“you Wrote Pankov Alexey Illarionovich, the leader of the group for karting at the House of pioneers city of Genichesk of the Kherson area. I appeal to you to help me and my kids in the construction of karts. Guys, after reading the materials about karting in the journal “modelist-Konstruktor”, came up with the idea themselves to build the map. But we have faced such difficulties: where to get tires for the map? Engine “JAVA-05″? Disks for wheels?”

“you Wrote Pankov Alexey Illarionovich, the leader of the group for karting at the House of pioneers city of Genichesk of the Kherson area. I appeal to you to help me and my kids in the construction of karts. Guys, after reading the materials about karting in the journal “modelist-Konstruktor”, came up with the idea themselves to build the map. But we have faced such difficulties: where to get tires for the map? Engine “JAVA-05″? Disks for wheels?”

After the publication of the series “All on the map”, which aroused great interest among the readers (“M-K”, 1973, № 10-12), the editors and the author began to receive letters, most of which begin with the words: where to get, how to do, what to read?

We asked the author, and public instructor of the experimental laboratory of micro cars of the Kursk Palace of pioneers M. R. Todorov to answer the questions most often encountered in these letters.

1. WHERE you CAN GET TIRES FOR the MAP!

Specifically for kart tire manufactures at the present time the Voronezh tire plant. Customer tire is, the Central Committee of DOSAAF, which distributes them to the regional DOSAAF committees in accordance with their bids. Therefore, to obtain the tire group leader should contact the regional Committee DOSAAF.

2. WHERE to BUY ENGINE “JAVA-05” OR “JAVA-20”!

These engines are sold in stores that sell motorcycles, in the range where there are foreign motorcycles and spare parts. For example, in Moscow, these engines are sold in the store “Moto-Java” in novokhoroshevs’ke highway.

3. WHERE to get TUBES FOR the FRAME!

Seamless thin-walled tubes of the recommended steels (30HGSA, 20S, 20) in the retail market are not available. For this question you should address to the company, which is the head of your school or House of pioneers. If your city has an airfield, you can ask there, the frame of the fuselage from a decommissioned aircraft such as the YAK-12. Some elements of the frame is made of suitable size tubes brand 30KHGSA. Sometimes these pipes are in the warehouse of the regional Committee DOSAAF.

4. HOW to MAKE RIMS FOR the WHEELS.

The rims in the sale and supply of clubs are not available, so athletes produce them themselves. In the workshops with the lathe, the wheels can be manufactured by extrusion on a mandrel.

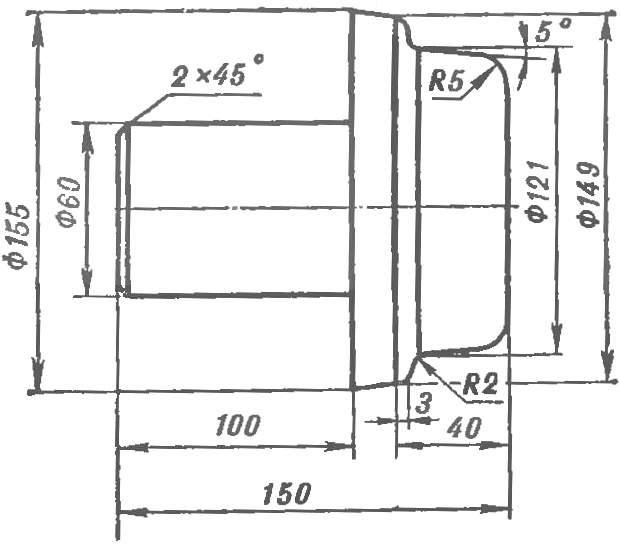

The mandrel is desirable to produce aluminum alloy (D16 or any other). The dimensions of the mandrel are dependent on the landing sizes of the used tires. Figure 1 shows a drawing mandrel, which should produce the wheels used with tires of the Voronezh tire plant.

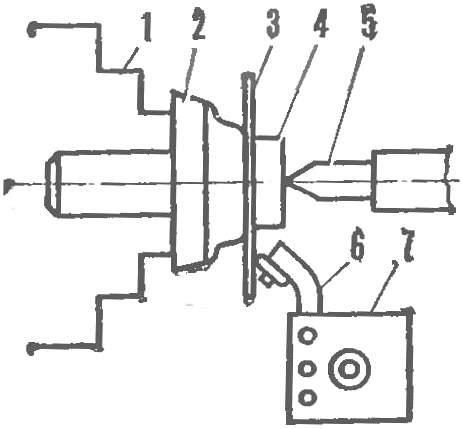

A mandrel secured in the Chuck of a lathe (Fig. 2). With the stop and the live center of the tailstock to the mandrel is pressed against the round billet, cut with scissors of mild steel. The thickness of steel sheet 1.2 — 1.5 mm. Diameter of the blank must be approximately equal to the length of a generatrix of the profile of the disk.

Fig. 1. The mandrel for the manufacture of wheel rims.

Fig. 2. Diagram of the extruding wheel disc ka lathe:

1 — cartridge; 2 — mandrel; 3 — billet; 4 — stop; 5 — rotating center; 6 — roller for extruding; 7 — tool holder.

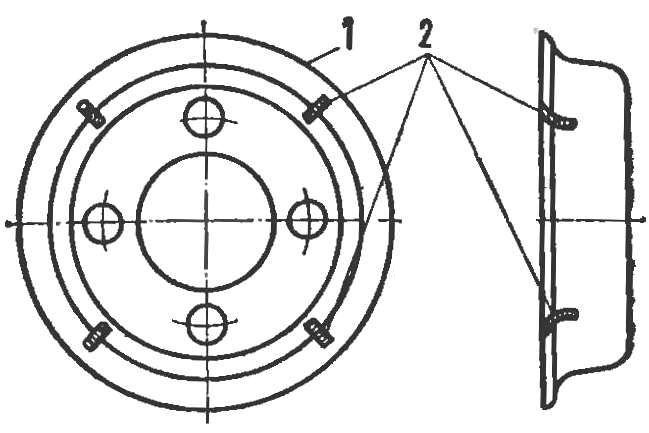

Fig. 3. The placement of ribs on disk:

1 — disc; 2 — ribs, a filler for gas welding.

In the tool post of the machine is mounted a roller for pressing, which is usually included in the equipment of the machine. When rotating spindle (120— 250 rpm) roller gradually draw in the workpiece, causing it to take the form of a mandrel. Metal while warming up, deformed. Its thickness in places of passage of the roller decreases. You need to strive to decrease the metal thickness was uniform.

At the end squeezing excess metal is trimmed. While the right cutting edge of the cutter must coincide with the future edge (Fig. 1). In this case, on the disc edge will be a stiffener in the form of a cylindrical ring with a height of 1-1,5 mm. the Finished disc is removed from mandrel and face piercing holes in the center of the bore hole for centering on the wheel hub. Then, in the disk drilled holes for the tie bolts. Bore and the coordinates of the holes of the through-bolts are selected in accordance with the existing or manufactured the wheel hubs of your card.

For better fixation of the tires on the wheels using the gas welding is fused a small rib height of 2 mm and a length of 10-12 mm (Fig. 3). The ribs, cutting his tire, prevent the tire spinning on discs and allow you to operate a bus under reduced pressure (0.8 ATM), which increases the stability of the card at the corners.

Manufacturing quality of the discs greatly depends on the skill of the performer, so do not be disappointed if the first drives will not be retrieved.

5. WHAT to READ ABOUT the DEVICE DESIGN AND MANUFACTURE go-KARTS!

In recent years, unfortunately not published a new book about this interesting and fascinating sport and its technical Arsenal. Therefore, we can only refer to some well-known newspaper and magazine publications.

Kononov L. S., Mikroavtomobili Kursk Palace of pioneers. Kursk, 1963.

Erecci M. I., Car-cards in school. M., Prosveschenie, 1969.

Richter, Thaddeus, Cartier. (In Polish). Warsaw, 1973.

“Driving”, 1962, № 1: 1963, № 10; 1964, №10.

“Modelist-Konstruktor”, 1966, No. 3 (cards on the ice); 1966, No. 5, 6 (card “b” class international); 1968, No. 7 (classification of karts. Cards pioneer); 1969, № 2 (forcing the engine map); 1969, No. 10 (Kursk cards); 1969 No. 11 (wooden kart); 1970, No. 8 (brake card); 1971, No. 11 (cards, “To”); 1972, No. 6 (thermometer and tachometer of stages); 1973, No. 10 (how to build карт7); 1973, No. 11 (forcing the engine Narta); 1973, No. 12 (winter karting); 1974, No. 3 (remote tachometer for map).

M. TODOROV