The club “Romantic” from the city of Krasnoyarsk our readers know of the recent publication (“M-K”, 1979, No. 4). The editors have received many letters with requests to acquaint them with the designs buggy club “Romantic”. Fulfilling readers ‘ wishes, we asked the head of the section of Amateur sports autostructure V. A. Hassan to talk about one of the most interesting cars.

The club “Romantic” from the city of Krasnoyarsk our readers know of the recent publication (“M-K”, 1979, No. 4). The editors have received many letters with requests to acquaint them with the designs buggy club “Romantic”. Fulfilling readers ‘ wishes, we asked the head of the section of Amateur sports autostructure V. A. Hassan to talk about one of the most interesting cars. The basis for most of our sports car was the motorized type of SZA. This was due to many reasons. In particular, the scooter has a tubular frame on which after amplification can be welded outer frame body. In accordance with the requirements of GAI it is allowed to manage from the age of sixteen. Important was the fact that we managed rather easily to get motorized with the assistance of the Department of social welfare of the Krasnoyarsk territory.

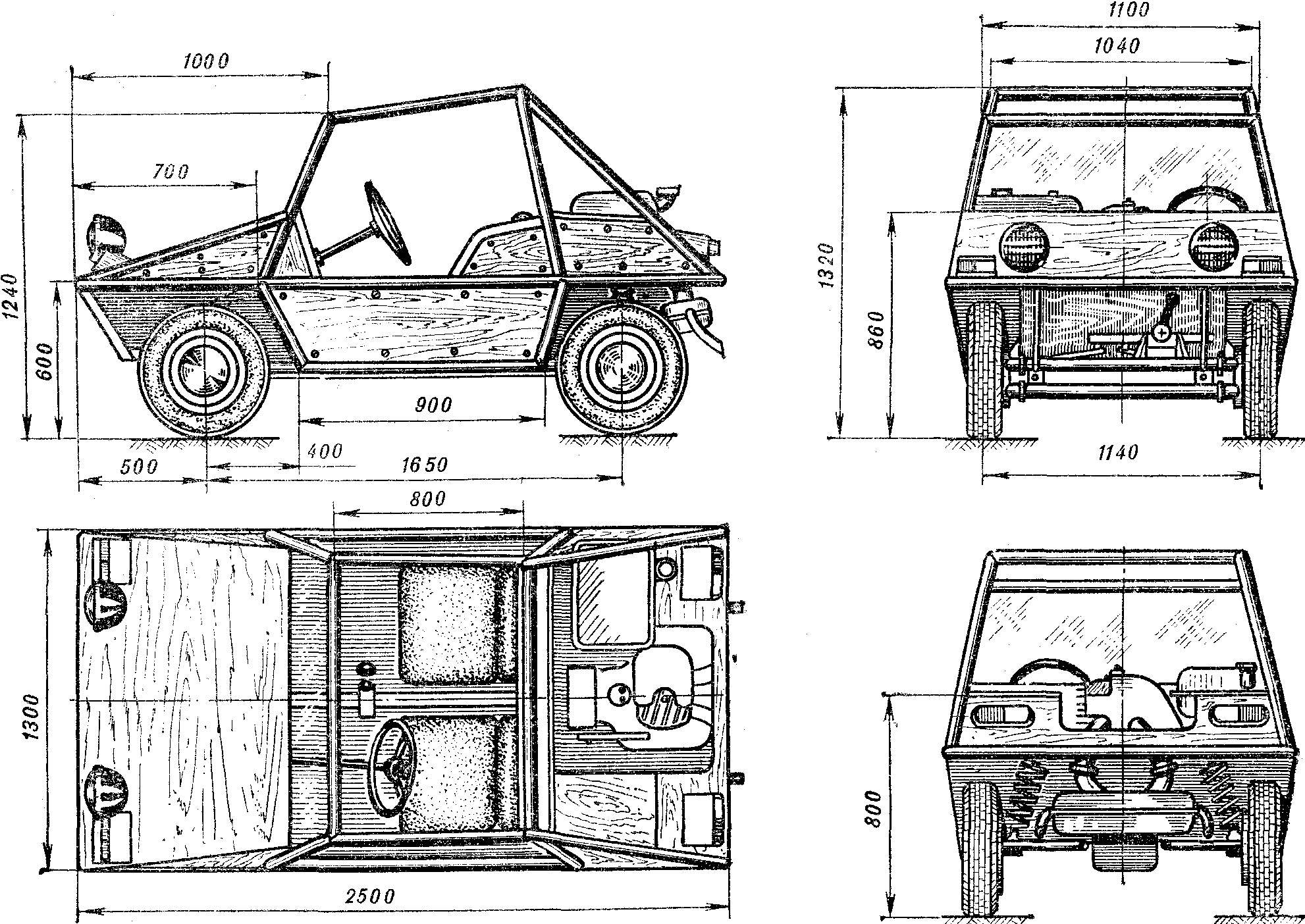

The design of the buggy is very simple and adapted to the capacities of our section, at the same time it is quite reliable and safe. Thus, the body shell has received an angular shape, as we have no tools for bending works. The front hood was made with a large angle of forward tilt is significantly improved overview, “close” part of the road visible to the driver. The rear arc of security (given that when tilting the machine it falls the main burden) reinforced by two braces. Front height below the rear by 50 mm. the Front and rear arcs initially connected to a pipe located in the plane of symmetry of the machine, but after an unplanned (but safely done) turning decided to put two. The design is tough and durable, as confirmed by repeated “production testing”.

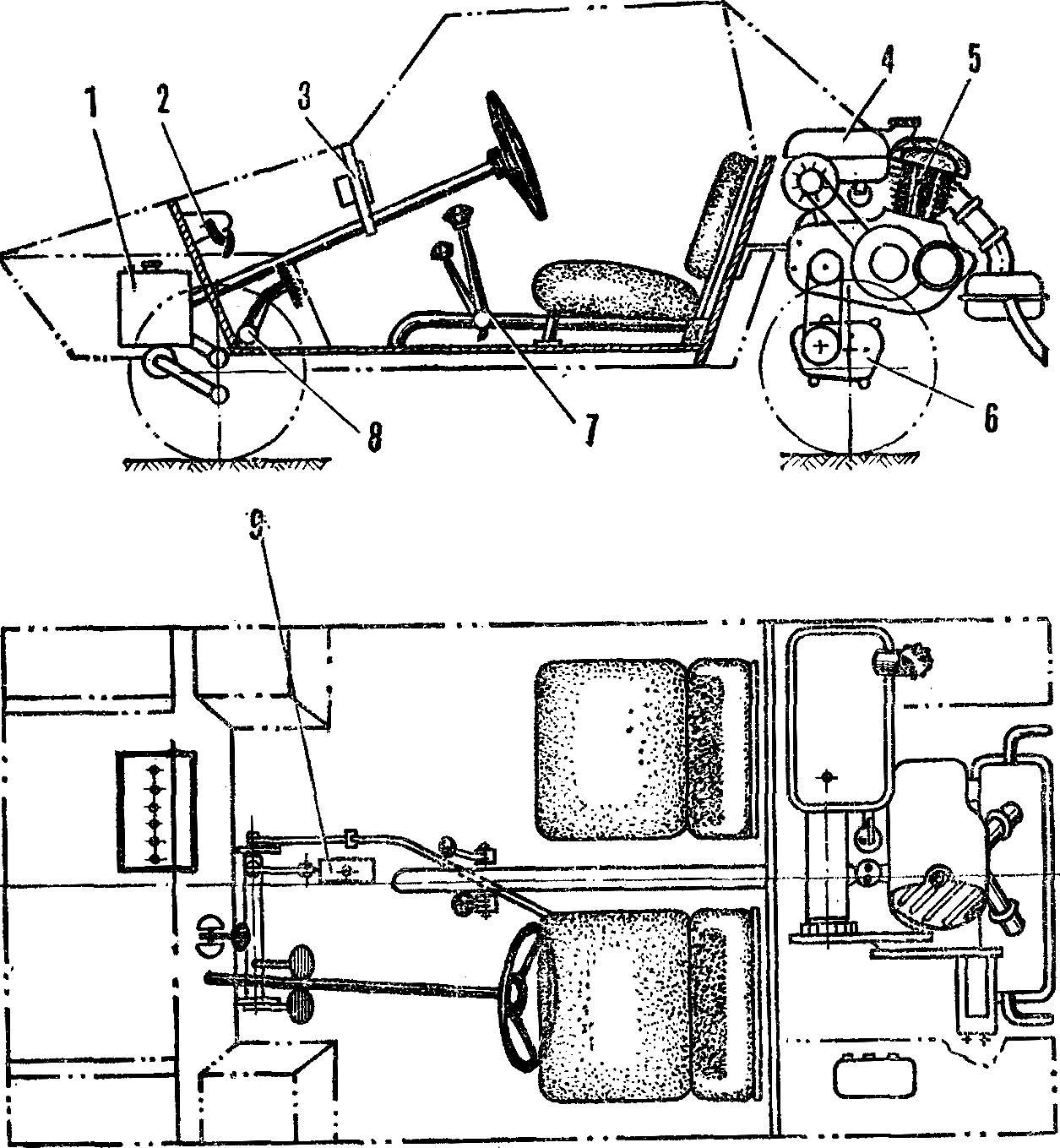

Fig. 1. General view of the sports car buggy-350.

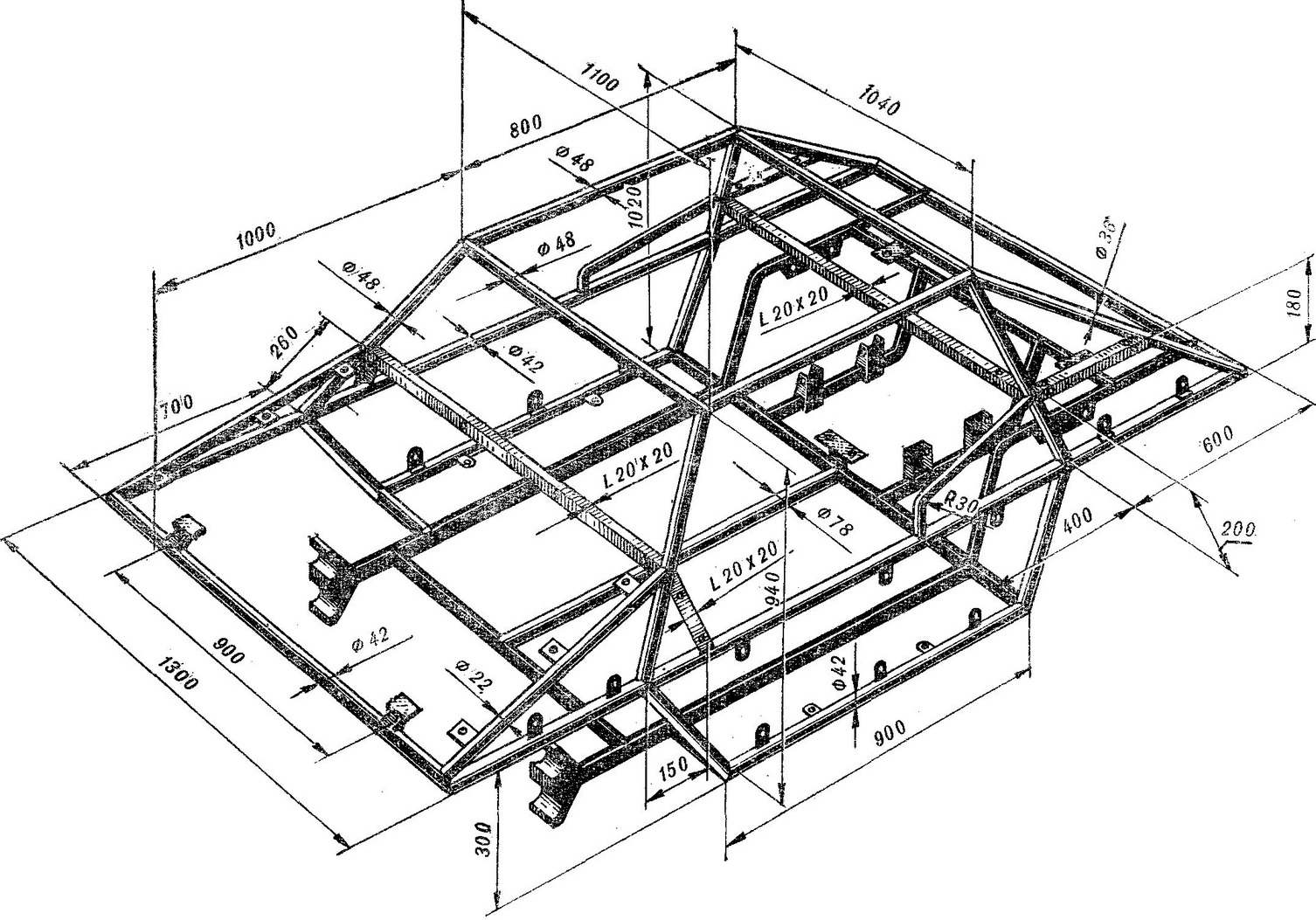

Frame. Its basis is a rectangle 1300X2500 mm, welded gas pipes with external Ø 36 mm. it is welded By arc security, struts, strut bottom trim. The frame is welded to a transverse tube of the frame, in addition, in the front of the car (between frame and frame) welded the two cut tubes with Ø 36 mm on the front of the cross — two steel angle profile 30X30 mm, plates with three holes each. The latter are used for connection of the frame with the front axle and perevorachivayutsya thereto by bolts M3. In the rear of the machine frame connected to the frame two lengths of pipe Ø 24 mm. Thus, the two elements are bonded in eight points.

Instrument panel and rear wall of the body attached to a welded pipe frame with steel corner shelves 20X30 mm, and a facing panel to a steel plate 40X40 mm, welded to the pipe frame.

Facing panels cut from plywood 10 mm thick. the Practice has shown that such panels easier to manufacture and easier to repair than metal.

Installed over the wheels, the mudguards, curved sheet steel 1 mm thick. They protect the body and the driver from flying from under the wheels of dirt and water.

The engine, main transmission and the sub frame is not altered. However, to simplify the operation with the engine removed the fuel pump, the tank is raised on the back of the body. So it will not be exposed hot air from the fan, it is shifted to the right.

Fig. 2. The main components and assemblies:

1 — battery, 2 — accelerator, 3 — dashboard, 4 — fuel tank 5 — engine, 6 — eye transmission, 7 — levers gear shift and reverse, 8 — brake pedal and clutch, 9 — brake master cylinder.

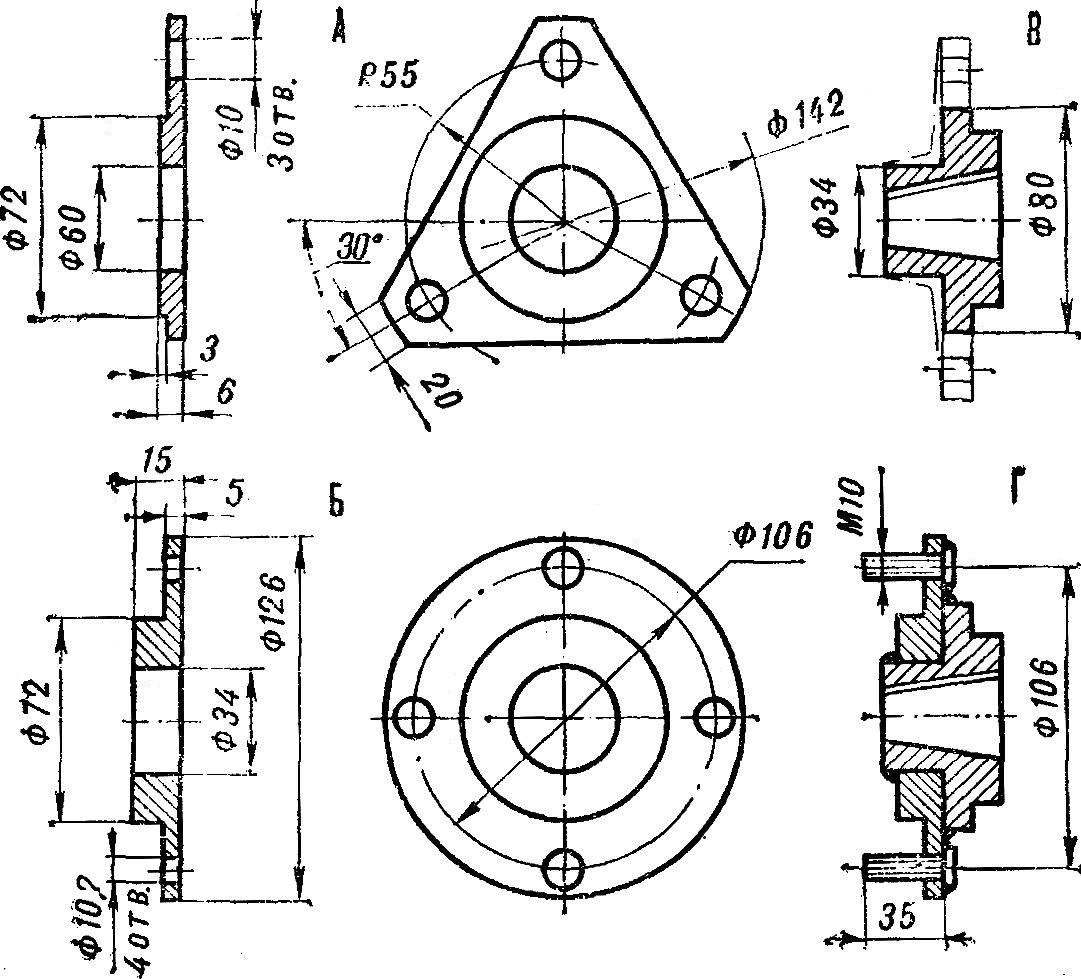

Fig. 3. Details for revision rear axle:

A — adapter flange cap brake drum FDD; B — adapter flange hub rear wheel (under the wheel brake sidecar FDD); — finalization of the hub, SZA, G — flange and hub Assembly.

A radical alteration has undergone a brake system, as a sports car should have brakes on all four wheels. For reliability, we replaced the mechanical brakes to hydraulic. This used front axle from motorized FDD, exposing some improvement levers of the rear wheels.

In particular, it has been removed cover the brake drums and in their place welded to the adapter flanges. To them three M10 bolts attached lid brake drums from motorized FDD. Further from the brake drums between the separated wheel, bored through them on a lathe, put in a makeshift adapter flanges and welded. Removed the brake drums, too, went into business. The center hole in them is wasted to Ø 72 mm and cut the lateral surface of the cylinder. Four drilled holes Ø 10 mm, received the fastening of back wheels, which together with the brake drums from FDD and put on the hub and secured by nuts M10. It has widened the track of the rear wheels up to 1140 mm. After such modifications, the hydraulic brake hoses from the sidecar FDD was a bit short, so they replaced the hoses from the car GAZ-51, cut at the connecting fitting new thread M12X1. For attaching the master cylinder to the Central part of the frame welded socket.

The electrical system on our car dvenadtsatiperstnoi, a little different from regular motorized FDD. Relay-regulator and ignition coil are mounted on the left rear fender, the battery is the same for a more uniform load distribution along the axes was carried forward and placed in the nest over the front axle.

Fig. 4. Frame and frame (the black frame is not recycled sidecar SZA).

Our buggy was designed more as training than sports cars, so they have a complete set of lighting and signal devices. For the best protection from dirt lights cemented over the front hood. Beep and Blinker “fit” on the front wall of the body under the hood.

Instrument panel machine sawed out of plywood with a thickness of 15 mm bolts and M6 prevernal to the base corners on the front arc side tubes frame. On the dashboard mounted speedometer, ignition switch and warning lamps high beam headlamp, stop lamp, and the inclusion of neutral transfer. Other equipment includes a headlamp switch, the switch of turn indicators, push-buttons, horn and the starter is located left of the driver on the panel welded to the side tube of the frame.

The color of the car is made so that it was visible from afar. Frame pipe light blue, and orange facing panels. The car interior is gray. Frame and fenders are covered with microgrants, and the bottom and front wall of the body — a mixture of bitumen and linseed oil (1 : 1).

Seat from the car UAZ-469. On each machine be sure to install the seat belts and carbon dioxide fire extinguishers. During long runs of complete buggy spare wheels (with their fastening on the front hood) and removable canvas awnings. Tent, in addition to protect the driver from the elements, helping further cool the engine, as the incoming air stream was directed directly at him.

In . HASSAN, Krasnoyarsk