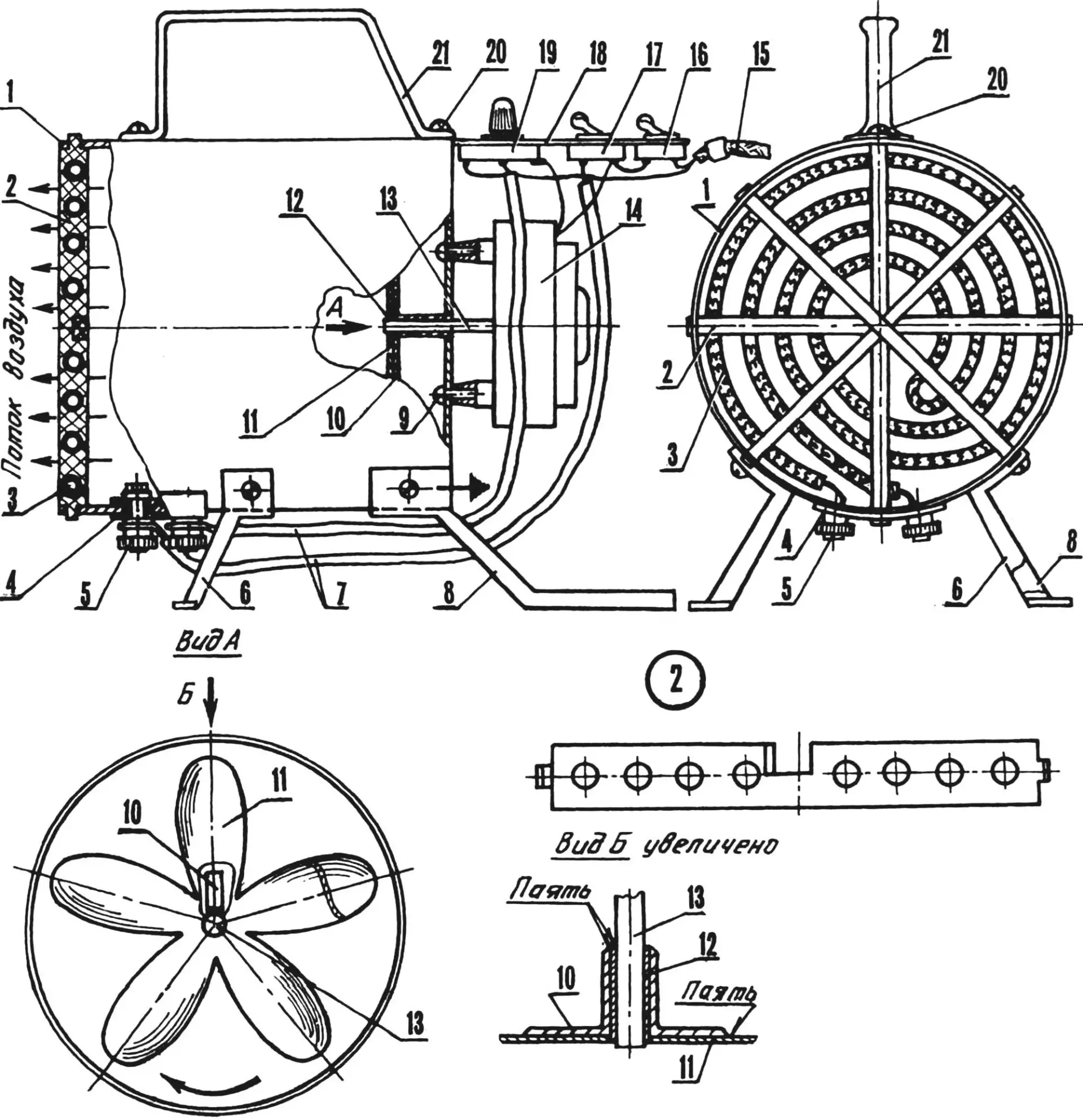

1 — housing; 2 — thermal insulator (slate, strip L150, 4 pcs.); 3 — electric heater; 4 — insulating insert; 5 — terminal (2 pcs.); 6,8 — legs; 7 — mounting wires in heat-resistant insulation; 9 — screw M4 (4 pcs.); 10 — angle bracket (quantity — according to the number of propeller blades); 11 — propeller; 12 — mounting bushing; 13 — electric motor rotor; 14 — electric motor with capacitor and resistor in the winding circuit; 15 — electric cord; 16 — main switch; 17 — electric heater switch; 18 — control panel; 19 — speed regulator; 20 — self-tapping screw (7 pcs.); 21 — handle;

plug and fuse are conventionally not shown; dimensions of homemade parts — as needed

As already noted, a tin can from paint was adapted as the housing for the homemade MEC. This was dictated not so much by the availability of the source material, but by maximum simplicity, and hence, reliability of the entire construction. With any other technical solution, it would have been necessary to take care of additional brackets for mounting the electric motor.

Here, brackets were not needed, they were replaced by… the bottom of the can. In it, strictly in the center, an air intake window was cut and holes were drilled for the electric motor mounting screws.

The electric motor from the “Yunost-301” record player was very well suited. It is compact, reliable and economical, and at the same time develops a sufficiently large torque and high shaft rotation speed. And most importantly—for operation in a household network, it needs neither a step-down transformer nor an imported adapter.

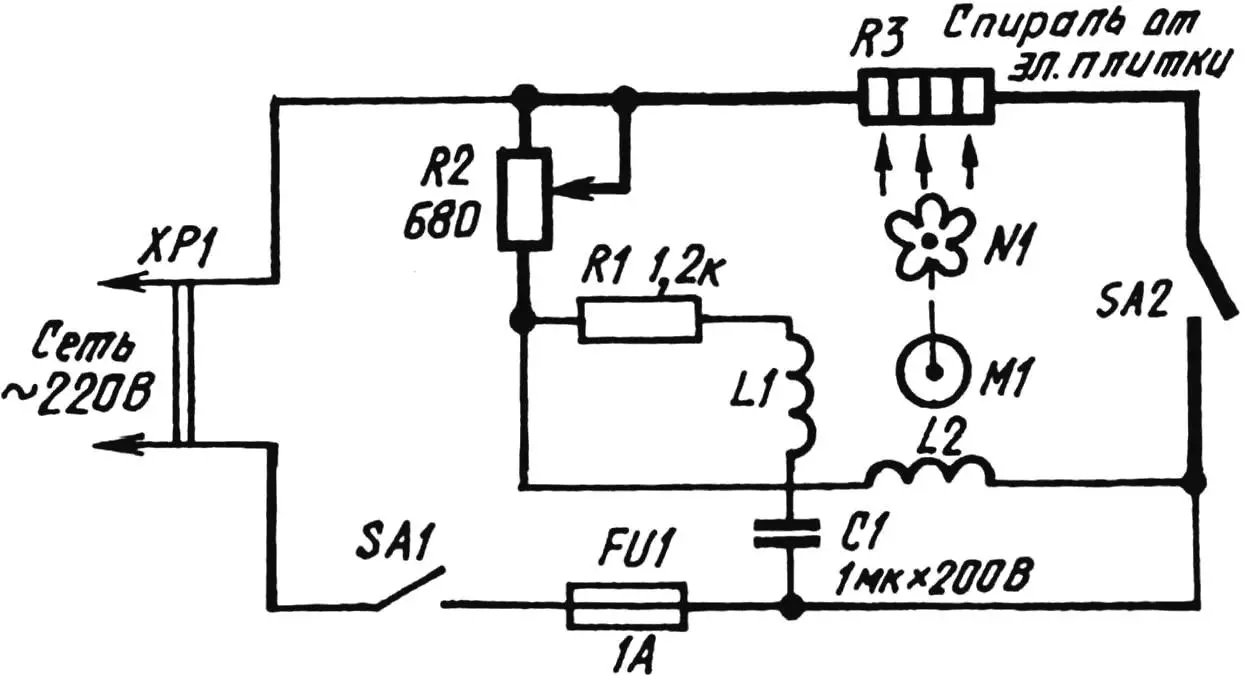

In particular, to a household 220 V network, this electric motor, which has only two windings, can be connected according to a circuit with a K-40P capacitor with a capacity of 1 μF and a PE-7.5 resistor with a resistance of 1.2 kΩ. And to make such a device more convenient to use, small improvements were introduced in the form of a variable resistor SP (1 W, 680 Ω) for regulating the air flow speed and a toggle switch for controlling the heater.

The propeller is cut from white tin from a can. The number of blades is chosen as desired—I limited myself to five. Such a propeller is mounted on the electric motor shaft using simple brackets (pieces of steel angle) and a bushing made from the same white tin. Soldering—with tin solder.

The nichrome heater is from an inexpensive electric hotplate. In the calorifier, this spiral is placed on heat-resistant slate spacers-thermal insulators, in which holes of the appropriate diameter and a central (for assembly in a tenon) rectangular cut are made. Moreover, the length of the latter in a pair joined in the form of the letter X is twice as large as in the cross-shaped variant.

For convenient connection of the heater to the MEC, special terminals are provided. In the calorifier, they are located at the bottom of the can-housing, on a special panel made of fiberglass laminate.

In the upper part of the air intake end of the MEC, a control panel is mounted on self-tapping screws with a fuse (not shown on the assembly sketch), a regulator for the electric motor shaft rotation speed, and toggle switches for turning on the household appliance both with and without the heater.

To make this entire construction stable, legs are screwed to the bottom of the housing, and a handle for carrying is provided on top. The mass of the homemade electric calorifier is slightly more than a kilogram. The power consumption depends mainly on the heater. In this variant, it is about 100 W.

A. KLOCHKOV