— Can not be? Well, look! — Short, stocky man bent low over the open trunk of a small yellow car and disconnected the battery contacts, took from his pocket the usual flat battery 3336L and licking to be sure shiny contacts are not “hooked”? — connect them to the wires of the motor.

— Can not be? Well, look! — Short, stocky man bent low over the open trunk of a small yellow car and disconnected the battery contacts, took from his pocket the usual flat battery 3336L and licking to be sure shiny contacts are not “hooked”? — connect them to the wires of the motor.

— Come on, Hera, switch on, — he turned to those sitting behind the wheel boy. He slyly looked around and waited for a dramatic pause, he flipped a switch. The car trembled and slowly pushed…

And now let me introduce you to. Driving the wonderful of electric Georgy Golovin, a pupil of the 8th class of the 84th secondary school in the city of Chelyabinsk, one of the “employees” design lab club of young technicians of the Chelyabinsk metallurgical plant, which is run by — you probably guessed it — the same short, stocky, person — Valentin G. Martyniuk. And gathered around a cheerful, suspicious, inquisitive people — participants of the VI all-Russian meeting of young rationalizers and engineers, dedicated to the 60th anniversary of the Leninist Komsomol, which was held last summer in Novosibirsk Akademgorodok.

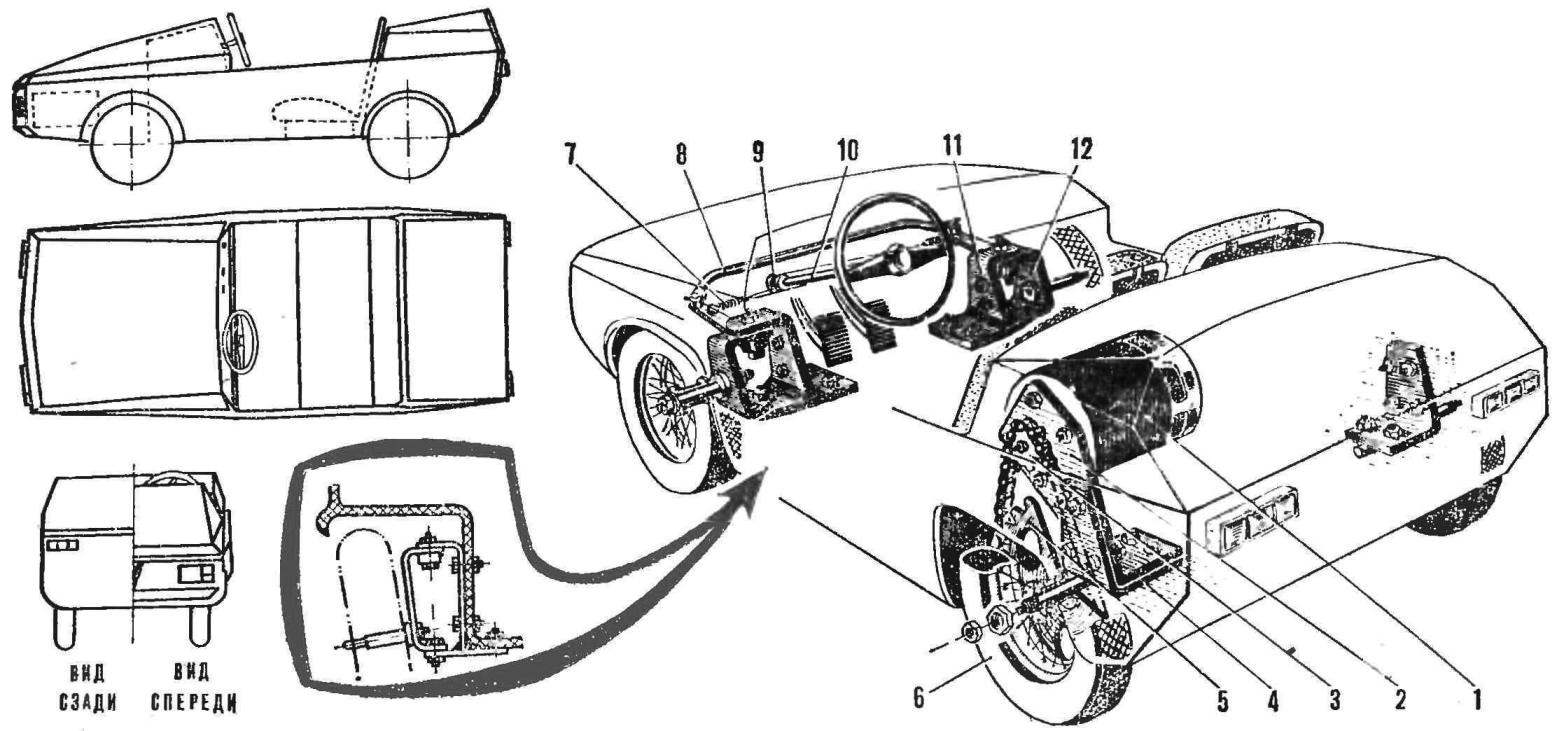

Electric ED-3 we called “Crocodile Gena” for a distinctive silhouette when open the hood. What is our design?

First of all, it is extremely light frameless car (its weight with battery is only 60 kg!) with a monocoque body, is laminated of fiberglass and epoxy on the blank, hammered together from boards, carefully crafted with a plane, vyskubenko, puttied up and blacked lubricated (with petroleum jelly). The thickness of the variable: sides — about 1.5 mm, bottom and hood — 2 mm. the Corners and flanging of the body have been reinforced with additional strips of cloth. Considerably stronger also wheel Kishi electric car — these are attached the suspension and engine.

Wheels from scooter. The rear axle is welded to a bent angle of steel plate thickness of 2.5 mm. bushing, drive wheel screw bike fixed sprocket (Z=48).

The rotary axle of the front wheels constitute a U-shaped snobs, bent from steel sheet of thickness 2.5 mm, which are welded to the levers — old Bicycle cranks. Axle pivotally connected to the plates mounted on wheel housings.

Electric — projection and details:

1 — motor, 2 — support bracket 3—sprocket (Z = 6), 4— second bracket with the axis, 5 — driven sprocket (Z = 48), 6 — rear, 7 — steering cable, 8 — transverse thrust steering linkage, 9 — cable drum 10 to the steering shaft, 11 — bracket, 12 — knuckles with the axle shaft.

The control of the front wheels cable. On the axis of the steering wheel is rigidly mounted a drum, around which hung a two-millimeter steel cable. Its ends embedded in the arms swivel axles of the front wheels.

The motor is improvised, or rather, radically transformed from industrial. So, the stator winding have him removed and replaced by a strong permanent magnet (dynamic speakers). Replaced and the rotor winding. The result is a motor with very interesting traction characteristic, to a very small extent dependent on the speed of the shaft. And because of the high efficiency the efficiency of this engine is so high that only twenty banks of batteries KN-28 the electric car can operate without recharging for about seven hours, traveling at a speed of 5— 8 km/h For the recharging of the battery requires six hours.

Speed adjustment for the motor by switching the groups of batteries is composed of five cans each.

The motor is attached to a steel bracket that is installed inside the electric vehicle in the left wheel well. On the shaft of the motor is setsuna asterisk, thus, the gear ratio of the chain transmission is 8.

Car double, which greatly facilitates the development of driving skills. It has almost all the attributes of the present — headlights, sidelights, “flasher” turn signal & horn.

G. GOLOVIN, member of the gathering, Chelyabinsk