A white sail gleams

A white sail gleams

In the mist of the blue sea…

These lines from a beautiful poem by the great Russian poet always evoke a dreamy sadness and a burning desire to go into the unknown… Remains the owner to build with their hands a fabulous sailboat. But how? The creation of a real cruising yacht — a complicated and expensive. And the dream remains a dream. She calls the craftsmen to look for ways to simplify the design and reduce the cost of technology for the construction of the vessel, receipt for sailing on rivers and inland waters of our country. This design was created and tested for use by members of the OKB in our magazine. And here’s the place it takes in the “table of ranks” of the sailing fleet.

The greatest distribution was now instructed sports and tourist sailing yachts. They are divided into groups, classes, and types in accordance with international and national regulations. Key among them (design features) — keel yachts, dinghies and “compromise”. How do they differ from each other!

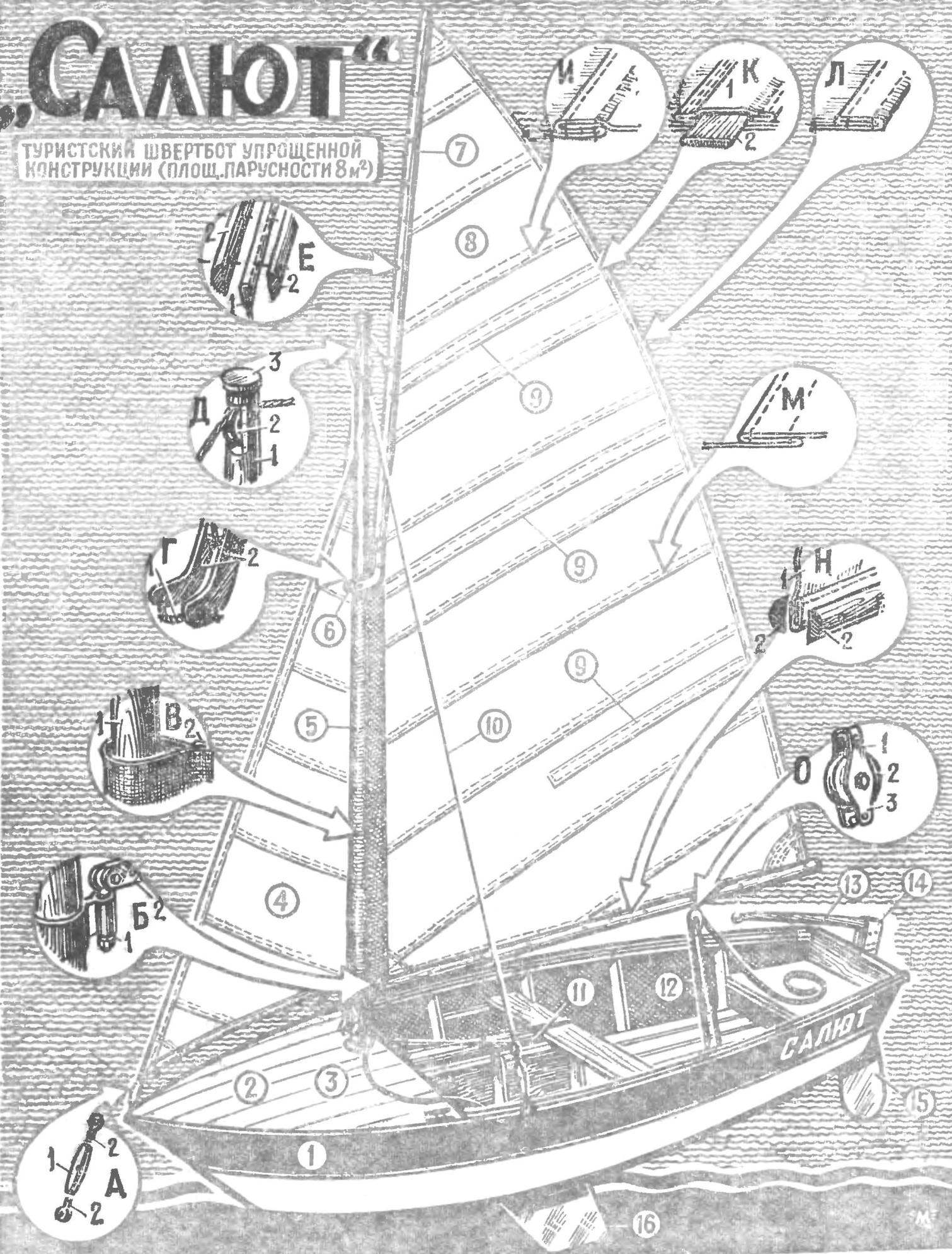

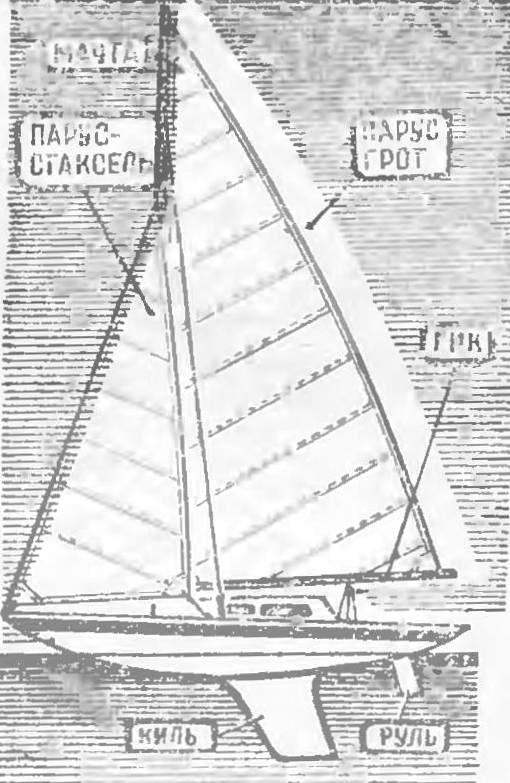

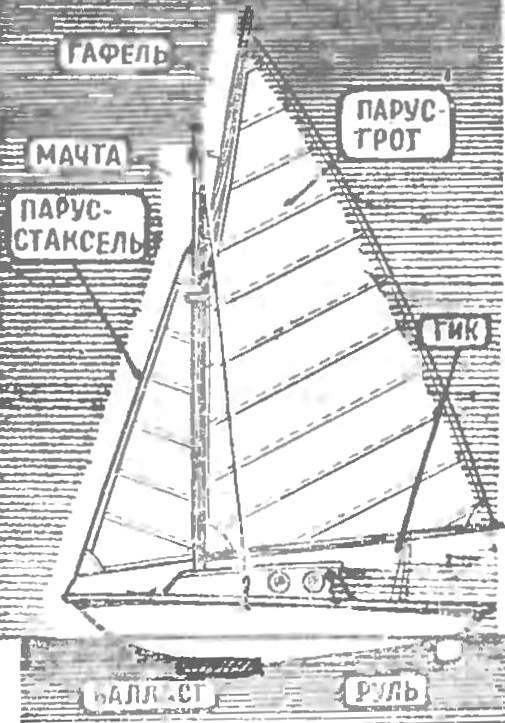

Housing first yachts have deep down in the water heavy keel (Fig. 1), through which the boat cannot tip over. Even the strongest gust of wind are not afraid of this kind of “Vanka-vstanka”. Keel yachts are intended for use at sea and large reservoirs. But deep keel does not allow these ships to sail on rivers and small lakes. Here they are replaced by so-called dinghies (Fig. 2) — sailboats with retractable keel-centerboard in the form of a steel plate, which is placed in an appropriate housing inside the boat and can get down in the water at the depths and rise up in the shallows. The Dinghy is very easy to operate, but their stability is unsatisfactory, especially if the centerboard is raised. So the designers of yachts in search of a way created another type of yacht that combines the advantages of the previous two: his so-called “compromise” (Fig. 3). The hulls of these boats like smartnote, but are attached to the bottom of the ballast. Not increasing in any significant draught yachts, this weight gives it great stability. Yacht “compromise” may have a centerboard and ballast; this allows it to float as shallow water bodies and the sea.

Fig. 1. Keel yacht with sail-type “Bermuda sloop”. Has two sails — a mainsail and jib; the mast consists of a mast and boom.

Fig. 2. Dinghy with sail type “cat”. Has one sail, the mainsail, up gavela (the so-called “Guara”); mast consists of mast, boom and Hafele.

Fig. 3. “Compromise” with the rigging of the “sloop”. Has two sails — a mainsail “Guara” and jib; the mast consists of mast, boom and Hafele.

Now will talk about the basic types of sails used in sports, tourism and business practices. The so-called “Bermuda” sail (Fig. 1), came to us from the inhabitants of Bermuda, with all its apparent simplicity, has a very high aerodynamic qualities. It is shaped like a bird’s wing. The only drawback of the Bermuda sail (operational) in that it requires a very long and strong mast, that in Amateur conditions to make difficult. So they often give preference to weapons of the type “Guara” (Fig. 2) also borrowed from the inhabitants of Oceania. It is very similar to the Bermuda, but the mast can be almost twice shorter and the sail is raised by means of the additional pole, called a gaff. The gaff has approximately the same length as the mast, and during transport, the sail turns into a small package, not beyond the dimensions of the hull of the Dinghy.

In addition to these, there are a great many systems using SIPU wind: rigid sails like airplane wings, rotating (“WindRotor”), etc.

We offer our readers a simple Dinghy “salute” with a length of 4.5 m and a width of 1.5 m — sailing ship with weapons “Guara”. Its design is according to numerous requests of readers is designed to use the most readily available materials. This allows us to hope that the dinghies of the “salute” will be widely distributed and will give impetus to the further development of Amateur construction of sailing ships in our country.

For the sheathing of Dinghy “salute” in advance of need to procure 15 good pine or fir boards with a length of 5 m and a width of not less than 200 mm and a thickness of 10 mm, and the frame is pine wood.

All the material should be well dried and planed on four sides (preferably not by hand, and on reissuance). When selecting wood it is necessary to make sure that she had no knots, rot, blue stain or wormhole: preference should be given to the Northern (grained, dense) varieties of pine (spruce), especially for such critical elements of the hull as the keel, bilge and RUB rails. If possible, the casing should be done out of plywood thickness 5— 6 mm, this will speed up work and to get the best results.

For sail will need about 10 m2 special sailing fabric is calendered Dacron or Dacron. But since these tissues are not everywhere you can buy, we will mention possible substitutes: crisp, Bologna, Cape-tent fabric, women’s panties, pillow tick. The amount of fabric is determined based on the width, with the addition of not less than 15% for seams and shrinkage during dekotirovaniem before stitching. So, if the fabric has a width of 90 cm, you will need 12 linear feet. Also need strong thread (preferably synthetic) and 30 m of cord with a thickness of 8-10 mm for the navigation system (production files and the Scots).

For centerboard and rudder suitable sheet steel of 8 mm thickness (the centerboard) and 6 mm (rudder); the sizes shown on the drawings. A small amount of plywood required for the manufacture of the brackets during Assembly samotnych framework and mold of the front of the hull.

The mast is fixed on the chassis by means of three extensions of a steel cable with a thickness of 5 mm; the front of these stretch marks is called the forestay, side — guys. Guys tighten screw rods (turnbuckles) that you can buy ready-made or make your own in accordance with figure 1A.

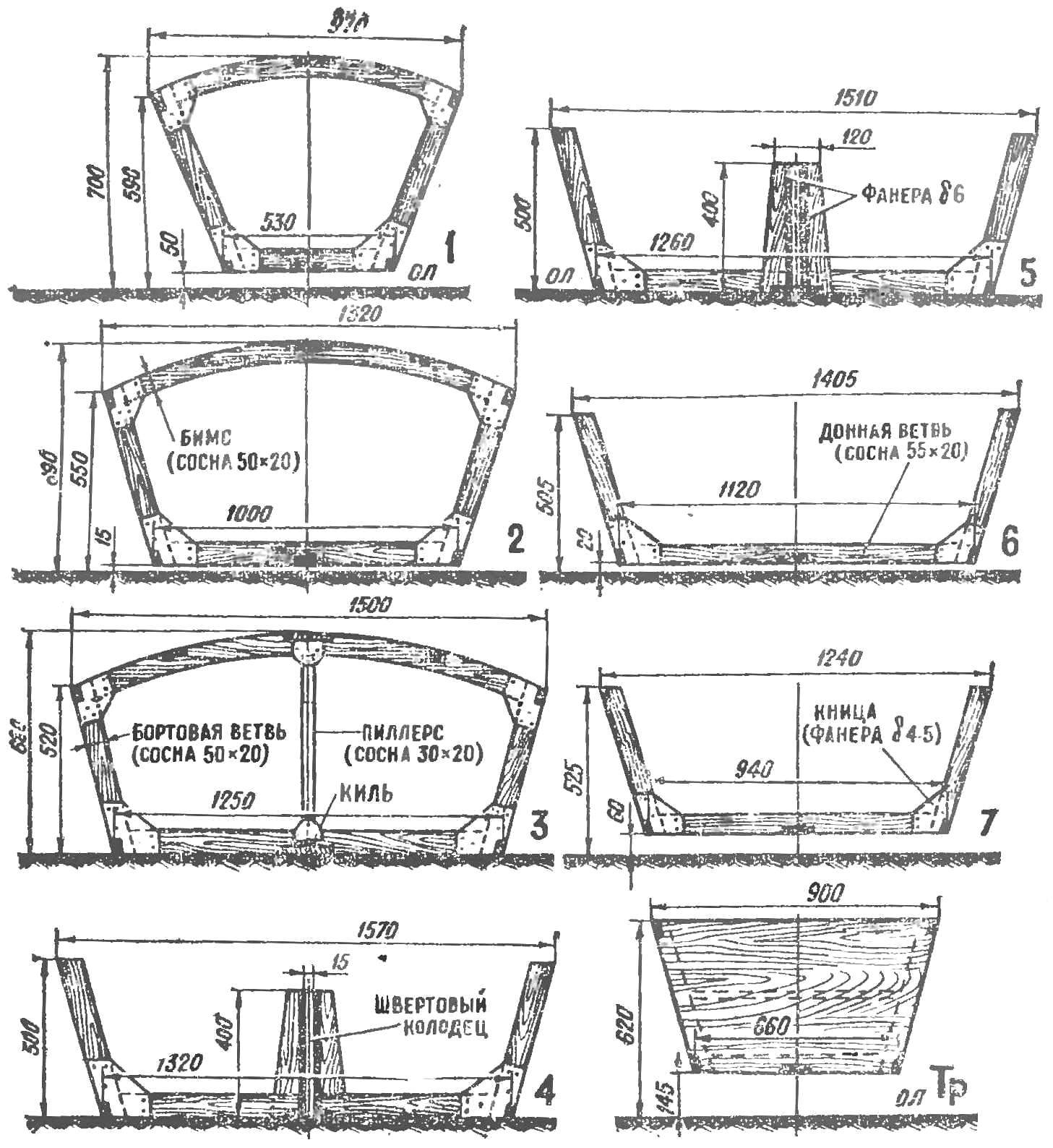

THE CONSTRUCTION OF THE HOUSING. The drawing of the Dinghy shown in figure 2, the sizes of the frames in figure 3 On them are made samotnie frame and all the details set. The housing is assembled with the keel down on a simple bench in this order: first the berth is fixed (or as they say shipbuilders, exposed), the keel with stem and transom Board. On the pile should be marked with the attachment samotnych framework in which pre-cut grooves for the keel and the slot rails (“flashings”). Frames are set on glue and fixed temporary pins and braces the position of the part is reconciled with a spirit level and a large square, with the main angle is 90°. After the glue sets, you are ready to install the longitudinal elements of the set. First, adjust the fenders (side) bars, then the cheek. Not to move from the field samotnie frame, fit bars fenders need to do it together, simultaneously bending the right and left bars and attaching them to the frame with strong twine. Start from the transom Board, attracted to it the ends of the bars by screws and to insure tying a strong cord. Bars fastened with screws or glue on thickly-grated oil paint. Protruding rib frames in the bow and stern pre-sostragivajut (malkhut).

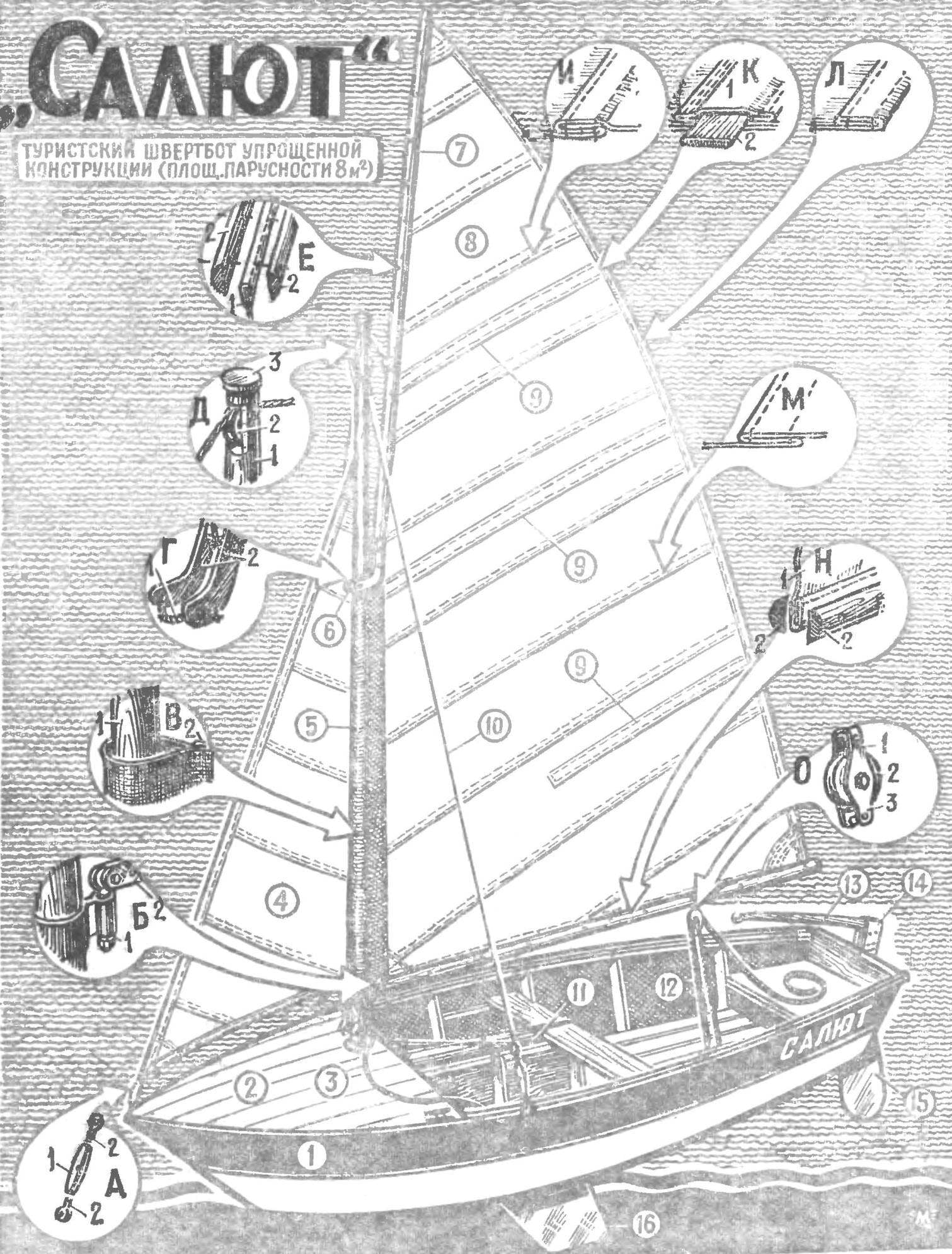

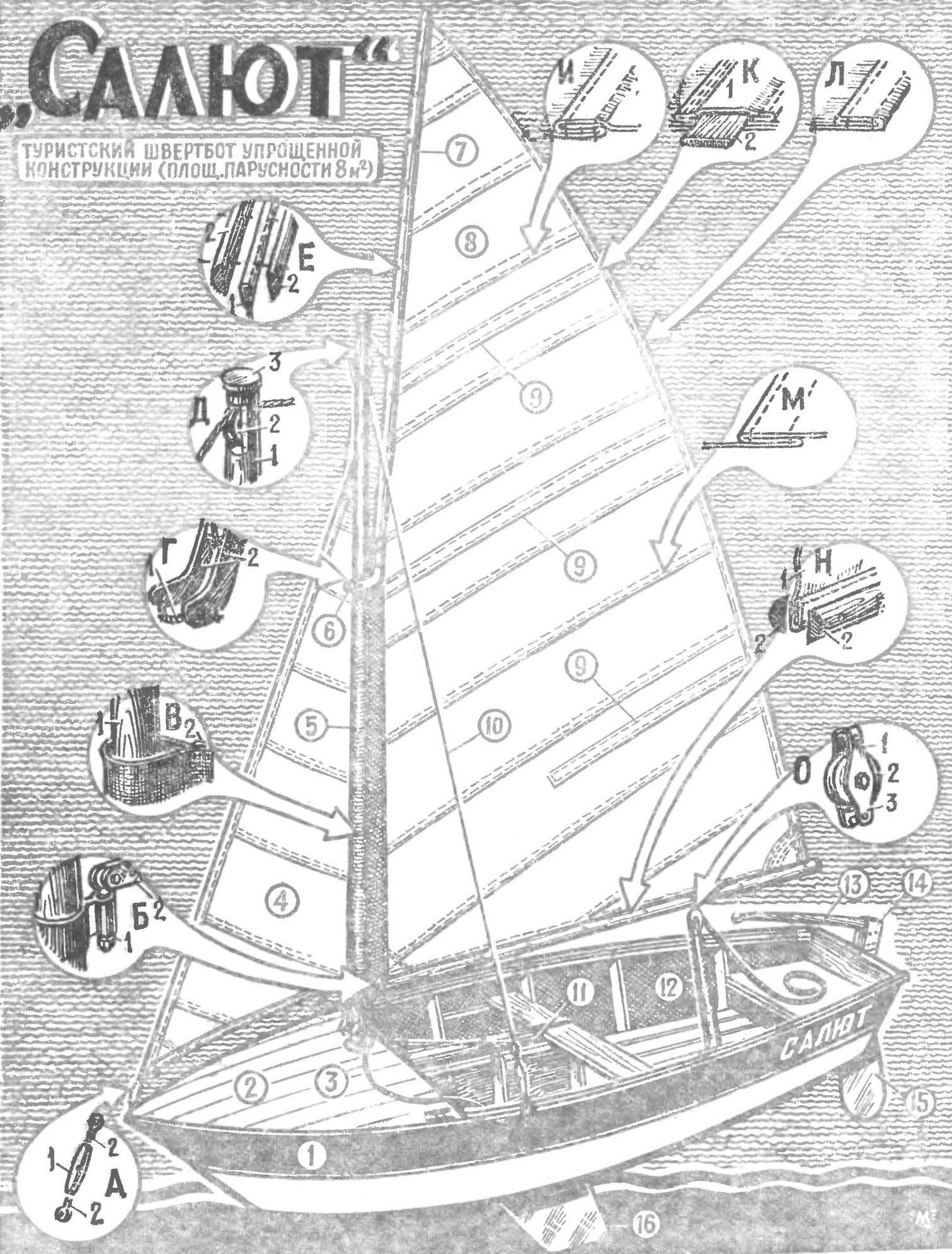

Fig. 1. Dinghy “salute” — communities and details:

1 — body, 2 — deck, 3 — staysail sheet, 4 — the headsail — staysail, 5 — mast, 6 — moustache Hafele, 7-jaw, 8 — main sail — mainsail, 9 — armor, 10 — guy, 11 — svartby well 12 — boom-sheet, 13 — tiller, 14 — head helm, 15 — rudder, 16 — centerboard.

A — lanyard (swivel) the forestay: 1 — body, right-and left-hand thread, 2 — the shank; B, the hinge connecting the boom with the mast: 1 — pin, 2 — gik; The “stocking” on the luff of the sail: 1 — mast 2 — sail; G — connection Hafele mast: 1 — Beirut (short line), 2 — moustache Hafele; E — top of mast: 1 — hole for pulley, 2 — pulley dirik-FAL 3 — mast; E — design Hafele: 1 — the front leech of the sail, 2 — ladles of Hafele connected by bolts M3; And — the seam that connects the sail between them; — the imposition laderman: 1 — Letterman, 2 — dellanna Lata (strap); L — the rear seam of the luff of the sail, M “fake seam” PA one-half the width of the cloth (to give the sail the proper shape); N — design geek: 1 — lower shka Gorin sails 2 — ladles geek, mated with M5 bolts; On — unit boom-sheet: 1 — yoke, 2 — pulley, 3 — lower eyelet.

Fig. 2. Constructive drawing of the case: the projection of the “side” and “Poloshirt”

Fig. 3. Constructive drawing frames.

Similarly are mounted cheek blocks. For greater strength of the frame, RUB rails are fastened to the bow by brestyan (Fig. 2), and aft — two oak brackets attached to the transom Board. After that you can proceed to the sheathing boards. When working with plywood is not a great practical difficulty will occur: the work is done from the stern to the nose, plywood attached with screws and nails with tapered head. Before applying the sheet covering a skeleton smeared with glue. The fitting should be conducted from the middle area of the sheet to its edges. The joints of the plywood sheets (if the sheet length equal to 1525 mm, there will be two) is best performed “on condition”, sostragivaja chamfer width of about 50 mm.

Sheathing boards is much more complicated and, in addition, has its own specifics. It would be ideal to cover each side with one very wide Board. But almost always have to deal with multiple boards, which in the shipbuilding practice is called Poaceae. Case “Salute” you can sheathe two Poaceae: boards with a width of about 300 mm will be one longitudinal seam. First sew the bottom Poesia, then top. The joint between Poaceae useful to close the slot from the inside lath (batten) which will give the Board greater rigidity and water resistance. After sewing the sides of the frame body can be removed from the pile and flip over to trim the bottoms. The sequence is: making sure that all frames smaltovane correctly (it is checked by superimposition from-centrifuged strap), make markings for tie-rods of the steam. The distance between them depends on the width of boards, prepared for sewing the bottom. With a width of about 150 mm interlocking slats shall be six (three on each side of the keel), as shown on the structural drawing (see Fig. 2). Interlocking slats cut flush with Fortenberry samotnych framework and the zygomatic block, is inserted in place with glue and screws zapressovyvajutsja 50X3 mm. After hardening of the adhesive the surface of the sheathing obtained is checked again trimmed and groove slats are applied to the longitudinal centreline, which will overlap with Board sheathing. They must be very carefully otfugovannymi edge and be parallel throughout its length. The first stacked boards on the keel bar, and plating is conducted from the keel to the sides alternately right and left. The last (closest to Board) bottom Board covering must be very accurately pricescan and carefully attached with screws to the zygomatic bars. Bottom lining it is recommended to put on the epoxy or heavy-bodied oil paint, and not the casein. Finally, the case overturned keel down and do all the work on the formwork and internal equipment. Case twice soaked inside hot natural linseed oil and covered with a good oil paint in linseed oil. Color is preferable to choose a non-staining, such as light gray or light brown.

The centerboard and rudder made from sheet steel. It is best to entrust an experienced welder to cut them on the outline or pattern, and then processing the edges on a planer or sandpaper press, giving them a pointed form. Drilled in accordance with the drawing, all holes in these items, it is advisable to cover them with any anti-corrosion primer and painted with lead red lead on natural drying oil. Even better to make the galvanic corrosion-resistant coating (Zenkoku or cadmium plating). To install the centerboard in the well produced line of sheet or strip steel, as shown in the figure. Rudder connected with the rudder by using bolts of Ø 8 mm.

The metal parts of sailing arms should be made carefully: they determine the reliability of the management of a sail. If there is a choice, for the manufacture of the forestay and the guys better take the stainless steel cable Ø 5 mm and turnbuckles to stainless steel.

Upper roller, used to raise sails, machined from lightweight aluminium alloy or brass as well as the rollers on the blocks of the boom-sheet. Cheeks blocks — stainless steel or brass.

For fixing of the forestay and the guys to the sides of the plate need to stainless steel with a thickness of 4-5 mm, so-called Venturini (see Fig. 1). One of them is mounted on the stem, the other two sides of the frame № 3 screws or bolts and nuts.

Mount the front of the luff of the sail to the mast is “stocking” of thin tarp or a raincoat-tent fabric.

(To be continued)

G. MALINOWSKI