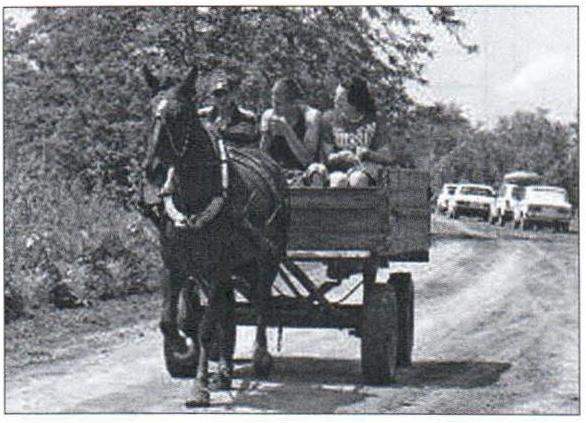

Meanwhile, a large number of queries on the design of the carts seen in the Internet, but the answers to them quite a bit, and then without drawings. Even farmers with information on animal-drawn carts, but rather on their design, no. With the desire to illuminate this gap I put on paper the design simple modern carts, the familiarity with which I had some years ago when repairing this vehicle from a friend-Kazakh.

Classic folk cart

A cart on wheels with pneumatic tires, putrescina, trucks, one-horse, Ogloblina. For all the classicism and rationality of the design of some parts and components even in the eyes looked frankly weak. Apparently, the “riveting” her from what was, and the connecting parts are welded as they could. As an engineer, I did not blindly reproduce on paper the cart with all its shortcomings, and tried to exclude them, but still adhering to the maximum designs available. Therefore, the configuration of some units and parts (or a assortment of their material) in the drawings may not coincide with the same elements in the pictures which are given for illustrative purposes.

Before proceeding to describe the construction of the cart should be defined with terminology. For all the similarity of structures, the names of the parts of one and the same destination often differ not only with different nationalities and in different places, but in the different dictionaries. Therefore, the story will stick to the great dictionary of the living language of Vladimir Ivanovich dal and begin with the construction of the cart, created and described by our ancestors.

The cart – one horse globalny who, four-wheel freight cart, which harnessed the horses usually (sometimes oxen, buffaloes, mules, etc.). Had a chance to be a witness, as a Laden cart “yoked” four men and carried it for quite a considerable distance.

Conventional animal-drawn cart is out of the running and the body. Between them the intermediate details – Ruchi-Tzu, designed in the shape of the body. In turn, the course consists of two axes Adonikam (amplifiers axes); four wheels (two for each axis), and the front smaller diameter than the back; two pillows racks (“in-car” hard suspension) – front and rear, and foxes (the relationship between the axes: more commonly called dissolution, divorce), embedded in both pads. One end of a Fox fastened to the pillow tightly, while the second – with the possibility of reinstalling the other cushion along it to adjust the distance between the axles (length of cart). The “blind” end of the Fox can to be sure raskreplenija alosinae. Front airbag is connected to the front axle through the turntable pivot (pin, core, trigger), that enables the axis to rotate on the pin. To the shoulders of the front axle is pivotally attached shafts that have is additionally connected to the ends of the axle heavyweights. For this purpose, the shafts secured to the comb, and put on the top of the loop strands, and the axes of the lower loop stick checks.

Most of the components of the cart – just wood and fasteners, axles, Yes the wheel rims – steel.

Varieties of carts: the hearse (a cargo wagon without a body), shelves (hearse with a wooden platform at the top), cart (cart with seat and goats).

Unlike the old rural models in modern cart quite a lot of metal parts, mainly power elements. And the wheels are wooden with steel tires-rims, and from farm equipment or a car with pneumatic tyres.

Modern animal-drawn cart (horse cart) on wheels with pneumatic tires (on rubber tires):

1 – removable body side (Board s20); 2 – removable padded seat (2 pieces); 3 – trim of the cargo area-the canopy (block 50×40); 4 – cargo area-the canopy (Board s30); 5 – substrate-ruchita (beam 54×50, 4-piece); 6 – frame (metal profile different mix); 7 – wheel 5x 10″ d292 (farm equipment, 4 items); 8 – securing ring (wire d10); 9 – plate strand (steel, sheet s6, 2); 10 – hook the cord (wire d10, 2); 11 – strand (wire d6, 2); 12 – loop strand (wire d10, 2 PCs.); 13 – adjusting the comb (steel, area 30×30, 2 PCs.); 14 – shaft (wood, solid hardwoods, pole d60, 2); 15 – stop tug of the clamp (conveyor belt s10,2); 16 – hinge (bracket, bracket and a pivot – bolt M 18×100) securing the shafts to the front axle; 17 – steering wheel; 18 – rear axle Assembly; 19 – front axle Assembly; 20 – gasket (s10 felt impregnated with petroleum jelly); 21 – a bolt (the bolt М20х100)

Frame:

1 – cross member trim (U-shaped profile 60x40x3, 2); 2 – longitudinal element binding (P-shaped profile 60x40x3, 2); 3 – spar (tube 60x40x3,2); 4 – median cross member (tube 60x40x3); 5 – front brace (tube 60x40x3,2); 6 – upper part of the turntable (steel sheet s10); 7 – rear rack (tube 60x40x3,2 PCs.)

Stroke (chassis), horse-drawn carts with wheels on pneumatic tyres

Front axle with turntable

Front axle:

1 – axis (steel pipe 048×3); 2 – tip axis (PT.45, the range of 48.2 units); 3 – nadolnik amplifier (channel № 6,5); 4 – the lower part of the turntable); 5 – bracket hinge shafts (steel sheet B6); 6 – pneumatic tire wheel (2pcs); 7 – disc wheel d102 / 4,00″ (2 pieces); 8 – flange of the wheel disc to the hub; 9 – hub; 10 – inner bearing (2 PCs); 11 – outer bearing (2 PCs.); 12 – nuts and lock nuts (8 PCs); 13 – plate connecting the cord to the axle (2 pieces)

Dump truck, “Hey, uhnem!”

The cargo version of modern carts

Simplicity of design and availability of materials allow to produce such a vehicle and experienced homebrew. All materials used can be replaced by suitable ones. The steel aluminum or stainless steel, pine – birch or oak, the channel – on the pipe or the area, etc.

This is possible because of the absence of the special state standard for animal-drawn transport. Therefore, after the acquisition of horses it is possible to harness to a cart and go in any form in any direction, where only the movement of road transport is not prohibited, do not even need a driver’s license and license plate!

About the horse the harness will not speak: there are many things that can make only masters of this business – the saddlers.

The optimality of the overall size and height of the cargo area and “elegance” designs are defined and tested for decades and even centuries and change is necessary unless at great need.

Modern wagon is more of the same, but several (and slightly modified) from other parts.

Frame. Usually it is now welded and manufactured from rolled steel or stamped (curved) profiles of various sizes. Usually consists of strapping, spars and cross members (one or more). Welded to the frame front (sloped) and rear (vertical) rack, raskreplennye struts, to the front of the rack from the bottom to the top is welded to the turntable. In modern horse-drawn wagon replaces the frame and the Fox, and pillows, and hearse. In the described construction, the U-shaped profile strapping invested suitable wooden blocks – they subsequently fasten flooring boards of the loading platform.

Front axle has retained not only his appointment, but, in principle, a construction. However, in Assembly with hubs, bearings, wheels on pneumatic tyres this site it is possible to call on-car – front axle. The main part of the axle is made from tubes of an external diameter of 48 mm and is reinforced with overlapping and welded to it a U-shaped profile. Tips – axis from the same machinery, their inner ends machined to the inner diameter of the pipe axis inserted in and welded in a circle. Mounting brackets a shaft and lower the turntable remains the same. Wheels, as a rule, not very large diameter (in this case, a size of 5×10″),

horses to make them easier to turn and they could go under the frame at a sharp (small radius) bends – from farm equipment or automotive.

The rear axle design and dimensions are identical to the front axle, only she’s missing the mounting brackets a shaft and lower the turntable. Wheels on pneumatic tires may be of the same size, and front or more.

Oiled the felt circle with a thickness of about 10 mm, installed between the upper (frame) and bottom (front axle) turning circles works as a sliding bearing when cornering and even as a shock. Suggests replacing this node in radialogy bearing, but it adds complexity to the design.

Couple a shaft Assembly with hinges, combs and bands remain a classic. But the materials can be applied and modern, suitable.

The body is manufactured under the anticipated traffic, but the most versatile is the platform type, representing the shelves – flat or slightly concave utility area (mostly from the boards). The wooden platform is equipped with removable or hinged sides and removable soft seats. In the passenger version as the carts adapt even body cars.

The most difficult, but therefore interesting for the designer: while trying to improve people’s constructive

tion (for example, make a dump body) is automatically increased mass, which is not very good for workhorse! If weld lightweight durable frame of light alloy (for example, from hromansilevyh or titanium) is very price rises, which is not like the boss. So try to strengthen the weaknesses of qualitative weld small braces and kerchiefs.

Finishing the story, I note that modern horse-drawn wagon should be provided with at least simple and cheap light-signalling devices: a pair of reflectors in white, and the sides of the front and rear pair red. In dark time or in poor visibility conditions, it is necessary to use the signal lights (or one combined) with the corresponding lights.

And again. The horse, of course, pet smart and obedient. But the situation on the roads happen and those that may frighten the horse and lead him out of obedience. Then the necessary on the wagon brake, which, however, may be useful in normal situations, such as stops on the descents and the climbs, although in this case you can dispense with the brake Shoe.

The “value” of an ordinary cart should be in the fact that it was a pity not to give into the bargain together with sold horse! Cheap, not cheerful.

A. MATVEICHUK, Zavodoukovsk,Tyumen region.

Recommend to read SUPPORT CLAY Medical bubbles, and especially the opened vial is very fragile, and spill their contents sometimes very simple. To avoid this, use a "tortilla" of clay: recessed in her glass bottoms of... “ARBAT” – CITY CAR I started designing this car a long time ago - maybe ten, maybe fifteen years ago. But this does not mean at all that I stood at the drawing board for all ten to fifteen years. No, I just...