Readers familiar in № 4’2006 a tractor trailer Muscovite V. Wheels, interested and yourself mini-tractor for this Amateur designer. Today we publish the description of technology of manufacture of this tractor and schematic of its main components.

Readers familiar in № 4’2006 a tractor trailer Muscovite V. Wheels, interested and yourself mini-tractor for this Amateur designer. Today we publish the description of technology of manufacture of this tractor and schematic of its main components.

If you have a house in the village, and even more so when you live there permanently, without transport and teleoperative equipment is necessary. Was this technique and I have: for the treatment of soils used walk-behind tractor with cutters, and for the transport of goods — a car “Lada” with a trailer.

But after I started to play tricks the heart, behind the wheel of a car I didn’t sit down.

However, a business without available transportation to perform was impossible. And then came the idea to make a small tractor to (buy a new one for me was beyond my means) and use it as a tractor truck trailer. In this case, helped the case.

One came on a large, vibrant market and saw several mini-Trak-tori, briskly scurrying between the market stalls and people and pulling a trailer on the truck. One such car stopped next to me and I don’t miss the opportunity to ask about her driver.

It turned out that this mini-tractor “Xingtai” the Chinese production with a diesel 2-cylinder, 12-horsepower engine and a rather unusual construction: it was not a frame (as in other tractors or trucks) or monocoque (like cars). Bearing elements was a unit of the power unit and the carters transmission (clutch, gearbox, auxiliary gearbox). These elements were rigidly connected together by bolts, screws or studs.

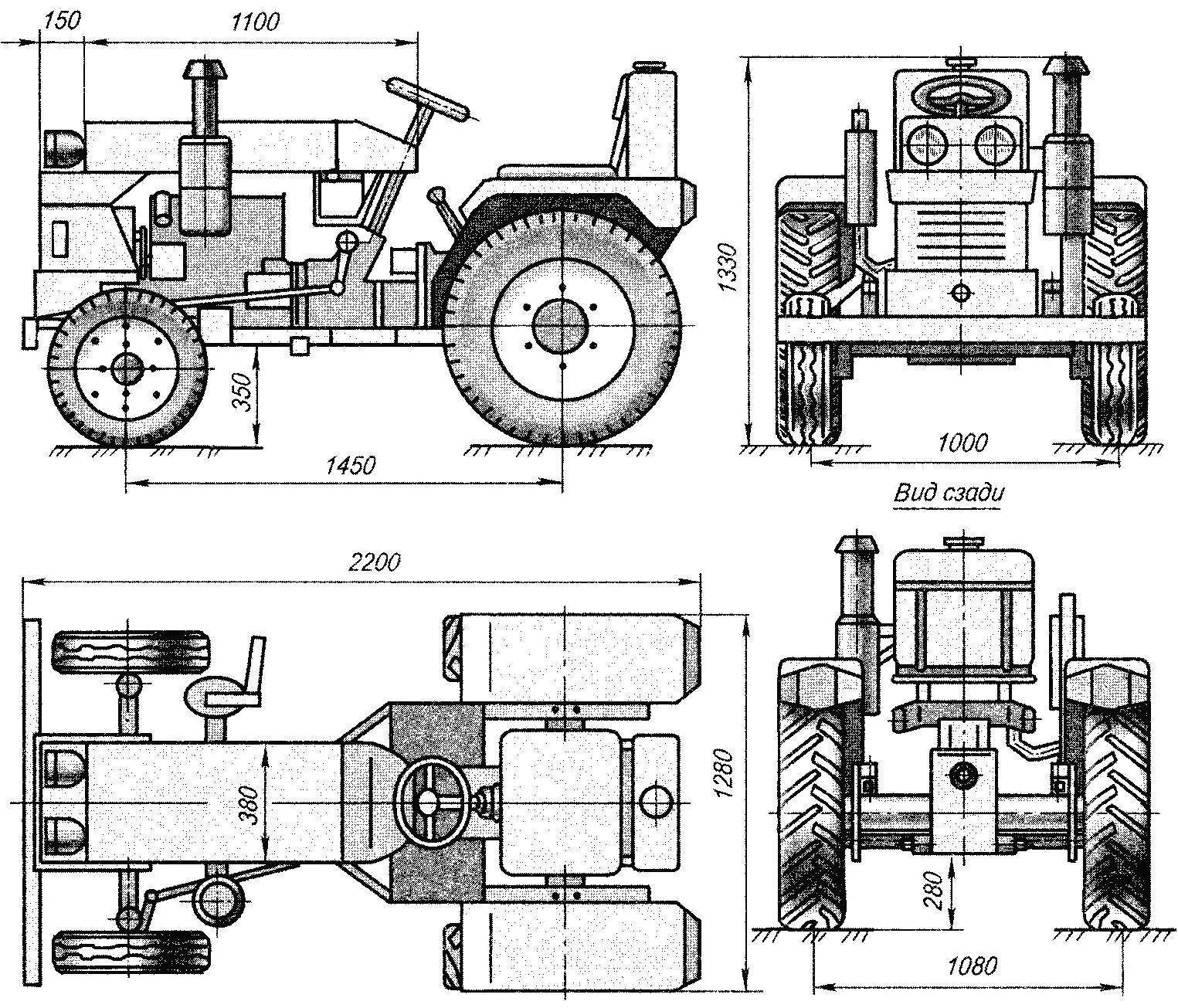

Geometry mini-tractor

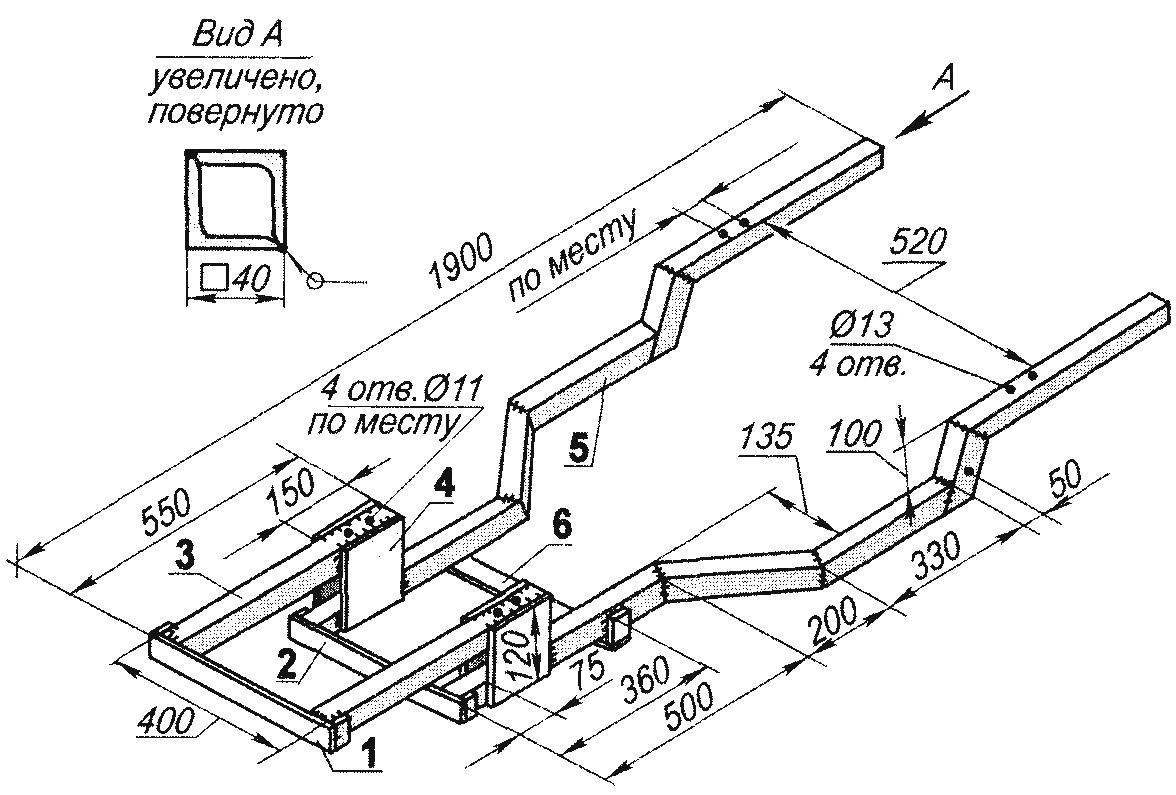

Frame:

1 — consoles cross-member (steel angle 50×50); 2 — cross member side members (steel angle 50×50); 3 console (two 40×40 area, welded in a square tube, 2); 4 — (sheet s5, 4x); 5 —spar (two 40×40 area, welded in a square tube, 2); 6 — under engine crossmember (sheet s5)

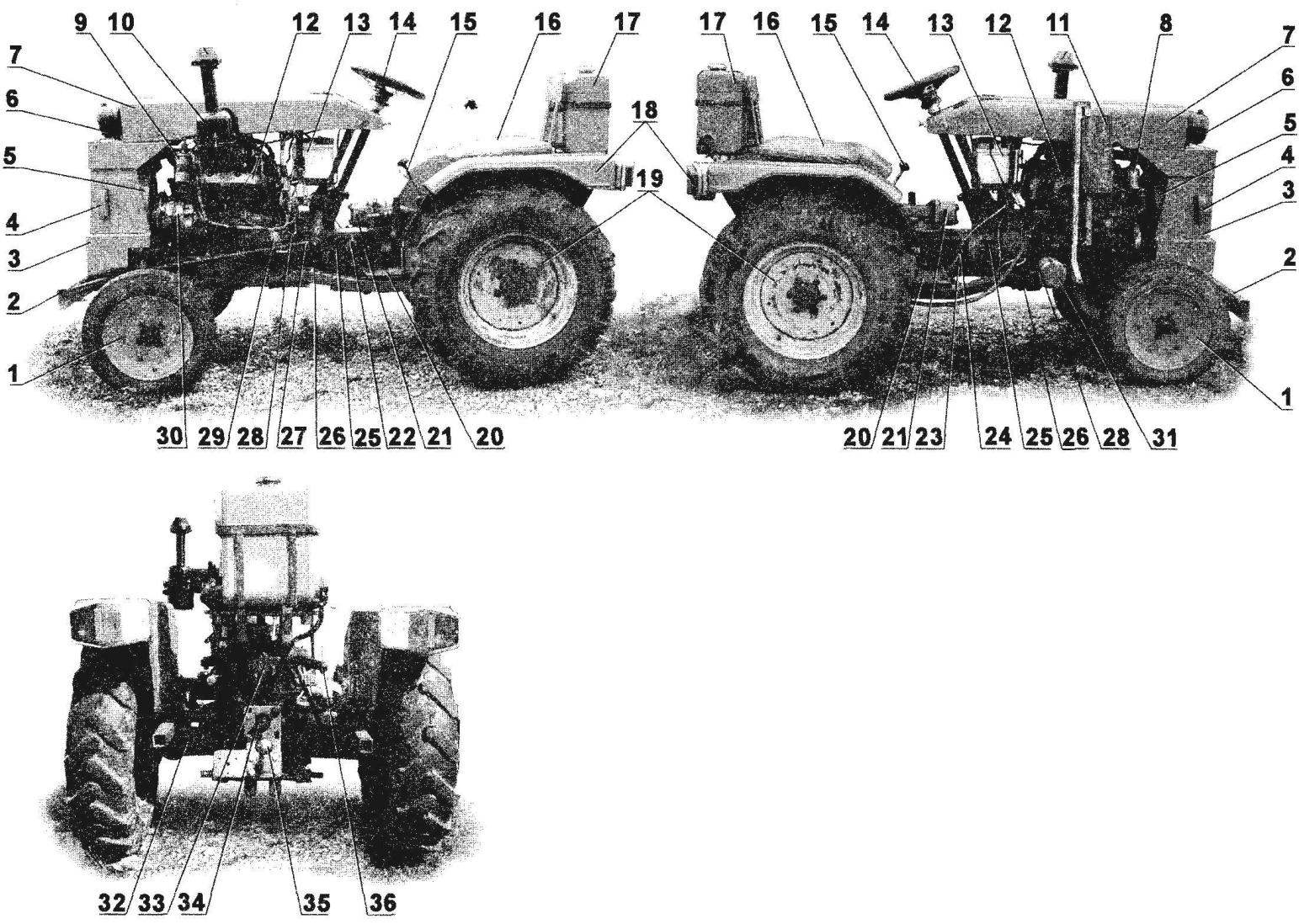

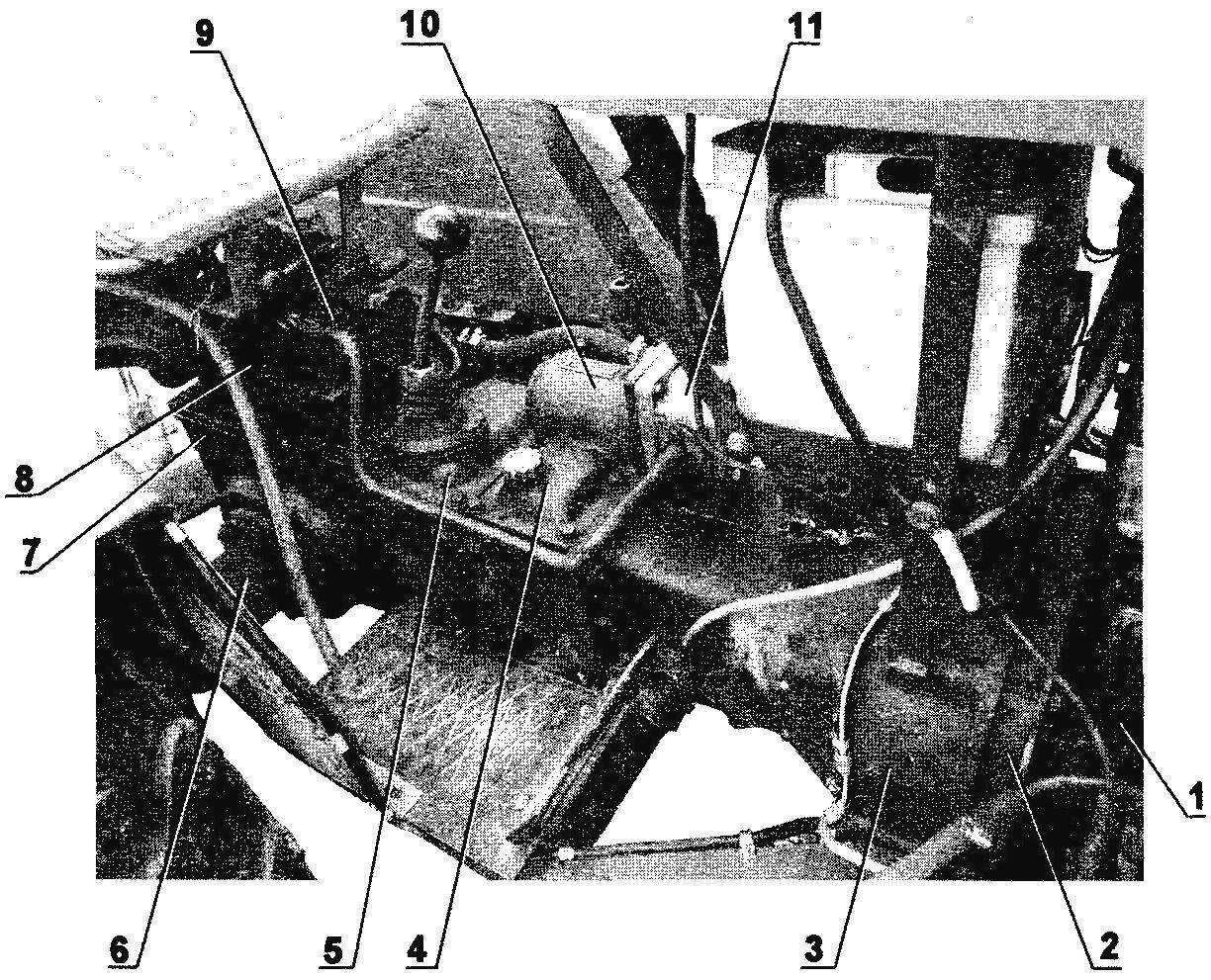

The layout of the mini-tractor (not specified position — staff):

1 — front; 2 — bumper (pressed steel channel 75x40x3); 3 grille; 4 — turning lights (from the car “Niva”); 5 — fan (from cars); 6 — lights (from the farm); 7 — a cowl; 8 — the filter of thin clearing oils; 9 — high voltage ignition coil (from car “Moskvich-408”); 10 — air filter; 11 — muffler (homemade); 12 — the engine (from the car “Moskvich-412”); 13 — battery (from cars); 14 — steering wheel (car); 15 — shift lever; 16 — seat (homemade); 17 — gas tank; 18 — blocks of the rear signal lights (from the car “Volga” GAZ-24); 19 — rear wheel (for tractor “Belarus”, front); 20 — pads for the feet (corrugated steel sheet s3); 21 — oil pump; 22 — clutch pedal; 23 — the brake pedal; 24 — gas pedal; 25 — transmission units; a 26—frame (homemade); 27—steering rod; 28 — the fuel pipe (improvised); 29 — a starter motor (from the car “Moskvich-408”); 30 — generator (automotive); 31 — strainer oil; 32 — rear axle; 33 — piston pump levers linkage; 34 — PTO shaft; 35 — the drag hook (homemade); 36 — lever hydromancy (2 PCs.)

Another driver suggested that they have in the hangar is the same faulty tractor, which initially wanted to sell, and now used for parts, and showed me where it is stored. Some of the tractors still have: front and rear axles, transmission units, facing panel. But many, and most importantly the engine, unfortunately, was not.

After a few days of pondering and wondering its ability to restore the mini-tractor, and then agreed on a reasonable price and purchased the remaining units and components.

The engine from the car “Moskvich-408” with a capacity of 50 HP gave me buddy. Its dimensions considerably exceed the dimensions of regular diesel, especially in length. In addition, the unit moskovichevskoe engine was not designed to carry any power load from the chassis. On the contrary, he needed the additional support. Therefore, in addition to its reliable coupling with the clutch housing, I had to think about making an additional and strength of the frame.

But restoring tractors started not from the frame, and with said docking station. The problem was that this does not coincide neither the size nor the number or location of mounting holes. The homebrew for this is usually made a special adapter ring. I have the same situation was complicated by the fact that the engine side clutch cover a much played with the starter gear (“Bendix”) starter. But, after thinking and working, and decided this task: the distance ring made of curly (with a bypass cap “Bendix”), and clutch housing were done under cover and even the neckline. The holes in the mounting flange adapter is drilled on the cardboard template, having on one side an imprint from the cylinder block, and on the other from the clutch housing.

But the trouble with the engine not ended. It was necessary as-that to improve and to make more efficient cooling system. The staffing system at low speeds is normal, too high-revving petrol engine to provide was just not able to. Again helped friends homebrew supplied me with a compact dual radiator fan shestilopastnye from some cars. When operating tractors with this system in further cooling problems never arose.

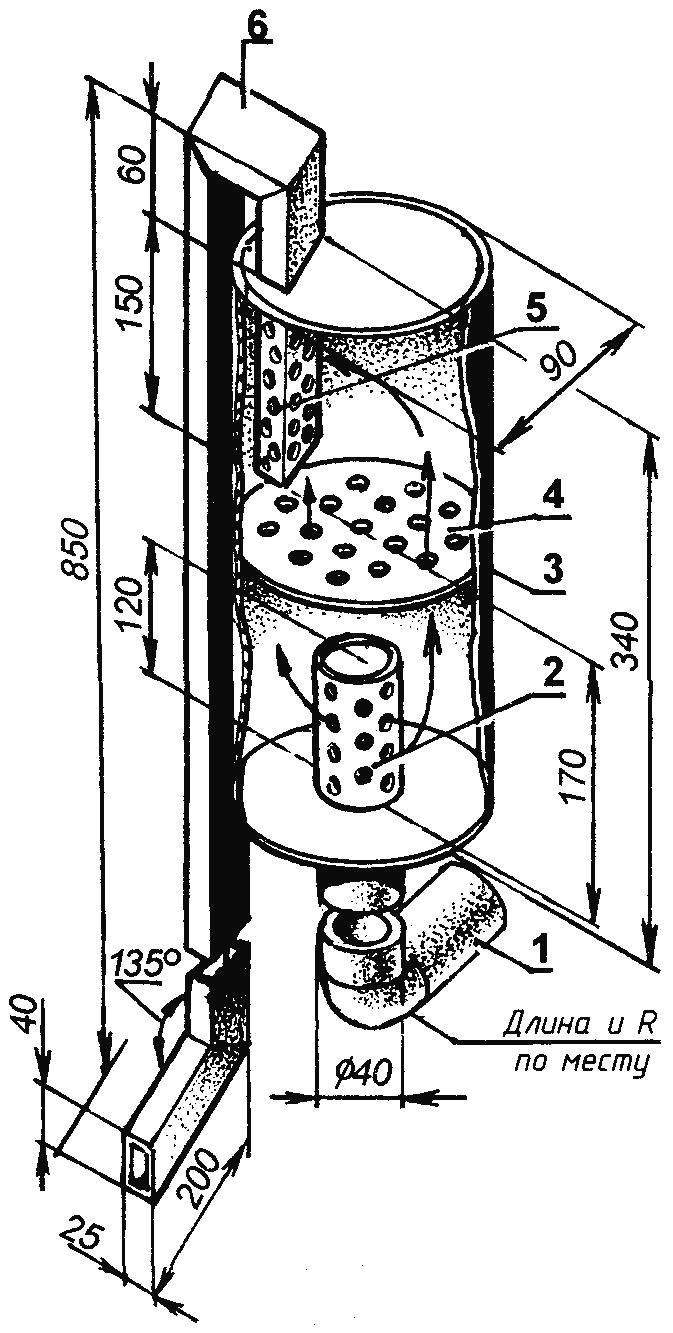

The muffler for the engine I had to make myself staff just wasn’t there. Its design is simple, but as practice has shown, quite effective: the exhaust was not louder than a passenger car. Silencer, elliptical, single, double, three junction. The first transition of the exhaust gas occurs at the moment of their exit through the holes of the inner nozzle pipe in the first chamber of the muffler. The second — in the point of transfer of gas through the partition from one chamber to another. And the third is in contact with the gases in the inner pipe of the exhaust pipe. At the same time, to avoid backflow of gases, the total area of the holes in each subsequent transition involved little more than in the previous year. Exhaust pipe pointing down, like cars, not up like most tractors.

The regular alternator on the engine was not, and therefore had to complement the existing old but still fit AC SetEditSem rectifier. More to the electrical system I bought a new battery.

Air filter decided to leave the tractor. It is, of course, outsized and requires maintenance, but very effective.

Now on the newly manufactured frame. Even though it was spatial, but is rather simple. It is based on two longitudinal members made of steel angle corner No. 4 (40x40x4 mm). But the parts thus assembled along the length of the edges of the shelves and welded in square tube.

The side walls are made integral, as in their past and had to change the distance between them, and raise rear over the front. The front part of the frame narrower than the rear — to allow rotation of the guide wheels. In addition, it is bunk. This is due to the fit of the frame simultaneously to heterogeneous aggregates — moskovichevskoe engine and Chinese components of the transmission and also to the suspension beams of the front axle. When this beam is suspended to the frame by means of adaptor plates used from the same Chinese mini-tractor, but modified. The part of the plate just cut off as unnecessary, and in the ears of the remaining part drilled new mounting holes. Beam is not hanging on the center pin and pounded on the frame, to the side members of the attached thick rubber padding.

Muffler:

1 — a reception pipe (pipe Ø40); 2 — inlet pipe (pipe Ø40); 3 — casing (steel sheet s2,5); 4 — bulkhead (steel sheet s2,5); 5 — outlet pipe (pipe 40×25); 6 — exhaust pipe (tube 40×25)

Dwuhlopastny the plow on the hitch. Front (RH) shield — homemade

The layout of the transmission units:

1 — engine; 2 — adapter with hand wheel; 3 — Carter with the clutch mechanism; 4 — Carter additional gearbox (dual); 5 — Carter, the main transmission shift lever; 6 — right cover rear (leading) axle axle shaft; 7 — Carter of the main transfer with differential and PTO; 8 — plunger pump with the lift levers hinge; 9 — the valve with lever; 10 — the oil pump; 11 — oil pump

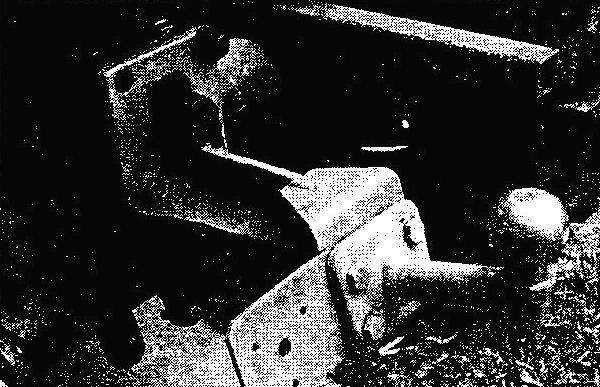

The drag hook for car trailer hitch

The rear part of the frame is also spatial, but the rails simply bent up at a steep angle, and then again directed in the horizontal plane. This curve was necessary in order to dock and attach the frame to the beam rear axle on top — there was already a threaded hole M12. With their help here in the past (in regular version) to the beam attached to the wings using a fairly high-bushings-spacers. Now place the spacers took the tube spars Yes, even strips of hard rubber.

The transverse elements of the frame a bit or two traverses Yes under engine cross member. They are all in the front part of it. In the rear part of the same link at the frame is the rear axle beam. The bumper can be considered also part of the frame, but it is made as a separate element and is attached thereto by four bolts M12. The bumper I made a new — and heavier overall than staff, suggesting in the future to hang on his bucket malapati.

It should be noted that the holes in the frame for mounting the components and assemblies swirlies mainly on the place, after careful alignment of the provisions of the latter.

Rear axle used completely “Chinese”, but the wheels here I had to adapt from a tractor “Belarus”, although the tires on them too regular.

Linkage for connection of tillers with plow odnoimennym was included (or rather, “shortages”) with a mini-tractor. But since the engine is mounted the more powerful, to increase your productivity when ploughing has taken another share in the image and likeness of the first and the additional node to its mounting on the plow. And the car not skidded due to lack of mass in such efforts, the wheels were fastened heavy iron discs.

Since a mini-tractor was supposed to use as a tractor trailer truck from cars, to hitch with him produced ball the drag hook. But in this site only improvised a connecting element, and a sphere of Commerce and manufacture. The trailer (it is homemade) hitch also industrial manufacturing. Technical requirements prohibit the use of Handicrafts in devices of this type.

However, the drag hook prevents free access to the shaft of the power take-off (PTO), but while this mechanism I have left unused and covered with plastic cap.

It should be noted that the majority of controls: steering, brake system, clutch was at the mini-tractor is in order and I used them almost without alterations. Only in connection with the increased distance to the front axle I had to lengthen the longitudinal tie rod. It is worth noting that the steering of the tractor is quite simple and does not have trapeze. Swing arms to the axles of the wheels are connected by a single transverse rod.

The hydraulic system has no pump and fine filter oil. These units came without fitting and alterations from domestic tractors. This fact is indirectly confirmed heard market version of that tractor was designed in our country.

Devices light signalling in the acquired nodes was not, and therefore they had to be purchased and installed again. Headlights — from agricultural machinery, the lights turns from “Niva” car, the rear blocks signal lights — from “Volga” GAZ-24.

V. WHEELS