Have you ever wondered what it would be like to build a real Formula 1 racing car with your own hands? No, not just put a spoiler on a Zhiguli, but make a car that feels and behaves like an F1 on the track. One stubborn enthusiast took on exactly this kind of adventure, and now we will tell you how he creates the racing car of his dreams from scratch – alone, in his garage, with a bunch of non-standard solutions, a headache and a huge belief in his idea. This is not just a story about technology – it is a story about character, persistence and the ability to go all the way.

An idea that took off

It all started with a simple but bold dream – to build a racing car that would give the closest experience to real Formula 1. Yes, without a cosmic budget, without access to supercomputers and factories. But with intelligence, hands and a head full of ideas. The basis of the project was the engine from the Yamaha R1. Motorcycle, light, powerful. Only 200 horsepower, but the weight of the car is 1.5-2 times less than that of serial sports cars. This means that the acceleration will be wild, and the control – sharp as a scalpel. The goal? To achieve a power-to-weight ratio close to Ferrari, but in our own assembly, without unnecessary pathos.

It is interesting that the author was inspired by the racing cars of the 90s and early 2000s. Those times when the shapes were aggressive, the wings were complex, and the technologies were on the verge of magic. Modern F1s seem too boring and formalized to him. And here there is freedom, every curve of the body can be done in your own way. The main thing is that it works.

Carbon, titanium and a sea of experiments

When it comes to materials, it becomes clear: this is not just a garage project with a grinder and a tin can. Real engineering technologies are used here. Carbon is the king of the project. There is more of it here than in many small-scale supercars. The author has mastered vacuum infusion, makes his own matrices, experiments with waxes, separators and even drying in a homemade oven.

The approach is interesting: first one version of the part is made, then the second, the third – each one is lighter and stronger than the previous one. For example, the front wing: the first version weighed about 800 grams, the second – 530. Each subsequent part is an experience, reworking, improvement. And he does it alone, literally from scratch. Mistakes, alterations, dozens of hours of grinding – and all for the sake of one part weighing half a kilo. Imagine what level of self-discipline is needed to not give up when the resin bubbles for the third time or the matrix is warped.

Carbon wheels are worth a separate mention. They are not just beautiful, they are also incredibly complex. Carbon is a capricious material. It is difficult to process, it dulls the tool, it requires ideal conditions. But the result is wheels weighing 3.5 kg – many times lighter than standard ones. This means less unsprung mass, faster acceleration, sharper response to steering wheel turns. And all this – at home!

Brakes, suspension and thousands of nuances

If you think that brakes are just “press the pedal and the car stops”, you are deeply mistaken. In this car, everything works differently. The first version of the braking system turned out to be weak: the pedal was hard, and braking was uncertain. The reason? Too large master cylinders. We had to install smaller ones in diameter, change the layout, increase the pedal travel. But now the force is transmitted effectively, and the car really brakes as it should.

The suspension is also not far behind in complexity. The levers, designed for huge loads, are welded, milled, tested. And again – more than once. And also – problems with the heat resistance of the resin, reinforcement with carbon fiber stockings, the fight against backlash and adjustment of angles. It is not easy to assemble – it must be constantly tested, adjusted, adjusted. Real engineering, only in a garage, without access to laboratories.

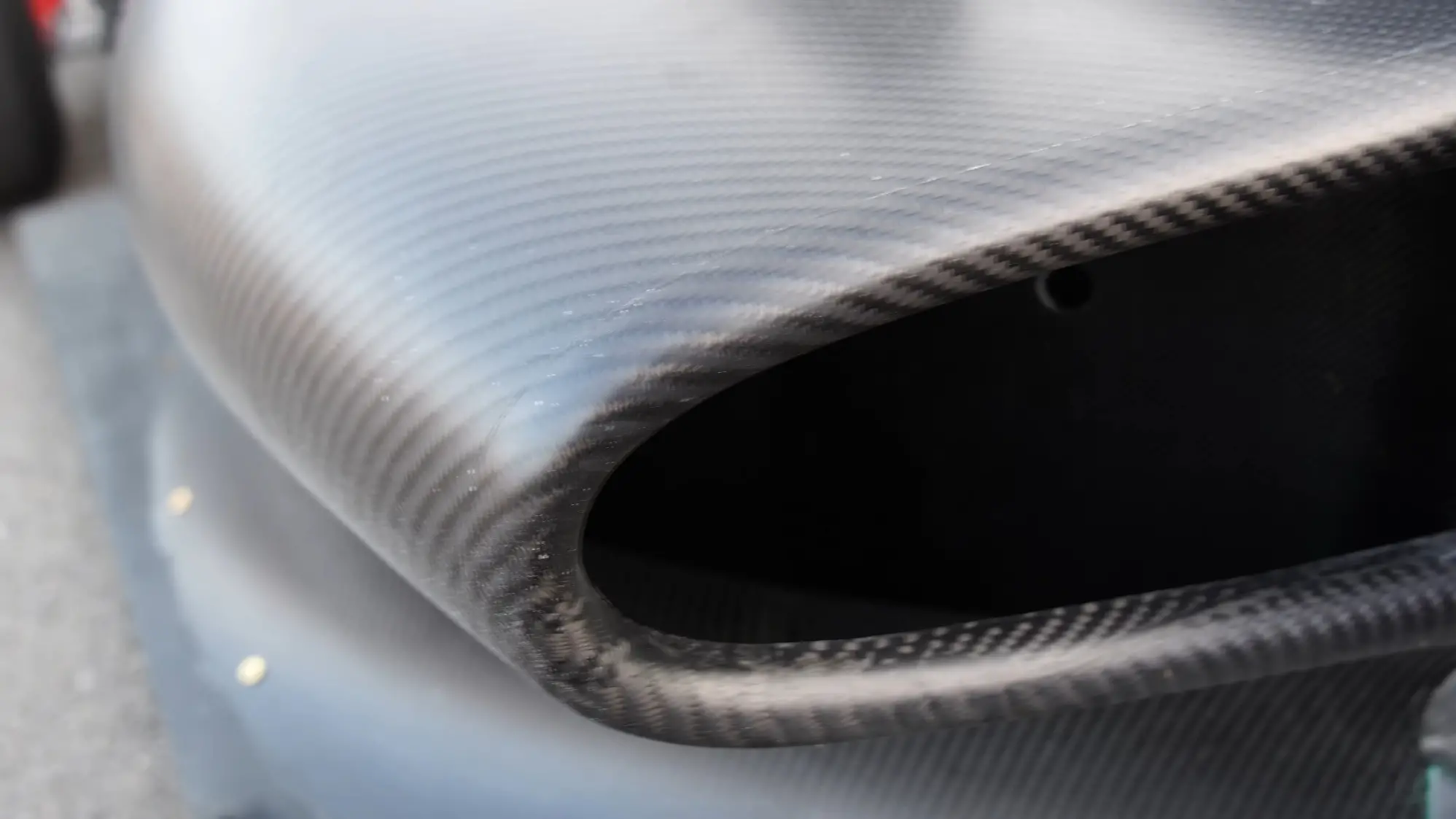

Aerodynamics and working with air

Aerodynamics is the soul of a racing car. Air can be your ally or your worst enemy. In this project, air is your assistant. The front wing is complex and multi-slotted. The bottom is as smooth as a mirror. The diffuser is powerful. Everything is designed to press the racing car to the track at high speed. And although simulations are a useful thing, reality often makes its own adjustments. That is why the author plans to conduct real downforce testing – to understand how accurately the theoretical calculations work.

Air intakes, openings, gills – all this regulates air flows. But not everything works perfectly right away. Sometimes you have to redesign, sometimes – sacrifice design for efficiency. But the result is stability, stability and control at high speeds. And the car has already accelerated to 190 km / h on a short straight!

Electronics, steering wheel and car intelligence

The steering wheel in this racing car is a mini-computer. Carbon body, anatomical handles, a display that shows everything: revs, gears, temperature, GPS timer. There is even a quickshifter – a system that allows you to change gears without a clutch. And it is homemade, built on strain gauges and pneumatic cylinders. This technology is usually found only in professional racing. And here – everything is done with your own hands.

Wiring? Not just wires, but a whole science. Aviation cables with Teflon and metal insulation are used so that everything can withstand the heat of the engine compartment. Every contact, every chip is measured, checked and re-soldered if necessary. The starter panel, relay, battery – everything is made to work stably in any conditions. Yes, there are no “twisted wires” here. There is an engineering approach to everything.

Trials, mistakes and small victories

The first ride is like first love. Exciting, scary, but unforgettable. The car starts, accelerates, enters a turn – and suddenly you understand: it was not in vain. Yes, there were problems. The wheels locked, the quickshifter glitched, the clutch behaved strangely. But the sensations were great. After fine-tuning the camber and toe, after adjusting the shock absorbers – the car’s behavior changed dramatically. It drove “as it should”.

Acceleration to 100 km/h in 3.41 seconds. A quarter mile in 11.6 seconds. These are results that even professional teams can be proud of. And here is a lone wolf, without a budget, with burning eyes and hands in the right place. Each test is a step forward. Even with mistakes, even with back pain from constant improvements, but forward.

Conclusion: When a dream is stronger than circumstances

This project is not just a car. It is a symbol. A symbol of the fact that with desire, hard work and a drop of madness, you can do things that seem impossible. The car is not finished yet, there is still a lot ahead – painting, tuning, competitions. But the main thing is that it has already been done. From scratch. From nothing. By the hands of a man who did not give up.

And this is inspiring. I want to believe that such stories will multiply. That other enthusiasts will say to themselves: “Why not?” – and start creating. Because great things are born not in laboratories, but in the heads of those who believe. Even if everything is against them.

I. NEGODA