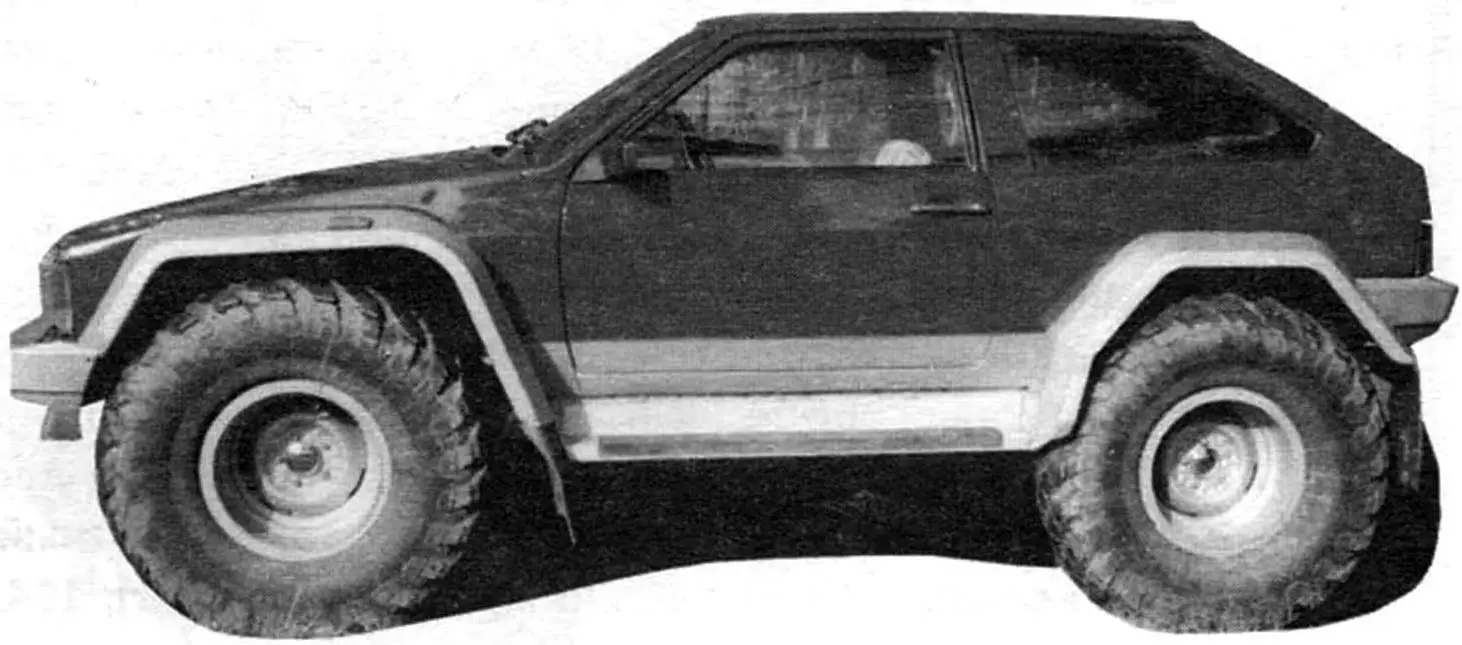

For residents of the Urals, Siberia, the North, and the Far East (that is, most of the country’s territory), the need for a vehicle like an all-terrain vehicle is simply a vital necessity. There are many reasons for this: good roads are few, the terrain is rugged, in winter almost half a year there is deep snow, and in the off-season and even in summer there is mud.

I have always wanted to acquire a vehicle that is not afraid of off-road conditions. Of course, a brand-name off-road vehicle, for example, a “Niva” on pneumatic tires (with them this vehicle is already twice as expensive as a regular one) — is beyond my means. However (probably due to the maximalism of my character), a homemade all-terrain vehicle (of the kind that enthusiasts often assemble with their own hands), which is hard to even call a vehicle, also did not suit me: I wanted something more.

The idea for an unusual vehicle design was born quite unexpectedly: I saw a parked “Zhiguli” car on the street with a wheel from a nearby GAZ-66 being repaired leaning against it.

It was precisely such wheels that could provide the qualities that easily achieve high vehicle cross-country ability: low specific ground pressure, reliable tire grip, and large ground clearance. Well, acceptable comfort would be provided by a passenger car body and its interior.

Moreover, both parts of the concept were quite feasible, since they are not associated with any shortage. After all, more and more old passenger cars appear every day, which owners are ready to give up and sell cheaply. And in skilled hands, vehicles can get a second life: restoring any domestic car practically from scrap metal is within the power of many DIYers — for them it’s only a matter of time and money for spare parts.

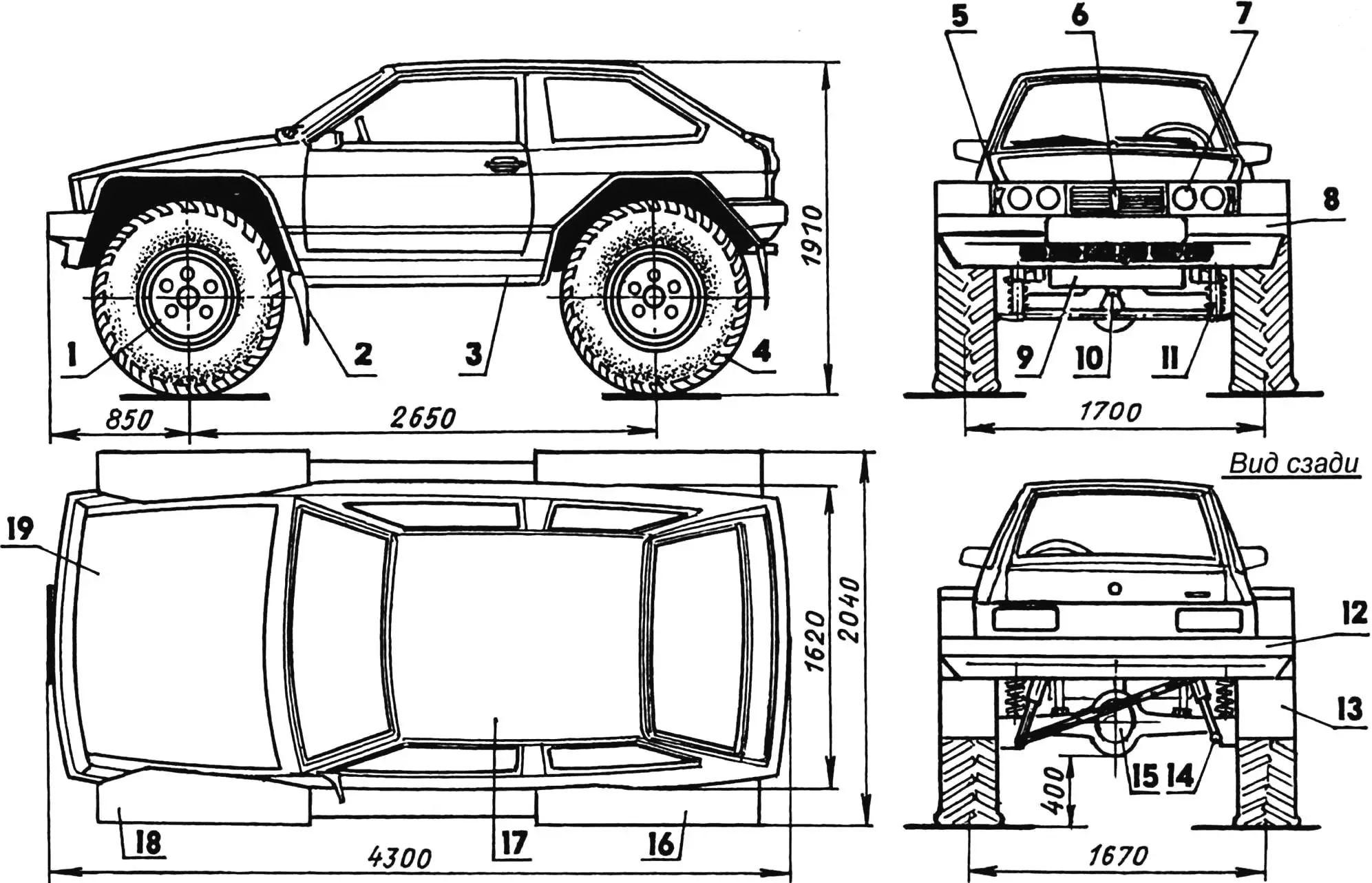

1 — homemade wheel with rim dimensions 457-254/18″-10″ (diameter— width); 2 — front mudguard (rubber s3); 3 — running boards (St3, sheet s1.5, 2 pcs. — mirror-reflected); 4 — tube tire, diagonal, lightweight, low pressure with dimensions 457-320 (18″—12.6″); 5 — front signal light (from Izh-2715 car, 2 pcs); 6 — radiator grille (from VAZ-2107); 7 — headlight unit (from VAZ-2106, 2 pcs); 8 — front bumper (made from two from VAZ-2108); 9 — engine sump (St3, sheet s1.5); 10 — rear driveshaft (from “Moskvich-2141”); 11 — front suspension (from VAZ-2121 “Niva”); 12 — rear bumper (made from two from VAZ-2108); 13 — rear mudguard (rubber s3, 2 pcs.); 14 — rear suspension (from VAZ-2121); 15 — rear axle (from VAZ-2121); 16 — rear fender (St3 cold-rolled, sheet s0.8, 2 pcs. — mirror-reflected); 17 — body (from VAZ-2108 with extended engine compartment); 18 — front fender extension (St3 cold-rolled, sheet s0.8, 2 pcs. — mirror-reflected); 19 — hood (from “Moskvich-2141”, modified)

For me, creating the all-terrain vehicle was also a test of my own engineering and design skills. After appropriate analysis (and weighing real possibilities), I decided that the most suitable body for an off-road vehicle is from a VAZ-2108 car. In the one I got, its front part and floor underwent modifications (a four-door body would have required more significant alterations). The engine compartment had to be lengthened. This was required by both the wheels (significantly larger in diameter than standard), extending beyond the front dimensions, and the engine, now positioned along the vehicle’s axis, like in the “Niva” and “classic,” and not transversely, as in the front-wheel-drive “eight.” But this lengthening did not spoil the vehicle’s appearance — the transverse welds turned out to be covered by new fenders and hood. The latter is taken from an old “Moskvich-2141,” accordingly modified and straightened.

In the floor of the cabin in the middle, I cut a longitudinal opening, and above it welded a housing, thus making a tunnel for transmission units and components. Its dimensions are the same as the “Niva’s,” so I made the housing development pattern from the flattened soundproofing pads of that vehicle. I reinforced the front panel of the body (between the engine compartment and cabin) with additional overlays and braces.

The jeep’s fender extensions in shape (in pairs: front and rear) are mirror-reflected. To make them, I first made cardboard templates, the edges of which that join with the body were carefully fitted to its contours, and then from the templates — the fender extensions themselves. They are made from cold-rolled steel sheet 0.8 mm thick. I bent them by hand, so their surfaces are quite simple — conjugate planes. Rigidity is ensured by continuous (along their entire length) flanging of the free edge. With the other edge (cut along the contours), the fender extensions are welded to the corresponding body “eight” fenders, after which part of the latter in the wheel wells was cut along the contour of the former.

The running boards (also mirror-reflected in shape) are made from steel sheet 1.5 mm thick (with flanges for rigidity). They are welded to the lower flanges at the joints of the sills and body floor. The running boards themselves are made with steps; they do not reduce ground clearance, but add convenience. Moreover, the steps cover the base space and create a more squat appearance for the all-terrain vehicle. To prevent the running boards from being slippery, their outer edges are covered with rubber.

The bumpers, both front and rear, are made full width of the vehicle. Each is assembled from two damaged ones (taken from auto repair shops). The bumper ends are connected to the fender extensions.

The engine is from a VAZ-21011 passenger car, de-rated to a compression ratio of 7.6, which allows using low-octane gasoline A-76 or AI-82 for it.

As already mentioned, under the hood of the VAZ-2108 body, the engine is now, unlike the standard one, positioned longitudinally. To install it, I had to make a special transitional subframe from 2 mm thick steel sheet.

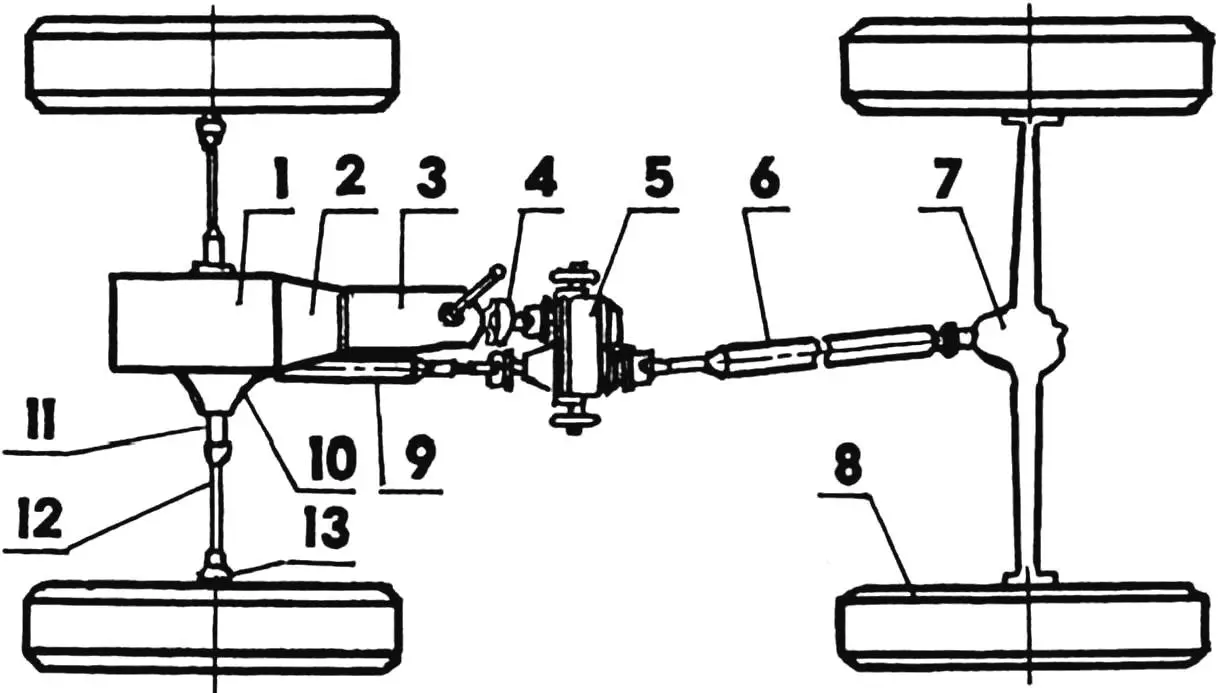

1 — engine (from VAZ-21011 “Zhiguli”, de-rated); 2 — clutch; 3 — gearbox (from VAZ-21011 “Zhiguli”); 4 — intermediate driveshaft; 5 — transfer case; 6 — rear driveshaft; 7 — rear axle; 8 — wheel (4 pcs.); 9 — front driveshaft; 10 — front axle; 11 — inner front wheel drive joint (2 pcs.); 12 — front wheel drive shaft (2 pcs.); 13 — outer front wheel drive joint (2 pcs.)

The transmission with its main units and components — clutch, transfer case, driveshafts — are used from the “Niva” — VAZ-2121 car. The gearbox (four-speed) is from “Zhiguli” (VAZ-21011), it connects with “Niva” units without modifications. Since the vehicle’s wheelbase increased compared to the “Niva’s,” the driveshaft from the transfer case to the rear differential had to be installed longer — from a “Moskvich-412” car. From the differential, the torque is transmitted to the wheels by two half-shafts from the “Niva” car.

The drive from the front differential to the wheels — open shafts with constant velocity joints — is also from VAZ-2121.

The running gear — front and rear axles, as well as suspension elements: springs, shock absorbers, levers, etc. — all from the same VAZ-2121 “Niva” car.

For the articulated connection of the rear axle to the body, the longitudinal links had to be lengthened, making inserts in some of them or welding one of two.

The wheels (what car enthusiasts, and many professionals, more often call rims) are taken from an old Polish-made “Żuk” microbus. On their rims are mounted (with “offset” to the outside) and welded also homemade rims with flanges from 2.5 mm steel sheet. The width of the new wheel rim is 254 mm (10 inches), the mounting diameter is 457 mm (18 inches). Tires are secured on them with split rings, as on trucks. The mounting holes in the rims match in size and location with “Niva” ones.

The tires themselves are tube-type, diagonal, high-profile, low pressure (in front — 0.8, in rear — 0.7 atm.). In size and tread pattern (“herringbone”), the tires are the same as those of the high-mobility GAZ-66 truck.

Brakes are from the “Niva,” without modifications, dual-circuit with vacuum booster; front — disc, rear — drum.

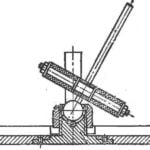

Steering is composite: mechanism — from a GAZ-24 “Volga” taxi, drive — from a UAZ-469 car. This combination is not caused by any necessity, these units were simply available to me.

Electrical equipment is also composite. Single-wire (with “minus” on the body) wiring — from VAZ-2108. Generator and starter — from VAZ-2101. Headlight units — from VAZ-2106; rear light units — from VAZ-2108; front marker and turn lights — from “Moskvich-412”; turn signal repeaters — from VAZ-2105.

The curb weight of the fully fueled and equipped jeep-all-terrain vehicle is 1330 kg. Overall dimensions are indicated on the general view drawing. Maximum speed, compared to the base vehicles, has decreased slightly and is about 120 km/h. But since the vehicle is designed for operation off-road as well — this is even too much. However, acceleration is rather low: with a driver and passenger, the vehicle accelerates to 80 km/h in 35 seconds. This is explained by the engine power.

Ground clearance (clearance) is increased and is 400 mm.

In addition to four passengers, the off-road vehicle can carry another 50 kg of cargo.

The all-terrain vehicle’s paint is two-tone. The body is painted in its “pristine” cherry color, and the bumpers, fender extensions, and running boards — in light gray.

“Modelist-Konstruktor” No. 1’2004, I. SHIRIKALOV