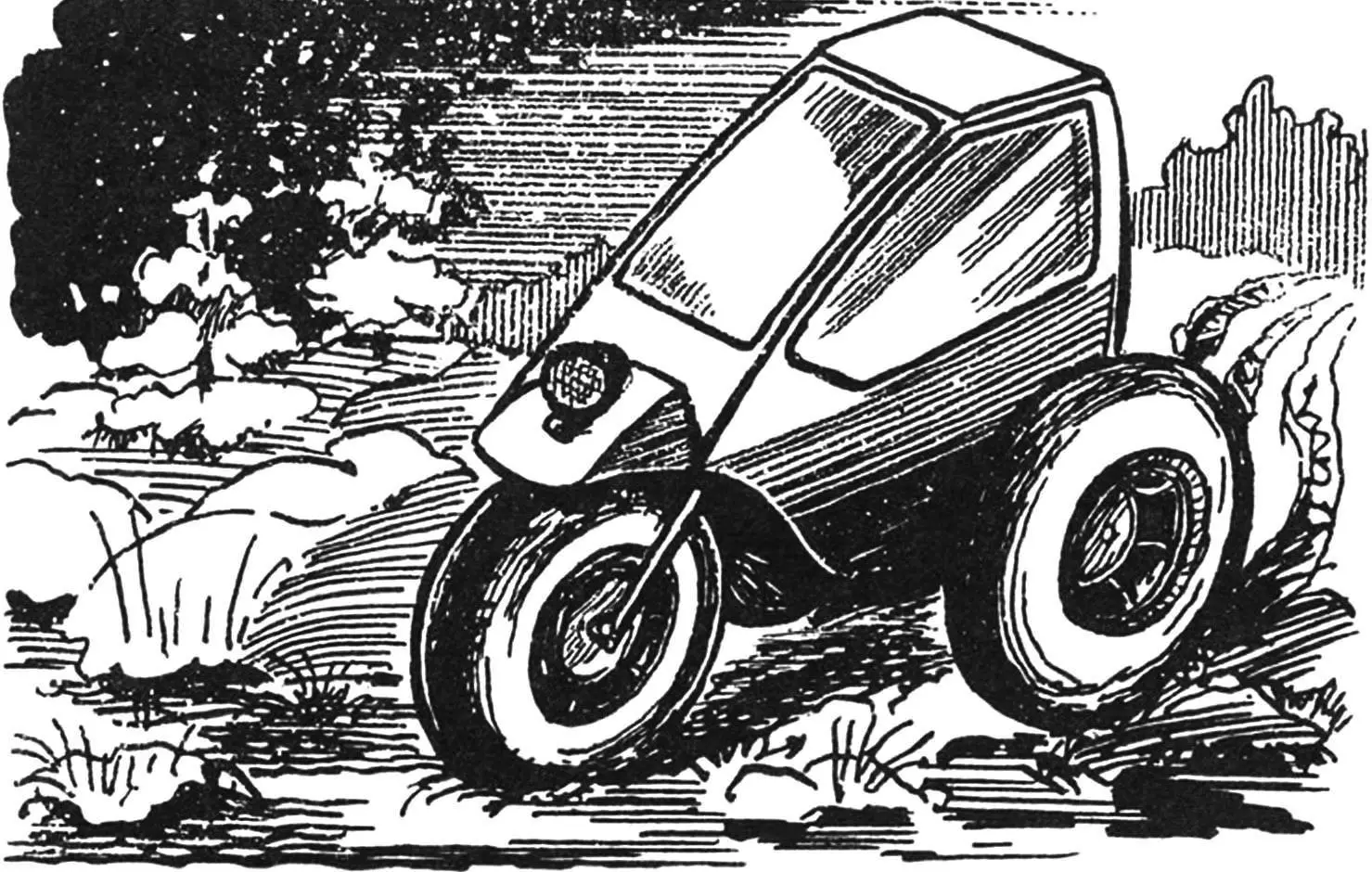

All-terrain vehicles on ultra-low pressure pneumatic tires are becoming increasingly comfortable. If a decade ago enthusiasts of all-terrain vehicles created mainly three-, four-, and six-wheeled vehicles devoid of even a hint of a cabin, today amateur designers send to the editorial office photographs of all-terrain vehicles they have built with comfortable and warm cabins designed for long journeys in low temperature conditions. Here is one such machine — the comfortable tricycle “Mini-200”.

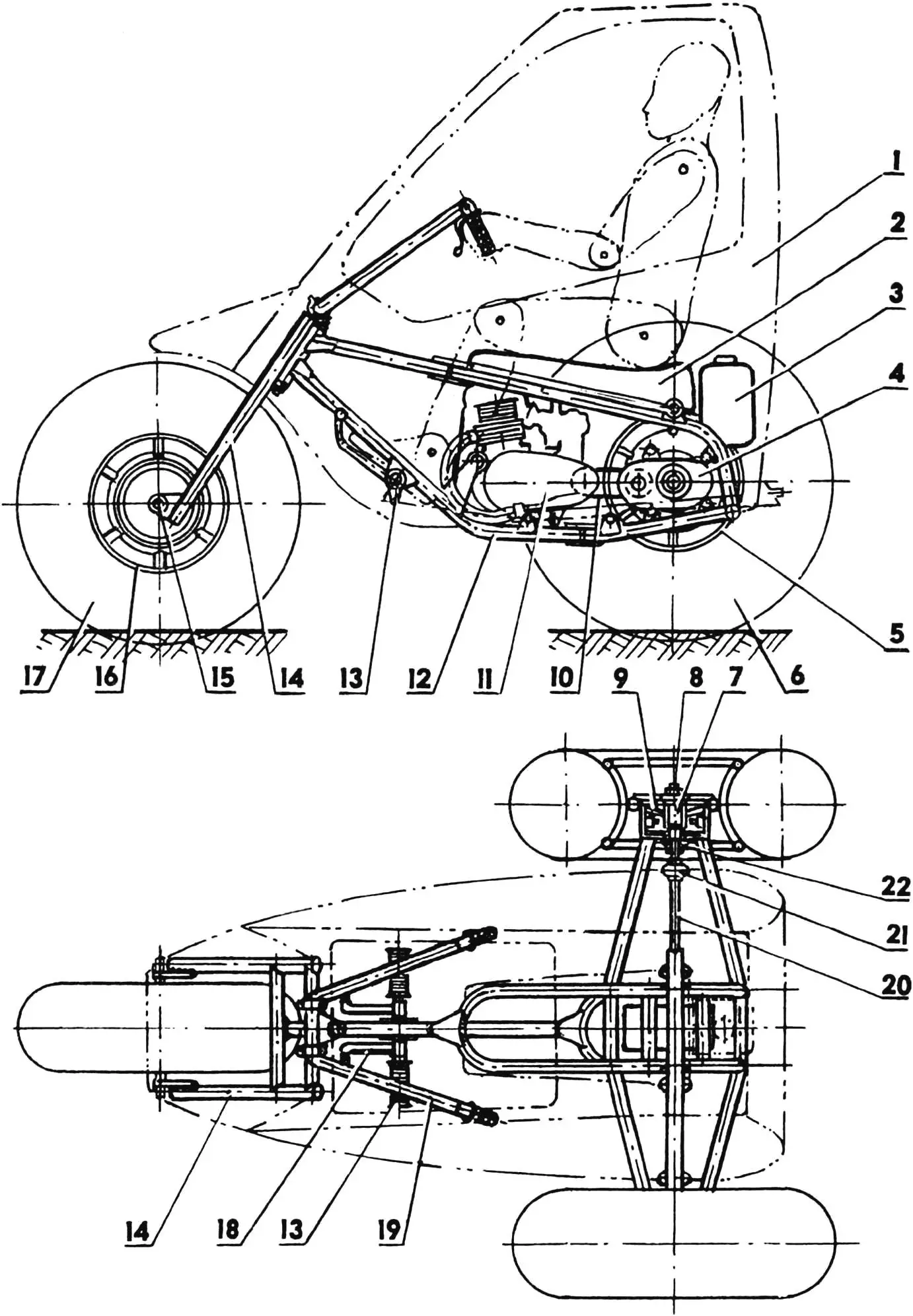

The power unit of the three-wheeled pneumatic vehicle TG-200M is from the “Muravey” cargo motor scooter. As experience shows, this is one of the most reliable among domestic two-stroke engines, also equipped with a starter and forced air cooling. The transmission of torque from the engine to the wheels is through a bushing-roller chain to a reverse reducer (main transmission from the SZD motorized wheelchair), and then through driveshafts — to the wheels.

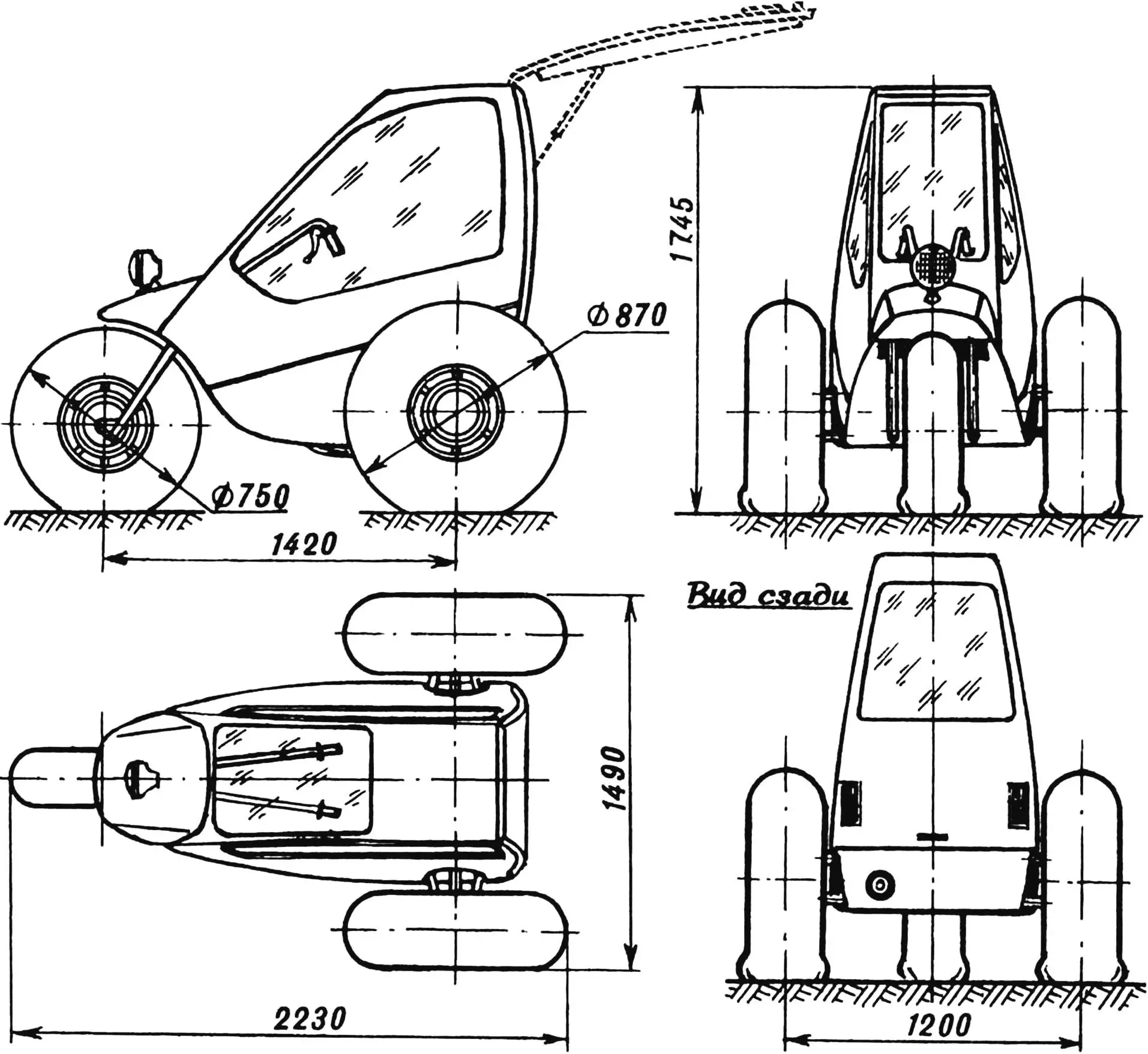

All wheels of the tricycle are braked, for which each of them is equipped with a brake drum from the “Minsk” motorcycle. The front wheel is somewhat smaller than the rear ones — their diameters are respectively 750 mm and 870 mm in the inflated state.

The all-terrain vehicle’s frame is spatial, tubular, all its elements are connected using a carbon dioxide arc welding machine. The rear axle is a truss consisting of three tubes welded to the frame. All joints are reinforced with gussets made of sheet steel.

The engine is mounted on the frame with front and lower docking units. To install them, it is most convenient to first secure these units on the engine, then use clamps and soft steel or copper wire to fix the engine on the frame with maximum accuracy, and tack the units with welding, then finally weld them to the frame after removing the engine. The main transmission units are mounted similarly.

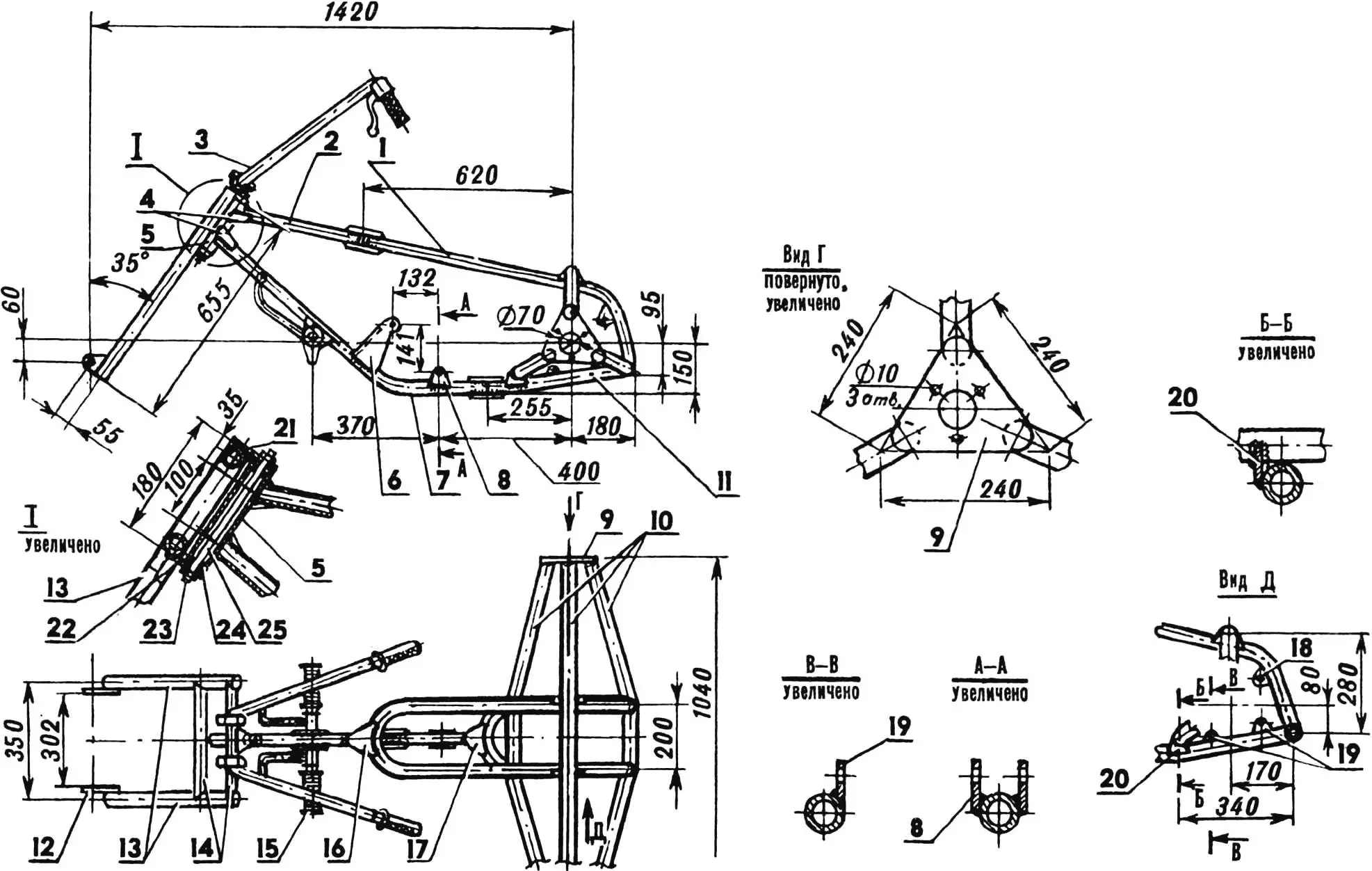

1 — body (shown conditionally); 2 — seat; 3 — fuel tank with capacity of 4.5 l; 4 — reverse reducer; 5 — rear wheel; 6 — rear wheel pneumatic tire; 7 — rear axle half-shaft; 8 — rear wheel mounting nut; 9 — hub with brake drum; 10 — bushing-roller chain of main transmission drive; 11 — TG-200M engine; 12 — all-terrain vehicle frame; 13 — footrest; 14 — front fork; 15 — front wheel nut and axle; 16 — front wheel; 17 — front wheel pneumatic tire; 18 — control pedal block; 19 — handlebar; 20 — right rear wheel drive driveshaft; 21 — universal joint; 22 — rear axle bearing unit

The front fork is welded from two tubular blades and two crosspieces. In its design, in principle, blades from a telescopic fork of any suitable motorcycle can be used, however, vehicles with ultra-low pressure pneumatic tires can quite do without spring-hydraulic shock absorbers. Gussets made of 4-mm steel plates are welded to the lower part of the blades — the front wheel axle is attached to them. Two lugs are provided for connecting the fork to the frame, secured by welding on the fork crosspieces.

The all-terrain vehicle’s seat is homemade, motorcycle-type. It is assembled from a plywood base, filler (rigid foam) and upholstery (artificial leather).

1 — upper fork (steel, tube 30×2); 2 — upper tube (steel, tube 30×2); 3 — handlebar (steel, tube 22×2); 4 — gussets (steel, sheet s2); 5 — steering column (steel, tube 32×2.5); 6 — engine mounting unit, front (steel, sheet s3); 7 — lower tube (steel, tube 30×2); 8 — engine mounting unit, rear (steel, sheet s3); 9 — flange (steel, sheet s3); 10 — rear axle truss crosspieces (steel, tube 30×2); 11 — lower fork (steel, tube 30×2); 12 — gusset (steel, sheet s4); 13 — front fork blades (steel, tube 40×2.5); 14 — front fork crosspieces (steel, tube 32×2.5); 15 — footrest; 16,17 — gussets (steel, sheet s2); 18,19 — main transmission mounting units (steel, sheet s3); 20 — reinforcing gusset (steel, sheet s3); 21,22 — lugs (steel, sheet s3); 23 — M12 nut; 24 — bushing (bronze or textolite); 25 — M12 stud

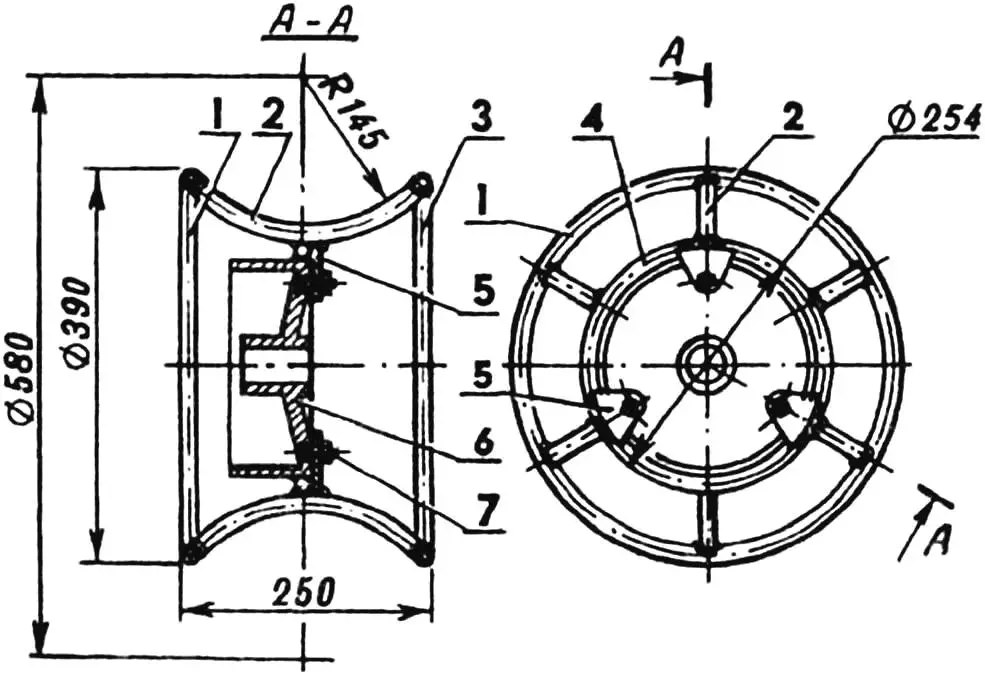

The tricycle’s wheels are lightweight, tubular, welded. Blanks made of steel tubes with a diameter of 18×2 mm are bent with a tube bender and assembled using welding. For assembly, it is necessary to use a simple jig, for which six posts made of wooden blocks are installed on a chipboard along the wheel circumference, on which the prepared wheel rims are mounted. After checking their alignment and parallelism to each other, crosspieces are tacked to the rims by welding. If this operation did not cause noticeable wheel runout, then the crosspieces are finally welded to the rims. Similarly, in two steps, the inner ring with lugs welded to it is installed in place.

Holes in the lugs are drilled in place when installing a motorcycle hub on the wheel; it is necessary to achieve strict alignment of the hub and the wheel itself. For this, the hub is first fixed on the wheel using clamps, and only after checking the alignment of these two parts, holes for bolts are drilled in the lugs on the inner ring of the wheel.

1,3 — rims (steel, tube 18×2); 2 — crosspiece (steel, tube 18×2); 4 — inner ring (steel, tube 18×2); 5 — lug (steel, sheet s3, 3 pcs.); 6 — hub (from “Minsk” motorcycle); 7 — bolt with M8 nut

The pneumatic tires hold quite reliably on the tricycle’s wheels and provide acceptable traction qualities with snow and sand, with plowed land and marshy soil. However, in some cases, to improve the all-terrain vehicle’s cross-country ability, the pneumatic tire can be wrapped with a nylon rope or rubber belts.

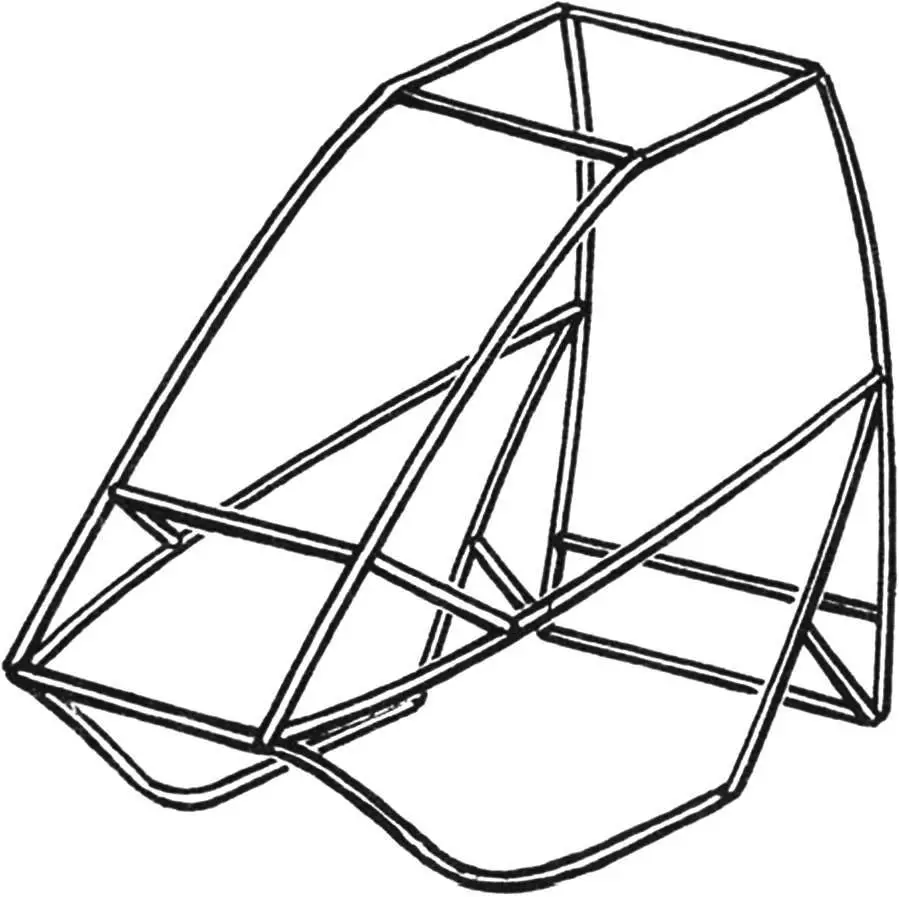

The cabin is of mixed construction. Its base is a light frame made of steel tubes with a diameter of 14×2 mm. Window frames, hinges of the single (rear) door, as well as three docking units, with which the body is attached to the frame, are hung on the frame.

In addition, the frame also performs a form-forming function. It would be possible, of course, to cover it with plywood or hardboard, however, panels with a ruled surface (or, as they are also called, single-curvature panels) significantly impoverish the appearance of the vehicle. Well, the simplest technology for manufacturing double-curvature panels under conditions of independent production can be considered molding the product from construction foam.

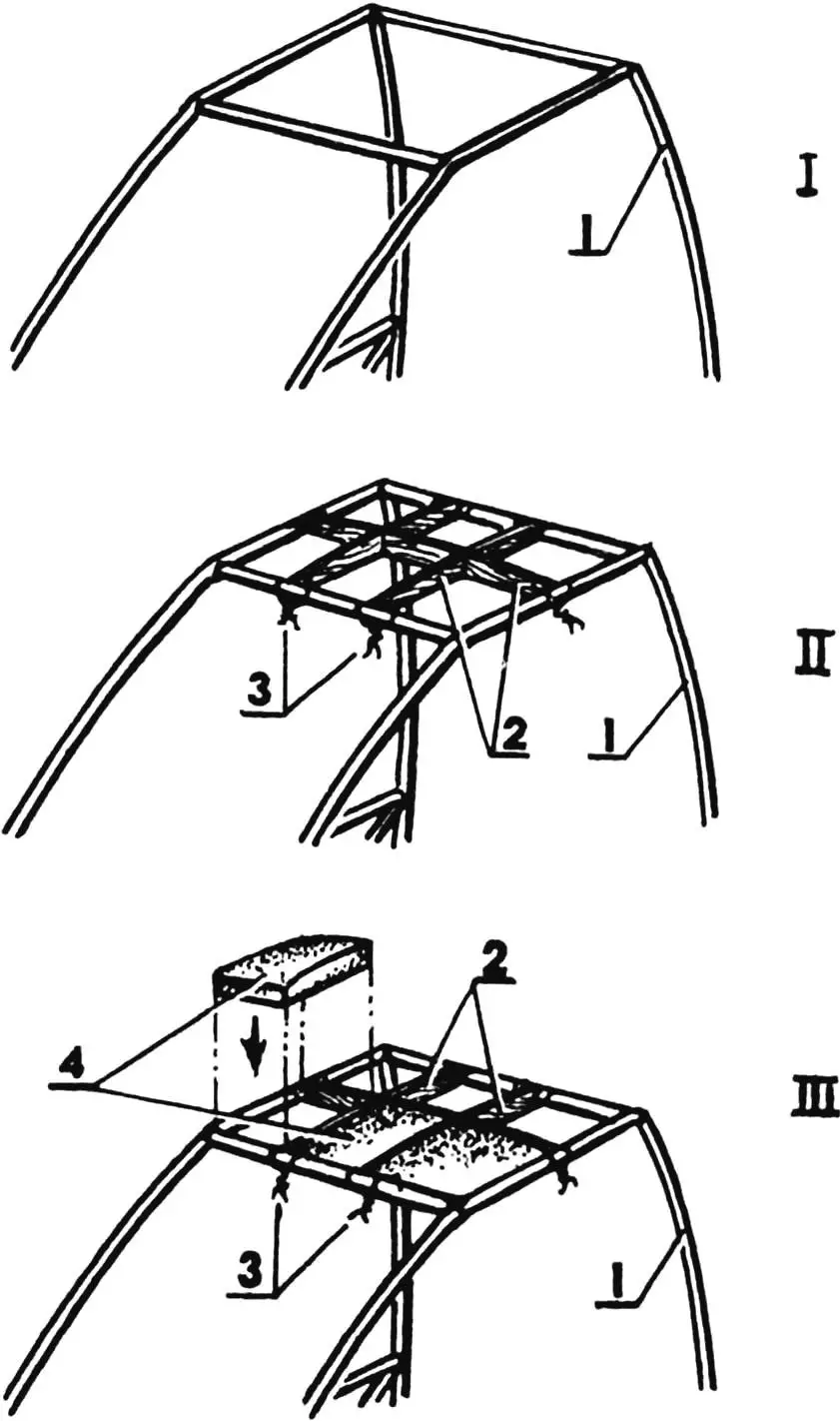

Before molding, it is necessary to secure a light grid made of 5-mm plywood on the tubular frame, which sets the shape of future panels. The grid plates are temporarily tied to the tubes with soft steel wire. Next, foam blocks are glued into the plywood “cells” with epoxy resin. After the resin polymerizes, excess fastening wire is removed, the body surfaces are processed along the contour, puttied if necessary, covered with a layer of epoxy resin and immediately covered with one or two layers of fiberglass.

The cabin has a single door — the rear one. It would be possible, of course, to make it on the side, however, sitting on a motorcycle seat, stepping over the frame inside a cramped cabin is difficult. The rear door, however, allows getting into the cabin quite easily. The door also has a frame made of steel tubes and foam filling with subsequent covering of surfaces with fiberglass.

The side and rear windows of the cabin are cut from 4-mm plexiglass. The front window is triplex, borrowed from a broken bus standing at an automobile dump. It should be said that the selection of the windshield determines the shape of the body, so it makes sense to start design drawings, focusing on the dimensions and shape of the already available glass.

1 — cabin frame; 2 — plywood “grid”; 3 — wire twists; 4 — foam blocks

The all-terrain vehicle’s control system is motorcycle-type. A throttle grip, front wheel brake handle (right) and clutch release handle (left) are mounted on the handlebar. A pedal block is placed on the footrest: right pedal — rear wheel brake, left — gearbox shift lever.

The brake system is cable-operated, with an equalizing mechanism for the rear wheel brakes. The drives of the carburetor throttle valve, gearbox and clutch mechanism work using cables in Bowden sheaths.

The tricycle’s fuel tank is a 4.5-liter plastic canister, equipped with a standard motorcycle sediment tap and secured to the rear of the frame.

The electrical equipment is the same as that of the “Muravey” motor truck. The lighting equipment consists of rear “markers” in a block with stop signals and a motorcycle headlight installed on the front mudguard.

“Modelist-Konstruktor” No. 12’2000, I. GALKIN, engineer