SABS-2 was conceived as a touring car for five people, with two sleeping places on the roof in the tent and three in the cabin. It, like the first, lasted seven years. They were very difficult, but if to me now suggested to start all over again, I would, of course, repeated them. However, I would like to warn beginners homebrew that can do this is possible only with full clarity in the following matters. First, what you make the car, and consequently, what kind is it and where it will be used. Secondly, “what you do” and therefore use materials, components and assemblies, as well as technology. Thirdly, which is also very important, where you make a car do you take into account factors like neighbors, weather, distance from home, do not forget you family. And the last question — Finance: do not be fooled that the home will cost for nothing — it is not. If you want to get in the end is a good thing, it will require committing substantial funds.

And now more details of the design (maybe useful to someone my experience, and it will put some ideas and solutions as the basis of his version).

On the drawings the General view of the principal section of the body. Specific dimension values on them (and the sketch of the frame) is not indicated because they depend on the available material and the dimensions of the car. Most of the designs I like laid and subsequently implemented the principle of complex configuration are obtained by compilation of the simplest. Moreover, as needed three-dimensional elements can be made of materials of different thickness. This gives a gain in the total mass of the structure. Connect the elements using gas welding, mostly without additives, melting the edges. Before welding, the components are assembled and fixed together by clamps, with a pitch of about 100 mm. Between the clamps boil point, and then after removal of the clamp — all seam entirely. Sometimes during Assembly it turns out that connecting two, three, four or more layers (e.g., section R—R, e—E, n—N); in this case, the “point” is set by melting of the edges and seams boil with the filler wire.

In the manufacture of the structural elements used a homemade bending machine. It was made of two beams with a length of 1600 mm (channel No. 12, welded in a box) that are connected by edge loops. One of the beams is fixedly attached to the pillars, and the other with two handles Ø 30 mm and length 700 mm. the workpiece is pressed against the fixed beam plate 16x120x1600 mm with a 45° chamfer. The plate is fixed with four clamps attached to a fixed beam by bolts. Straight bends are performed by turning the movable beam by the handles and the back as well, only part (depending on cross section) are clamped using spacers of various heights. As the last use wood, steel or other strips of the desired size and length. With this fixture I was alone, bent steel sheets with a thickness of 0.1 to 1.5 mm in length and 1600 mm. the Details are so qualitative that do not require additional edits and putty.

All the elements of the trim panel bottoms, the roof is made of aluminum alloys is a profitable and weight, and it is good from the standpoint of corrosion resistance. However, there is a disadvantage — the difficulty of painting. To obtain high-quality part surface must be anodized. This operation I performed at the Tashkent aircraft plant.

To steel frame casing is attached to a different technology ways — rivets, screws, “screws”. To avoid the phenomena of electrochemical corrosion due to the heterogeneity of the materials, all the joints of the body and frame were covered to Assembly with anti-corrosion wax.

If someone has any doubts about the attachment of parts of the plating on the screws, want to dispel the covering of doors, for example, fully assembled with hidden screws M3 with a step of 50…70 mm. After Assembly the inner surface should be coated with anti-noise anti-corrosion mastic; and because the threads of the screws filled this with putty, then they will not turn from vibration, and rust away from moisture. Place countersink before installing the screws with countersunk heads exposed primer, and fasteners to the raw paint.

Fig. 1. General view of the vehicle of SABS-2:

1 — the frame of the door frame (Art. 3), 2 — divider glass, 3 — lip seal of the door opening, 4 — windshield 5 — seal of the windshield (from the VAZ-2101), 6 — frame for rear window, 7 — stand, 8 — rivet, 9 — the outer covering (Д16АМ), 10 — increases the channel (1,2х15х30 mm), 11 — “tapping”, 12 — frame rear side door 13 — inner lining (Д16АМ, mounted under the door seals), 14 — flange seal rear window, 15 — rear window 16 — the average rack, 17 — the bottom (Д16АТ), 18 — the rib bottoms (Д16АТ), 19 — rubber seal, 20 — strip (VAZ-2101), 21 — clip of the inner liner, 22 — frame middle door (St. 3), 23 — threshold (Art. 3, thickness 1.8…2 mm), 24 — siding (Д16АТ), 25 – inner lining (Д16АТ, thickness 0.8 mm), 26 — decorative finish (artificial leather, foam), 27 — wing (Д16АТ), 28 — wheel arch liner (Д16АТ), 29 — covering of hatches (Д16АМ), 30 — paneling Luke (Д16АМ), 31 — harness openings, Luke (St. 3), 32 — longitudinal trim panel roof (St. 3), 33 — a longitudinal rail (thin-walled tube Ø 35 mm), 34 — pad reinforcing, 35, a drainage groove, a 36 — frame glasses, 37 — side stand, 38 — front door, front, 39 — pipe, 40 — door, 41 — bolt 42 — door trim, 43 — door hinges (from IZH-Combi), 44 — lining side of the body, 45 — gasket (rubber sponge), a 46 — rail windshield, 47 — roof, 48 — plate connecting (Д16АМ), 49 — front shield (Д16АМ), 50 panel wiper 51 — roof, 52 — connection of roof and 53 — harness rear door, 54 seal the tailgate.

R and S. 2. Diagram of a powertrain of the vehicle and the location of major components and assemblies:

1 — body, 2 — engine (GAZ-24), 3 — gearbox (from GAZ-24), 4 — transfer box (own design), 5 — control transfer case, 6 — rear axle (from GAZ-24),7 — front axle (from GAZ-24), 8 — a sink (from the VAZ-2121), 9 — fan radiator (from the VAZ-2106), 10 — propeller shaft (GAZ-21), 11 — compressor, 12 — wheel (from GAZ-24), 13 — gearshift lever, 14 — driveshaft drive compressor, 15 — steering gear (GAZ-24), 16 -battery 6СТ60, 17 — fuel tank (capacity 75 liters), 18 receiver, 19 — seat driver and front passenger, 20 — hoist, 21 – shaft of the winch.

R and S. 3. A sketch of the vehicle frame with the main cross sections of the spars. Numbered holes for body mounting.

In the design of the car we do not forget about possible future repairs, because nothing is eternal. Besides, statistics show that every 10-15 years you’re not so you can “trim”, so I can confidently say that homemade design should be coarse-grained. In my version it can clearly be seen. The machine has seven doors, three of them workers, and four removable bolts. The upper bolts for the rear doors are hinged and allow her to open together with the rear signal lamps. Middle, right along the door has one loop and corrective leash that allows you to open the entire doorway, “having withdrawn” the door parallel to the body at a distance of half-width doors in cramped Parking conditions this option is very convenient. The front part of the body, along the line of the axes of the hinges of the front door, removable and secured with six bolts M10. Back, lower edge of the rear door is also removable. The wings are serviceable: they are attached to the frame through a strip of porous rubber by means of “screws” in increments of 70…100 mm. the body is fixed on the frame through rubber cushions eight studs Ø 16 mm with thread M12. Last for relief is made hollow.

In the cabin there are two rows of seats. The first two single chairs, the second one with one double and one single. Since the car is designed for long-distance tourist trips, the number of seats is designed for five. In principle, the volume of the cabin allows you to install another row of passenger seats. In my case the second row is made morph — when folding chairs turns the load platform dimensions mm 1730×2300 that in the campaign plays the role of the bed. If you turn in a residential only single back seat, then there is a possibility of the presence in the trip, the two drivers to provide one of them a complete rest, without stopping the motion. A rested driver is known to be a pledge of security.

Biggest challenge in car car layout with a front engine layout associated with the installation and dismantling of the power plant. In the SABS-2 is taken into account. Installation and removal of engine Assembly with gear box and “razdatkoy” I perform alone. For this, the cabin is equipped with a detachable device. Right opposite, in the course of the first pillar has a fixing rotary crane. Removed front seat with the winch mounted on the crane beam, the whole power unit Assembly extends to the middle door and falls to the ground. The installation is performed in reverse order. Ease of maintenance engine creates and removable interior floor, covering it from above; this allows in most cases to dispense with an inspection pit or trestle.

Transfer box is used for low transmission, and in fact in the car not five “speeds”, and ten. In addition, “razdatki” there is a PTO shaft to drive the compressor and winch, to use which as the product of the pressure and movement. Design transfer box homemade, the type of the GAZ-51. Examples are two shafts, one of which fits on the splines of the secondary shaft of the gearbox and ends gear (all used gear — spur). A second shaft coaxial with the first and is “floating” on the splines of the gear with external gearing. The modules of the gears are the same.

“Transfer case” has in-line arrangement of the shafts horizontally along the powertrain. On the left while the car is stationary the shaft of the gear unit on needle bearings allowing the unit to rotate and to move along the shaft when enabled, a reduced set of “core” speed of CIT. Right installed the splined shaft with the gears of the PTO, which is movable on the shaft and be in engagement on the move or stationary.

The movement of gears on shafts are three Autonomous forks, mounted on three rolling pins. The latter are located along the shafts and have the ability to move in the longitudinal direction, selecting the desired position, and toporas special clamps.

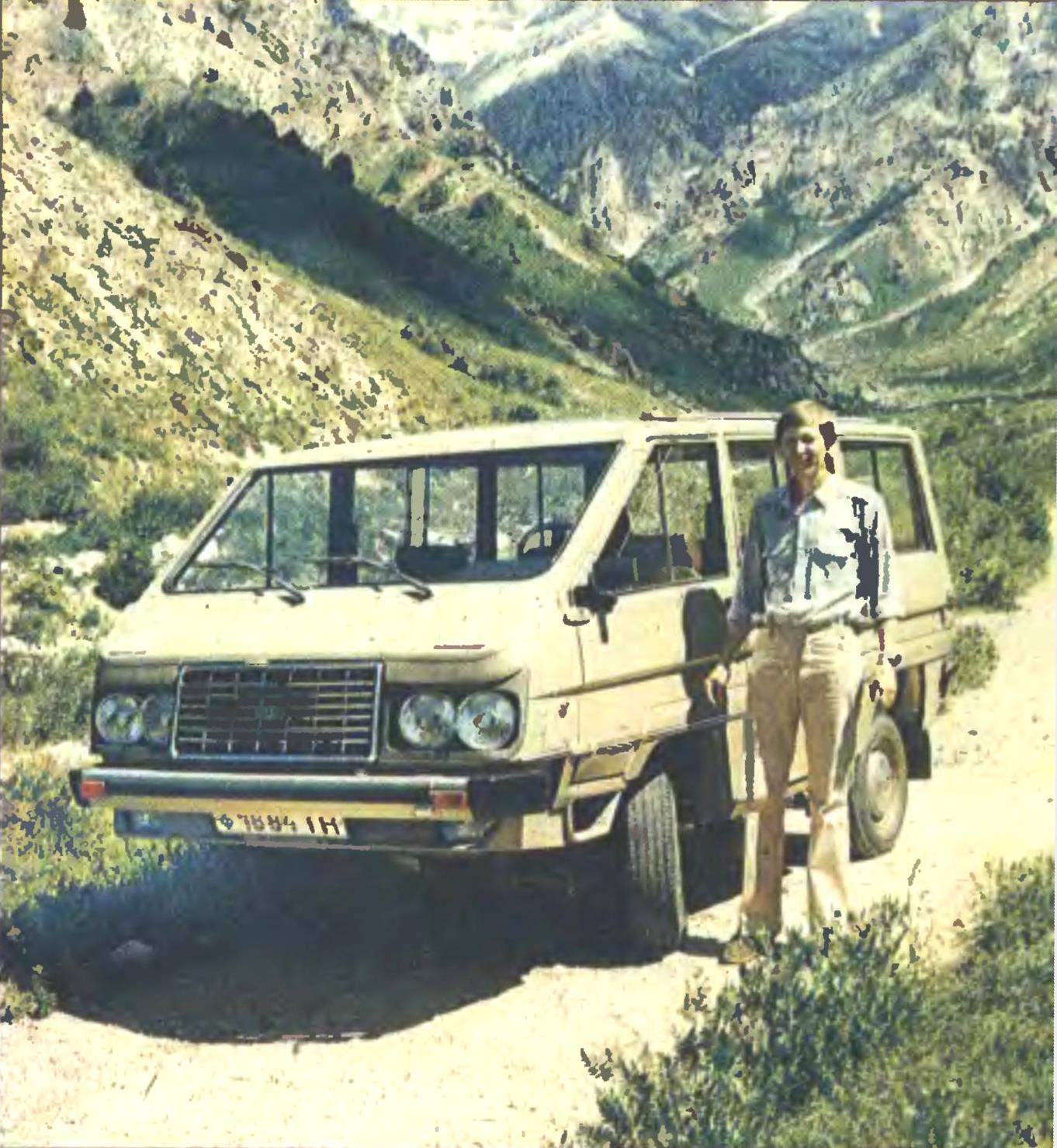

Car SABS-2 in process of construction. Note how open the side door.

Carter assembled boxes of duralumin plates with a thickness of 16 mm. Tightness is ensured by the ties from the M8 bolts. After assembling the walls together chiseled holes for mounting bearing supports shafts. Plates should be zastepowane to perform this operation.

Most of the components of the chassis (front suspension, rear axle, springs) are borrowed from the GAZ-24. In the braking system used power from the VAZ-2106 in the block to the brake master cylinder GAZ-24 connected via an adapter. The tie rods and the steering gear also taken ready-made from the “dvadtsativosmi”, with the addition of another longitudinal thrust and pendulum lever from the overage of the steering mechanism. From his left stocking, fry and axle with tapered slots. In place of the roller in repressirovannoy socket bolt M12 with three sides pinned lever, which ends in the hole under longitudinal thrust. He steering mechanism is located at the front of the frame on the bracket with two fixing bolts M16.

To ensure passive safety in the vehicle has seat belts, energy absorbing bumpers with hydraulic drives, soft upholstery and protrusions of the interior of the arc security. The latter formed a powerful racks and power elements of the framing of the roof.

Ventilation of salon is carried out through the Windows and the hatches in the roof, equipped with electric drive. It uses double worm gearboxes from the wiper. For heating the cabin are two in-series water heater. One is located in front of the cabin under the windshield and have air flow from outside through the intake. The catchment area — driver seat and front passenger front and front side glass. The second heater is located between the front seats and runs through only the cabin air, thereby providing a comfortable environment for rear passengers.

When planning long journeys in desert and mountainous terrain, provided in the van facilities, water tanks for drinking water, as well as four lights, having the ability to turn tracking with a lever position of the steering wheels. When driving in normal conditions, the city lights are fixed in a Central position. In the lower part of the body are fog lights.

That’s basically all I wanted to tell you about your car. In my opinion, in the volume of journal articles are unlikely to need more detail to give a description of such a complex design: for those who are not versed in the art, does not have veins of homebrew, whether description even the most detailed to the last screw, use it still will not do. Conversely, a creative person finding him can help even the most casual of the above decision. I think that the real homebrew I understand.

And another appeal to the readers, owners and sponsors of the cars are designed like my car, for long trips. It is time for us to get together and organize a joint run? To take and travel, for example, countries of Europe? Or arrange for the homemade “voyage century” silk road on the route Tashkent — Beijing?

In short, if you have thoughts about this — write to the editor or to me at: 700060, Uzbekistan, Tashkent , St KL. Zetkin, d. 16, kV 24, Bolshakova Sergey Konstantinovich.

S. BOLSHAKOV

Recommend to read TSIATIM FROM THE TUBE Do not rush to throw the used tube of toothpaste or shampoo. Carefully Unscrew the end of it, straighten it, and wash it with hot water. After drying, fill Ciation or other dense... HOW TO COLLECT THE ASHES? Any stove is the ash pit, and if the fuel is solid, it is always accumulated ash, which occasionally have to shovel. To simplify this work, I invented a kind of scoop drive. It is...