The idea of making motorcycle sarts, and such that they could be ridden on loose snow, took possession of me a long time ago, about fifteen years ago. But I was in no hurry to get to work; I carefully thought about how I would like my snowmobile to look. So gradually a constructive scheme with a mover in the form of two blocks of skis surrounded by a light caterpillar belt took shape in my head.

What prompted me to such a design? Of course, many years of skiing practice. Skis in our area are truly a necessity; it is difficult to do without them. I remember how in childhood we made them ourselves, and the quality of modern factory ones is hardly better.

So, while skiing, I noticed two things. First of all, if any object accidentally gets under the ski – a pole, a smooth branch, etc., then the glide improves. And one more thing: when climbing uphill using a “ladder”, even loose, freshly fallen snow holds the skier well, without sliding down. These two observations prompted the installation of skis inside the “endless” ladder-caterpillar. This design, in my opinion, should have ensured low specific pressure and good cross-country ability even when moving along fairly steep hill slopes.

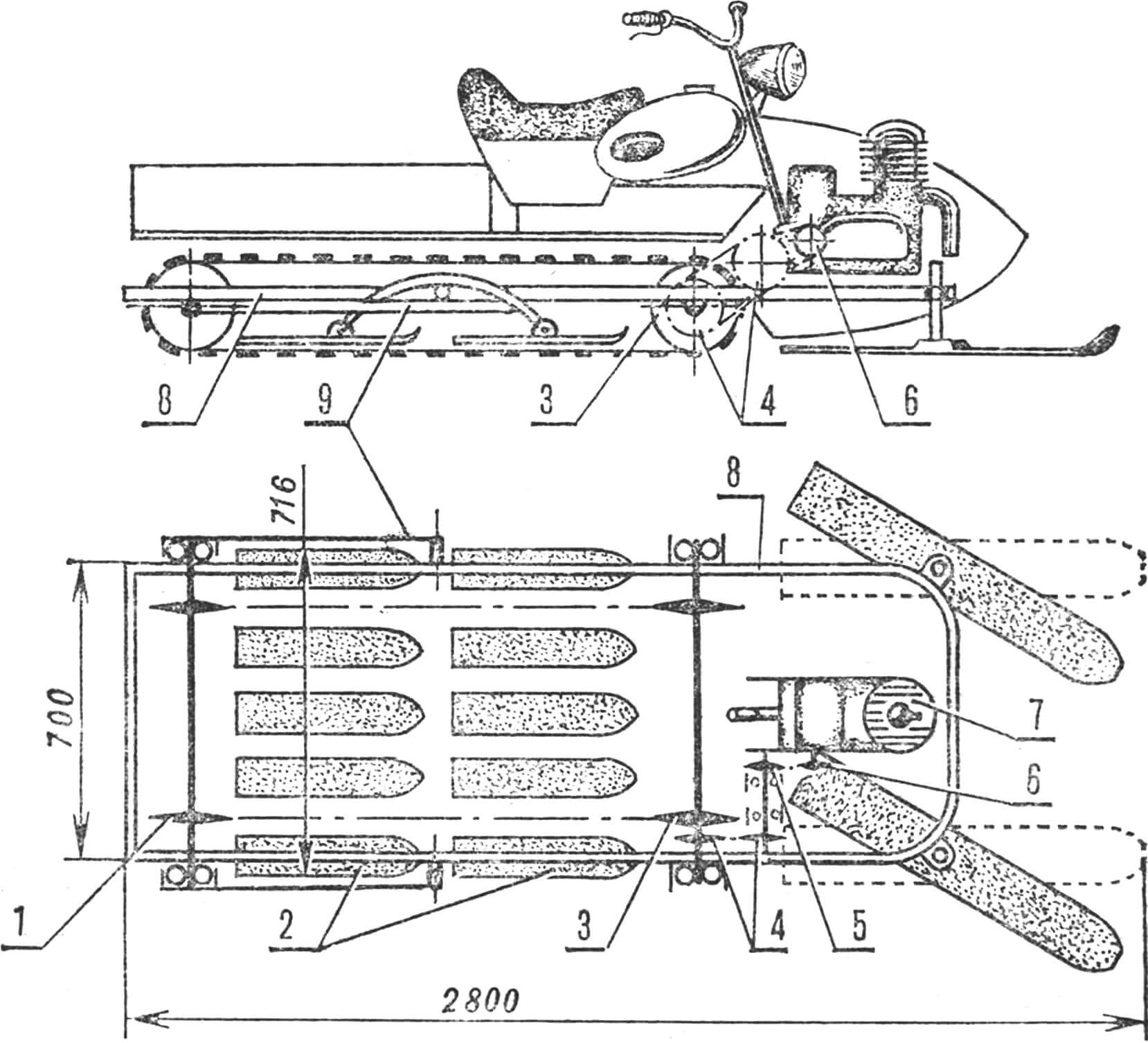

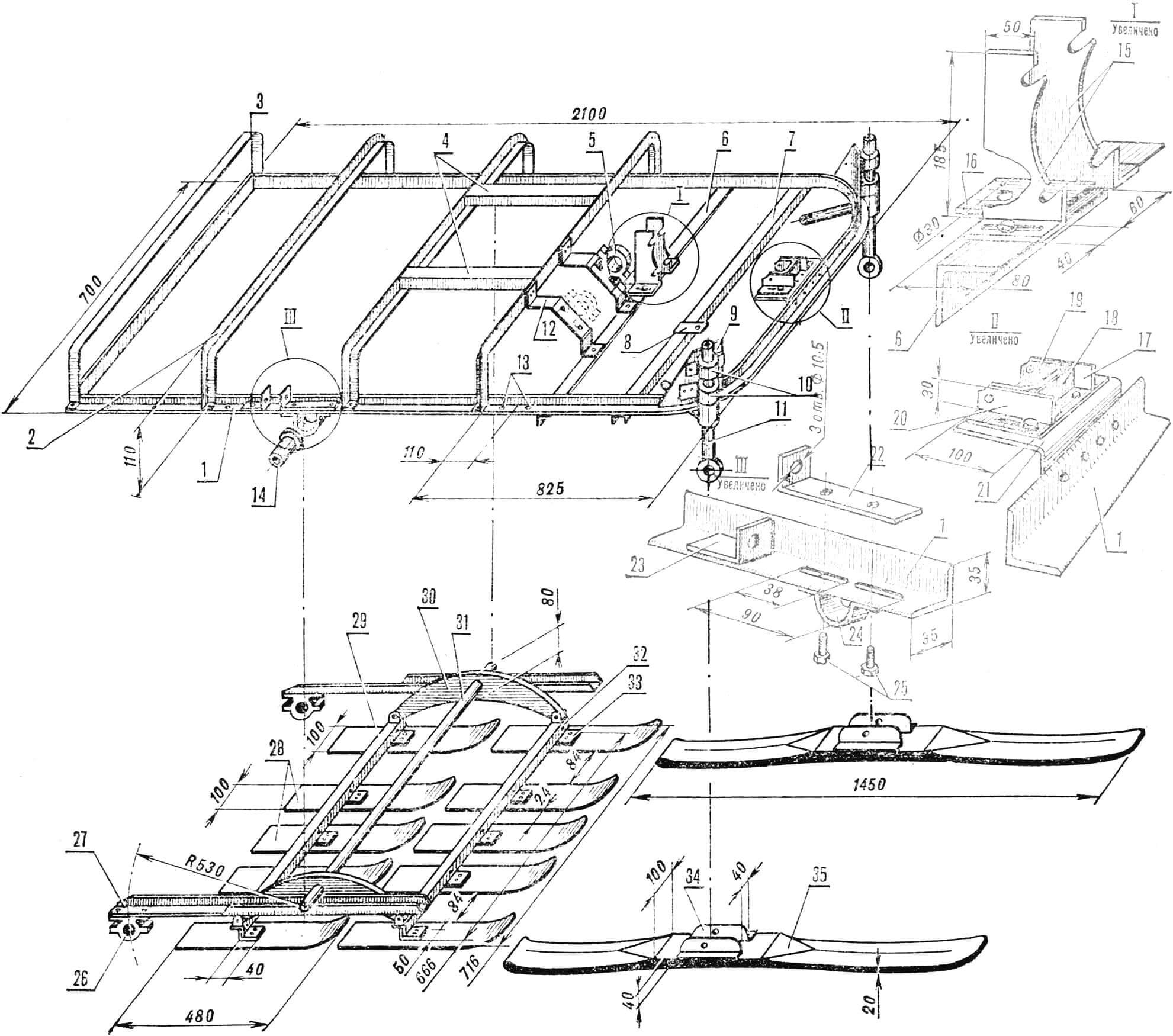

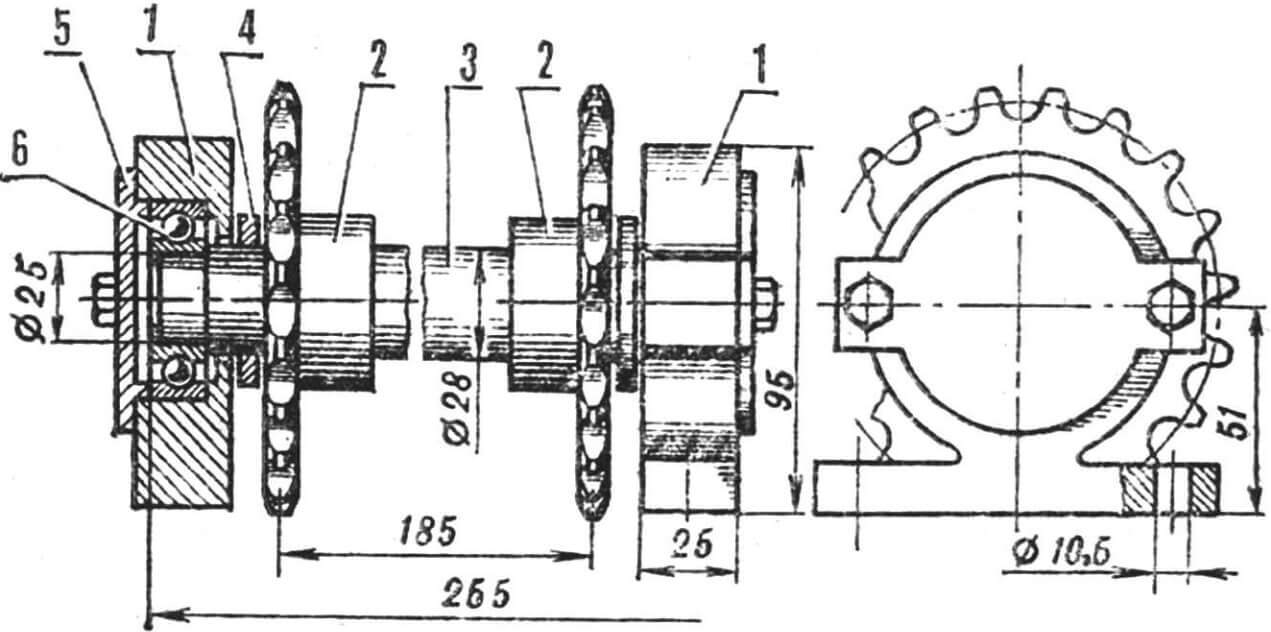

1 — driven track sprocket Z = 14, 2 — carriage support skis, 3 — drive track sprocket Z = 10, 4, 5 — motorcycle sprockets Z = 19, 6 — engine output sprocket, 7 — Izh-Planet engine, 8 – frame, 9 – carriage.

And more than ten years of operation of the snowmobile confirmed my assumptions. Practice has shown that fears of reducing the overall efficiency by using such a scheme and increasing wear due to friction turned out to be in vain. The fact is that snow always gets between the skis and the track bars, and this is an excellent lubricant! The propeller works even better at a temperature of -10°…-20° C – then a thin ice crust forms on the tracks, along which the iron-clad skis glide. At above-zero temperatures, the resistance to movement increases noticeably, but this disadvantage is inherent in serial “Burans” to an even greater extent.

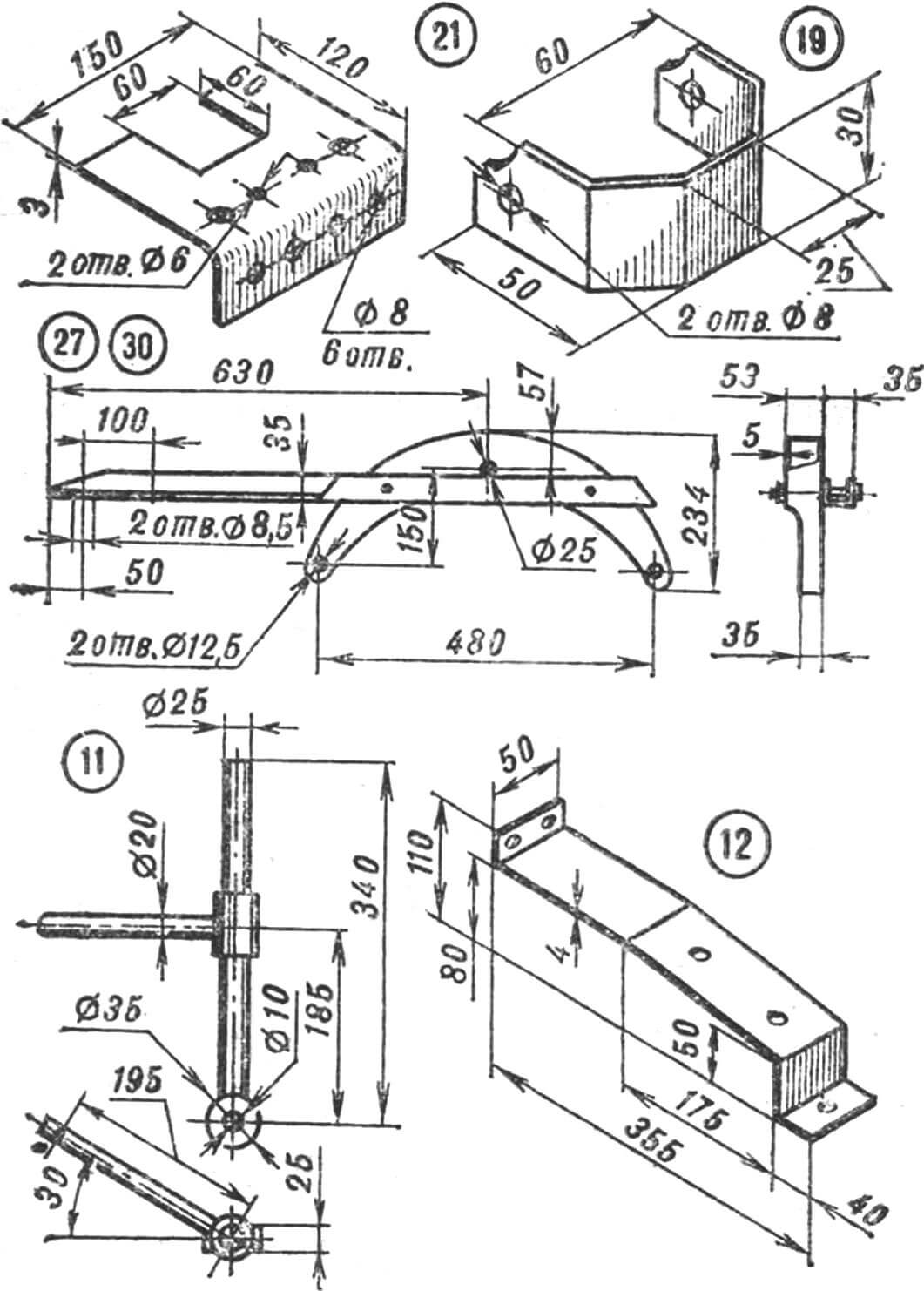

Now about the design of the snowmobile . The frame is made of angle section 35X35 mm; the front part is curved after heating in the oven (however, this is not necessary). Basically, its elements are welded, but individual parts are fastened with M10 bolts. The transverse beam for the rocker arm of the steering device, since it does not bear the main loads, can be made from rolled products of a smaller cross-section.

Engine 13.5 liters. With. with forced cooling taken from the Izh-Planet motorcycle of the first production. The car does not have reverse gear, but if desired, it can be done by installing an additional gearbox instead of the intermediate shaft.

1 – frame (angle 35X35 mm), 2, 3 – transverse arches, 4 – longitudinal spars, 5 – bearing housing of the transmission intermediate shaft, 6 – sub-engine spar (angle 35X35 mm), 7 – transverse beam for mounting the steering mechanism (channel 20 mm), 8 — platform for the steering gear rocker, 9 — gusset for fastening the rotary axle, 10 — clamp for the rotary axle, 11 — rotary axle, 12 — bracket for the intermediate transmission shaft, 13 — holes for mounting the drive shaft of the tracked mover, 14 — axle bushing carriages, 15 — sub-motor bracket, 16 — steering column support plate, 17, 20 — engine mounting angles with longitudinal slots for chain tensioning, 18 — angle, 19 — bracket, 21 — platform, 22, 23 — movable and fixed angles of the tensioner track belt, 24 — clamp for fastening the carriage axle, 25 — M10 bolts, 26 — bearing housing of the driven shaft of the caterpillar mover, 27 — longitudinal beam of the carriage, 28 — support skis of the carriage, 29, 32 — transverse beams of the carriage, 30 — arc of the carriage, 31 – carriage axis, 33 – corner for attaching the ski to the cross beam, 34 – corner for attaching the swivel ski to the front post, 35 – swivel ski.

The transmission is chain, assembled from motorcycle parts. The first stage is from the engine output sprocket to the intermediate shaft, the second stage is from the intermediate shaft to the drive shaft of the propulsion unit. Gear ratio of the second stage – 1; its necessity is caused by the layout. The length of both chains is the same – 22 links (44 rollers); the stars are also the same – Z = 19.

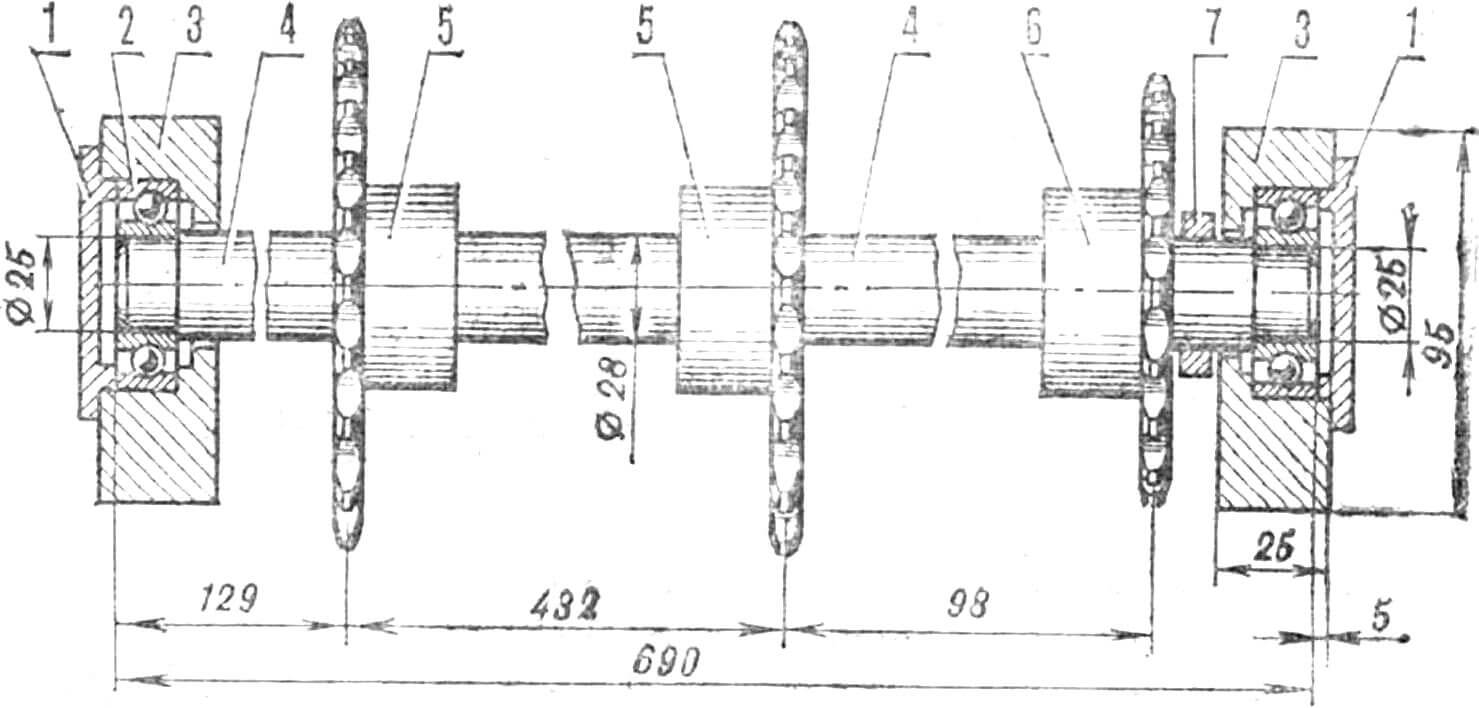

The mover includes a caterpillar belt, two shafts with sprockets and a carriage with two ski blocks. Two Z=10 sprockets are installed on the drive shaft under a chain with a pitch of 38 mm from a decommissioned grain harvester. On the driven shaft there are sprockets of a slightly larger diameter, Z=14. Both shafts (as well as the third – intermediate) are installed in bearings No. 205. The bearing housings of the propeller drive shaft are fixedly fixed to the frame with M10 bolts, and the driven shaft housings are fixed to the longitudinal beam of the carriage. The chain tension is adjusted by moving the carriage axis with a special device. The carriage axis is a thick-walled pipe Ø 25 mm (the steering column is made of the same). The carriage arcs are welded, box-shaped, the ends are connected on hinges with two transverse beams – corners with a section of 30X30 mm. Five skis are attached to the beams. The width of each is 100 mm; the gaps between the central ones are 24 mm, between the outer ones – 84 mm (for the passage of the track chain).

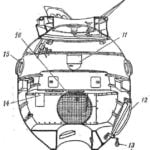

1 – covers, 2 – bearing No. 205, 3 – bearing housings, 4 – shaft, 5 – sprockets Z = 10, 6 – motorcycle sprocket Z = 19, 7 – washer.

The carriage skis are homemade, made from a birch trunk with a curved shape. The latter is necessary, since skis made using conventional technology can almost completely straighten out after several trips in wet snow. The ski runners are bound with a thin steel sheet or tin. Nails are not recommended; It is better to provide the required number of special petals when cutting the sheet. And we should not forget that the skis, except for the central one, must have a metal edge along the entire length from the edge where the caterpillar chains pass.

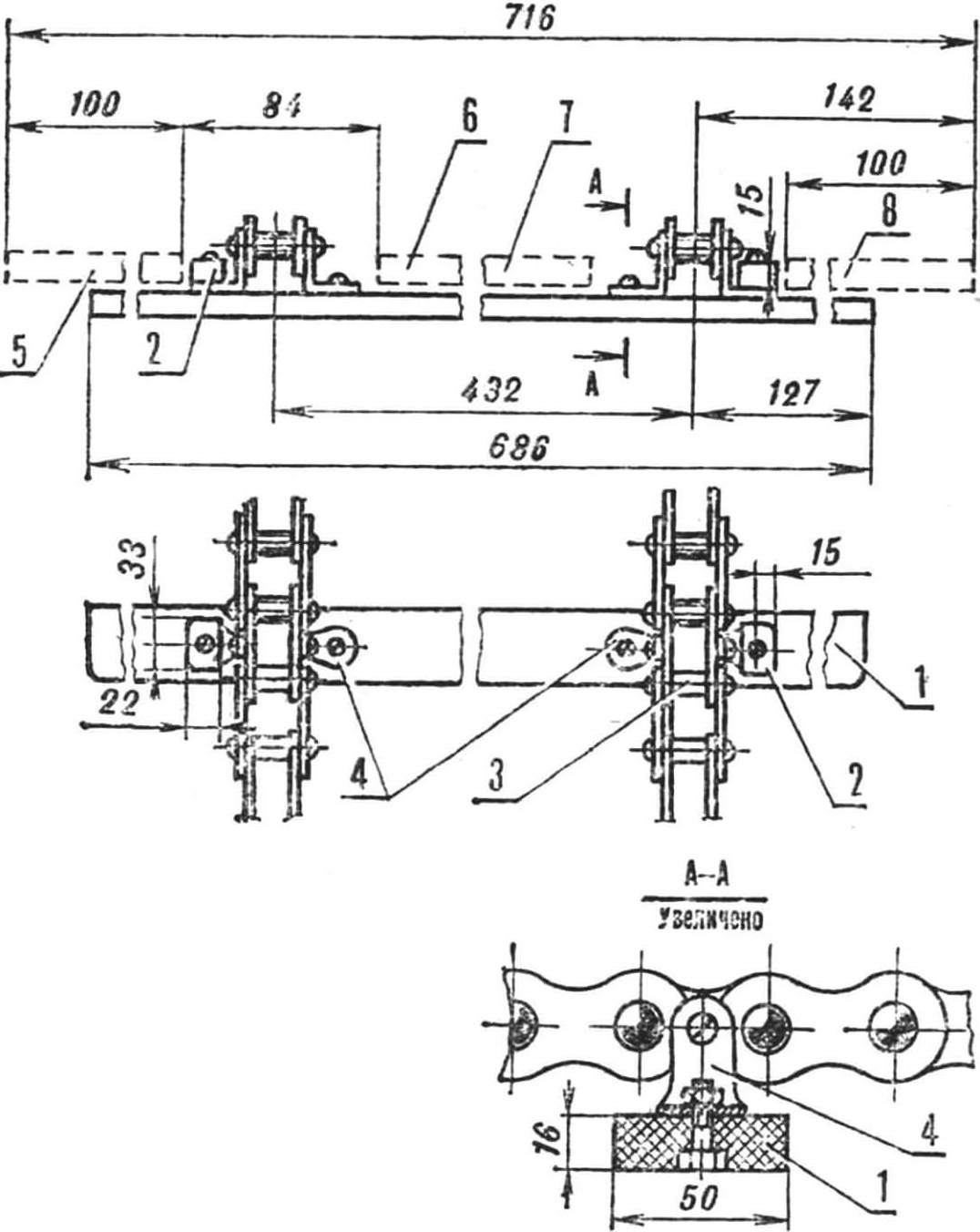

The caterpillar track consists of two chains with a pitch of 38 mm, to which tracks – plastic strips with a cross section of 50X16 mm – are attached through a link on special corners with M6 bolts. The slats were originally made of wood; I drove at least 10 thousand km on them. However, it turned out that in warm weather and when driving on well-worn roads they behave unsatisfactorily, greatly increasing resistance. Then I made a steel mold and cast new tracks from molten plastic (and they can even be equipped with a unique “sole” pattern). Since then I have not complained: with the same mass, the new caterpillar is superior to its predecessor in all respects.

The tracks (through one) on the outer sides of the chains have steel limiter bosses. They are necessary for centering the track: their rounded side slides along the metal-edged side of the outer skis.

1 — plastic bar, 2 — stopper bosses, 3 — chain link (pitch 38 mm), 4 — chain mounting angles, 5, 6, 7, 8 — skis (not shown in the top view).

In general, the propulsion carriage should be designed in such a way that when driving on an uneven surface, the caterpillar at the top does not touch the frame of the snowmobile.

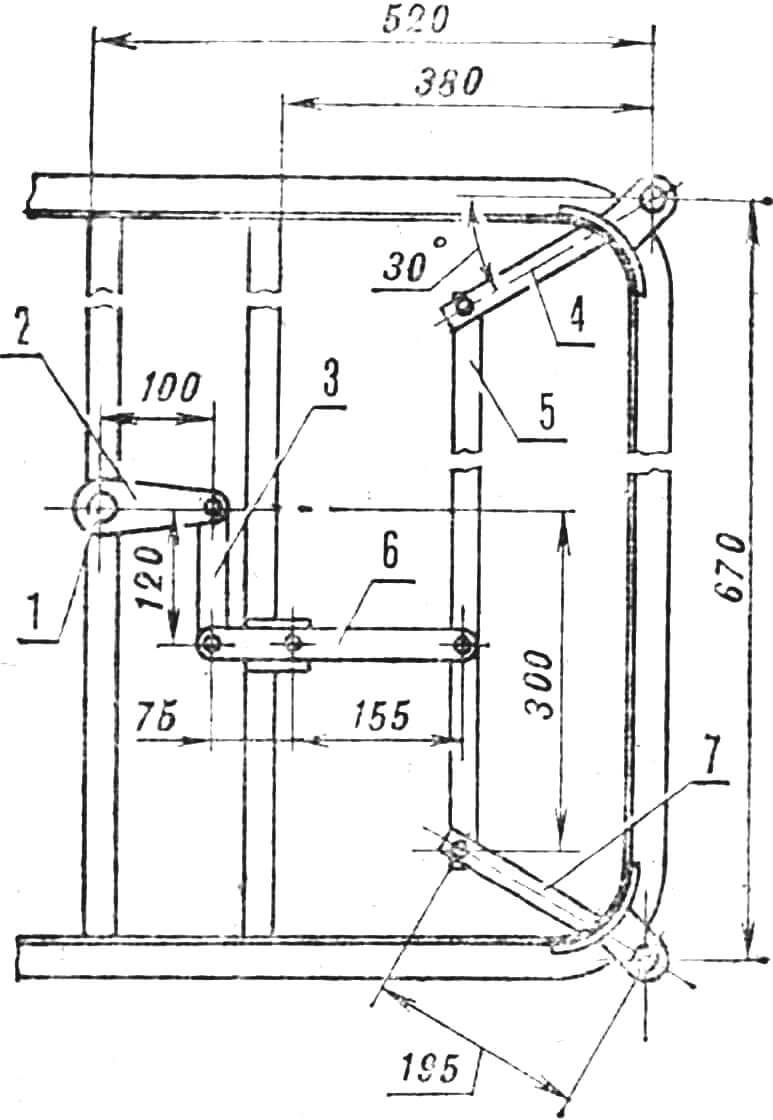

The steering of the snowmobile includes two front rotary skis on vertical axes and a system of levers and rods. In general, the control scheme is clear from the above figure, and it can certainly be improved.

1 – steering column, 2 – steering column lever, 3, 5 – small and large thrust, 4, 7 – steering axle levers, 6 – rocker arm.

It is also worth improving the engine mounting scheme. On my snowmobile there is an additional element – a screw, one end of which rests on the intermediate shaft bracket, and the other on the sub-engine bracket. It serves to “tighten” the engine as necessary, thereby ensuring normal tension of the chain of the first stage of the transmission, since the design of the sub-engine frame is not so rigid as to prevent possible weakening of the chain. I do not provide drawings of the screw, since it would be more expedient to make a special tensioning device.

1 – bearing housings, 2 – motorcycle sprockets Z = 19, 3 – shaft, 4 – washer, 5 – cover, 6 – bearing No. 205.

In conclusion, about the operational characteristics of the snowmobile. He has served me, as I already said, for more than ten years and has never let me down. The cross-country ability is excellent: half a meter of freshly fallen snow, for example, is far from an obstacle for it. Speed is about 40 km/h, average fuel consumption is 20 liters per 150 km. The load capacity of the body is 250 kg; you can also use an additional ski semi-trailer – then you can take more cargo. If necessary, the snowmobile can be towed by a car: to do this, you need to remove the track and the car will lower directly onto the skis.

E. MIROSHIN