In the late winter of 1974, on the snowy fields near airport “Domodedovo” there was an unusual car, like the egg of a magical bird, the ROC, or a giant cocoon. Leaving behind clouds of snow dust it with remarkable speed glided across the plain and easily overcome the pretty steep climbs. Maneuverability it aroused universal surprise: a complete course “cocoon” was unfolding just in one place!

In the late winter of 1974, on the snowy fields near airport “Domodedovo” there was an unusual car, like the egg of a magical bird, the ROC, or a giant cocoon. Leaving behind clouds of snow dust it with remarkable speed glided across the plain and easily overcome the pretty steep climbs. Maneuverability it aroused universal surprise: a complete course “cocoon” was unfolding just in one place!

It was the second experimental snowmobile was built in Domodedovo public KB, run by young engineers Vladislav Maltsev and Alexander Podomatsky. A few years ago they organized youth design office in the village of Domodedovo, where many employees of the airport and there are material opportunities for the development of technical creativity through periodically written off airport aircraft components. The editors supported the initiative of Vladislav and his comrades. Soon it was received and the room was empty transformer box. The Komsomol Committee and heads of technical services of the airport helped to acquire the necessary equipment; something that the guys brought from home — each found a fair amount of need for the planned teamwork of parts, tools and materials. So began his creative activity another a small branch of OKB “M-K”. Now it regularly employs six engineers and technicians. A lot of young guys, mostly high school students from a local school come in the evenings in the Studio and as adults participate in the creation of interesting models of transport technology. The main direction in activities of Domodedovo OKB — development of all-terrain vehicles. Following the snowmobile, which we tell readers in this room, on the bench there is another amazing car — a scooter amphibious. This apparatus, as conceived by the designers should combine the properties of individual land vehicles and single boats. It is created on the base of the scooter “Tula tourist”, produced by the domestic industry.

…And on the drawing Board, covered with a curtain, drawn the contours of a small trimaran also of an unusual design, with a folding side floats. The model of this machine is already tested and showed encouraging results. Will soon begin construction of full-size cars.

Domodedovo EDO has participated in several contests of all-terrain vehicles. Traditional winter festival in the suburban town of Khimki snowmobile from Domodedovo participated in demonstration and competitions were awarded by diplomas of magazine “modelist-Konstruktor”, “Tekhnika — molodezhi” CC DOSAAF.

About how to create a snowmobile in public KB Domodedovo, the head of the project engineers Vladislav Maltsev and Alexander Podomatsky.

Sometimes we are asked why we are organizing youth public design office, began to build a snowmobile and not something else. City dwellers, accustomed to the pure asphalt of the streets, even in snowy winters, it is difficult to understand. And around our airport snow lies thick carpet from November to April, and its glistening white beckons, and calls to ride without a path, without fear of ice, snow banks and drifts! That is why when discussing the work plan our little creative team decided: the first development — the snowmobile. Technical design requirements: high throughput, good aerodynamics, the highest possible comfort for the crew. Passenger capacity — two people, including the driver, the engine of 25-30 HP

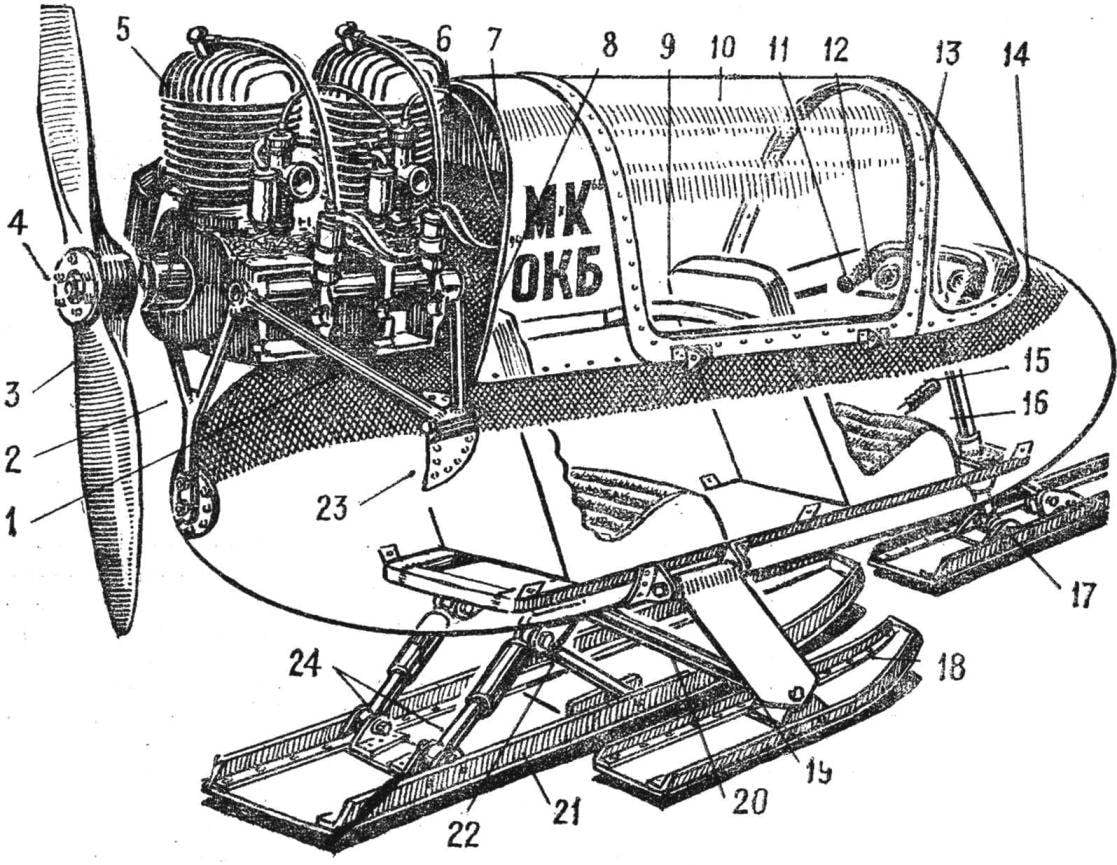

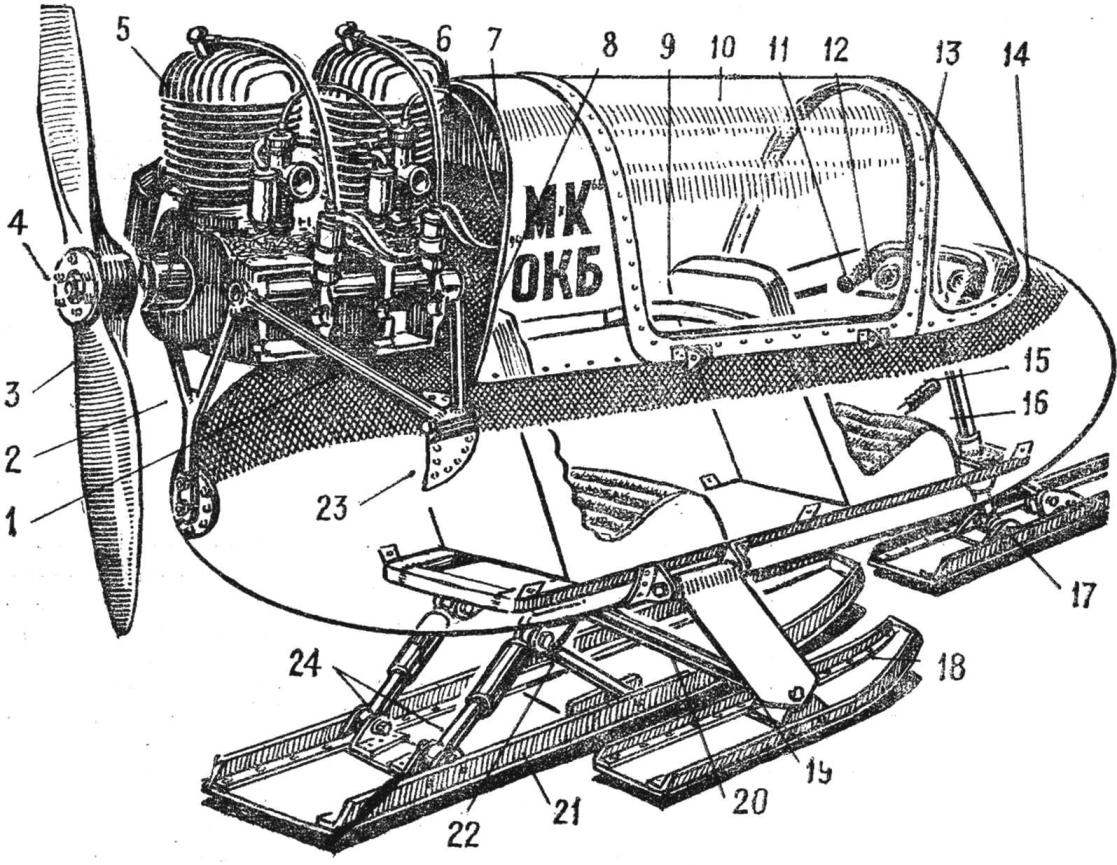

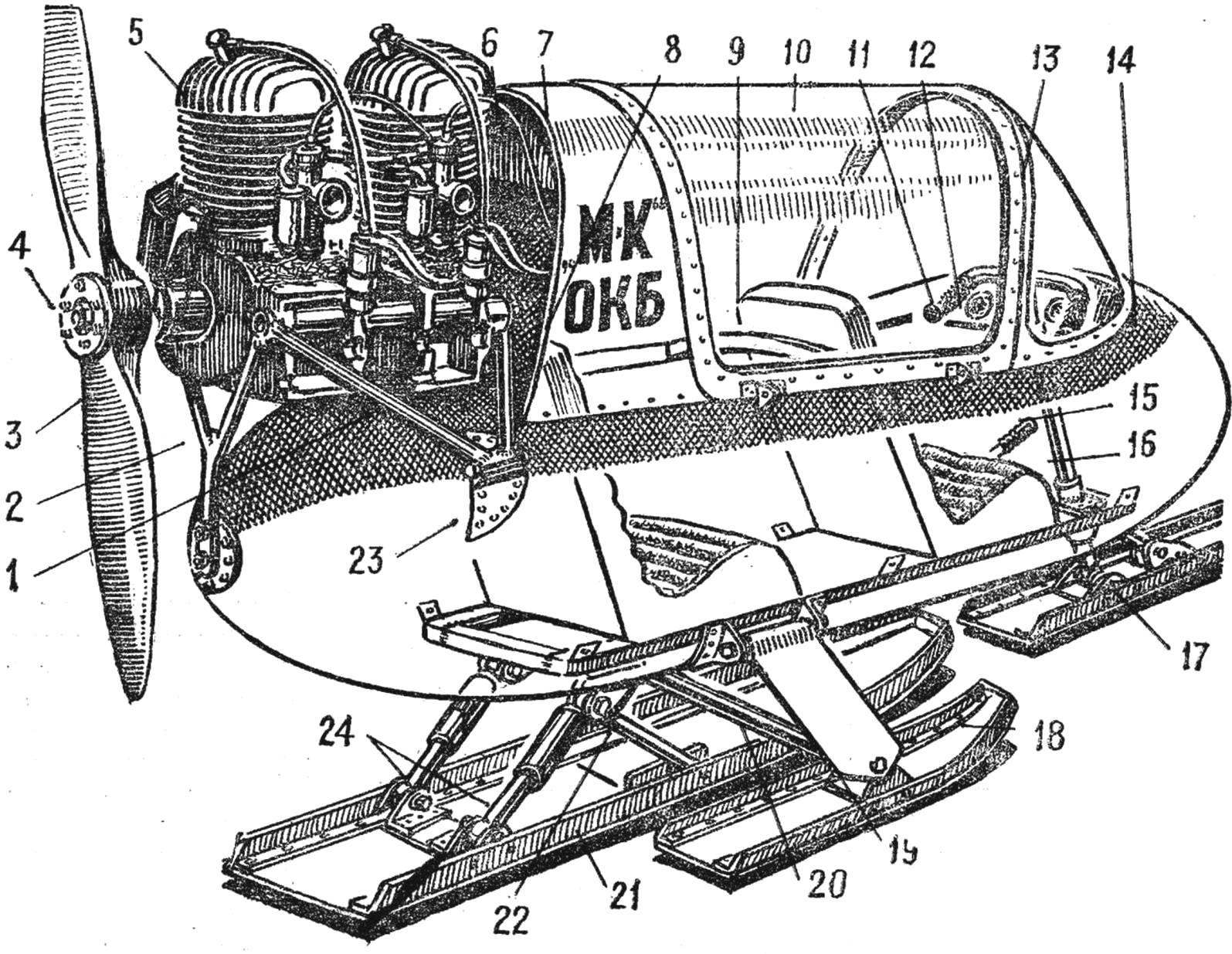

Fig. 1. The overall layout of snowmobiles:

1 — cook the aft body, 2 — rear fork sub-frame, 3 — propeller, 4 — propeller hub 5 — engine (two coupled engines of the motorcycle “Jawa-250”), 6 — fuel tank 7 — fairing, 8 — back seat, 9 — front seat, 10 — movable part of the lantern, 11 — wheel motorcycle Tina, 12 — instrument panel, 13 — front (fixed) part of the lantern, 14 — front of the COC, 15 — steering shaft, 16 — brake lever, 17 — front (steering) skiing, 18 — side-ski, 19 — strut suspension side of the ski 20 to brace the side of the ski, 21 — 22 main ski bracket ski core, 23 — a shock absorbers main ski, 24 — side mount sub-frame.

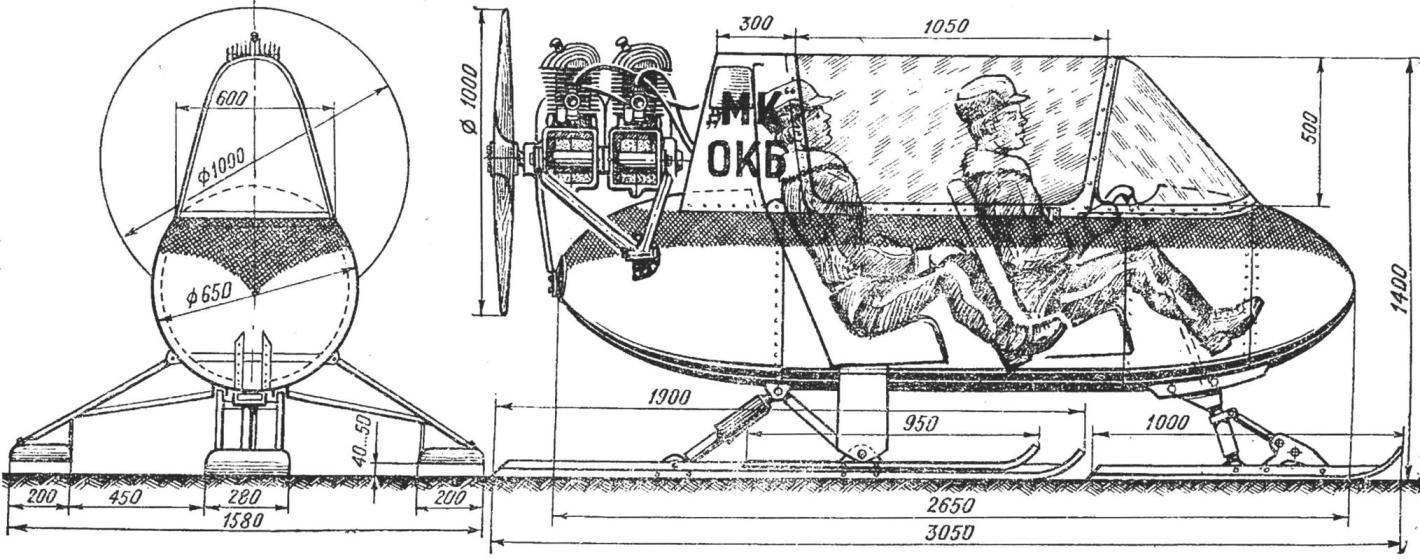

Fig. 2. Side view and front.

Before starting the design, we met with many Amateur-built snowmobiles. At the stage of preliminary design tried to borrow all the good that he saw, and sought to circumvent the drawbacks of a particular design. We loved the sleigh Valeria Kukina (see “M-K” № 10, 1970). However, the proposed control system turns we decided to drop by applying the usual front steering ski: it is more stable on loose snow. The rest of our sledge like sledge V. Kukina: the main skis (tilt and bearing) arranged one behind the other, on “Cycling” scheme; supporting the right and left of the housing (Fig. 1). We knew that this scheme is advantageous in terms of virgin snow, loose snow, when riding in the woods and the Bush. The housing has a frame — base (Fig. 2); welded from steel tubes of rectangular cross section to which the spring shock absorbers mounted steering and carrying the skis. The lateral support of the ski is made easily removable and are mounted rigidly on brackets, welded of steel thin-walled tubes. The center of pressure of the side of the ski coincides with the center of gravity of the loaded snowmobile in a plane perpendicular to the direction of motion, which is beneficial to the stability of the machine.

Ski carrier made of steel sheet of thickness 1 mm and reinforced with four longitudinal dural squares 30X30 mm. It is attached to the base hinge with the frame-rocking, welded from thin steel tubing and sprung steel spring shock absorbers from a moped “Riga”. Also hanging from the steering ski. Shaft, ending with a steering wheel in the driver’s cab, attached to the subframe of the body at three points, provided to reduce friction textolite inserts. Steering and both side skiing is a sheet of aluminum 2.5 mm thick — reinforced longitudinal dural corners 25X25 mm.

The outer shell of the body is made up of two motor Kokov Il-18 (a rotational body) and the intermediate cylindrical insert of duralumin sheet thickness of 2.5 mm. the Lantern consists of fixed (rigidly attached to the body), a streamlined frontal part and the swivel side of the back cover of cylindrical shape. A good proportion of the body and the lamp gives the car a very compact look. Seats are placed one behind the other so that the legs of the back seat of the passenger are placed on the sides of the front seats. This allowed extremely to shorten the body and a few to save some weight.

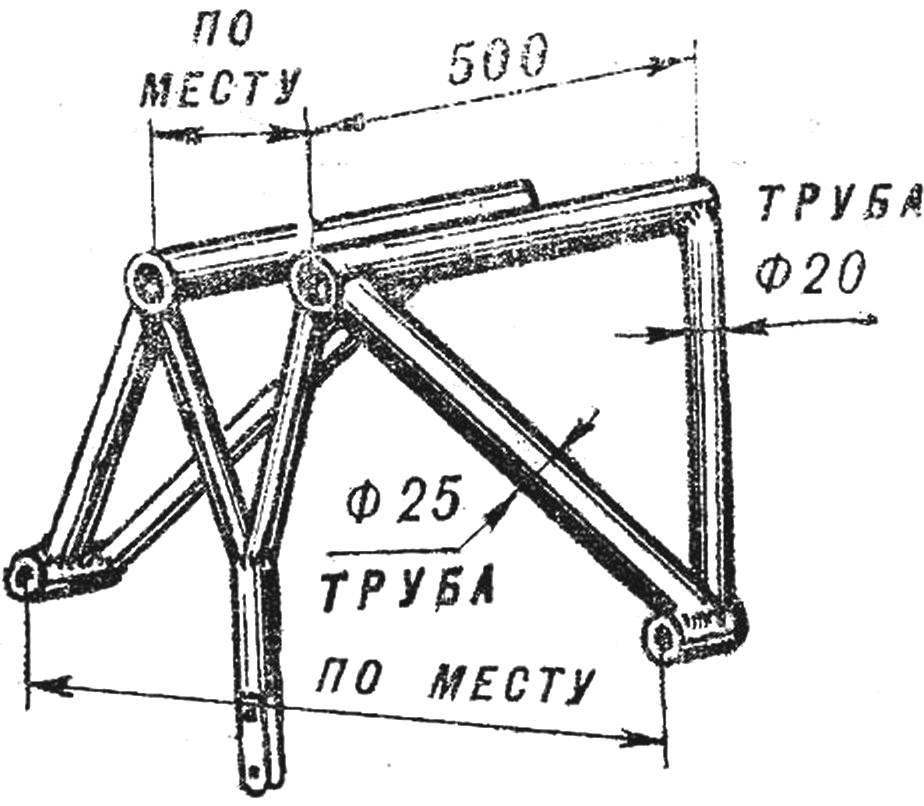

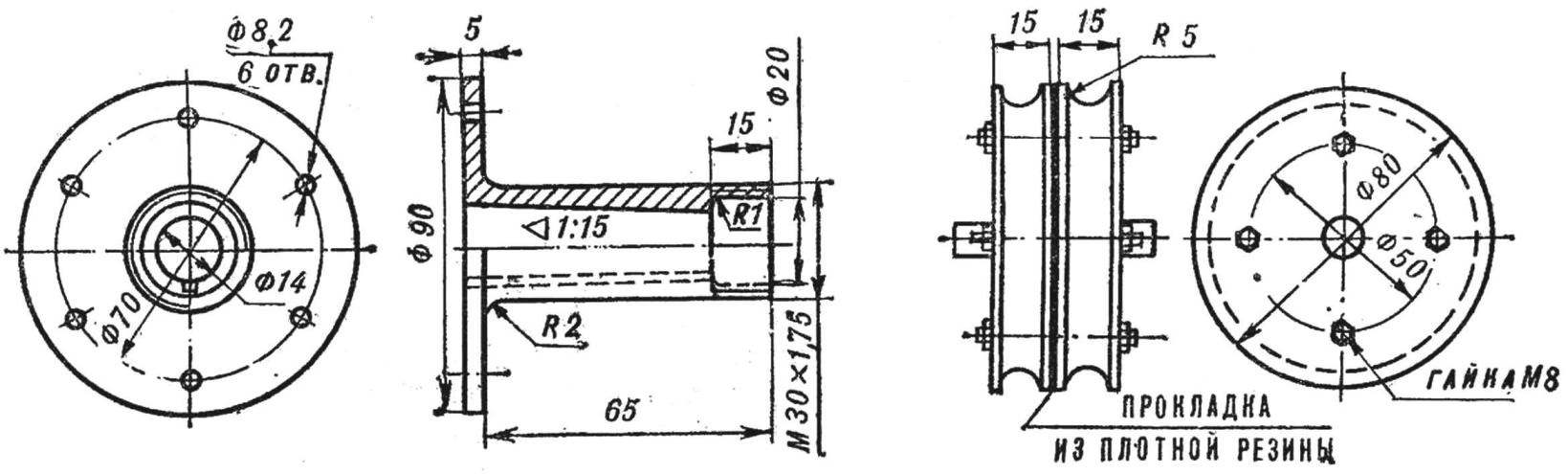

Motor installation snowmobiles — easily removable, on a special welded tubular subframe attached to the body at three points (Fig. 4). A stretcher is quickly dismantled along with the motor and can be installed on any other machine. The engine is created on the basis of two arranged one behind the other motorcycle engines “Jawa-250”, which cut off the gearbox and crankshafts are connected to the outer rigid coupling. In the course of former experiments with the engine we tested also semi-rigid connections with rubber gasket. Tests showed that the rigid scheme is more reliable and simple. As is known, this connection requires high precision pairing work surfaces. We achieved this by sanding on a lathe, half-coupling, already impaled on the shanks of the crankshaft. The crankshaft remains in the engine block fixed on the caliper of the machine, and uniformly rotated by hand. Tolerance sanding between 0.2— 0.3 mm. Coupler is provided with a groove for the starter cord (Fig. 5).

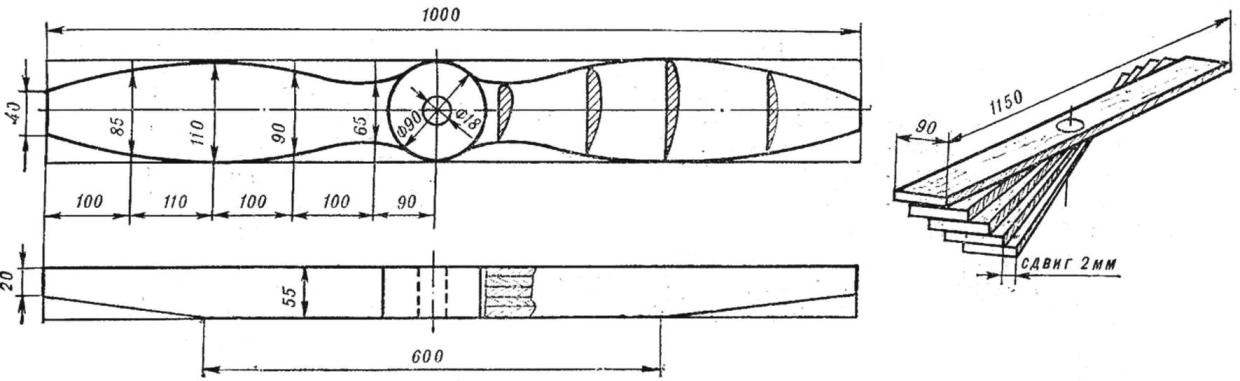

Fig. 3. The principal dimensions of the propeller

Fig. 4. Design and basic dimensions sub-frame.

Fig. 5. The propeller hub and coupling.

When you remove the gearbox, clutch and start the body of the crankcases need to be trimmed so that the remaining part is preserved of the bore of bearings of a secondary shaft. When docking engines in these openings are inserted in grooved steel pipe threaded on both ends, being simultaneously retaining and centring element (see figure 1). The second centering element is itself a rigid coupling, tightening the ends of the crankshafts.

For greater rigidity of the crankcases of the engines is additionally connected struts.

The propeller snowmobiles — left rotation Ø1,0 m in increments of 450 mm, glued from the gorse (Fig. 3). The blades are covered with one layer of fiberglass, ASTT(b) and polished. Screw mounted directly on the shank of the crankshaft. The hub shown in figure 5.

We applied the ignition system of the motorcycle “Java-350” has been modified. The changes affected primarily the block breakers. Its base is mounted on a rotating holder that allows you to set the optimum angle of an advancing of ignition depending on the operating mode of the engine. Managing the spark advance is synchronized with the flow of gas. This ensures reliable and safe start-up and sustained operation at low speeds and maximum power output limit mode. Fuel feed is by gravity from a tank mounted above the engine. On the dashboard of the snowmobile includes electromanometer (made according to the scheme published in the magazine “M-K” No. 5 of 1973), the temperature gauge heads of the engines, the two-point speed indicator with scale from 20 km/h.

For two seasons of operation of a snowmobile any serious construction defects not revealed. Maximum speed on Packed snow of the order of 50-55 km/h.

V. MAL’cev, A. PODOMATSKY, engineers