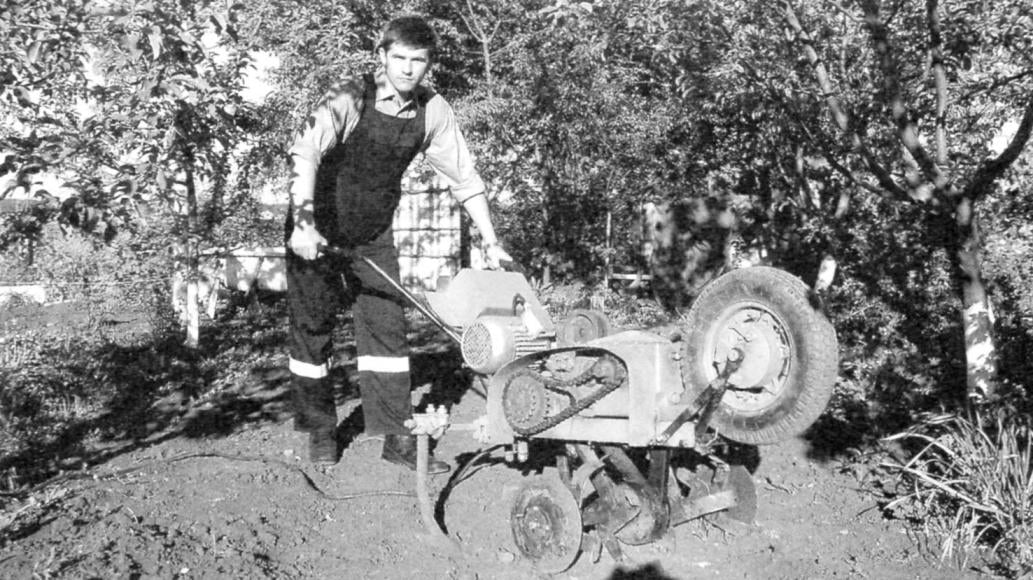

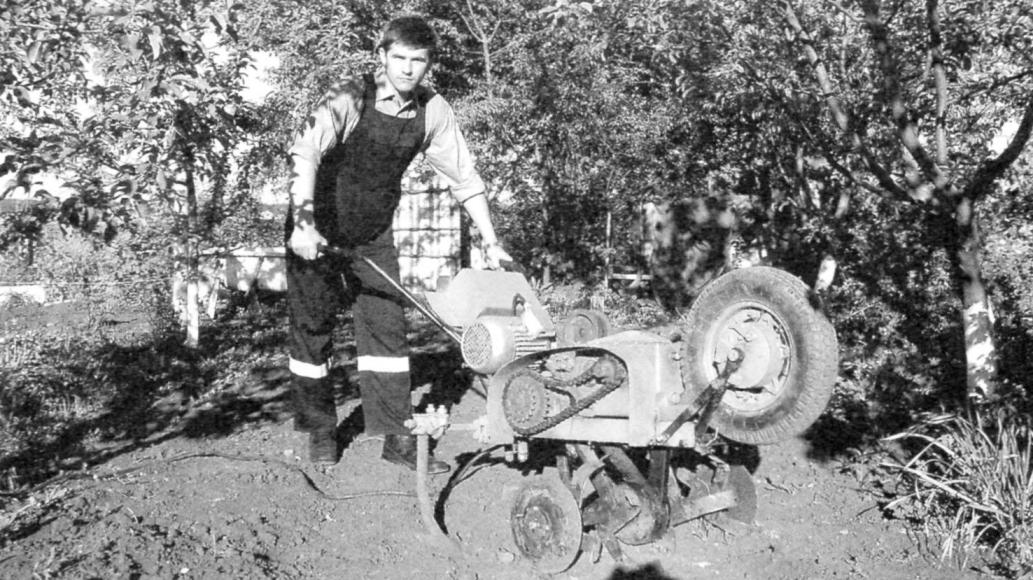

Electrofresh is intended for soil (top soil) household and cottage (with electricity) sites, hilling potatoes. Considering the rather difficult conditions: long continuous work, continuous overload, dust, preference was given to more severe and large industrial three-phase motor is totally enclosed, front manifold, DC.

Electrofresh is intended for soil (top soil) household and cottage (with electricity) sites, hilling potatoes. Considering the rather difficult conditions: long continuous work, continuous overload, dust, preference was given to more severe and large industrial three-phase motor is totally enclosed, front manifold, DC.

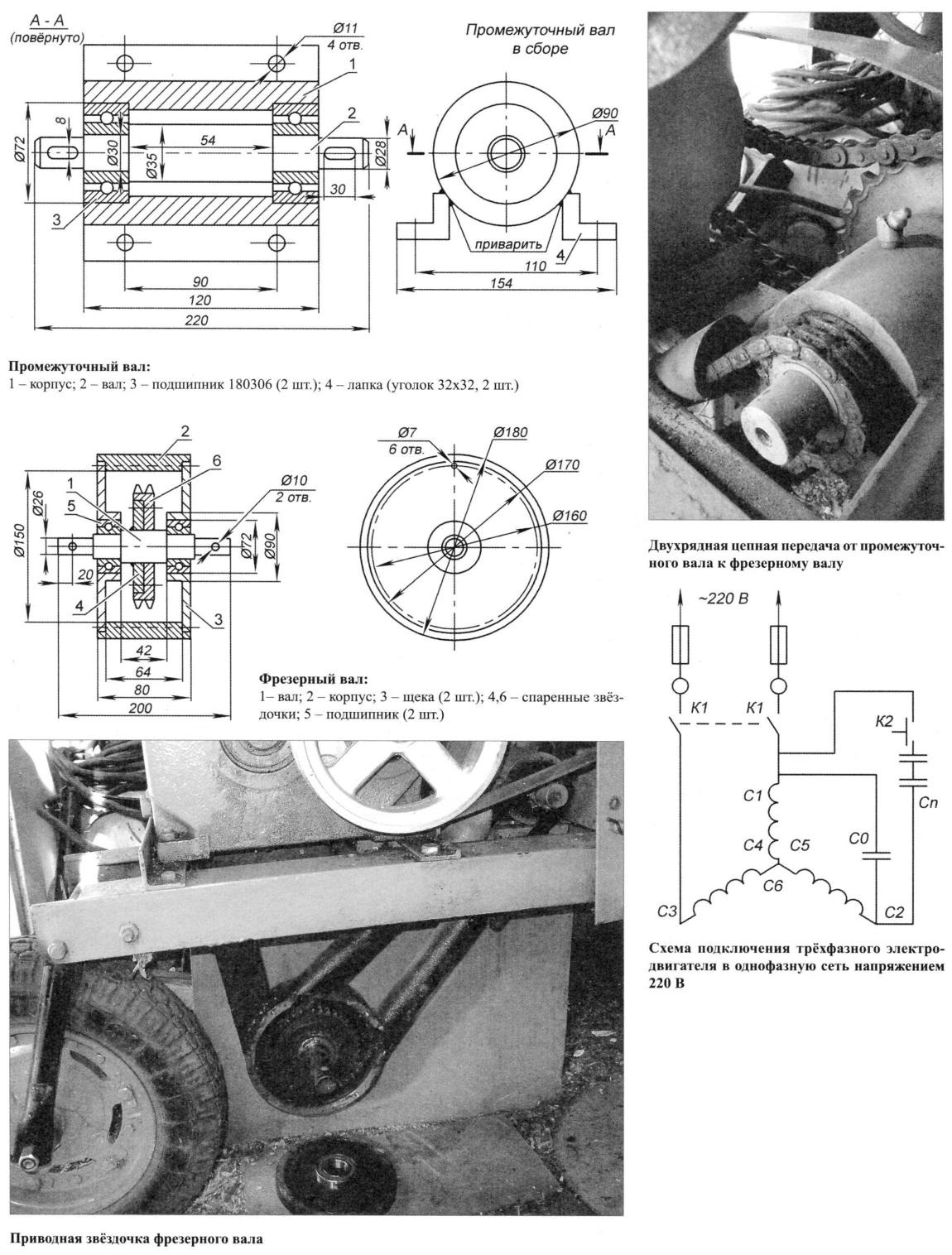

This asynchronous motor can work in the scheme of three-phase and single-phase power capacitor (coupling star). The required capacity of the capacitor Bank is then equal to:

CP=2800 Inom/Unom,

where Unom is the nameplate voltage of the motor Inom – passport current.

The design uses a gear type RTS with gear ratio i=4 from decommissioned corn combine harvester SK-5. The frame is made of angle section 63x63x5 mm as a pair of parallel side members. The crossbars serve as housing units and units attached to them, as well as the rear cross member to install ploskorezy hoes.

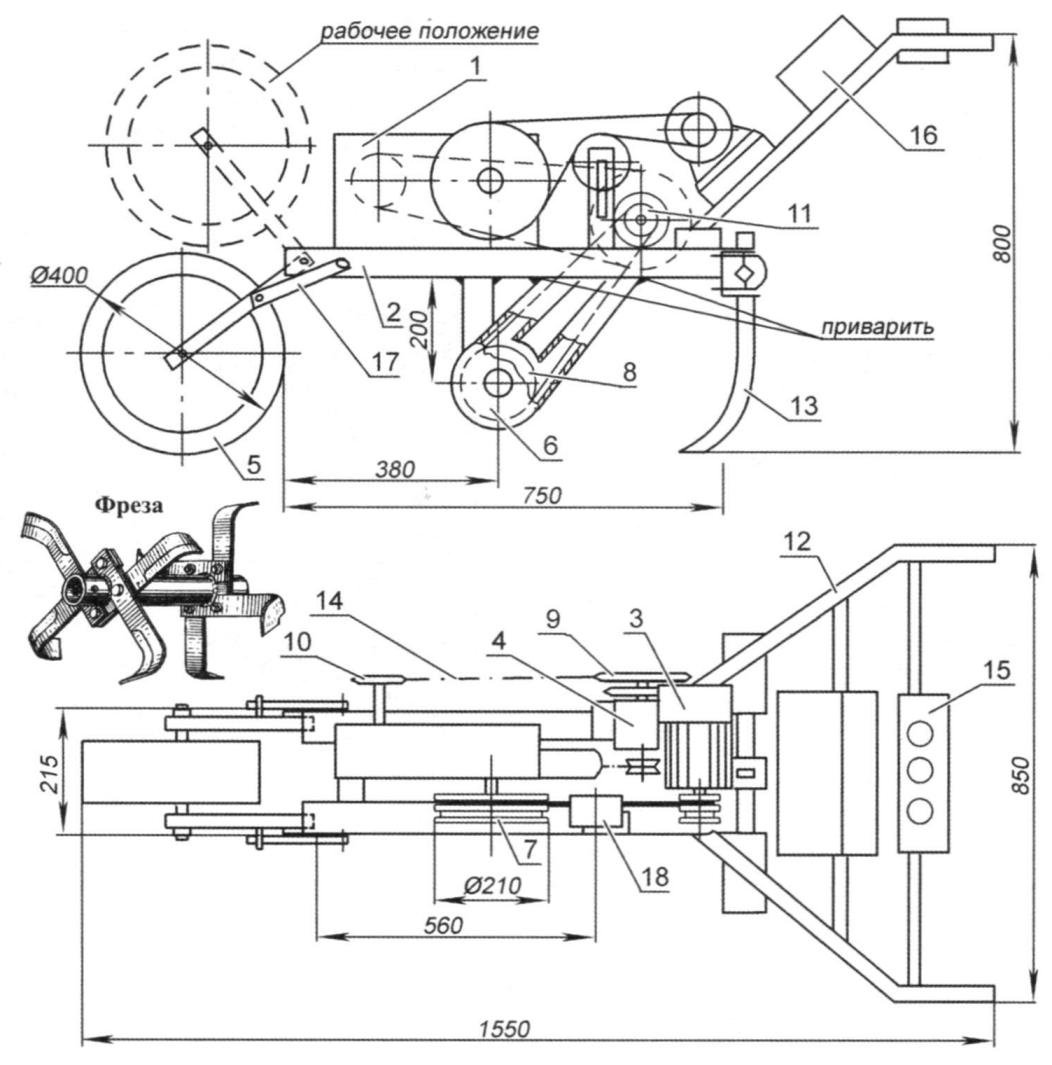

Tilling electrofresh:

1 – reducer; 2 – frame; 3 – motor; 4 – an intermediate shaft; 5 – transport wheel; 6 – milling shaft Assembly; 7 – driven pulley; 8 – double row chain; 9 – star unit; 10 – sprocket; 11 – sprocket output shaft of the gearbox; 12 – lever control unit; 13 – a brake; 14-the chain(pitch 19,05); 15 control unit; 16 -; 17-lock wheels; 18 – idler pulley

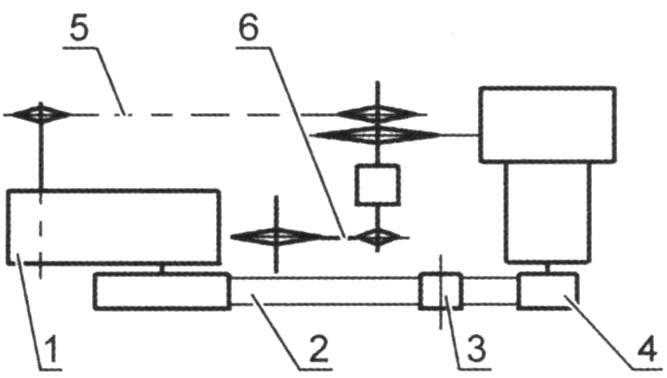

Kinematics electroforez:

1 – motor; 2 – belt transmission; 3 – tensioner roller; 4. gear; 5 – chain transmission (t=19,08); 6 – chain transmission (t=19,08)

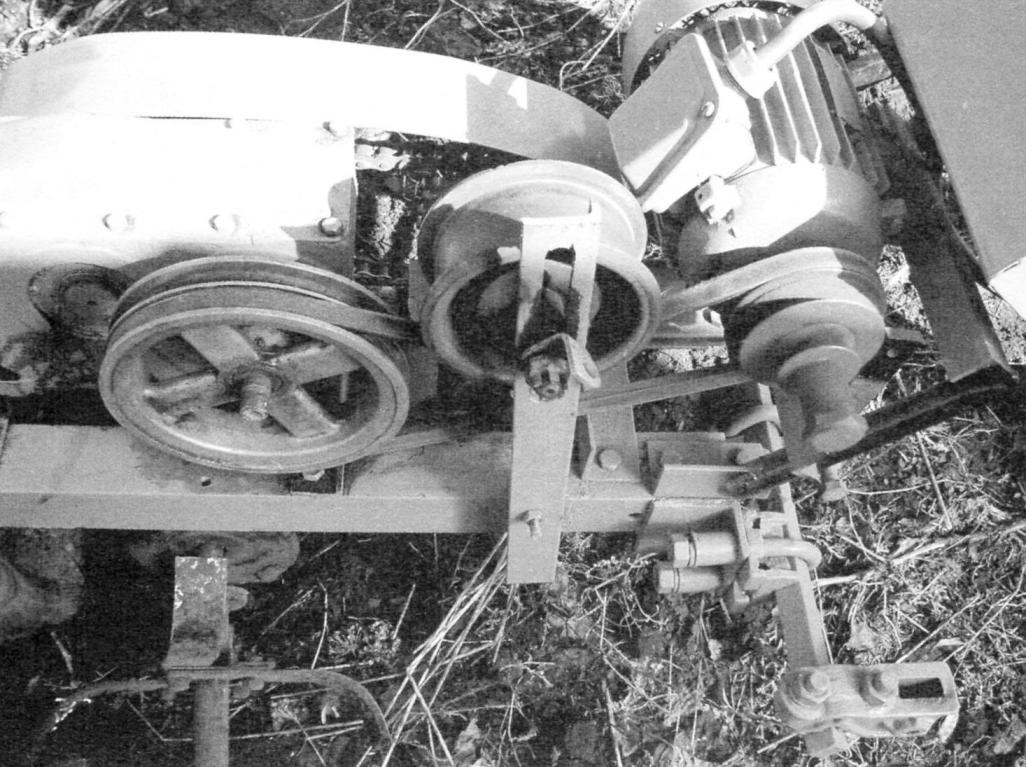

To the rear ends of the side members are welded onto the levers of the unit. The levers are connected by crossbars on which are located the motor, instrumentalsandmore box and push button station on-off Rotation from the motor to the gearbox is belt drive (belt type A-1400). The belt tension performs a video that can work as a “clutch” the Gear causes the rotation of the intermediate shaft of the cutter by means of a chain transmission (chain pitch 19 mm). The transmission can be used with i=1.5 or i=2.4, z2= 18 (29); z1 = 12. The speed of the cutter shaft is 44 or 38 per minute. The shaft of the cutter is driven by a double-row chain (from the camshaft VAZ 2101, i=2, the asterisks are modified in-place)

Motor – asynchronous, squirrel cage. Its capacity is 1.5 kW (efficiency – 0,79).

Voltage AC 380 V (or 220 volts – for single phase connection);

Current Is 4.2 A.

The number of revolutions of the engine is 1410 per minute;

Gear ratio – 32(37);

The basis of the layout of the mill laid the equilibrium condition in the working position with the aim of reducing the strain on the handles control.

V-belt drive from motor to reducer

Chain transmission (t = 19,08) from the output shaft gear to the intermediate shaft

Reducer mounted on the frame by means of two transverse plates of 10 mm thickness.

The corps of cutters is welded to the frame with tubes with a diameter of 1 1/4″ (“quarter inch”). Inside these tubes is chain transmission.

Food elektrofarez can operate both from three-phase network with voltage of 380 V AC and single-phase (domestic) power grid voltage is 220V (in this case three-phase asynchronous motor is included in the single-phase network through a condenser capacity). Connection elektrofarez to the single-phase network is carried out using household extension cords. It should also be noted that the voltage drop leads to a reduction of engine torque. The use of a wire with cross-sectional area of less than 0.8 mm2 unacceptable.

During operation, you should periodically monitor the condition of the contacts and connectors, checking if they are not heated.

Turning on and turning off the engine is done with the KU-2 and the reversing magnetic starter type PME. The presence of reverse significantly easier to manage (narrow sections, work in the greenhouse)

Significant in the work of the mill is the installation and adjustment of the brakes. On electromuse it is located at a distance of 380 mm from the centre of the cutter shaft and 160 mm below the center of the shaft (the horizontal arrangement of the machine). During operation of the cutter part of its mass is almost constantly on the brake. Engine torque is not always enough when fully loaded cutters, so moving forward is a short-term unloading of the brake light by vertical swinging of the handles.

Possible applications of the unit may be milling of dense snow and ice from sidewalks. It will serve as a drive unit for pumping fluid. While timing chain is removed, and at the rear of the engine installed water pump (e.g., from diesel TO-661М).

V. SHKARIN, p. Stroitel, Belgorod.