In the ideal case, VA = Vл (the maximum angle between the vectors is 45°). For the mechanism shown in figure 2, this equality is unattainable. However, it is useful to estimate the maximum speed of “dancing” the car at a known frequency of rotation of the rotor and a known length of the beam. Thus the position of common points, the team asked the levers, determines the direction and rate of movement of the apparatus.

For the permanent contact of the wheels with the ground the rays of the rotors damped springs. They also have U-shaped cutouts, reinforced liners, planting them in the swing in the grooves of the hub. Deviation this sets the embedded segments. When the wheel is rolled, say, a stone, the beam of the rotor on which the eye sits, rotates relative to the rotor hub on the segments, and at the same time moves with them up the grooves of the hub. At the same time compressed a spring, cushioning the blow wheel on a rock.

Fig. 2. The concept of “dancing posture” of the car:

1 — tie wrap, 2 — the command levers, 3 — body, 4 — ball joints, 5 — wheel, 6 — common point of the axes of opposite wheels, 7 — line of the axes of the wheels 8, 11 — beams of the rotor, 9 — slip joint, 10 — core, 12 — hinge rotation of the wheel, 13 — rod, 14 — lever, 15 — a pair of bevel gears 16 motor, 17 is rotor, 18 is the cross coupling 19 — cross 20 — eccentric.

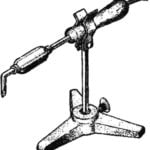

Fig. 3. The design of the rotor:

1 — body, 2 — power elements of the case, 3 pair of bevel gears 4 / command arm, 5 — housing, 6 — rod, 7 — slip joint, 8 — bottom of the rotor housing, 9 — spring, 10 — beam of the rotor, 11 — enhancing inserts, 12 — screws M8, 13 — segment, 14 — support pads, 15 — bottom of hub 16 — hub-17 — rocker stone, 18 — rivet, 19 — rod, 20 — lever, 21 cross coupling, 22 — cross, 23 — eccentric.

Finally, a bit about how you can still use the mover “dancing” car. If you combine it with skiing, “Ziban” will turn into a maneuverable all-terrain vehicle. The grip of the wheels-ski with the snow is great, great and the thrust of such propulsion.

It is possible that the Rover will have buoyancy due to the skis, then wheel-skis will provide traffic and on the water with a speed about 100 km/h.

High maneuverability “Sibuna” useful in the mechanization of loading and unloading in close, cluttered environments.

On the basis of “dancing” of the car can also develop new sports. What’s wrong with, say, motorized water Polo, soccer or figure skating?

N. KACHKO engineer

Recommend to read

AND COUPE, AND A MINIVAN

AND COUPE, AND A MINIVAN

European sales of this vehicle started in September 2001. An incredible price for a fully "packaged" AVANTIME sellers were asking $ 36 000!— not deterred buyers. The car cost them and... “COLLET” SOLDERING

“COLLET” SOLDERING

The conventional electric soldering iron (100 watts, voltage 220 V) through the use of technological replacement of nozzles turns into a versatile tool that allows you to perform several...

In fact, the first word of the title should not be enclosed in quotation marks. Because the vehicle N. Katchko can waltz, that was demonstrated to the participants one of the programs of the Central television “you can.” On his “Sebane” Nicholas whirled to the music in the Studio, intricate curves. This is a truly unique maneuverability of the apparatus with the propeller, protected by the copyright certificate № 1039790.

In fact, the first word of the title should not be enclosed in quotation marks. Because the vehicle N. Katchko can waltz, that was demonstrated to the participants one of the programs of the Central television “you can.” On his “Sebane” Nicholas whirled to the music in the Studio, intricate curves. This is a truly unique maneuverability of the apparatus with the propeller, protected by the copyright certificate № 1039790.