Console bracket is made of metal pipe. Set the console ka two steel crossbars-bars Ø 8 mm, welded to the struts. In its upper part is drilled a hole for the axis, manufactured and installed in the same way as on the front bearing.

Box back support is made of sheet metal with a thickness of 2 mm. of Their principal dimensions In mm. 280Х185Х30 boxes placed on four rollers, each of which consists of two halves connected to each other by screws M6. Set the rollers on bearings No. 200. Bushings-spacers, machined from steel rod Ø 18 mm, prevent the bearing roller from the lateral shifts. Material for the rollers can be used not only steel, but aluminum or bronze.

To eliminate the possibility of a descent of the upper rollers from the rails, it is necessary to provide possibility of adjustment in height. To do this, the holes for the upper bolts it is better to make an oval.

Console rear strut their bases are attached to boxes with M6 bolts. To avoid deformation of the walls of the box when tightening the nuts between them, it is advisable to introduce a sleeve cut from a metal pipe. Console machined from bar Ø 30 mm; these are welded plate thickness of 2-3 mm, in which holes and inserted the bolts.

Front rear supports, which is a welded construction made of sheet metal with a thickness of 2 mm. Preferred method of attachment of the strut to the box — welding. But you can also use a threaded connection on the four M6 bolts.

Axis and the front support, made of steel rod Ø 8 mm with holes for cotter pins.

Material lining the rear of the ski is a metal sheet with a thickness of 2 mm. they drilled 12 holes Ø 3 mm and 2 holes Ø 8.5 mm, and chamfer the latest chiseled bottom. Smaller holes are designed for screws with which the pads are fixed to the ski, more for M8 screws with countersunk heads. After welding the heads of the screws M8 welds cleaned.

Ski-pusher (Fig. 5) made of sheet metal with a thickness of 1-2 mm in the form of a box with a pointed and bent up front. All the elements of the ski are joined by welding. At its upper and lower surfaces are cut out of the window. In the upper Windows are provided stops the rotation of the cleats. The latter are made of metal plates with a thickness of 10 mm. They are mounted on the ski, hinge, axis — steel rods Ø 4 mm, the ends of which are drilled holes Ø 2 mm and a depth of 3 mm. After it is installed on the ski of their flare.

Fig. 5. Ski-pusher:

1 — skiing, 2 — axis, 3 — grouser, 4 — comb 5 — bracket.

To grundsatzen M3 screws that attach the comb from a sheet metal thickness of 2-3 mm. On the combs, and grantsearch, cut the teeth are triangular in shape. The angle between the forming of the top is 60°. The height of the teeth of the cleats — 6 mm, combs — 4 mm.

Brackets, attached to the plate by M8 screws, ski-pusher is connected with the supporting ski, the plane of the slide which must be below 5 mm.

As a carrier the rear of the ski, we use the standard “Forest”, they are only slightly cropped.

Ideally, the functions of the pusher and the base of the skis have to carry one item. This design can be recommended, for example, for children with willigerod.

For the manufacture of rod connecting the lever with the console back support, used a metal pipe of Ø 16 mm and a length of 600 mm. At its ends are mounted with round nuts M8 flange. They can be machined out of rod Ø 15-16 mm. to eliminate the cranking and axial shifts, the nuts must be secured, better welding.

With the lever rod connects an l-shaped bolt, bent from steel rod Ø 10 mm; bending place obvalivautsya (before you bend the rod, place the bend saw a round file, the deepening). The part of the bolt, which enters into the sleeve on the arm, is processed identically to the console end of the back support. On the other threaded M8.

Console rod connects the adjusting bolt M8; hole it rastaquouere to Ø 10 mm. If the hand is not standard, make it yourself, privaris to washer stud or grub screw.

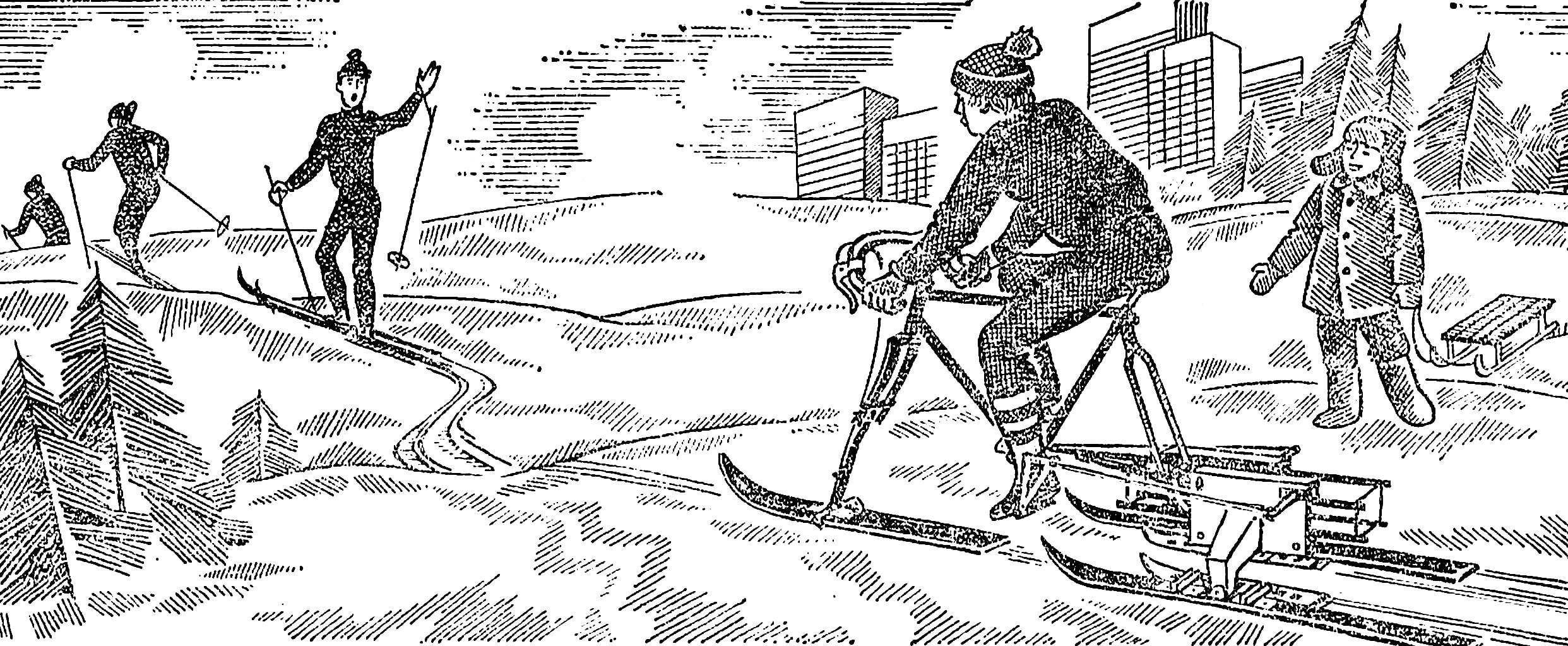

Technique ride villagewide kitsch is no different from a Bicycle. Moreover, since it is more stable bike, then learn to control it much easier.

When pedaling the rear feet with skis, moving on rollers along the guide rails of the bracket, making a reciprocating motion. When ski-pusher begins to slide back, combs clinging to the road surface and the lugs coming out the bottom of the Windows, rested in the snow. Slide stops and willigerod takes a step. Its length corresponds to the diameter of the circle described by the bushing, which is inserted l-shaped bolt. When sliding forward lugs are hiding in, ski-pusher. Sticking them on the snow is thrown through the upper Windows. Limiters eliminate the ceasing of the cleats.

On villagewide even untrained people can easily reaches speeds of 8-10 km/h of Course, for the trained athlete is not the limit. If someone would be hard to pedal, it is possible to shorten the step. However, after that drop the speed, but will decrease and effort.

The maneuverability of willigerod small: turning radius is 2 m. Therefore, it is better to travel on a relatively flat and straight tracks on the frozen river beds, channels or clearings.

Each occurrence of willigerod is a constant concern. People come up, ask about the design and capabilities of the machine. Many people light up the idea to build such a snowmobile for yourself or your children. I hope that this publication will help them to produce their own willigerod.

L. GORYNSKI, A. KOROTKOV

Recommend to read ROCKETS “CIRCLE” In the mid-1950s it became apparent gradual lag of the arms of the Soviet army air defense assets from the reached by that time, the capabilities of air attack. Continuous improvement of... PROFILE ONLY (THE BUILD-POLYOPIA). Building the model-polyopia begin with the manufacture of the fuselage (Fig. 1), the contours of the lateral projection should most accurately reflect the...