Unfortunately, it’s not very often that the pages of the magazine feature descriptions of homemade constructions that surpass the current level of serial Russian, let alone Western technology. And this is understandable: after all, such amateur machines are usually made in a shed or garage, where the entire machine park consists of an electric drill and a welding machine.

But here’s an all-terrain vehicle from the village of Sermenevo in Bashkortostan, made by Khadis Shagalievich Shagalin and his sons, which, in my opinion, surpasses similar machines of the domestic automotive and tractor industry in many parameters.

The all-terrain vehicle is assembled mainly from serial units and components of various automobiles and agricultural machinery. Much of it, disassembled, still remains in “techno-cemeteries” in abandoned quarries and ravines of the Russian hinterland; even “Vtorchermet” has no use for it. What’s important is that all these diverse but reliable mechanisms are successfully combined in one construction and work in it very harmoniously. This suggests a thought: is it worth it sometimes for our engineers to struggle with creating “personal” units for each new machine. Wouldn’t it be simpler to adapt a suitable and proven unit for it, even from another construction.

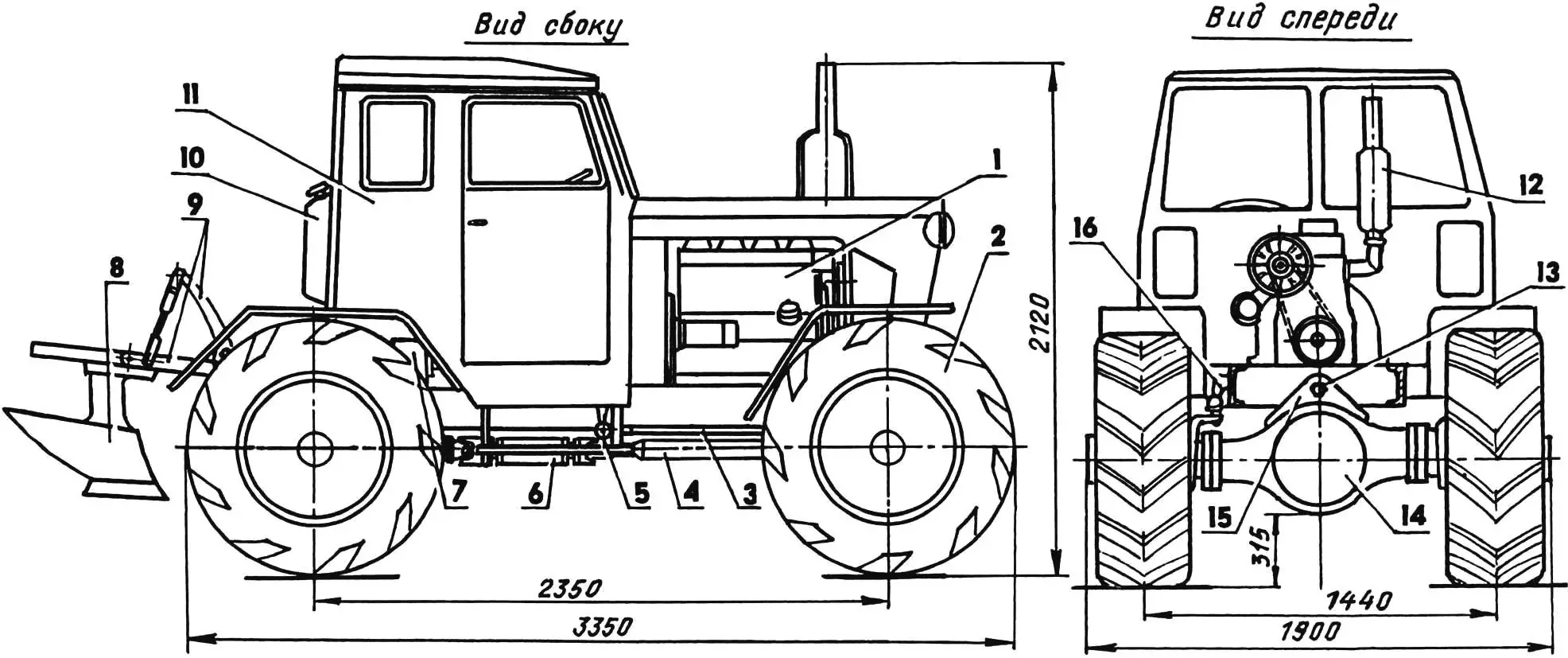

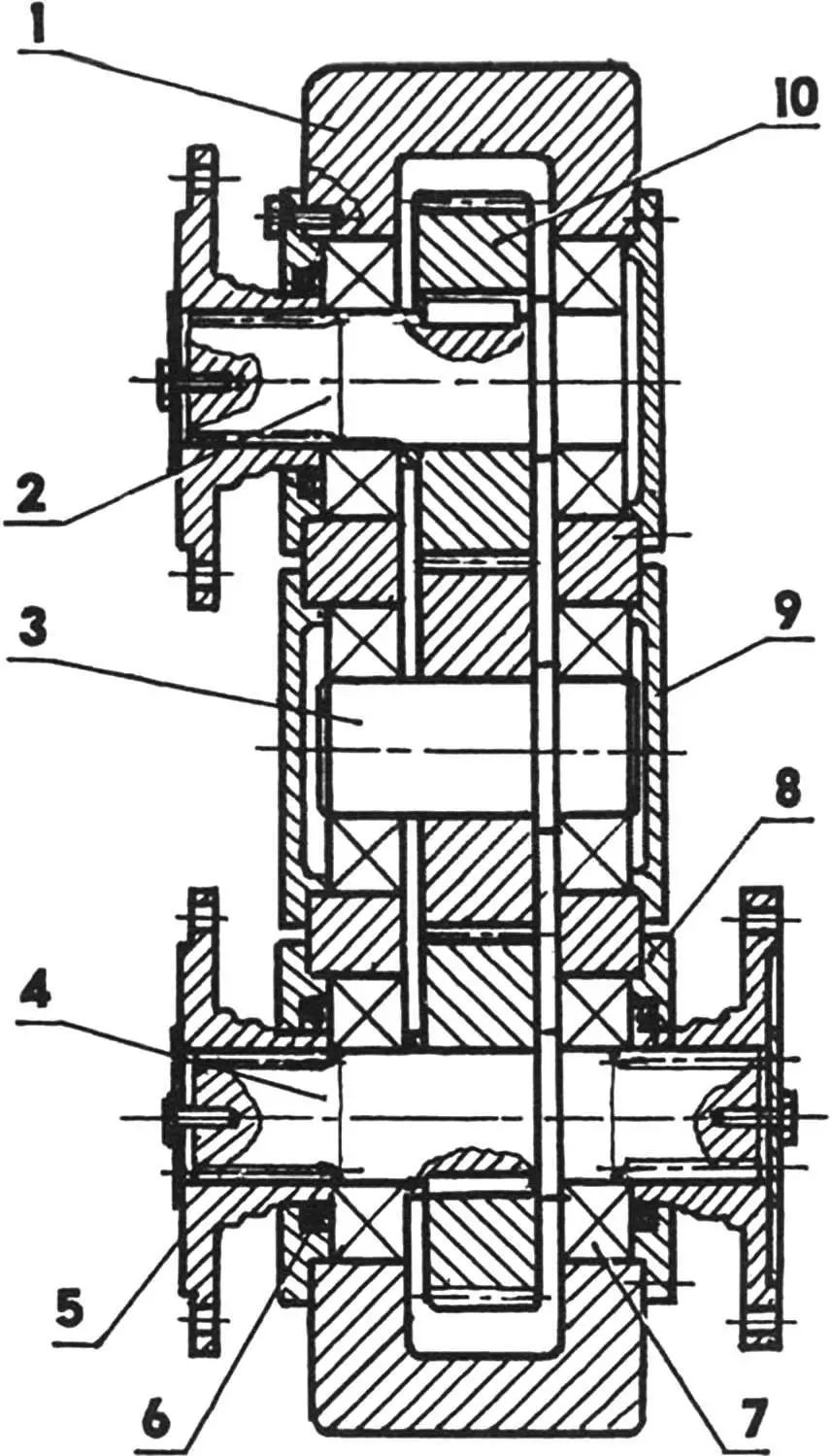

1 — engine (D-37 from T-40 tractor); 2 — wheel (18″ from GAZ-66 vehicle, 4 pcs.); 3 — longitudinal steering rod (from “Belarus” tractor); 4 — cardan shaft of front axle drive; 5 — steering arm (from “Belarus” tractor); 6 — front axle drive engagement mechanism; 7 — transfer case (reducer from forage harvester); 8 — towed agricultural implement (plow) or transport cart with capacity of 4.5 t; 9 — implement linkage levers; 10 — fuel tank (from DT-75 tractor); 11 — cab (from T-4 tractor); 12 — exhaust pipe-silencer; 13 — front axle suspension kingpin (steel, round Ø40); 14 — front axle (from GAZ-66 vehicle, shortened); 15 — front axle suspension bracket (steel, sheet s16); 16 — steering mechanism lever (from “Belarus” tractor). Frame buffer and hood not shown

The all-terrain vehicle has a simple frame consisting of two longitudinal side members made from channel No. 16a and five cross beams. At the front, the distance between the side members is 700, and at the rear — 720 mm.

When equipping the all-terrain vehicle with an engine, the amateur constructors faced a choice: install a gasoline one (from Volga or UAZ) or a diesel? The choice fell on the D-37 diesel from the T-40 tractor (four-stroke, four-cylinder, with a displacement of 4.2 L and power of 40 hp at 1600 rpm).

With the axles, there was no such problem, although there was also a choice: take them from a “UAZ” or from GAZ-66? But since large-diameter wheels were planned to be installed on the machine to ensure better cross-country capability, the UAZ chassis was immediately rejected — there was concern that when overcoming “normal” off-road conditions, they might not withstand the loads.

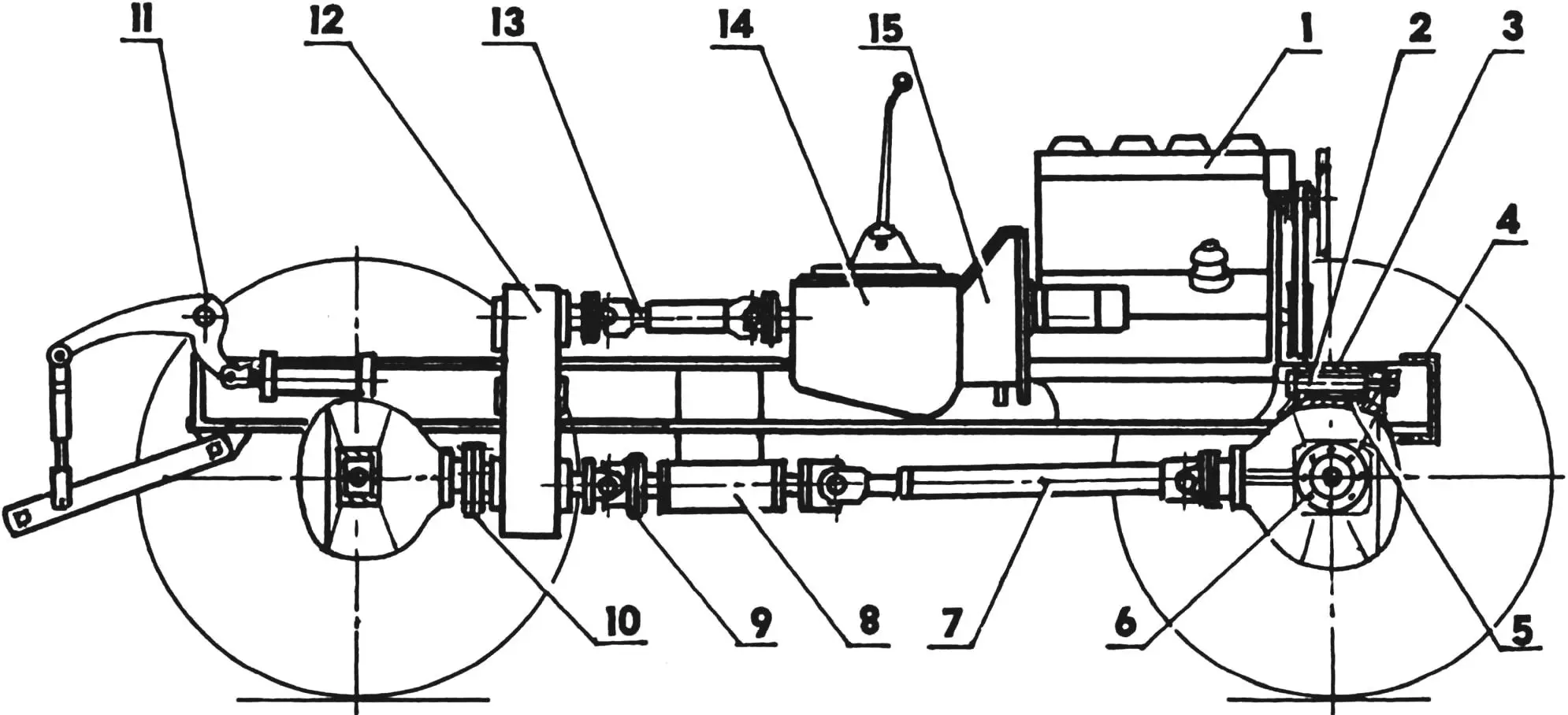

1 — engine; 2 — front axle suspension kingpin; 3 — front cross beam; 4 — buffer (from GAZ-66 vehicle); 5 — front axle suspension bracket; 6— front axle; 7 — front axle drive cardan shaft; 8 — front axle drive engagement mechanism; 9 — universal joint (5 pcs.); 10 — flange coupling (5 pcs.);

11 — implement linkage system (three-point); 12 — transfer case; 13 — intermediate cardan shaft; 14 — gearbox (from ZIL-130 vehicle); 15 — clutch basket (from ZIL-130 vehicle).

Right wheels and their hubs not shown

The axles from GAZ-66 (with cam-type limited-slip differentials, ground clearance of more than 300 mm, centralized pneumatic system for changing tire pressure of 18″ diameter wheels, well “developed” tread lugs) suited the all-terrain vehicle perfectly. Moreover, these axles are tested and reliable, and for driving on country roads, wheels of even larger diameter (20″) can be installed on them — from ZIL-131 “Ural”, as is done on the army version of the GAZ “Sadko”. Therefore, I was not surprised when I read in some automotive magazine an article about the “Wild GAZel”, on which axles from GAZ-66 were also used for operation in difficult road conditions. Another significant advantage was that an old “sixty-sixth” could be purchased for a purely symbolic price. The only drawback is the considerable weight: 345 kg for the front axle, 253 for the rear, and 108 kg for each wheel (together with the brake drum) — the price for reliability and the ability to move off-road.

The rear axle is rigidly fixed to the frame by means of four angle brackets and U-bolts, the front one has a classic balanced kingpin suspension for wheeled tractors. For this, a bracket welded from 16 mm thick steel sheet is bolted to it from above with M16 bolts. The kingpin is 40 mm in diameter. Both axles are shortened and have the same track of 1440 mm. Then the axle halves were mated and centered before welding using a pipe precisely matched to the internal diameters of the axle tube ends. The front axle was shortened only on the side of the longer tube, and the distance between its flanges was 835 mm, with the reducer positioned exactly in the middle.

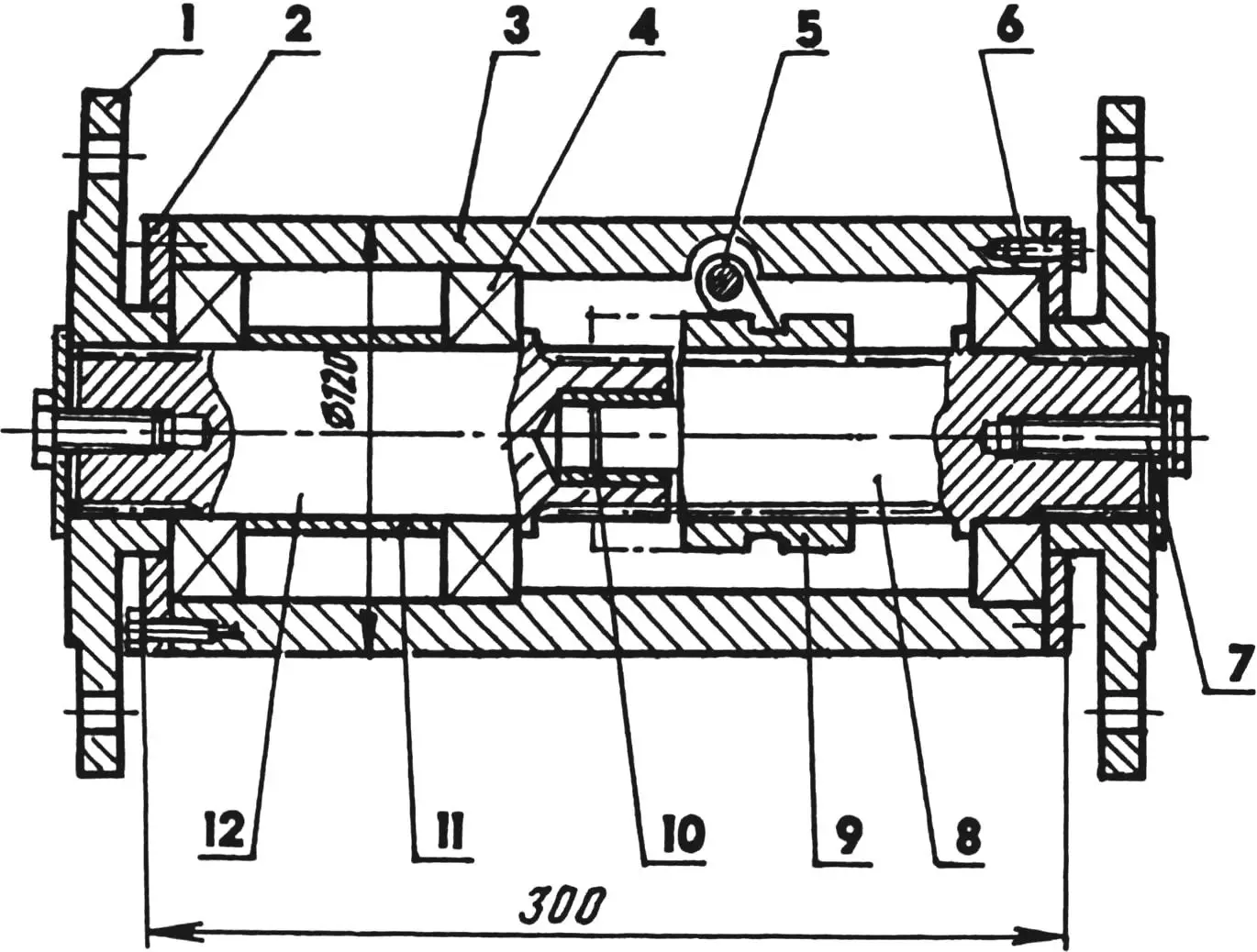

1 — flange (2 pcs.); 2 — housing cover (2 pcs.); 3 — housing (steel, tube 120×20); 4 — bearing 208 (3 pcs.); 5 — switch; 6 — screw M6 (8 pcs.); 7 — flange mounting screw M10 (2 pcs.); 8 — secondary shaft; 9 — engagement clutch; 10 — plain bearing; 11 — spacer bushing; 12 — primary shaft

Such modification of the axle allows using a standard short axle in place of the former long one, if such can be obtained. If not, then the long half-shaft will have to be shortened. For this, the jointed (on the rear — hub) part is cut off from it, and the splined part is cut to size; a mating connection is prepared on a lathe. Then both parts of the half-shafts are joined, centered, and welded.

The all-terrain vehicle’s transmission: clutch basket, gearbox — from ZIL vehicle. For mounting the clutch basket, the flywheel half-casing was removed from the engine and a 8 mm steel plate was installed in its place. For mounting the gearbox, a disc with an outer diameter of 370 mm with a recess to 317 mm was made from 10 mm steel plate. The work of mounting transmission units will be greatly simplified if using the flywheel housing from a welding diesel generator with a D-37 engine.

From the gearbox, torque is transmitted through a short cardan shaft to the primary shaft of the transfer case. A reducer from a forage harvester with three identical cylindrical gears (one is idler) is adapted as the case, so its gear ratio equals one. The case is mounted on the frame so that the axes of all its shafts are in the plane of symmetry of the machine.

1 — housing; 2 — input shaft; 3 — intermediate shaft; 4 — output shaft; 5 — flange (3 pcs.); 6 — seal (3 pcs.); 7 — bearing 206 (6 pcs.); 8 — bearing cover (3 pcs.); 9 — plug (3 pcs.); 10 — gear (3 pcs.)

One end of the transfer case output shaft is rigidly connected to the rear axle through a flange coupling. From the other end of the shaft, drive goes to the front axle through an intermediate engagement mechanism. The mechanism housing, made from steel tube with an outer diameter of 120 and length of 300 mm, is rigidly fixed to the all-terrain vehicle’s frame, its control is located on the cab floor.

The mechanism’s basis consists of two coaxial shafts. The primary rotates in two bearings. The secondary shaft is supported by one bearing and a bronze bushing pressed into the end socket of the primary shaft. Both ends of each shaft have splines. Flanges are fixed on the outer ones, and a splined engagement (disengagement) clutch of the front axle, fitted with a sliding fit, moves along the inner splines. The clutch is controlled by a lever installed on the cab floor using a fork.

The all-terrain vehicle’s cab is from the T-4 tractor, three-panel and quite comfortable, equipped with a heater and radio. Behind the cab, a 180 L fuel tank from the DT-75 tractor is installed.

The steering mechanism together with the longitudinal rod from an old “Belarus” tractor is mounted without changes. The transverse steering rod is used from the GAZ-66 vehicle, shortened.

Electrical equipment — from T-40 tractor, battery of 180 ampere-hours.

Before starting to design the all-terrain vehicle, its creators determined that along with cargo transportation work, land cultivation would not be the least of its tasks, and equipped it with an implement linkage system from T-40. (When oriented mainly toward transport work, the spring suspensions of the axles should be preserved and the GAZ-66 track left unchanged.) Using the linkage system, a two-furrow plow or other necessary agricultural implements can be mounted on the machine. For cargo transportation, a standard two-axle tractor cart with a capacity of 4.5 tons will be most suitable.

There was another reason to make the all-terrain vehicle in the tractor version: currently, registering homemade transport equipment with the tractor inspection is still simpler than with the traffic police. At the same time, a speed limitation is imposed on the all-terrain vehicle — no more than 55 km/h. This same speed on a good road is also the “cruising” speed.

P. KOPYEV