Today is a story about the buggy-350, created in the auto design laboratory of the city of Kharkov under the leadership of V. L. Taranukha. According to the results of our competition for 1975, this machine is the best in its class, and its creators were awarded a diploma from the Modeler-Constructor magazine.

Valery Leonidovich Taranukha is known as a talented designer, an original teacher-organizer and a first-class driver mechanic. He and his students are participants in many (if not all!) All-Union shows of amateur micro-automotive construction. At each of them, the team headed by Valery Leonidovich always exhibited something new, original and, as a rule, very promising. For example, in 1966, at the first review-competition, they were shown a microcar, which was a kind of prototype of a sports car for young people, “officially legalized” many years later and now widely known as “Youth”. And the next year, a car of an original design was presented, which can be considered the prototype of today’s buggy. This direction in the work of V. L. Taranukha was generally identified very clearly: at a show in Kyiv, Kharkov home-made workers showed a whole family of off-road vehicles. Our magazine informed readers about one of them in issue No. 11 for 1970 ( “Tourist” is the younger brother of “Volyn” ).

People with the gift of technical foresight always evoke a feeling of deep respect in us. After all, they are the right-wingers of technological progress, boldly looking into the future, heroically carrying on their shoulders a heavy burden of responsibility for the next experiment, constantly searching and dissatisfied with what has already been done.

Such is Valery Leonidovich Taranukha. Just as it is no coincidence that the organization that he now represents is called the “Club of Eternal Search” – KVP, it is no coincidence that the achievements of the car created here are not accidental: the young racer Yuri Trusov, riding it, twice became the winner of various autocross competitions, and its designers and the “Club” eternal search” was awarded the title of NTTM laureates.

This is what V. Taranukha says about the buggy created in the “Club of Eternal Search”.

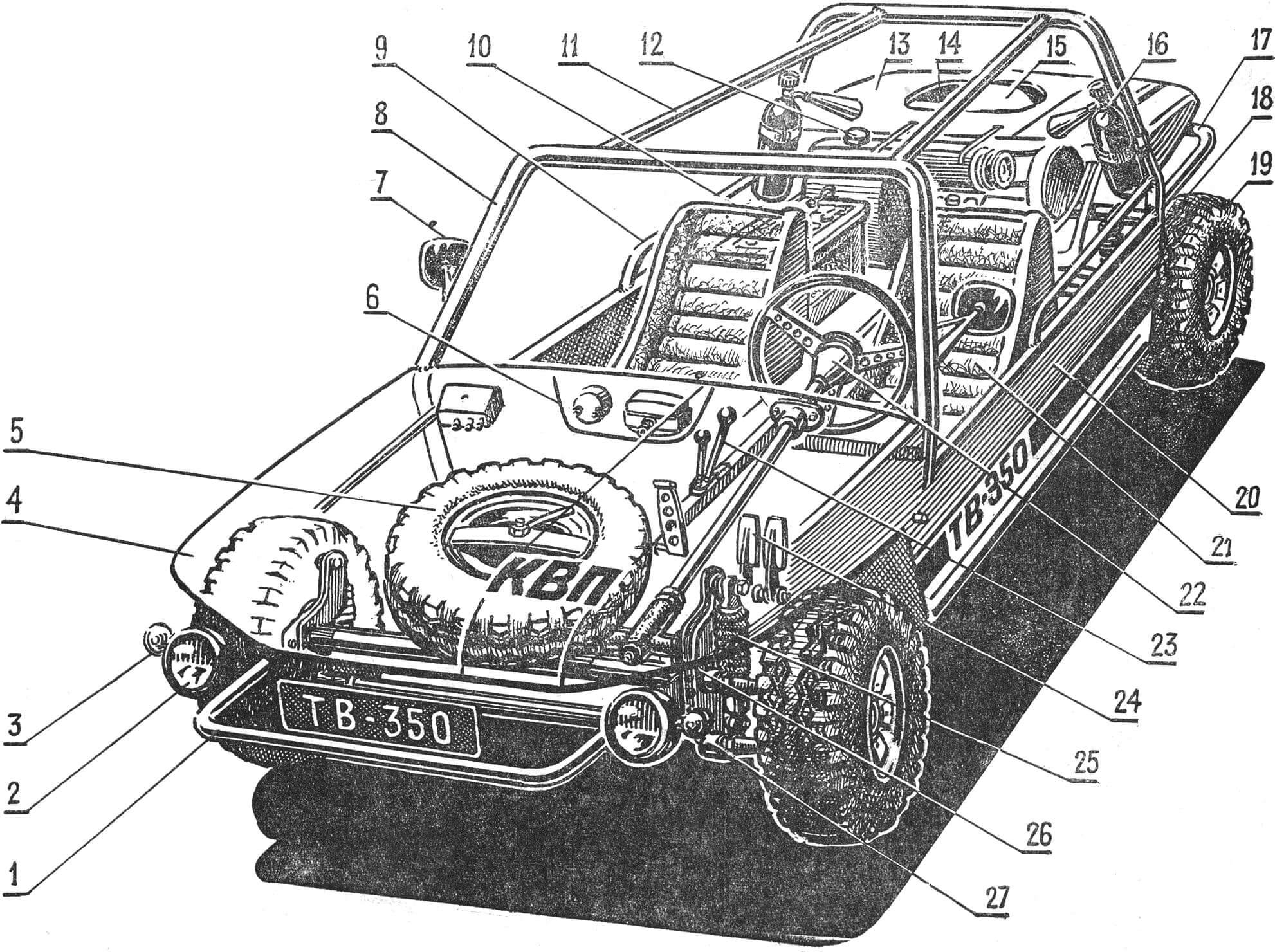

1 – front bumper frame, 2 – headlight, 3 – sidelight (dimensions – turn), 4 – front hood, 5 – spare tire (under the hood), 6 – instrument panel, 7 – rear view mirror (both sides), 8 — front safety bar, 9 — handrail, 10 — battery, 11 — longitudinal safety pipes, 12 — fuel tank, 13 — rear hood, 14 — ventilation hatch, 15 — engine, 16 — fire extinguisher, 17 — rear bumper, 18 — rear suspension, 19 — drive wheel, 20 — body side, 21 — driver’s seat, 22 — steering wheel, 23 — gear switches, 24 — control pedal unit, 25 — spring-hydraulic shock absorber, 26 — front axle, 27 — front suspension arm .

Many people are now interested in buggies. This is natural: buggies turned out to be a logical link between karting and “big” motorsport, allowing you to master all the intricacies of driving a car over rough terrain at minimal cost. However, not everyone and not always succeeds in obtaining the desired results.

The main reasons for this are lack of experience, low quality of components and assemblies used in the construction of a car, especially in the 350 cm 3 class, where parts of used motorized strollers, various motorcycles and scooters are widely used. The competition held by our magazine (see No. 12, 1973) undoubtedly contributes to the speedy creation of a buggy car design that can satisfy the most stringent requirements.

We periodically introduce our readers to the materials submitted for the competition. We invite micro-automotive enthusiasts to take part in the discussion and evaluation of submitted projects.

When starting to create a buggy sports car, we already had some experience in building microcars in general and off-road vehicles in particular. As soon as the buggy-350 class was legalized by the USSR Automobile Sports Federation, we got to work, and our car in question was one of the first in the country to hit the sports tracks.

Like most other designers, we used many components and parts from the SZA wheelchair. But this does not mean that you can turn it into a buggy by removing the body and installing the required equipment: roll bars, fire extinguishers, etc. After all, a motorized stroller is designed for “normal” use in road conditions, and not at all for competitions on rough terrain, competitions , in which the endurance of the car and its driver are subjected to the most serious tests.

Long-term operation of buggy predecessors (“Tourist”, “Druzhok”, etc.), created in our laboratory, where parts of the SZA motorized stroller were used, allowed us to thoroughly study the advantages and disadvantages of both individual components and the machine as a whole. I must say frankly: there are a lot of alterations and improvements, but without this it is impossible to get a reliable sports car.

The engine requires particularly careful and thoughtful tuning. How successful we were can be judged by the power indicators: before boost, it developed about 20 hp. With. at 6 thousand rpm, after – 26 l. With. at 8500 rpm. This was achieved by installing the cylinder and head from the IZH-Planet-3 engine, selecting jets with higher performance and increasing the compression ratio by trimming the cylinder head by 1.2 mm, as well as thoroughly polishing the bypass, suction and exhaust channels. With further fine-tuning, which we have not yet done, it is possible to polish the windows in the cylinder according to one of the schemes common among motorcycle racers, install a unit magneto instead of a battery ignition system, seal the crankcase, etc. – all this is described in sufficient detail in specialized literature.

The main transmission is a chain from the engine to the differential and then through cardan joints to the drive axle shafts. The main brakes are shoe brakes on all four wheels, with a mechanical drive and an equalizer system. The parking brake is on all four wheels with a mechanical drive. The brake support panels are from a T-200 scooter, the drums are turned, with a ribbed outer surface (for better cooling).

The front suspension is independent, on trailing arms, torsion bar, with additional shock absorbers from the IZH-350 or Pannonia motorcycle and reinforced mounting of the shock absorbers to the arms.

The rear suspension is independent, on wishbones, with spring-hydraulic shock absorption (a converted rear axle from a SZA motorized stroller).

Wheels – combined: inner disk from a SZA motorized stroller, stamped, without modifications; outer – cast from magnesium alloy, widened, equipped with decorative spokes to increase rigidity. Tires – tube, size 5X10; On the widened rim, the tire takes on the shape of the most advantageous grip on the road. The car has the ability to install a windshield, windshield wipers and an easily removable awning, as well as doors, thanks to which it can easily be transformed into a general-purpose touring car that can be used every day. This does not contradict traffic rules and technical conditions.

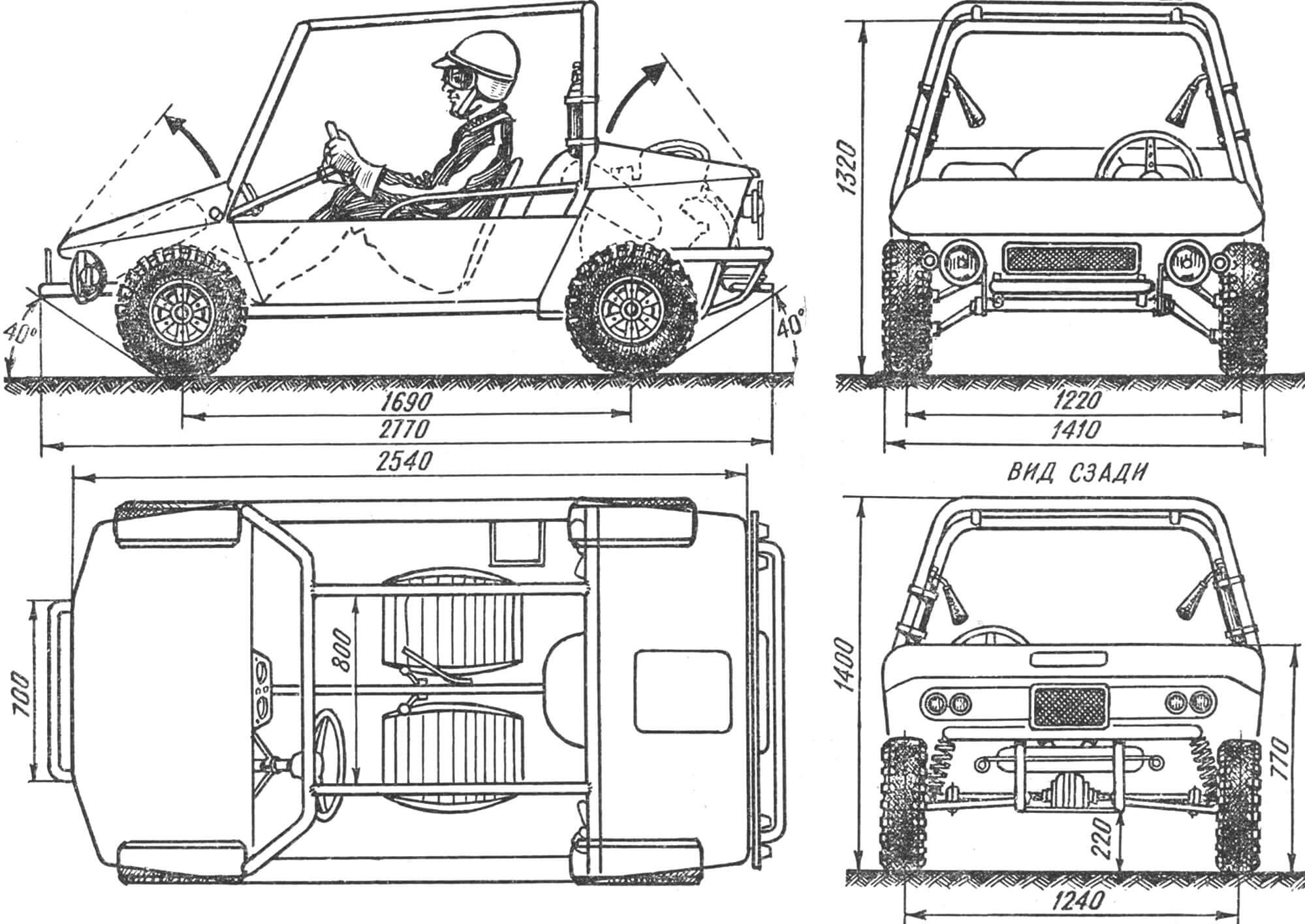

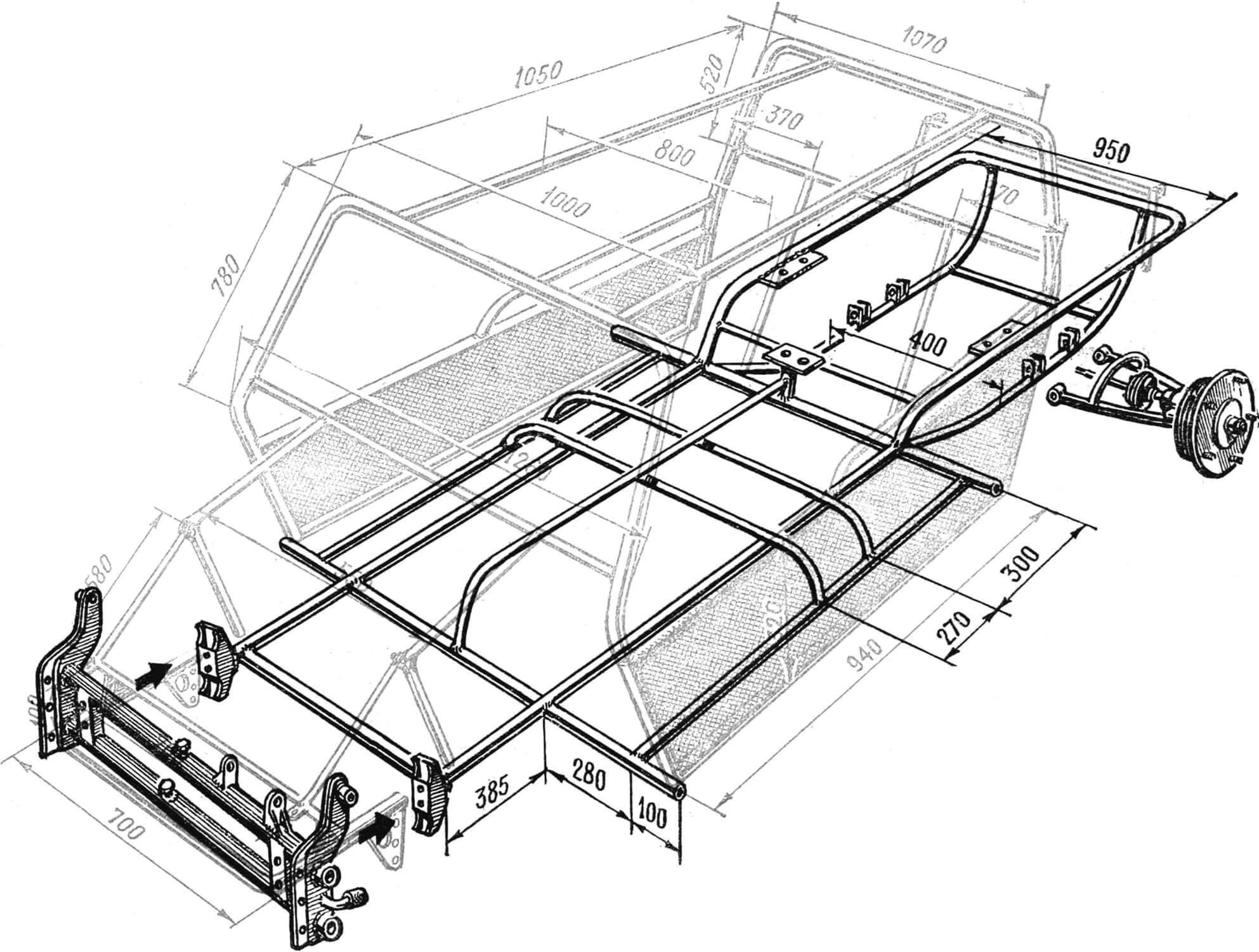

The general view of our “KVP” buggy is shown in Figure 1, the design diagram is in Figure 2. All sections and dimensions of additional parts that form a sports-type body are also given there.

Unlike other cars in this class, our buggy does not use fiberglass. The front and rear hoods are made from old hoods of a GAZ-51 car, reshaped accordingly, and the sides of the body are made from a steel sheet 1.1-1.9 mm thick, bent on an edge bender and welded “dotted line” after fitting to the load-bearing elements of the frame.

Car color: body – bright yellow outside, dark gray inside; headlight housings, side lights, steering wheel, pedals, handles – black; seats, fire extinguishers – red; stripes, inscriptions on the body – black (KVP, TV-350); the racer’s surname and blood type are red; wheel rims – silver.

THE COMPETITION FOR THE BEST BUGGY-350 CONTINUES

At the start there is a car with the inscription: “Buggy-MK, Belorechensk.” An exciting moment: the first starting number, the first swallow, followed, we hope, by others, also created by the golden hands of young technicians in the city of Belorechensk, Krasnodar Territory. Evgeny Maslennikov, Alexander Kulagin and Nikolai Rudenko took part in the construction of this machine under the guidance of the teacher of school No. 68 Harry Ketz. Here are its basic data (in mm):

Overall width 1200

Height 1620

Length 2450

Base 1680

Speed max. 65—70 km/h

Built on the basis of the SZA wheelchair. Housing with sheet steel casing, frame made of steel pipes and angles.

BUGGIES START

The 1975 sports season was marked by a significant expansion of the geography of competitions on special cross-country buggy-type cars. These cars started in Moscow, Zaporozhye, Latvia and Estonia. The most representative was, by all accounts, the second open championship of the Baltic republics. This time, about 40 cars arrived in the capital of Latvia – on the territory of the famous Bikernieki racing track. Essentially, this meeting had the character of an all-Union competition – after all, not only representatives of the Baltic republics – Estonia and Latvia, but also athletes from Moscow, Leningrad, Ukraine, and Georgia arrived to measure their strength in cars built with their own hands.

Along with the “heavyweights,” each team also included cross-country cars of the “junior” class – up to 350 cm 3 , which our magazine took patronage of by announcing a competition for the best design. They were attended by racers from the DOSAAF sports and technical club in the Pervomaisky district of Moscow, their fellow countrymen – students of the technical college at ZIL, athletes of the Zaporozhye regional council of the Avtomotolyubitel society, the Kharkov regional sports club, the Latvian secondary school No. 3 from the city of Jekabpils, the Riga Polytechnic Institute and the Republican automotoclub of transport workers. A representative of the Republican DOSAAF motor club arrived from distant Georgia. The idea of a buggy structure also appealed to rural athletes: they were part of the Latselkhoztekhnika and Estselkhoztekhnika teams.

According to the judges, the most interesting and technically promising design was presented by a young Estonian athlete. Jaan Tilt. Unlike many cars in his buggy, the frame, front and rear suspension, many components and parts were not serial, but hand-made in a collective farm workshop. Perhaps, only the Izhevsk engine and wheels remained factory. The excellent driving characteristics of this car and confident driving skills allowed Jaan Tilt to become champion in the class up to 350 cm 3 .

The Baltic Championship and other buggy competitions indicate that the class up to 350 cm 3 has confidently taken its place in cross-country buggy racing. Youth buggies are being built today by many teams; every competition brings designers and racers new discoveries and opens up new opportunities for improving technology. I would like to wish that the DOSAAF Central Committee would find the opportunity to hold official all-Union buggy competitions in the near future, one of the prizes of which could be the “Modelist-Constructor” magazine cup for the best design in the class up to 350 cm 3 .

V. EGOROV, Honored Trainer, Head of the FAS USSR buggy group, our special. corr.