The times when caring for people’s health in our country was a state matter are long gone.

The quality of free medical care now depends only on the doctor’s conscientiousness, while paid care depends on the amount you can “fork over,” and even that’s not always the case. Therefore, I advise taking care of your health yourself.

As is known, physical education is health’s sister, and sports is its brother, and their first helpers are sports equipment. One of the most well-known and simplest structures of this kind is the pull-up bar—an elastic horizontal bar mounted on supports.

In gyms, the horizontal bar is mounted on telescopic supports (to allow adjusting its height), and the supports themselves are secured with guy wires.

In everyday life, one can often see a horizontal bar mounted on two posts or between two trees.

I “borrowed” the design of my pull-up bar from children’s swings. They don’t have posts as such, but rather two pairs of struts installed at equal angles to the vertical, supporting each other and the horizontal bar. Each pair is connected by a cross brace. Well, I had to figure out the underground part of the structure myself.

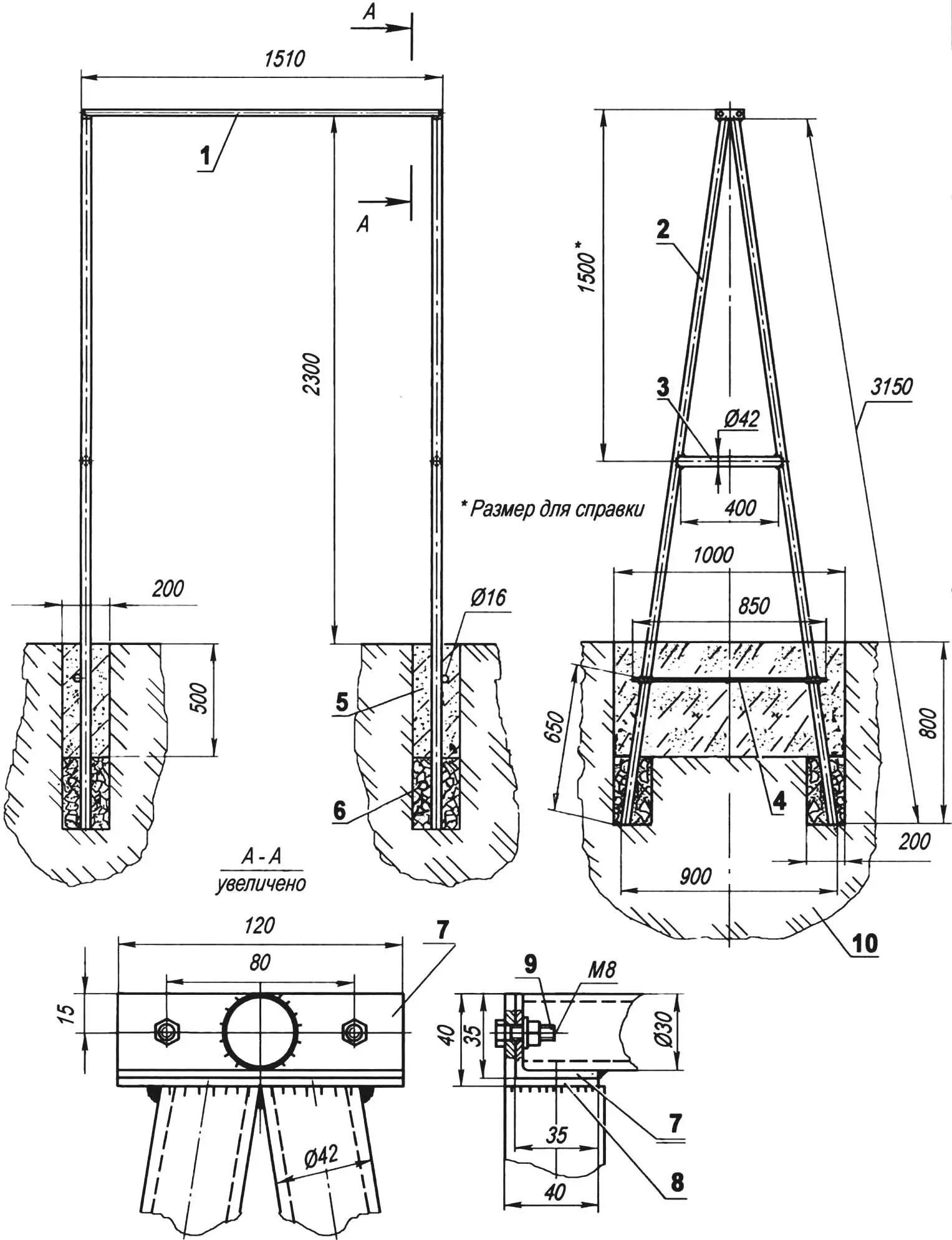

1 — horizontal bar (steel pipe 30×2.5); 2 — strut support (steel pipe 42×2.5, 4 pcs.); 3 — cross brace (pipe 42×2.5, 2 pcs.); 4 — tie rod (steel reinforcing bar Ø16, 2 pcs.); 5 — foundation (monolithic concrete); 6 — backfill of pit (soil, crushed stone, brick rubble, 4 pcs.); 7 — horizontal bar bracket (angle 35×35, 2 pcs.); 8 — strut support bracket (angle 40×40, 2 pcs.); 9 — fastening of horizontal bar and strut support brackets (bolt M8, 4 pcs.); 10 — natural ground

The strut supports are made from steel water pipe with a diameter of 42 mm and a wall thickness of 2.5 mm.

At the top, the ends of the strut supports are connected by an angle bracket (welded to it), in the middle—by a cross brace (a section of the same pipe), and closer to the lower ends, in the foundation section, also by a tie rod made of steel reinforcing bar with a diameter of 16 mm. I should also note that the angle brackets were made from equal-leg angle 40x40x5 mm, with the inner radius milled out (so that the horizontal bar brackets fit tightly against the strut support brackets). The holes for the fastening bolts in the joined brackets were drilled simultaneously.

The horizontal bar is cut to size (1500 mm) from thick-walled water pipe with an outer diameter of 30 mm. I consider this the optimal thickness. If you take a thinner pipe, its strength and rigidity may be insufficient, while a thicker one will be difficult to grip with your fingers “in a lock.” Brackets made from 35×35 mm angle are welded to the ends of the pipe.

To install the strut supports at the chosen location, a separate foundation is built for each pair. Small trenches measuring 1000x500x200 mm (length x width x depth) are dug for the foundation, and their bottom is deepened at the edges by a spade’s depth—square pits are made for the lower ends of the strut supports, which are lowered into them. One must ensure that the distance between the supports at the bottom equals the upper gap when the horizontal bar is attached, and that the horizontal bar itself is positioned strictly horizontally. The pits are backfilled with soil, crushed stone, brick rubble, etc. At this time, the position of the strut supports in the vertical planes is checked, and the backfill is tamped. Then the trenches are filled with concrete mix, which is “butted” for economy—filled with large stones.

You can start using the pull-up bar only after two to three weeks, when the concrete has gained sufficient strength to prevent the supports from shifting under loads.

I should mention that the sports equipment is used not only for its intended purpose—for morning exercise. On fine days, I often hang children’s swings on it—I even made my own horizontal bar for them—with rolling bearings. The pull-up bar is also frequently used for household purposes—it’s convenient for hanging carpets and rugs for cleaning, as well as for drying winter clothing on hangers in sunny weather, etc.

A. MATVEYCHUK