At that time, when decided to build a snowmobile, any particularly original design decisions and was not planned — the car was needed as a winter vehicle. However when picked up the necessary components, materials and set to work, began to appear the idea of different constructive solutions of some nodes. Even had some time to suspend work on the construction of the snowmobile and “to consider” the entire structure again — on paper. In the end, some decisions were not only unconventional (maybe not new, but considerably forgotten and not found in modern machines), and some original. Note design features.

At that time, when decided to build a snowmobile, any particularly original design decisions and was not planned — the car was needed as a winter vehicle. However when picked up the necessary components, materials and set to work, began to appear the idea of different constructive solutions of some nodes. Even had some time to suspend work on the construction of the snowmobile and “to consider” the entire structure again — on paper. In the end, some decisions were not only unconventional (maybe not new, but considerably forgotten and not found in modern machines), and some original. Note design features.

First- the suspension of the power unit (not installing it, as usual) secondly, the steering “wagon” type — it is carried out by turning not only ski, but only on the front axle. And last Return the same controlled bridge with ski in the starting position and hold it on the course of the forward stroke is produced not so much the wheel, as the torsion bar, which acts as arc’s security.

Describing the design of the snowmobile, immediately say: because of the lack of argon welding all the connection details in the nodes had to do a bolt with bushings and brackets, and sometimes riveting.

The frame of the snowmobile spinal — type single-spar. Docked and connected to the longitudinal beam of the rear axle and front engine mounts supported by the strut Connection of the power elements of the frame — mostly split. So I made them for disassembly of the snowmobile and are very dimensional frame for summer compact storage.

The spar and strut is made of duralumin tubes with a diameter of 70 mm with wall thickness of 2.5 mm and a beam rear axle and struts — also from dural pipes in diameter and wall thickness of smaller — respectively, 40 mm and 1.5 mm, the Role of struts struts engine mounts are still seats handrails, grab bars although they can be called only conditionally — they hung lodgements seats driver and passenger, wykroczenie of duralumin sheet thickness of 2 mm. the seat is made of thick foam sheet and covered with a canvas cloth.

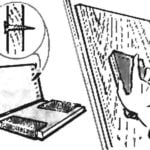

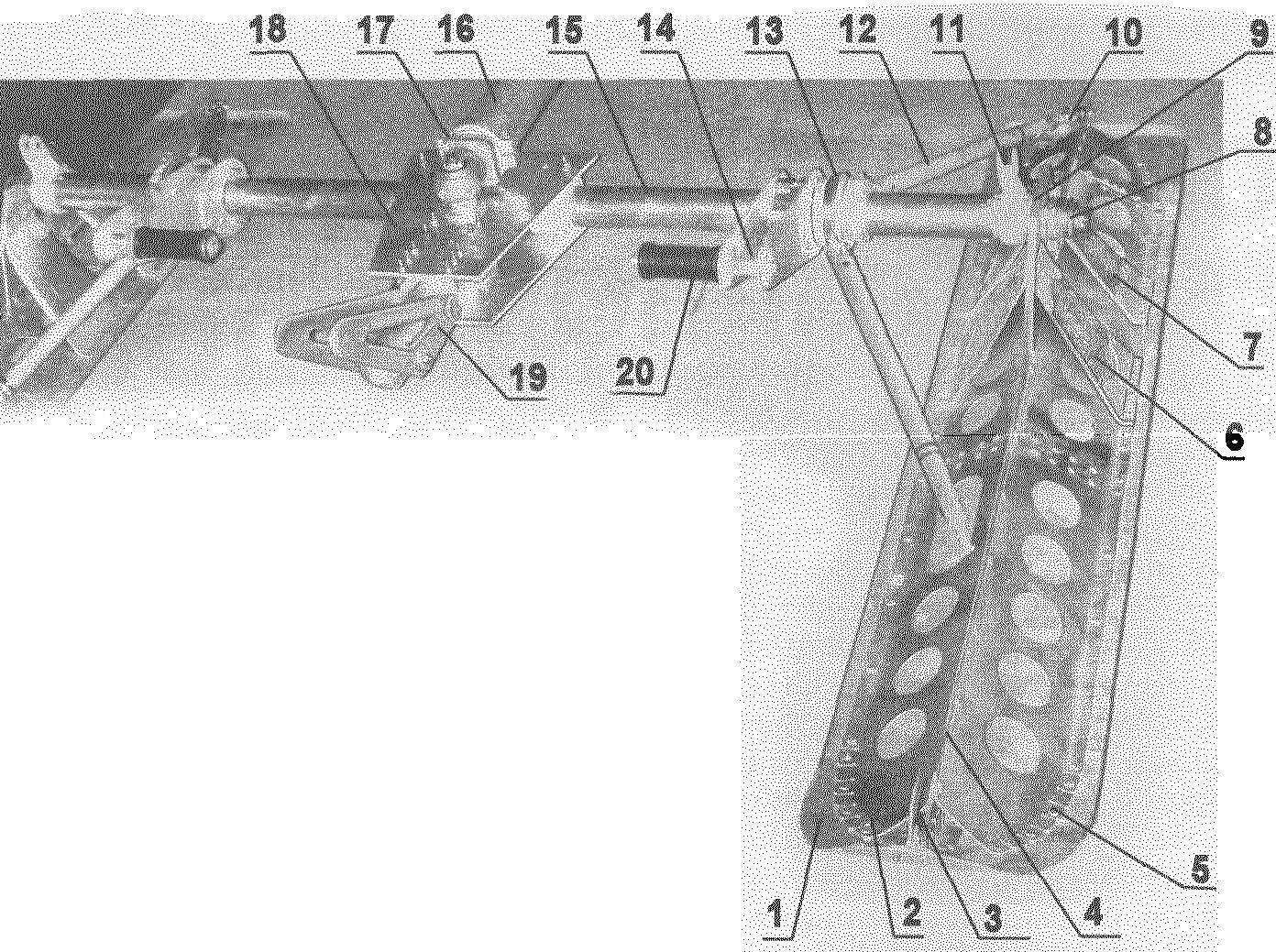

Snowmobile with mounted rotor and “wagon” front axle (details of all positions, except specifically stated, is made of duralumin D16T):

1 — the engine (from motoart “Buran”), 2 — chetyrehluchevoy V-belt transmission(I= 1,85); 3 — propeller Ø1400(wood with metal end trim), 4 — cantilever beam, 5 — upper stretching engine mounts (steel wire rope Ø4, 2 PCs.), 6 — basic strut (tube Ø70×2,5), 7 — bracket connecting the roll over bar to the rack (sheet s5, 2 PCs.), 8 — upper part of the arc security (tube Ø50×2), 9 — fastening of a cable of gas to the arc of safety (rubber, on demand), 10 — connecting parts bracket roll over bar (sheet s5, 2 PCs), 11 — sloping part of the arc security (tube Ø50×2); 12 — longitudinal (pipe Ø70×2,5); 13 — wheel (motorcycle-type), 14 — Central front steering (steel pipe Ø28); 15 — side front steering (tube Ø14. 2 PCs); 16 — bushing arc security (washing machine), 17 — connections, security arc and the front axle (sheet s5,2 PCs ), 18 — removal (pipe Ø30×1,5), 19 — side brace, strut (tube Ø40×1,5, 2), 20 — rear passenger seat (foam in fabric cover); 21 — tool tray rear seat (sheet s5), the 22 — bar brace (pipe Ø30×1,5, 2 PCs), 23 — the cradle of the front seat (sheet s5); 24 — front seat (foam in fabric cover), 25 — rope of gas (from a motorcycle); 26 — stretching the lower engine mounts (steel cable Ø4. 2); 27 — thunder (2 PCs), 28 — fuel tank (20 liters), 29 —rear tow (tube Ø64), 30 — rear axle, 31 — rear ski (2 PCs), 32 — mounting pad (cord, 2 PCs), 33 — a platform (“tissue aevent”, 2 PCs), 34 — beam front axle controlled (trumpet Ø40×1,5, 2), 35 —front ski (2 PCs)

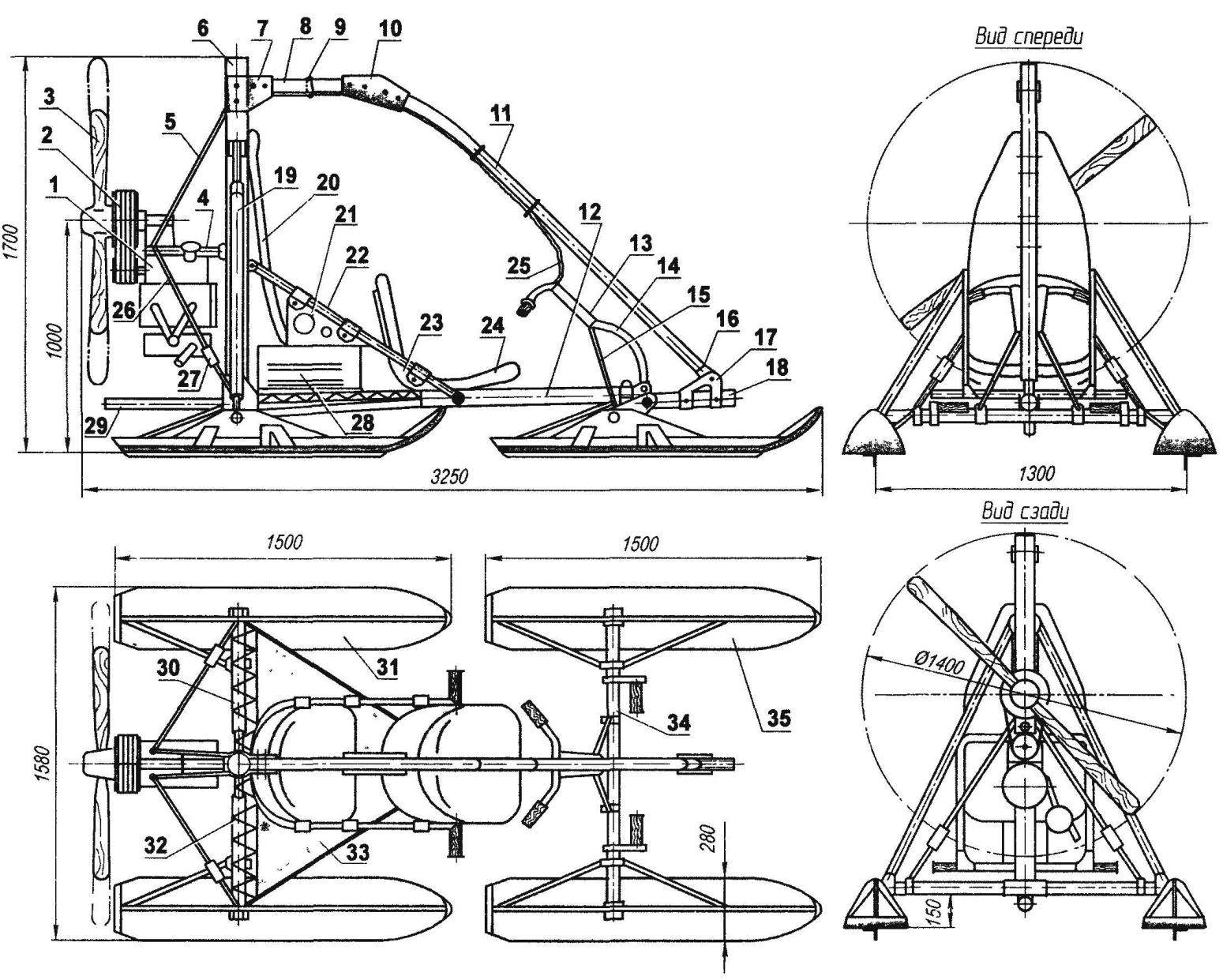

Rear axle and its connections to the frame:

1 — spar, 2 — bracket-mounting clamp to the side rail crossmember frame and seat struts on the rear axle, 3 — cross bar frame seat, 4 — brace, 5 — ski 6 — bracket-clamp-to-rear axle struts, 7 — bushing mounts for the rear axle brace-ski, 8 — beam rear axle (2-piece), 9 — brace stand (2 piece), 10 — frame seats, 11 — the main strut; 12 — loop fastener of the base of the seat to the frame (10 PCs.); 13 — bracket-mounting clamp to the front seat frame and motor, 14 — mounting bracket to the main spar of the rack 15 of the sleeve mounting the frame seat to the spar and main pillar (2 PCs); 16 — connecting brace beams (2 PCs)

To the frame can be attributed to another element of the snowmobile — the arc of safety. It is made of two stacked plates of the segments of the dural tube with a diameter of 50 mm and a wall thickness of 2 mm, However, it would be better to make the arc of one-piece pipe (I have, unfortunately, at the time of manufacture of such was not) because it performs a role of damping suspension managed the front of the bridge and is a kind of strut main landing. But about the arc later.

As a managed bridge as the cart, I misspoke. Back to the already half-forgotten scheme steering was also inspired by its simplicity, moreover, it is very combined with a shock-absorbing arc of safety and single-spar frame. The front axle is joined to the front end of the side member through the shaft and bushings (rubber bushing), the body of which is inserted into the front hole of the pipe member. Pivot is a bolt M22.

The connection of the front axle with the arc of safety (aka a torsion) carried out not directly, but through the removal — cantilever anchored at the middle of the bridge (perpendicular to it) cut the pipe with a diameter of 40 mm with a wall thickness of 1.5 mm. Free (front) end of the removal is also connected with the front end of the arc security “dvuhmesyachnik” triangle bracket. Length of removal was determined experimentally in the range of 200 — 250 mm. Less in length degrades the “feathered” self — retention of the machine on a straight course, and large — makes it difficult to control the snowmobile (helm) by the Way for ease of turning the steering wheel later at the end of the torsion bushing attached (though there is the opportunity to help and feet, like on an airplane).

When you turn the steering wheel, and hence the front axle with skis security arc deflected to the side and even slightly twisted After the withdrawal of effort on the steering wheel, the arc seeks to return to its original position, keeping the ski on a straight course.

The wheel — motor type, only fixed it on the bridge at three points using the struts-levers. From the wheel in an arc-torsion laid a rope of the throttle of the engine. At the ends of the front axle (as, indeed, and back) on the axes is installed the ski. For side-impact protection ski to the bridges additionally attached braces (it would be better shock absorbers) through the bearing bushing: front two, rear one (in the back) and turn in a vertical plane with skis.

Ski’s homemade — all the same. Riveted from a 5 mm sheet duralumin brand D16T aluminum rivets. To stiffen in the middle of the ski is welded to a longitudinal stripe-wall, and the wall — and even strip the struts. The sole is made from a sheet of polyethylene with a thickness of 5 mm and width 10 mm more on each side. In the curved part of the sock sole to the ski attached studs, and the length is just pressed against the undercut of the steel area below the sole due to differences in thermal expansion does not warp. A small portion of the rear end of the skis together with the sole is also bent upwards by 50 mm At the ends of bridges beams skis are mounted on ball bearings, housings which are fixed to the uprights of the ski.

Rotor installation itself is traditional and consists of a power unit from a snowmobile “Buran” with a capacity of 28 HP and a homemade pusher propeller with a constant pitch.

Screw diameter 1400 mm blade: wooden, metallic ferrules at the ends of the Maximum thrust that is created by them, is about 95 kgs, which allows the snowmobile to reach the speed of 70 km/h on the ice of a frozen river. The transfer of torque from the engine to the propeller is via chetyrehluchevoy V-belt transmission. The driving pulley diameter — 205 mm, and the slave — 380 mm, that is, the gear ratio is 1.85. Belt tension by turning the eccentric axis in the sleeve with the subsequent fixing of a single in the other clamp.

Front axle and ski:

1 — the basis of ski, 2 — brace ridge, 3 — arc, 4 — ridge, 5 — rivet 6 — front strut brace (2 PCs.), 7 — rear strut brace (2 PCs.), 8 — the case of the rolling bearing, 9 — stand, 10 — eyelet brace of skis to the ridge (2 PCs), 11 — rib with a fork, 12 — rear strut of the ski (2-piece), 13 — bushing mount brace to the beam of the bridge, 14 — bracket, footrest, 15 — beam axle, 16 — spar, 17 — joint hinge of the axle beam and spar, 18 — bracket connection of the beam and the take-out, 19 —bracket connection and removal of the roll over bar, 20 — step

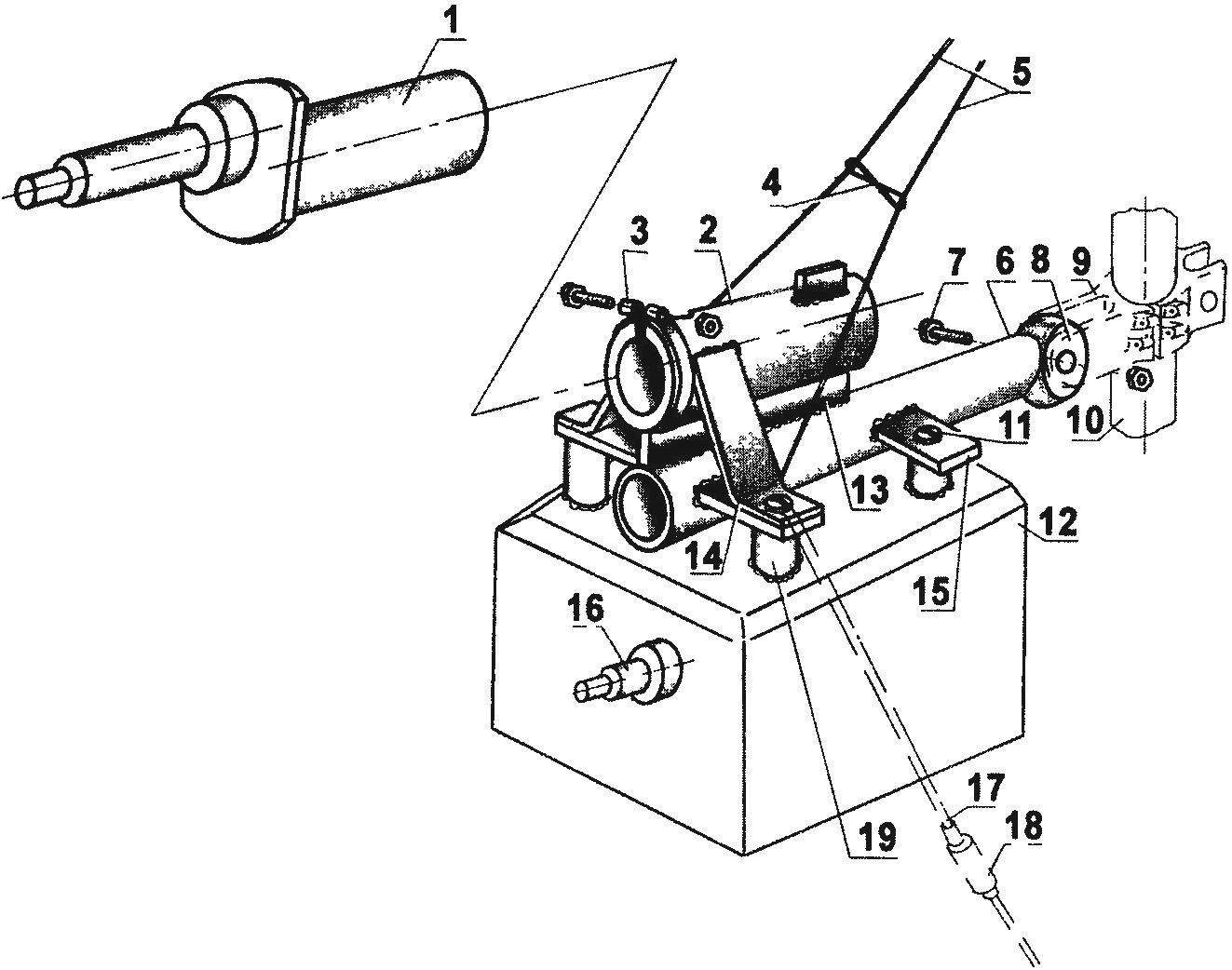

Suspension of the power plant on the cantilever beam and rope extensions:

1 — eccentric axis, 2 — bushing (steel, pipe Ø50×2), 3 — a clamp with clamp bolt, 4 — tie top-stretch (rubber band), 5 — upper tie, 6 — cantilever-beam (steel pipe Ø40×1,5), 7 — the axis of the hinge (bolt M16), 8 — silent, 9 — bushing-bracket engine mounts to the main rack, 10 — the main strut; 11 — unit fastening the engine to the console Balka (4-piece), 12 — engine, 13 — bushing 14 — brace bushings (2 PCs), 15 — wing beams (4 PCs.), 16 — output shaft of the engine 17, the lower stretch (cable Ø4, 2 pieces) 18 — thunder (2), 19 — bushing-gasket (rubber, 4 pieces)

Mount the power unit on the frame is not quite normal. First, it is not installed on it, and is suspended on a cantilever beam and attached to it through the rubber grommet-strip Cantilever beam is simultaneously focused through which is transmitted the thrust from the propeller. Moreover, a beam attached to the bar through the hinge bushing. Additional motor mount to the frame and is extraordinary — a stretch marks — aircraft flexible cables with a diameter of 4 mm with tensioning tenders. This suspension propeller installation on the frame virtually eliminates the vibration of a snowmobile.

Fencing screw yet of Course, a rotating propeller is dangerous But if you do like to remove the fence, then it can play with the person operating the sled, especially with a passenger “a cruel joke” In psychological terms, they will think protected. In fact, the probability of injury from the rotating screw remains. If we do the fence, full in the form of a thin grille on both sides and circumference.

And the screw did not touch upon the failures of the back of the snowmobile, the snow, the more ice, made the tail — the rear part of the spar is inserted the pipe is thinner.

Dry weight of the snowmobile is about 140 kg. Fully equipped (two men and 20 litres of fuel) — is close to 300 kg Brakes snowmobiles no, stop fairly quickly is due to the friction of the soles of the skis on the snow after you reset the “gas”.

S. KOCHANOV-SOROKIN, Omsk