Humanity has accumulated a huge variety of patterns, layouts, and drawings of trailers for all occasions. There are even trailers for transportation of yachts and aircraft.

But I was interested in more simple and immediate – a cargo intended for the carriage of materials. For myself, classified them according to the following principle:

- trailers spring suspension;

- the trailer on a spring suspension;

- without suspension.

The last type I was charmed by its simplicity of manufacture in a home workshop, but the assumption that not all cargo carried in such a trailer, will stand directly transmitted to the jolts and bumps from the Russian potholes, dismissed it completely.

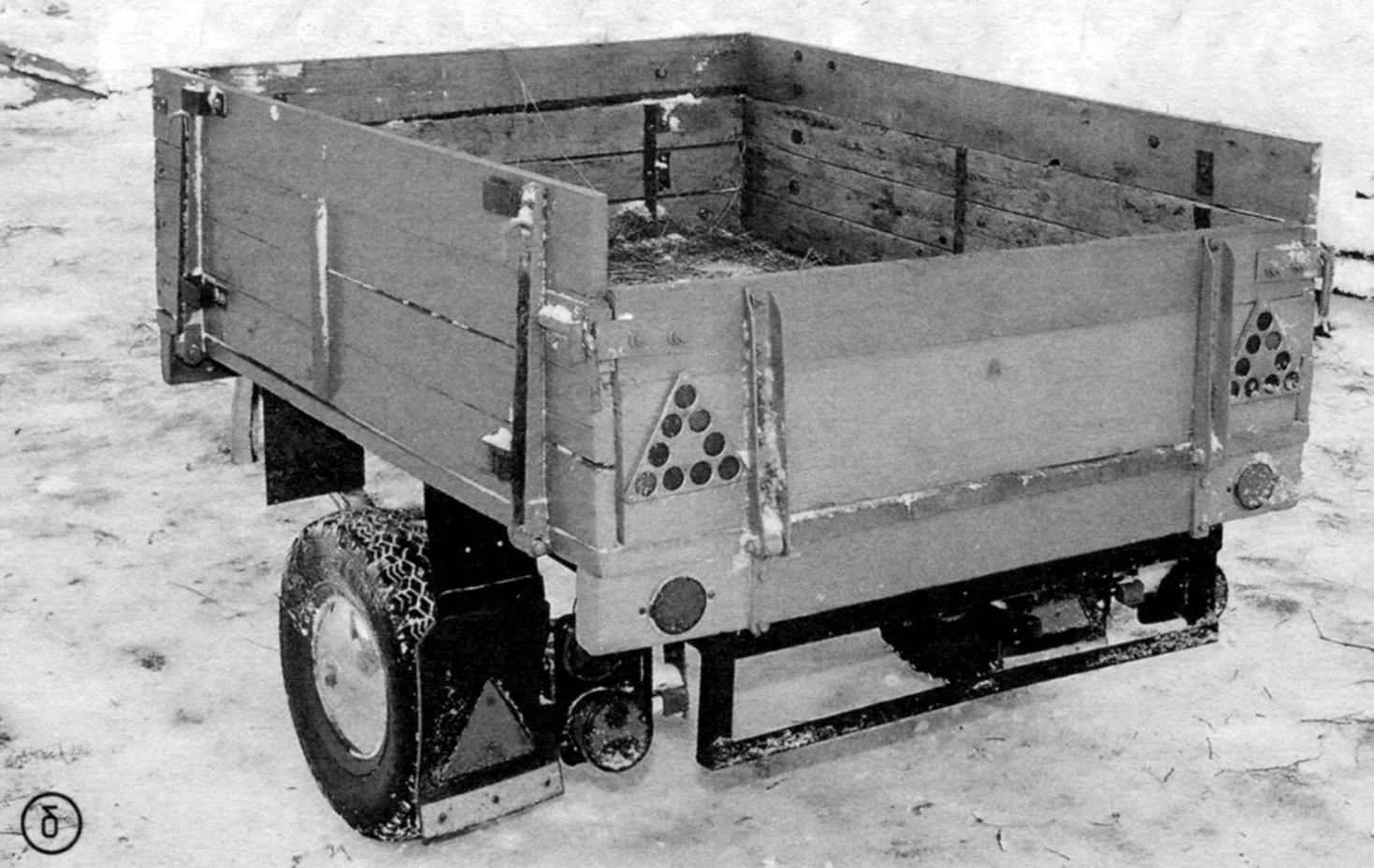

The trailer “Zhiguli” car: a – front view ; b – rear view

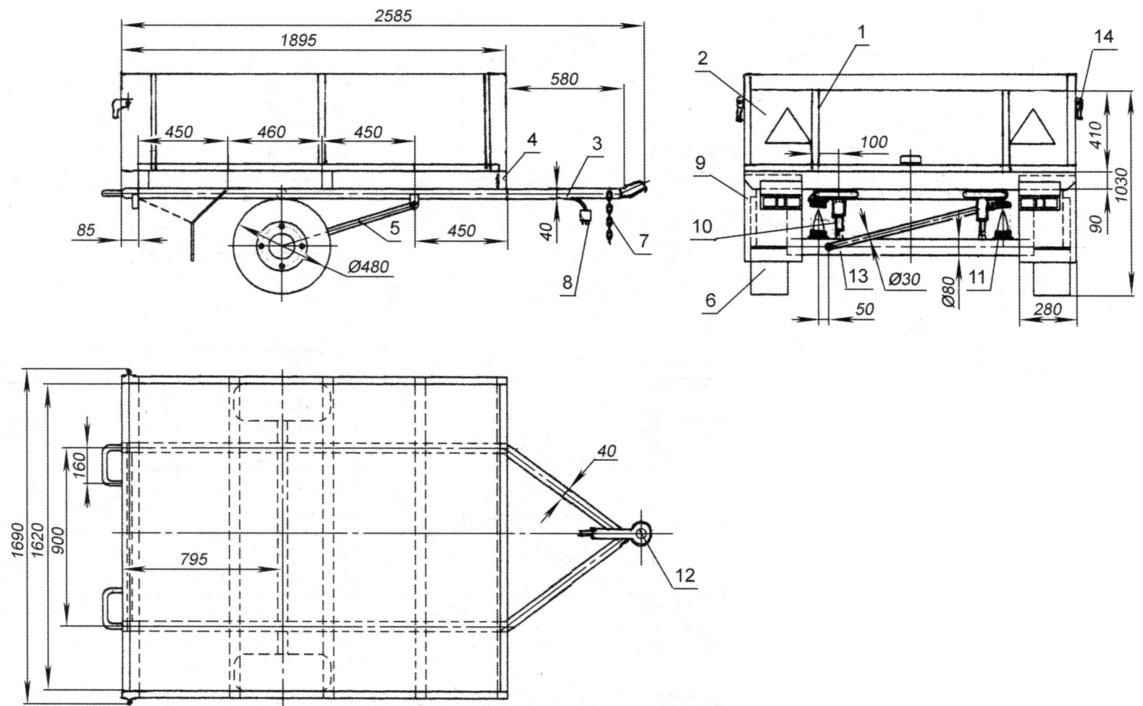

Cargo trailer for passenger cars type “Lada”:

1 – binding elements of the sides (tractor trailer);

2 – Board (Board-vagonka 16, 4 PCs.);

3 – frame (steel pipe 40×40);

4 – cross member (pine timber 90×50, 3 PCs, medium – short);

5 – pull (tube Ø30, 2 – longitudinal, 1 PCs cross);

6 – wheel with the hub (from the machinery);

7 – safety chain;

8 – the wiring connector;

9 – splash guard with sling (belt);

10 – shock absorber (from a motorcycle “Ural”, 2);

11 – spring with rubber bumper;

12-travostino device (purchase the product);

13 – axle beam (steel pipe 80×5);

14 – lock the tailgate (2 PCs.)

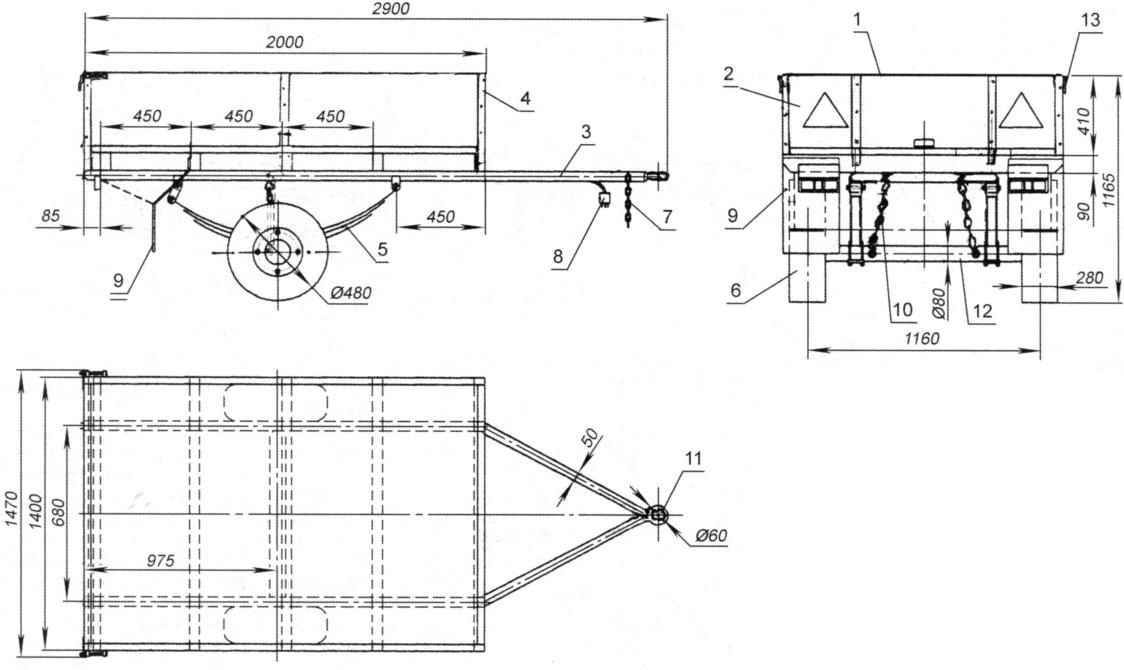

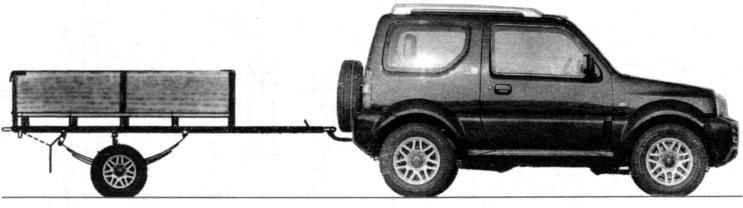

Cargo trailer for UAZ-469:

1 – binding elements of the body (area 35×35);

2 – side (Board-s20);

3 – frame (tube 50×3);

4 – cross (90 * 50 pine sticks, 4 PCs.);

5 is a longitudinal spring (from the car “Moskvich-412”, 2);

6 – wheel with the hub (from agricultural machinery, 2 PCs.);

7 – safety chain;

8 – the wiring connector;

9 – splash guard (conveyor belt) chain sling;

10 – chain guide spring (2 PCs.);

11 coupling ring;

12 – beam wheel (steel pipe Ø80×3);

13 – lock the tailgate (2 PCs.)

The trailer for the UAZ-469: a-front view ; b – rear view

The decision had to be taken depending on available materials, spare parts, components and assemblies. Something were hoping to buy. The approach should be creative and reasonable:

- on the basis of the future use of the trailer to determine its approximate size and on a sheet of paper on the scale to sketch the General form and the most complex assemblies. I somedelicious “pencil hand does not have time”. But to think the design is better on paper, since the method of trial and error, more expensive and long;

- podobral in his garage and familiar components components, parts and materials, bought the missing;

- prepared the necessary tools, including welding and discorus.

The most reasonable and affordable for making visible the trailer frame and the drawbar of the square pipe, spring suspension from the car “Lada” with shock absorbers of the motorcycle “Ural”. Him and drew on a sheet of paper wetmanski. And the drawing was already easier to plan and order the execution of the works (technology). It briefly outlines:

- Cut from a square tube 40×40 mm blank for frame, drawbar and weld them. The angle joints to strengthen the triangular patch plates (gussets).

- To make: pull – two longitudinal and one transverse, and four bearing Cup under the springs.

- Weld the axles to the beam and put on their wheels.

- Welded to the frame and the beam lugs, shock towers, rods, cups, springs.

- Assemble the frame with the bridge, setting in place the springs, dampers and thrust and try bought the towbar.

- Weld the trailer hitch to the drawbar of the trailer.

- Cut the parts, weld them to the frame and attach wood cross bars.

- Cut the size of the corners of the floor frame of the body and cook it. Lay the floor and to fasten the screws to the bars, and the frame is bolted to the frame, cover it with galvanized steel sheet.

- To assemble the side boards or plywood.

- To hold the wiring connector and attach the necessary signal lights with the Parking lights, brake lights and turn indicators; category-reflectors, mud flaps.

- Paint in your color (or available paint) – this will record the traffic police in the registration and to change it would only be possible with further re-registration.

The second trailer made for my buddy. This option – spring suspension (from the car “Moskvich-412”). In addition, he has a different towbar -ring type because the trailer is designed for the automobile “UAZ-469”, which already have the drawbar. Frame from round tubes with a diameter of 50×3 mm. the side members of the frame are made as one piece with the tongue (let the length of the pipes). However, they can be welded from separate pieces of pipe.

The production hardly differs from the above option, but easier. The tailgate – only the rear. Instead of the shock had taken a restrictive circuit.

After production, the path will lead to the registration window ROS-GIBDD where will require documents:

- reference-expert report on the suitability of the trailer for operation, which provided expert advice voluntary society avtomotolyubiteley (such companies are in any provincial town), but to carry the trailer will have in the back of the truck;

- three colored photos of the trailer at different angles;

- certificate account applied in the trailer materials and components.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.

Recommend to read

THE BATTLE OVER THE FOREST GLADE

THE BATTLE OVER THE FOREST GLADE

Kordovye aircraft models — the most popular among modelers. First among them is "air fighters". And it is clear. The airfield may be a stadium, any forest or meadow flat area with a... AN OTTOMAN WITH A SECRET

AN OTTOMAN WITH A SECRET

Good to have in the hallway a small chair or Ottoman for pereobuvaniya. If you don't, I suggest to use this kind of hint. Take any wooden box (even mail order) and simple Refine it:...

The need for a cargo trailer occurs periodically when it is necessary to carry does not fit the vehicle or soiling the cargo over long distances. Trucking services are very expensive, and the prices of finished industrial trailers is just insane. After buying a new car, especially on credit, trailer, of course, not buy…

The need for a cargo trailer occurs periodically when it is necessary to carry does not fit the vehicle or soiling the cargo over long distances. Trucking services are very expensive, and the prices of finished industrial trailers is just insane. After buying a new car, especially on credit, trailer, of course, not buy…