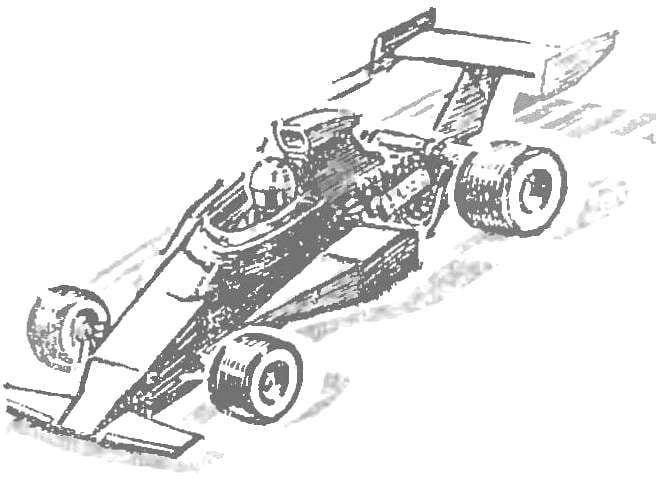

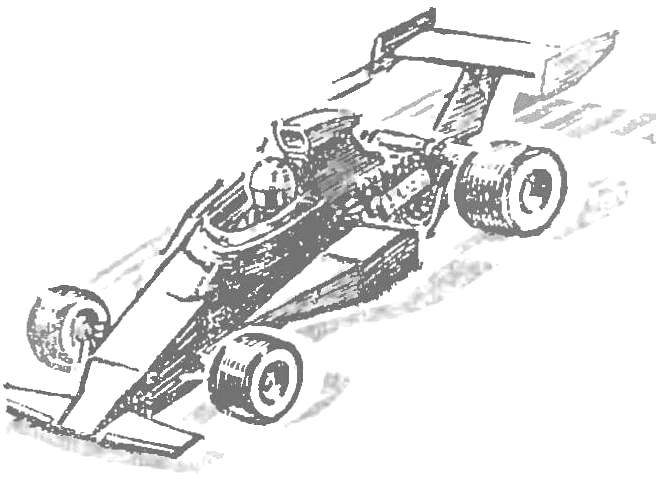

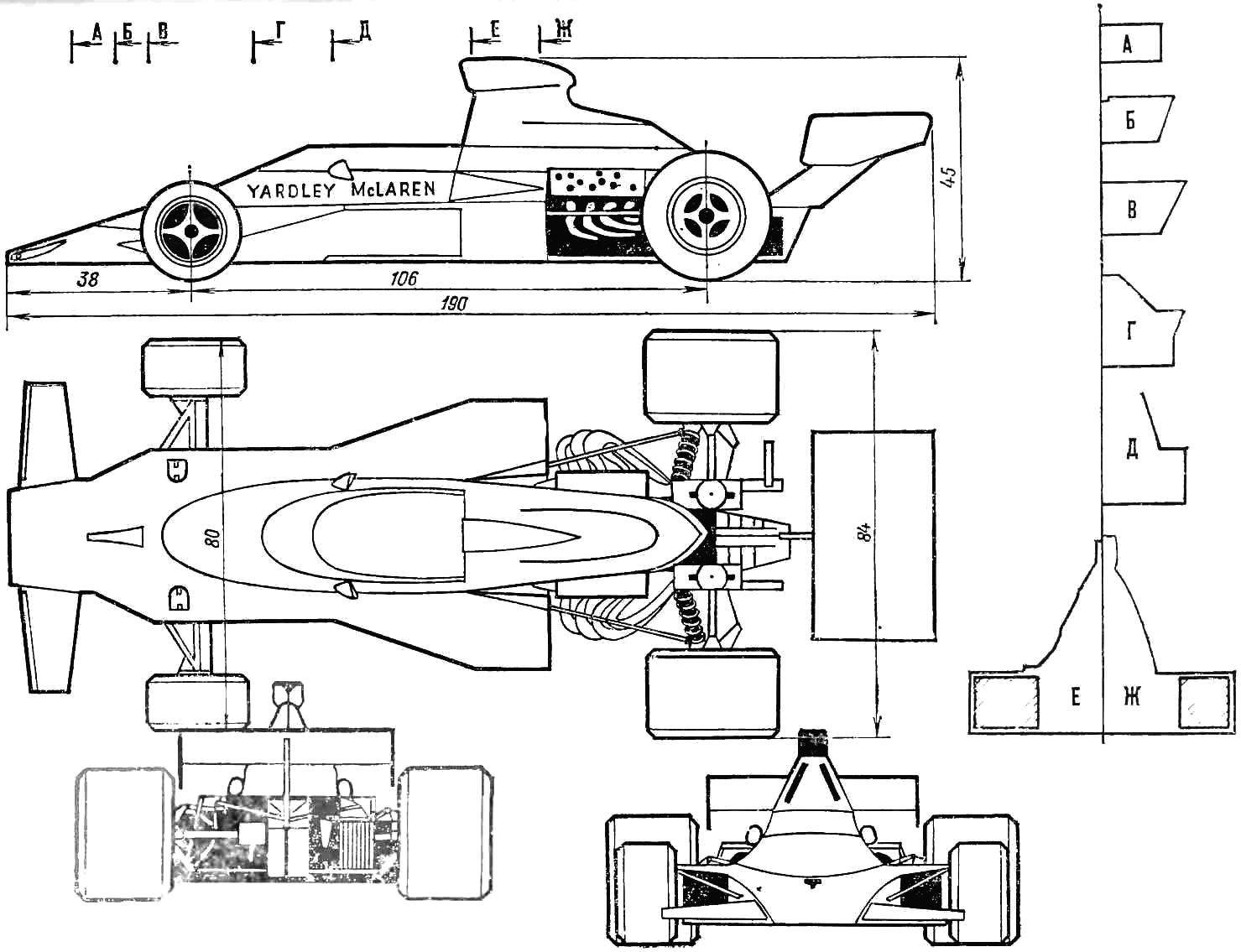

Today young automodellista offered drawings and a brief description of trace model of class A. as a prototype adopted a race car “the McLaren” M-23, scale is 1:24 to nature.

Today young automodellista offered drawings and a brief description of trace model of class A. as a prototype adopted a race car “the McLaren” M-23, scale is 1:24 to nature.

Electric motor factory “Norma”, mounted on a model designed for a working voltage of 4.5 V Having small dimensions, the electric motor develops sufficient power to produce high speed, the layout of the body led to the use of an angular transmission with disc gear. Such gears are often used in clockwork and electric toys, where usually and extracted. The number of teeth of the pinion Z1=9, Z2 big=36. When selecting the gears should aim as accurately as you can stand! this ratio because it is determined empirically and provides the highest speed.

For painting the model can use the services of the website http://storehouse.ua/service/powder-coating/ whose paint powder at the highest level.

A model vyklevyvajut on a wooden disc, made in advance, subject to a final thickness of the finished body. Technology vyklicky depends on the material. If it’s paper, then go carpenter’s glue, glue BF-2, enamel. If a subtle fiberglass “matting” — epoxy resin. A commercially available epoxy adhesive (set of two components) contains a plasticizer, making the gluing or laminated product is more durable. Allowing the body to dry out well, finally its finish: carefully shpaklyuyut, treated with fine emery paper with water or kerosene and the cover of airbrush (spray) three or four layers of colorful nitroenamels.

Fig. 1. Appearance and cross section of the body of the model race car “the McLaren”.

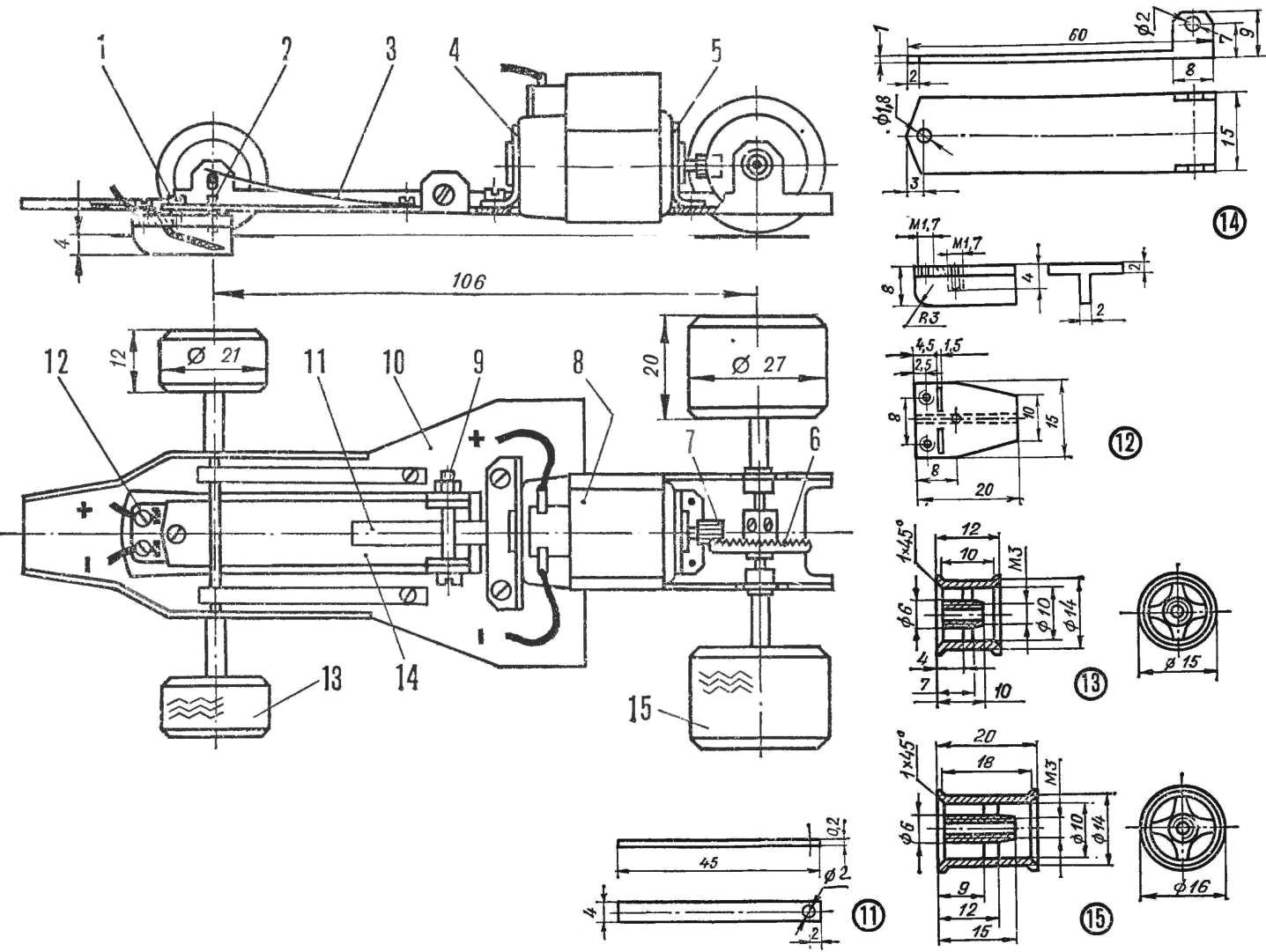

Frame model of thick mild steel 0,6—0,8 mm is 8 according to the drawing. Drilled the required holes, the edges zagotovki treated carefully with needle files, Flex along the lines of markup.

Motor brackets of mild steel of thickness 0.5—0.8 mm fastened to the bottom of the frame on the one hand with screws and nuts M3, and on the other by rivets.

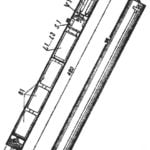

Contact-the guide is installed on the rocker lever screws. The best material for the body of the contact device of the fluoropolymer. It provides the least friction and wear. As a substitute you can use plexiglass or polystyrene. The contact lamellas are made of phosphor bronze thickness 0.15—0.20 mm or braid shielded cable, made by flagellum.

The rims are made of aluminum. They put in axis screw-M3 and zakanchivaut on the inner side of the nut.

Fig. 2. Chassis model (body shot):

1 — screw (the axis of the contact device), 2 — rotation limiter, 3 — spring suspension, 4 — removable motor bracket, 5 bracket (focus motor), 6 — driven gear with hub, 7 — pinion gear, 8 — electromotor, 9 — lever axle contact devices, the 10 — frame*, 11 — spring, 12 — body contact device, 13 — front wheel **, 14 — lever, 15 — rear wheel.

* Frame dimensions in the drawing are reduced according to the thickness of the body.

** On the callout shows the rims of the respective wheels.

Tires — thick (12 mm front, 20 mm rear) microporous rubber. The inner hole is cut, razor-sharp pipe clamped in the Chuck of the machine. Tube diameter for tires of the front wheel 12 mm, 14 mm. Outside rear wheel is neatly trimmed with a sharp knife (a scalpel) at the circular markings. You can make a jig from two tubes of different diameter that will cut a “wheel” in a single pass. The interference when installing the tires on the drive must be at least 1.5—2.0 mm that allows to install it without glue. The final diameter of the cutting tool is determined empirically and depends on the hardness of the rubber and the thickness of the tube wall.