Mount the side of the trailer to the mini-mokik is a left longitudinal-to-longitudinal traverse attached to the frame of the tractor on the right side, and posts-lanyards. The traverse is made from the same area as the longitudinal side frames of the trailer, only installed a shelf up. The yoke mount to the frame is carried out using a pair of special clamps made in the form of counter braces with welded thereto threaded studs of the M12 bolt. For lanyards in the tubes of the frame are drilled corresponding holes or welded lugs with the same hole.

The turnbuckle adjusts the angle of the camber side of the trailer relative to the plane of symmetry of the mini-mokiki, making it easier to manage mini-mokik on the turns. To save the already small usable area of the platform of the trailer lanyards made curved. The angle of convergence of the same wheels that eliminates “cravings” of the trailer to the right is regulated with the help of rubber washers-bushing, insert between the left side rail of the trailer and the traverse.

If necessary, the side of the trailer quickly (it takes about five minutes) and easily detaches.

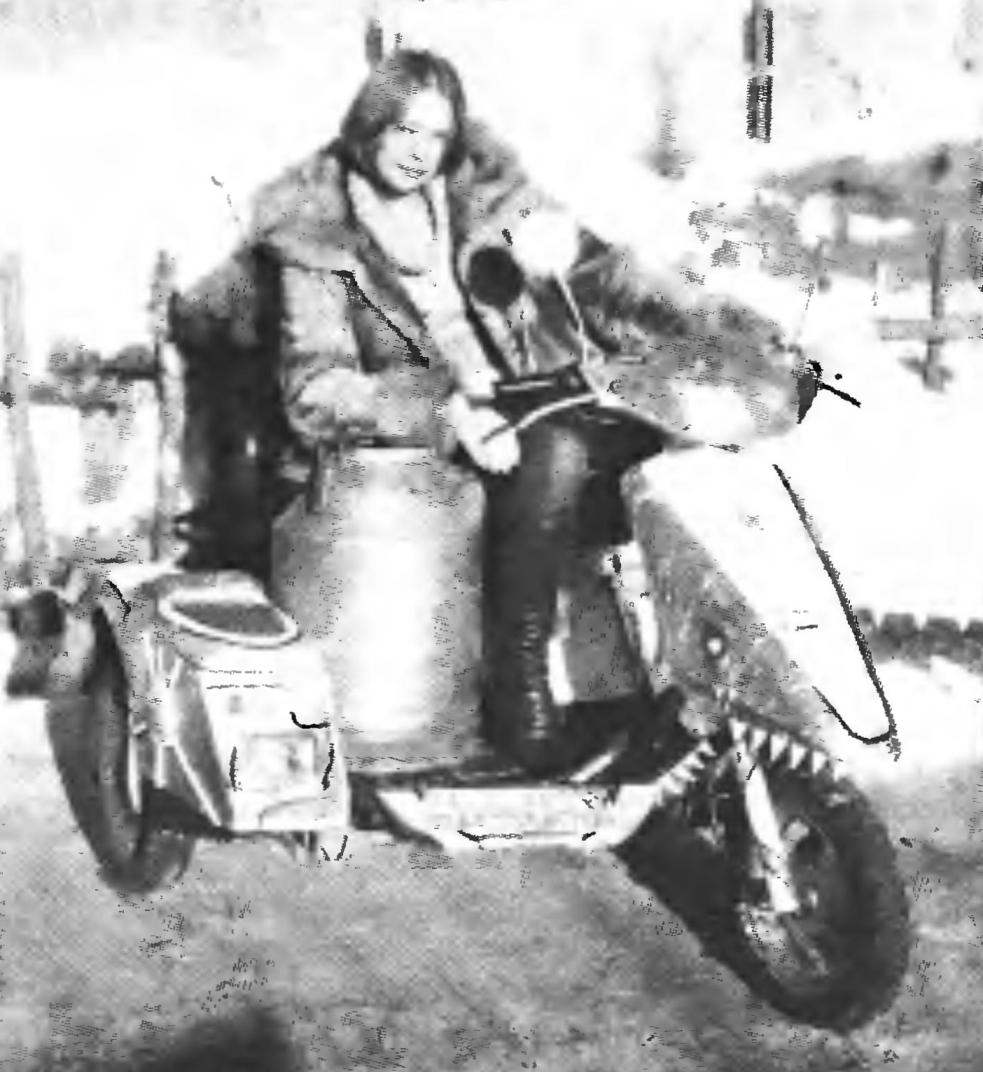

Fully manual control (all controls on the mini-mokiki focused on the steering wheel) and three points of support provide the opportunity to use it even a person with a disability of the lower extremities.

The trailer is equipped lighting signalling devices (brake, tail and turning lights) from a motorcycle “Ural”, which allows you to travel on a cargo mini-mokiki and on public roads. Well, the driver’s “rights” to control such a vehicle (with engine capacity up to 50 cm3) are simply not required.

Wheel, mudguard (fender) and a box of spares:

1 — wheel (mini-mokiki, 3.00×10″); 2—wing (half wheel rim of the motorcycle wheel, modified); 3—a box of spares; 4 — lid of spares; 5—indicator lights; 6—piping box of spares; 7—frame side of the trailer (right side rail); 8—spring; 9—step ladder; 10—spring (2 PCs); 11—rivets; 12—bracket of the wing to the frame (steel strip 30×4); 13 —wheel hub (from a motorcycle “Ural”); 14—additional spokes (steel strip 30×4); 15—shelf rim

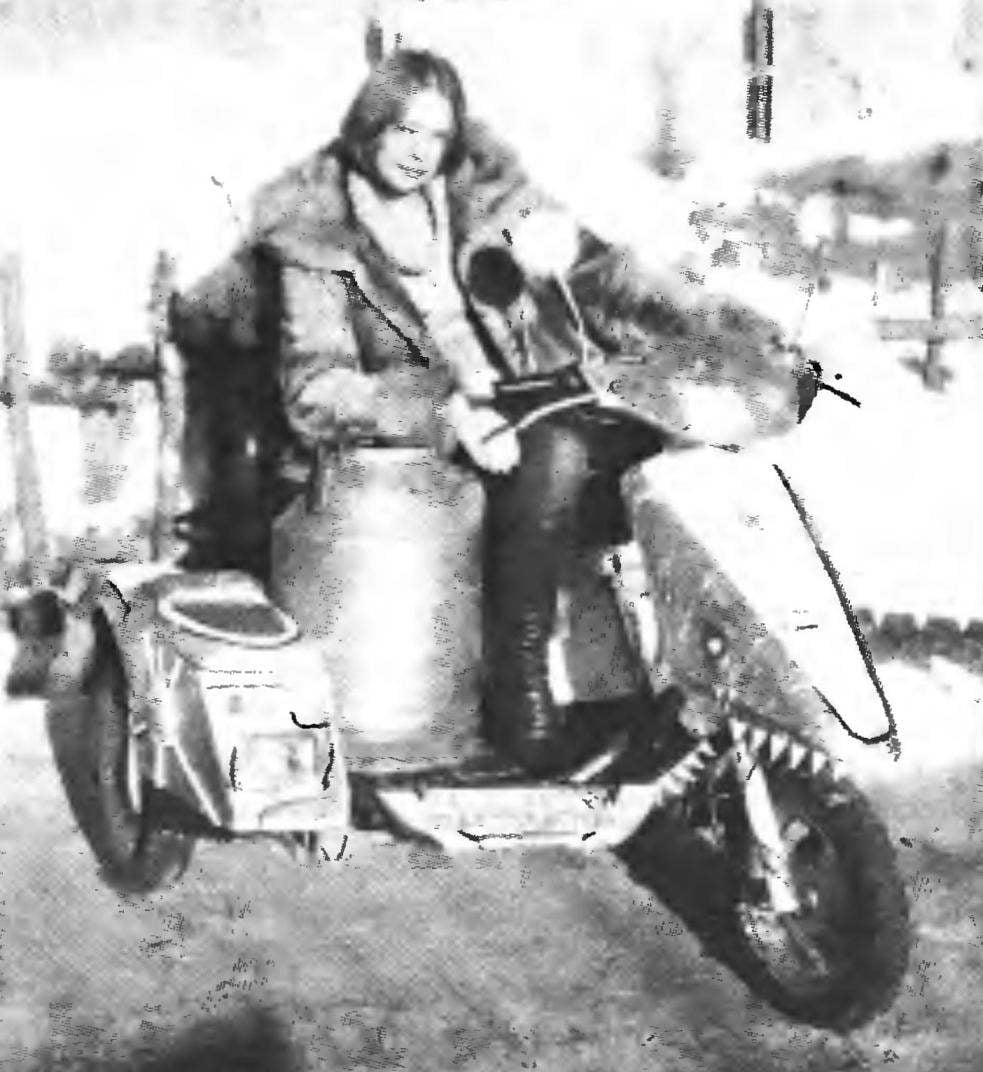

Out of the woods with firewood for groomed winter road

On one mini-mokiki, to increase ground clearance (clearance) to the feathers of the front fork welded an extension tube (length about 50 mm). Did the same thing with the rear shock absorbers, although it was easier for them to be replaced by longer ones. But at that time I had no such, and then left as is, because breakdowns do not happen

It would be unfair not to mention “acquired” mini-mokik in the modernization of the disadvantages. So, significantly increased the consumption of gasoline, often have to change the piston group of the engine, harder to wear out the tires. But the long-term operating experience shows that these costs are more than compensated. With a sharp turn to the right, there is a risk of stalling on the side, which, however, is characteristic of all motorcycles with the lateral trailer.

In four years of operation hitting 3800 km. Annually harvested through mini-mokik to 12 m3 of wood. In one year moved on it in four months, about 12 tons of bricks from a distance of 2 km, loading at one time from 30 to 50 pieces. In General, he works like a dray horse.

G. ZARANKIN, POS’yanovka, Primorskiy

Recommend to read

BARRIER WHEEL – NOT AN OBSTACLE!

BARRIER WHEEL – NOT AN OBSTACLE!

Maybe someone will seem ridiculous the claim that wheel the machine can fly over the fence, but not young technicians from the laboratory of experimental modeling and design Cute... Motorcycles. From the convenience to epinephrine

Motorcycles. From the convenience to epinephrine

People of the older generations still remember those days when motorcycle in Russia was a full-fledged means of transportation. In extreme shortage of cars and their very high cost, the...

I’m a longtime admirer of the magazine “modelist-Konstruktor” and subscribed to it for many years. Then, due to financial difficulties had to deny yourself this. But since last year started to write again. I am glad that, as before, in publications find lot of useful information.

I’m a longtime admirer of the magazine “modelist-Konstruktor” and subscribed to it for many years. Then, due to financial difficulties had to deny yourself this. But since last year started to write again. I am glad that, as before, in publications find lot of useful information.