The idea to make a cross-country passenger car came to me at the beginning of 2004, when the opportunity arose to purchase a “killed” Mitsubishi-Pajero all-terrain vehicle – only the body remained suitable for use. The power unit, transmission and chassis were in such poor condition that it was not economically feasible to restore them or replace all these components with new ones.

I must say that this idea did not frighten me, but on the contrary, it inspired and turned me on. After all, I have been involved in technical creativity almost since childhood, as I remember – from the age of eight. At first I drew and drew maps and buggies, spied in the magazine “Modelist-Constructor”, then moved on to practice. The first “victim” of my technical creativity was the “Sura” bicycle – first I studded its tires for riding in winter, then I made a trailer for it to transport loads. The next “victim” was the “Riga-12” moped – I transplanted its “heart” – I installed a motor from a “Minsk” motorcycle, then adapted it for winter driving: I put a ski in front, and put a chain “bracelet” on the rear wheel, then The rear wheel was replaced with a pneumatic one, and the suspension was also redesigned. When the “Tula” motorcycle, which had an unusual design for those times, went on sale, two months later I made a similar one based on the “Minsk” motorcycle and wheels from a motorized stroller.

In my youth, the ultimate dream of mine as a fisherman, hunter and tourist was the Buran snowmobile, which I did not have the opportunity to purchase. Therefore, in 1988, in between his studies, he began building an all-wheel drive amphibious all-terrain vehicle – and in 1991 he was already driving in summer and winter, and sailing in a car that looked like a buggy with huge pneumatic wheels, the only obstacle for which was sheer walls higher than meters.

Then there came a more than ten-year break in my technical creativity, spent studying at a university (graduated from the Ufa Aviation Institute with a degree in Economics and Enterprise Management in Mechanical Engineering) and working to create a material base for my family. But all this time I was mastering many working professions: mechanic, turner, milling machine, welder, mechanic, and nurtured the idea of creating something like that… or, more specifically, a machine for the soul. I shared this idea with my like-minded friends (they love technology as much as I do) – they not only supported it, but also promised to help implement it. Together we discussed which car chassis would be best adapted for the future all-road vehicle. We went through almost all suitable domestic all-terrain vehicles: cars and trucks: UAZ-469, KamAZ-4310, ZIL-131 and even Ural-4320. Each of them had some significant drawback that made their chassis unsuitable for my project: either the dimensions were not suitable, or the weight, or the strength was in doubt. The choice was made on the GAZ-66 truck chassis as the most suitable one. Well, we knew firsthand that the GAZ-66 has enviable cross-country ability – we ourselves have seen more than once how this wheeled vehicle not only passed along those routes where tracked tractors got stuck, but also helped them get out of impassable mud.

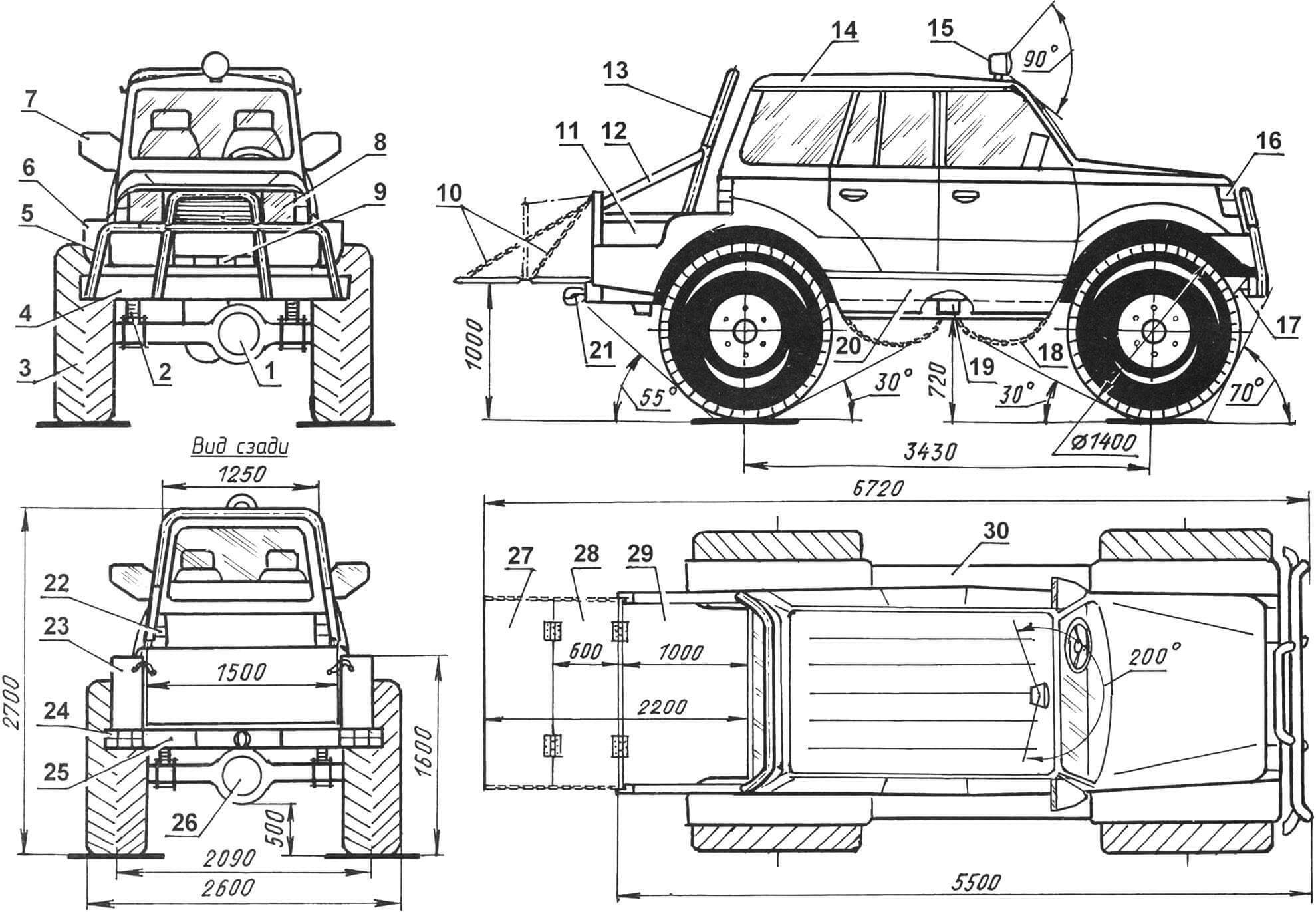

1 — front drive axle (from GAZ-66); 2 — suspension spring (from GAZ-66, 4 pcs.); 3 — wheel (combined, 4 pcs.); 4 — front bumper (from GAZ-66); 5 — front protective grille (steel pipe Ø46); 6 — front wing (from the Mitsubishi-Pajero body, 2 pcs.); 7 — side mirror (from Mitsubishi-Pajero, 2 pcs.); 8 — headlight (from Mitsubishi-Pajero, 2 pcs.); 9 — fog and additional lights (purchased products, 5 pcs.); 10 — travel limiters for additional platforms (chain, 4 pcs.); 11 — platform side (from the Mitsubishi-Pajero body, 2 pcs.); 12 — roll bar strut (channel No. 5, 2 pcs.); 13 — safety bar (steel pipe Ø52); 14 — body (from Mitsubishi-Pajero); 15 — spotlight (from special equipment); 16 — block of front signal lights (from Mitsubishi-Pajero, 2 pcs.); 17 — frame (from GAZ-66); 18 — footrest (chain, 4 pcs.); 19 — frame cross member (from GAZ-66); 20 — side screen (from the Mitsubishi-Pajero body, 2 pcs.); 21 — tow bar (from GAZ-66); 22 — rear signal light (from Mitsubishi-Pajero); 23 — rear wing (from the Mitsubishi-Pajero body, 2 pcs.); 24 — additional rear signal light (from KamAZ, 2 pcs.); 25 — rear bumpers (from GAZ-66, 2 pcs.); 26 — rear drive axle (from GAZ-66); 27 — outer cargo area — outer wall of the tailgate (heating battery); 28 — middle cargo area — inner wall of the tailgate (heating battery); 29 — loading platform (heating battery); 30 — running board (from the Mitsubishi-Pajero body, 2 pcs.)

After a short search, we managed to find a GAZ-66 car from the military – almost my age (I’m 33 years old), but without mileage – from conservation – and my friends and I got to work.

Who would have thought that the chassis of a domestic truck with a wagon layout would fit so well with the body of a Japanese bonnet-type passenger SUV! And what is especially valuable is that they turned out to have almost the same distances between the side members. And there were quite good coincidences in length: the GAZ-66 power unit fit completely under the hood of the Pajero, and the clutch and gearbox with transfer case fit in its transmission tunnel.

Anyone familiar with the design of the GAZ-66 truck knows how inconvenient it was to change gears on it with a long curved L-shaped lever – after all, the gearbox was located far behind the driver’s seat. Now all the control levers are concentrated where they should be – to the right, slightly ahead of the driver.

Installing the body on the frame and fastening them together with stepladders and bolts through rubber gaskets was not a difficult task, and it was all done “on site.” However, it was impossible to do without some modifications to both the chassis and body.

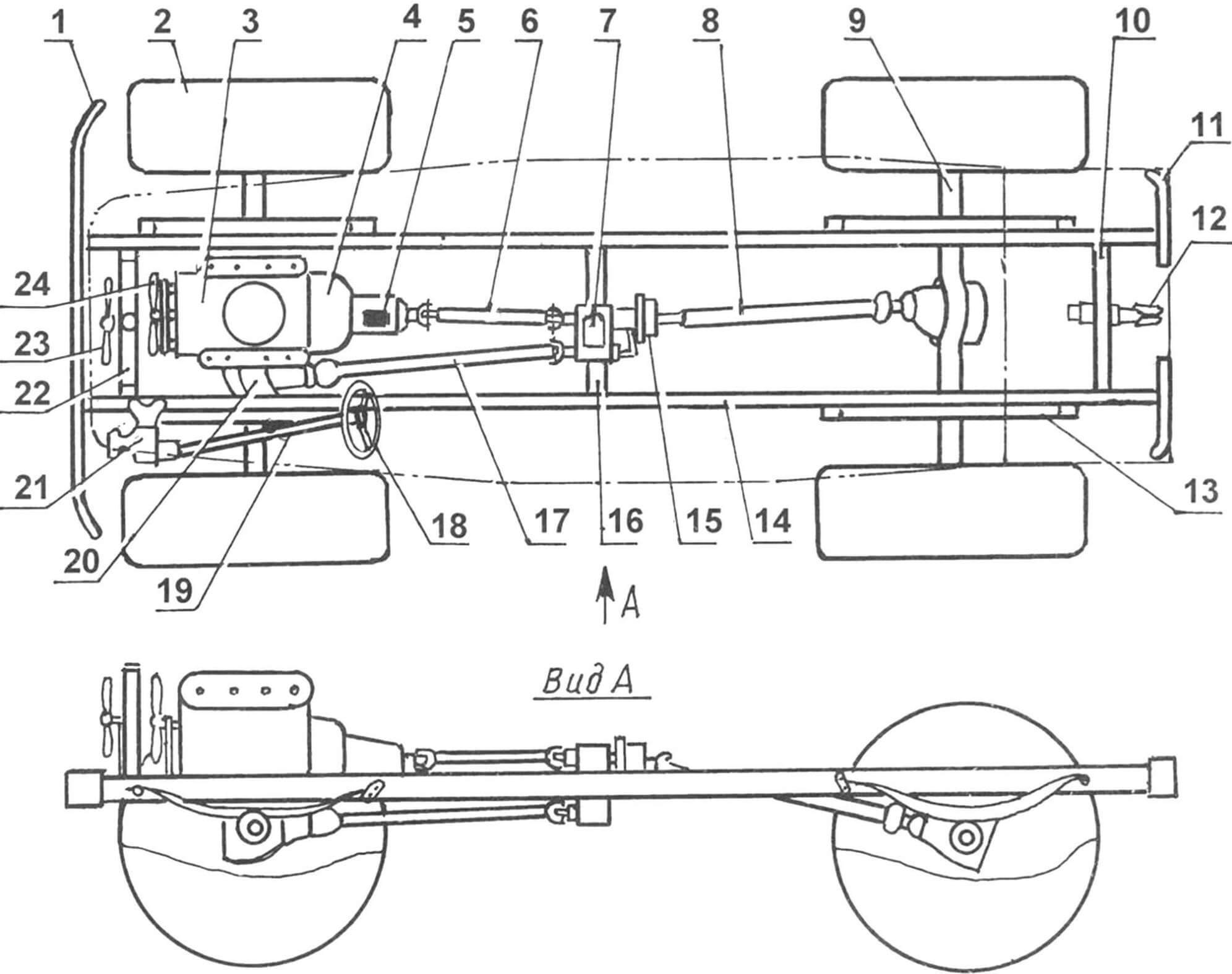

Thus, the front axle of the chassis was moved forward along the frame 130 mm – this required lengthening the driveshaft of the front wheel drive and removing the winch. Here the position of the steering mechanism was changed (it was turned up 30 degrees), which forced a change in the configuration of the steering bipod, which had to be bent while hot. The steering wheel shaft was replaced – now instead of it, an extended axle shaft with a CV joint (constant velocity joint) from the Oka car was installed.

I weakened the chassis springs by cutting off all the leaves (except the main ones) right down to the clamps holding them together. However, it must be said that the “softness” of the car’s ride is ensured not so much by the springs as by the tires of the wheels, which are, in fact, pneumatics—the pressure in them is only 0.7 atm, and the rubber is relatively plastic.

Wheels are combined. The discs in them are from GAZ-66, and the rims welded to them are from the Niva combine. The tires (and in fact, rollers half a meter wide) – from the T-150 tractor – have a landing diameter of 21 inches, and a running radius is about 700 mm. Such wheels transfer the dynamics and driving comfort from the GAZ-66 truck, if not to a passenger car, then close to the “Gazelle” ones. To reduce the force on the brake pedal, a vacuum booster from Mitsubishi Pajero was added to the brake system.

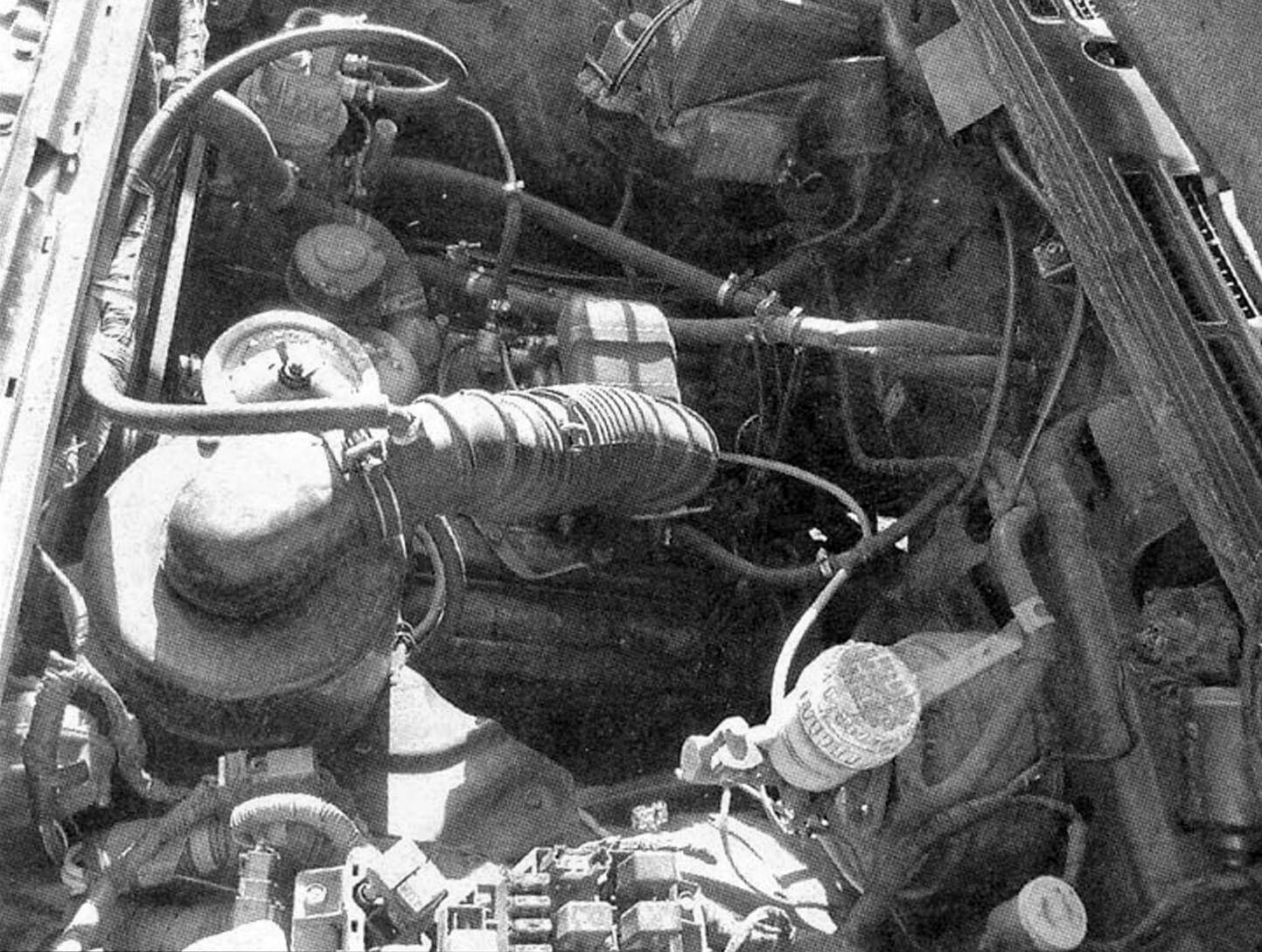

Let me remind you that the GAZ-66 engine is an 8-cylinder, V-shaped, with a volume of ^25 liters and a power of 115 hp. with a speed limit of up to 3200 per minute. Fuel is A-76 gasoline, consumption is about 25 liters per 100 km.

In the engine, the rubber oil scraper caps on the valves of the hydraulic distribution mechanism were replaced with silicone and high-voltage wires of the ignition system (shielded ones were installed – in armored braids with silicone tips).

In the engine cooling system, the radiator fan was replaced with a “Gazelle” one and an additional one was installed – an electric one, from a Pajero, activated by a temperature sensor when the liquid is heated to 90°C in difficult conditions. An expansion tank was also provided.

The transmission from the GAZ-66 was used without changes. It consists of a clutch basket, a 4-speed gearbox, a 2-speed transfer case with a mechanism for engaging the front drive axle. Drive axles have cam limited-slip differentials. The transfer case has a reduction gear with a gear ratio of about 2, that is, it functions as a range multiplier.

1 — front bumper; 2 – wheel (combined: tire – from the T-150 tractor, rim – from the Niva combine, disk – from the GAZ-66, 4 pcs.); 3 – engine; 4 — clutch basket; 5 — gearbox; 6 — main driveshaft; 7 — transfer case; 8 — rear propeller shaft; 9 — rear drive axle; 10 — rear cross member of the frame; 11 — rear bumper (2 pcs.); 12 — towbar; 13 — spring (4 pcs.); 14 — frame spar (2 pcs.); 15 — parking brake mechanism; 16 — middle cross member; 17 — front driveshaft; 18 — steering wheel (from Mitsubishi-Pajero); 19 — steering shaft (axle shaft from the Oka car); 20 — front drive axle; 21 — steering gearbox; 22 — radiator of the cooling system; 23 — additional electric fan (from Mitsubishi-Pajero); 24 – main cooling fan

As unnecessary, I dismantled the power take-off shaft mechanism and the pneumatic system for centralized wheel tire inflation. All this, taking into account the winch, lightened the weight of the car by about half a ton.

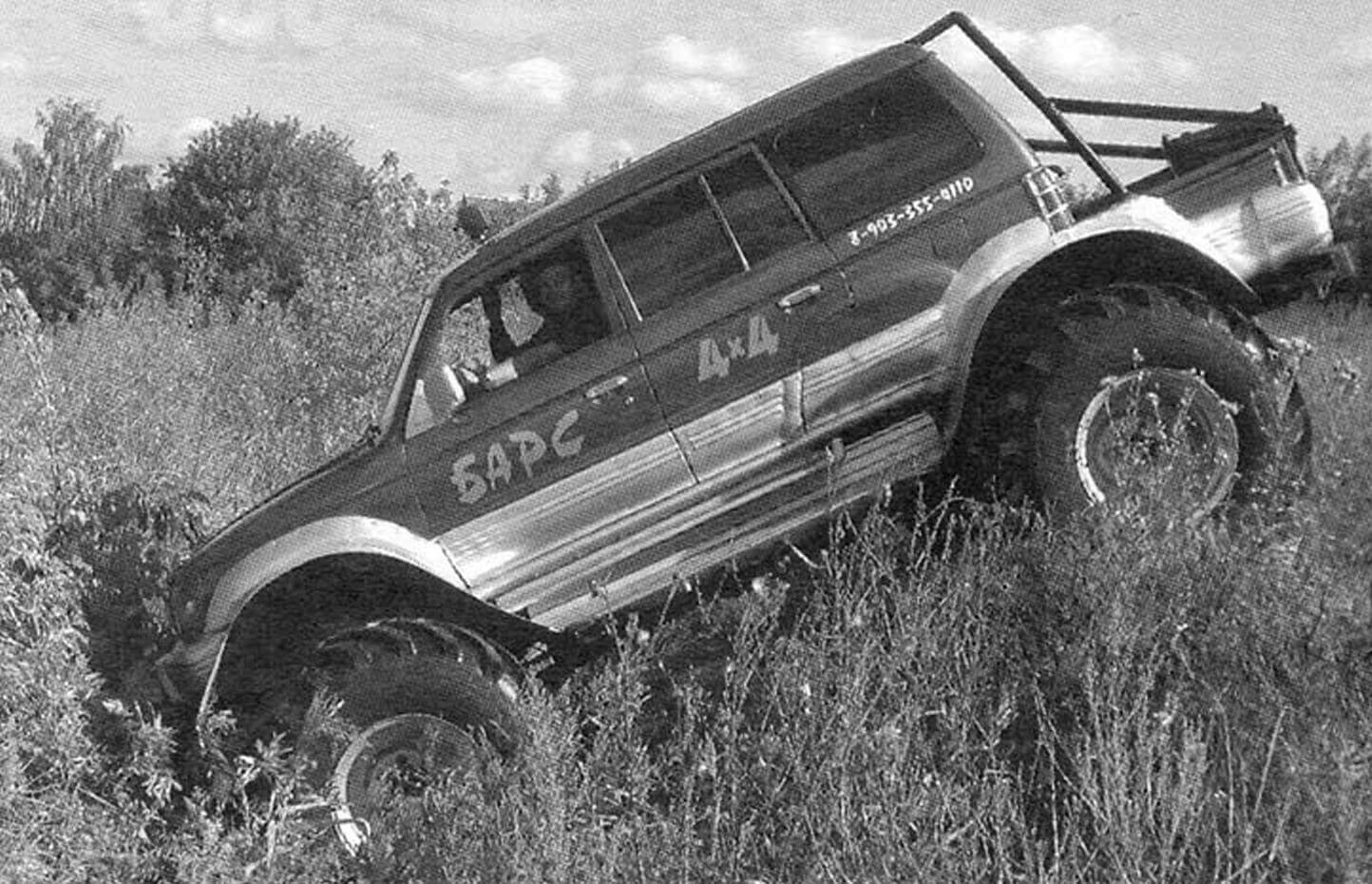

To tell the truth, the body from the Pajero had to be assembled from two before being used in the car – for this I purchased another one, an emergency one. The wheel arches were mainly altered: the front ones were widened; the standard rear ones were sealed, and the new, expanded ones were shifted further back and only their front half remained within the body, and the rear one ended up in an open cargo platform attached to the body. The platform “turned” the car into a pickup truck. The rear side of the platform is folding and folding. With the tailgate folded out, the area of the platform more than doubles and allows you to transport not only long loads weighing up to 1.5 tons, but also a snowmobile, for the transportation of which, in fact, the platform was made. There are screens on the sides of the body (to cover the frame and transmission units) and steps with additional chain steps – without them it would be difficult to get into the car.

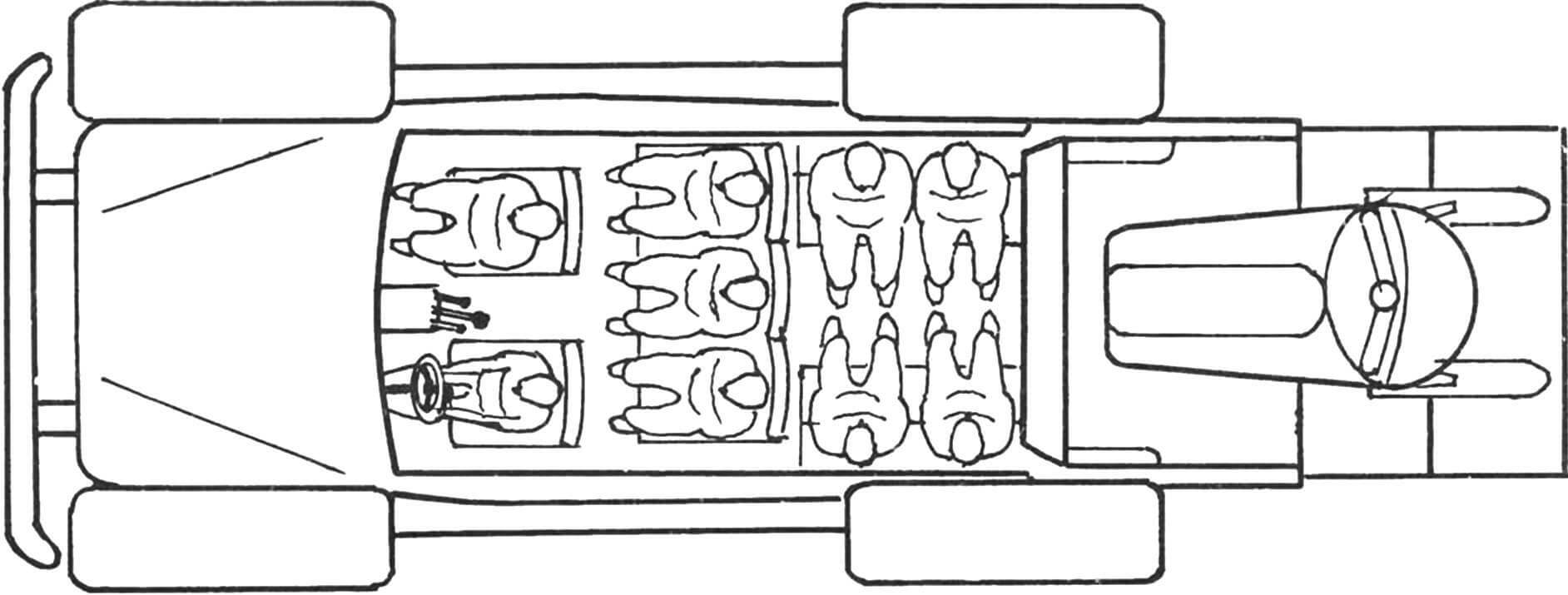

The interior of the body has not undergone any significant changes, except for the fact that in the luggage compartment there are two slings installed on the sides – spartan bench seats for two people each. Entrance to the luggage compartment is through the rear door, which also swings.

The standard light alarm system of the Mitsubishi body, both internal and external, is completely preserved. In addition, additional lighting devices are installed: a spotlight on the roof controlled by a handle from the interior and fog lights on the front bumper of the body. At the rear of the bumper, additional signal lights from KamAZ are also installed.

Technical data of the machine. Most of the dynamic characteristics of the vehicle correspond to the base GAZ-66 truck. First of all, it has a top speed of about 85 km/h. For rough terrain and off-road it is quite enough, but for the highway, perhaps not enough. To increase the “maximum speed” I plan to boost the engine in the future. But if I make another similar car (and there are such plans), I will try to install a diesel engine (and a more powerful one) with a 5-6-speed gearbox on it. The empty weight of the car is about 3800 kg. Overall dimensions: length x width x height – 5500x2600x2700 mm. The fuel supply in two tanks (90-liter from the Pajero and 105-liter from the GAZ-66) is 195 liters. The tanks are communicating, fuel is taken into the carburetor from the bottom of the “gas” tank, and refueling is done through the standard neck of the Pajero tank.

The angle of the climb is about 40°, and the depth of the ford is up to 1.6 m (if such a depth can still be called a ford).

The number of passenger seats is up to 9, while the car, in addition to people, can also carry up to 1500 kg of cargo on an open platform.

Finishing the story about the car, I would like to name those who took part in its creation. It was built in a little over six months. But without the help of relatives and friends, the project would have been difficult to implement and would have taken many times over time.

First of all, this is my wife Lyudmila, who provided me with moral and financial support for the project. The Chubatyuk brothers, Eduard and Vitaly, carried out the entire range of electrical and installation work; Radik Ibragimov performed the sheet metal and painting work, and Valery Ivanov and Vladislav Mikhailov inspected and fine-tuned the power unit. But everyone, together and separately, always came to each other’s aid. Other enthusiasts also helped build the all-terrain vehicle.

The financial costs for the car amounted to approximately 450 thousand rubles. But I’m happy with the “Bars” (that’s what we called the car for its “all-terrain capability”) – it has enormous potential for all-terrain capabilities and allows the owner to feel like a “lord of the off-road.”

A. MASKAEV, town of Chishmy, Bashkortostan