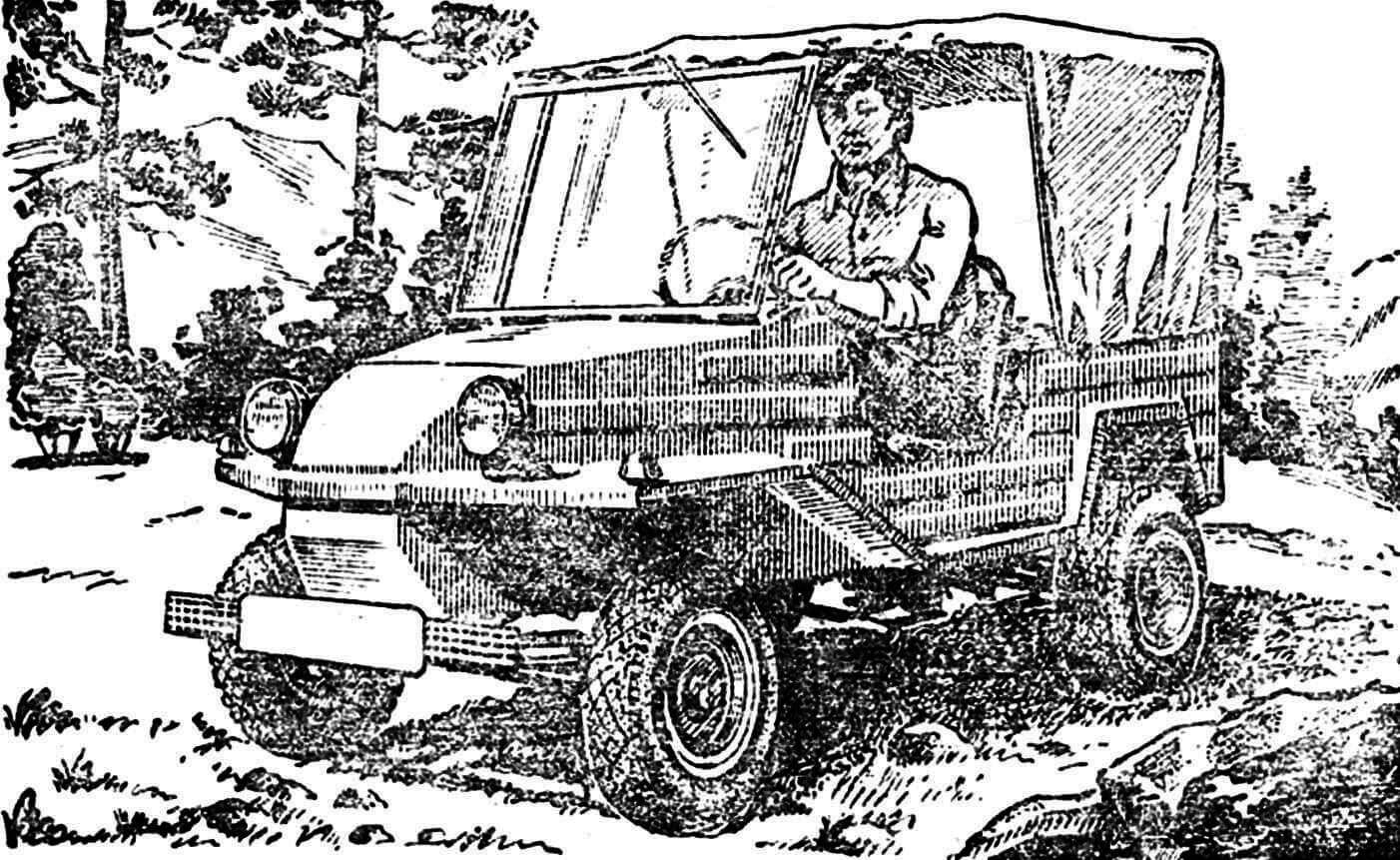

Club members from the Vologda House of Young Technicians named their microcar “Camel” for its high cross-country ability and unpretentiousness. Along with serial components (mostly from a motor scooter), the car also uses home-made chassis elements – for example, the front axle. Working on the machine allowed novice designers to gain not only practical skills, but also initial theoretical knowledge in the field of mechanics, materials technology, and strength of materials. Today, the head of the children’s auto design laboratory, A.V. Krylov, talks about the car.

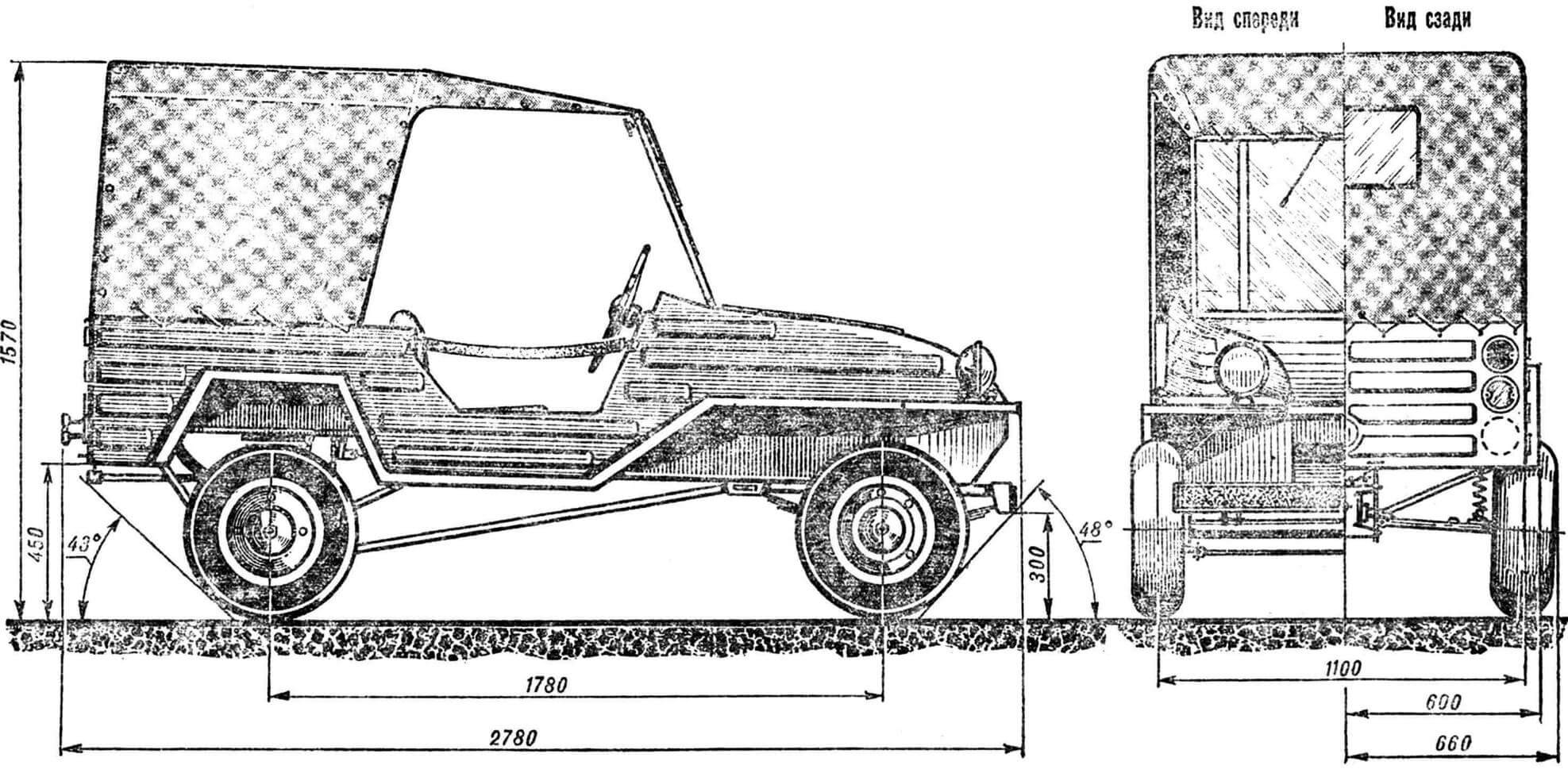

We conceived the Baby Camel primarily as a car for teaching schoolchildren the basics of driving. And not only on smooth asphalt, but also in difficult road conditions. Despite its modest size, it can be classified as a cross-country vehicle – “jeep”. Thanks to significant departure angles and a low dead weight, our minicar is capable of covering even areas that are only feasible for UAZs and Nivas.

We used the T-200M scooter engine as the power unit. Only the power system (the air purifier was taken from the M-105 Minsk motorcycle) and the ignition system (a magneto from the PD-8 tractor launcher was supplied) underwent partial changes. The muffler was used from the factory, and the fuel pump was from a boat motor, for which it was necessary to insert an additional fitting into a hole drilled in the engine crankcase under the cylinder, where the bypass passage passes. The fuel tank capacity is 12 liters and is enough for a range of 200 km.

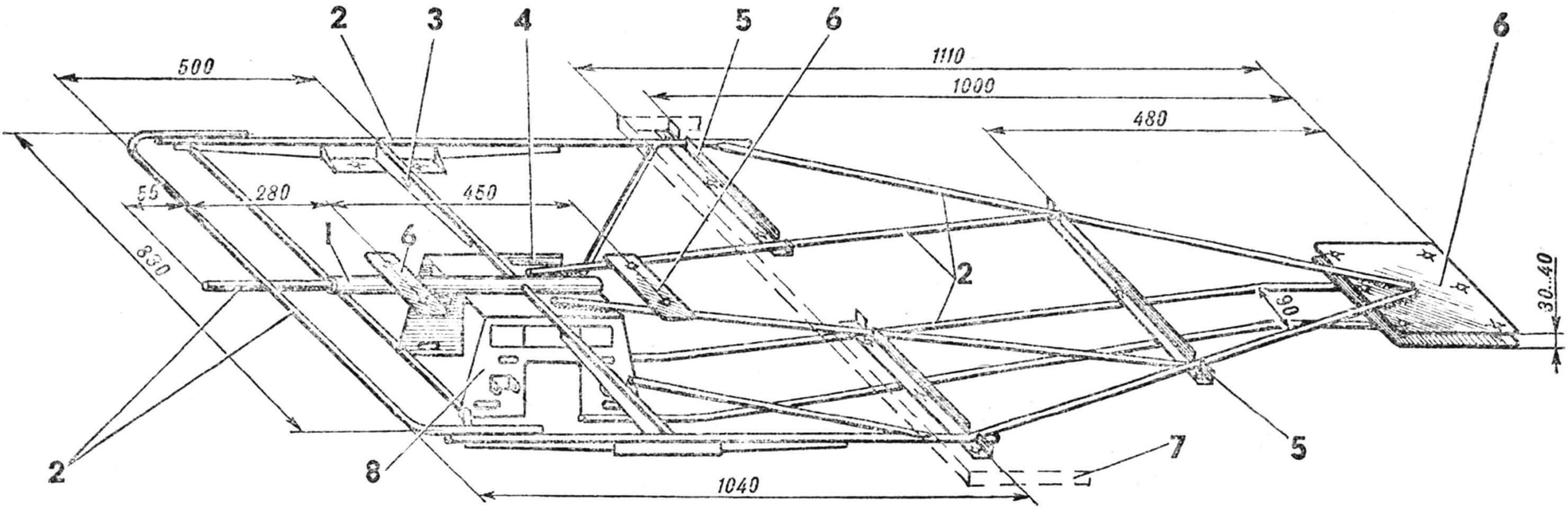

The transmission of the “genie” consists of an unchanged clutch, gearbox of the T-200M unit and a chain drive. A 12.7mm pitch chain connects the transmission sprocket to the differential driven sprocket; the latter is borrowed from a cargo scooter. The use of a differential with a built-in clutch made it possible to provide reverse gear.

1 — pipe Ø 34 mm, 2 — pipes Ø 21 mm, 3 — holes for sprinkling the muffler, 4 — cut for the chain, 5 — transverse side members, 6 — body mounting plates, 7 — underbody line, 8 — rear axle housing.

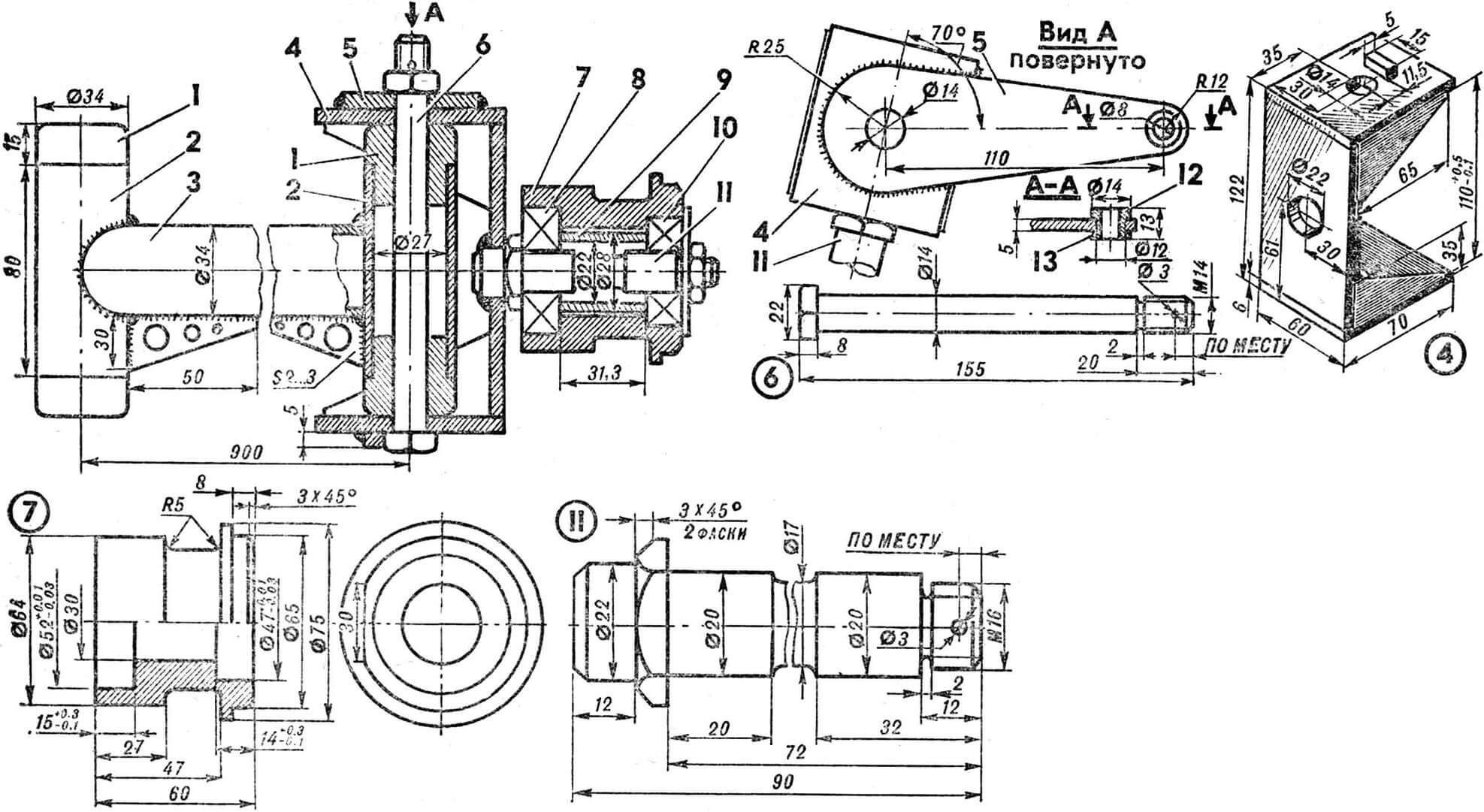

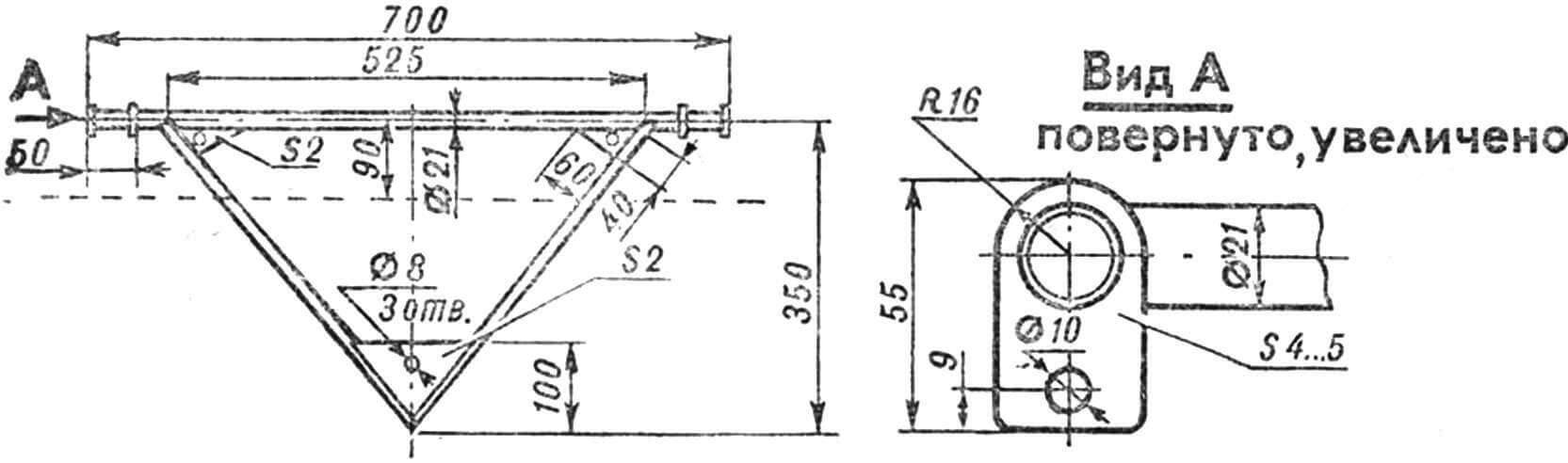

The wheels are taken from the S3D motorized stroller. The front axle is homemade, it is a continuous pipe with a dependent suspension on two longitudinal springs. Steering knuckles with pressed-in sliding bearings are welded to the ends of the pipe. These knuckles are fitted with pivot brackets with wheel axles welded into them. The steering mechanism (column and gear) was borrowed from the Moskvich-401 car, the trapezoid was made independently according to the simplest scheme.

Rear axle from a cargo scooter. It has independent suspension on four coil springs and is attached to a specially fabricated body welded to the frame’s metal structure.

1 — sleeve bearings, 2 — steering knuckle housings, 3 — transverse beam of the bridge, 4 — pivot bracket, 5 — swing arm of the large transverse rod, 6 — king pin, 7 — front wheel hub, 8 — bearing No. 304, 9 — spacer bushing, 10 — bearing No. 204, 11 — front wheel axle, 12 — plain bearing (bronze), 13 — retaining ring. In view A, the kingpin is not shown

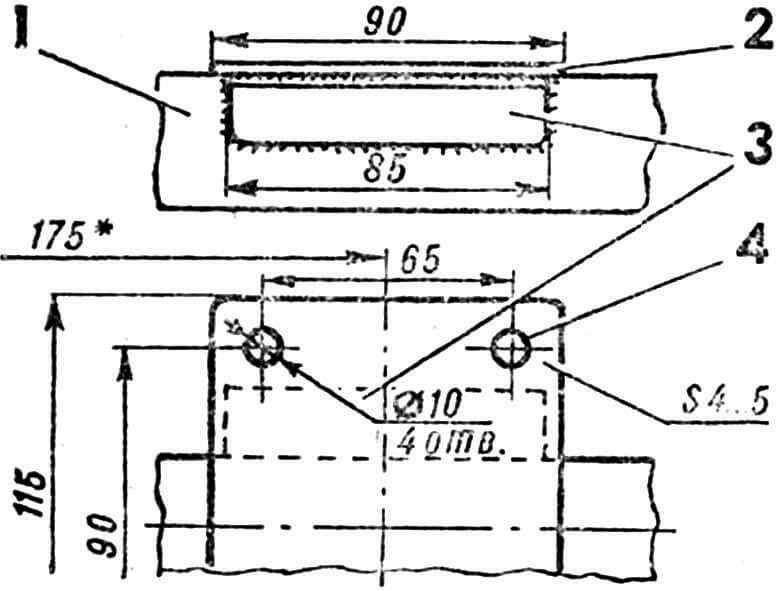

Body – double, open, full-supporting type; It is a typical joinery construction, fastened with screws, bolts and epoxy glue. The thickness of the plywood sidewalls is 8 mm; the necessary rigidity is ensured due to the curvilinearity of the sides, the presence of frames-stiffeners and gluing with fiberglass in one layer.

1 — front axle beam, 2 — plate, 3 — reinforcing angle (15X15 mm), 4 — holes for spring ladders. The asterisk indicates the size to the front axle kingpin axis.

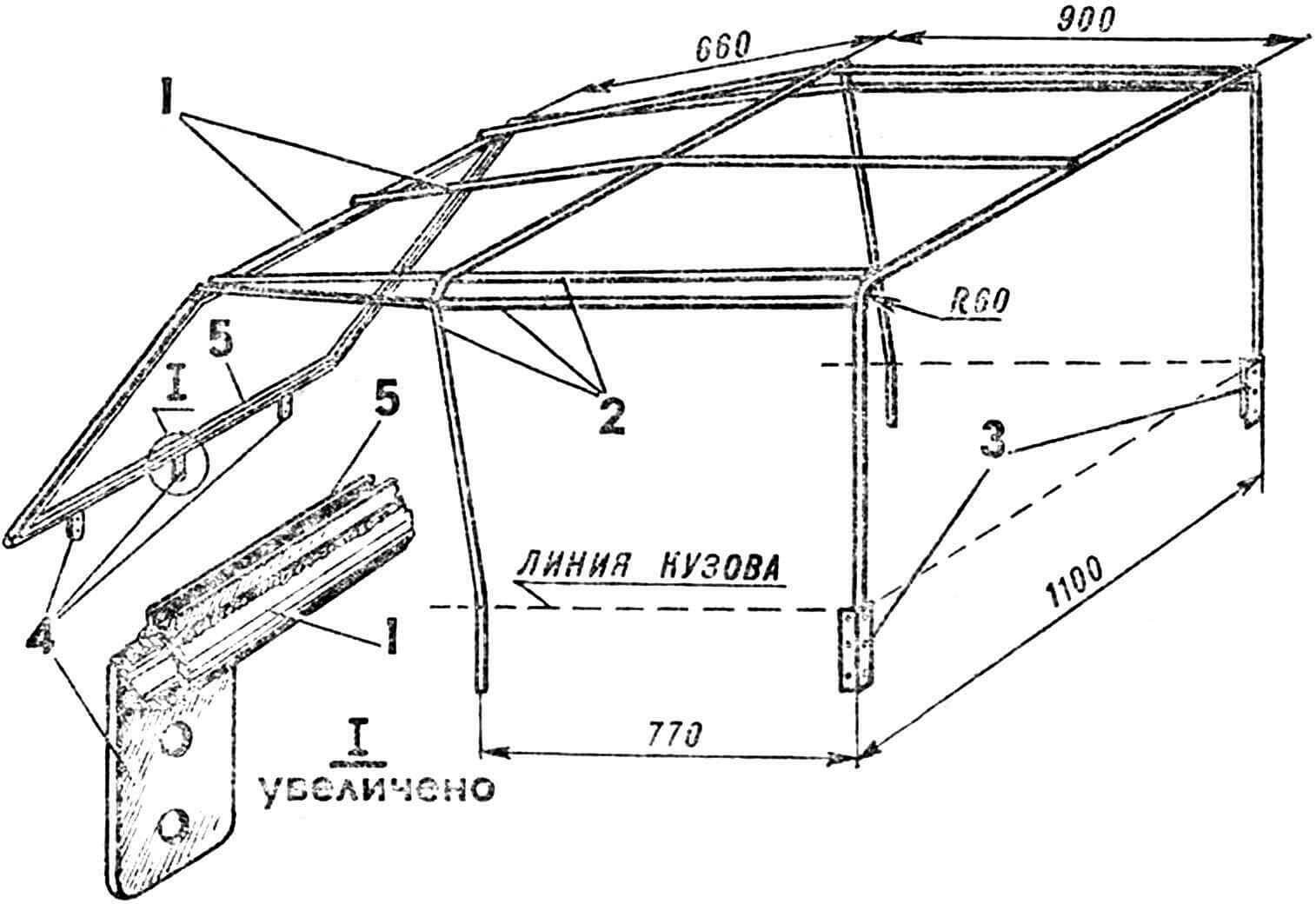

All units are attached directly to the body – usually with bolts and large washers. The hood and trunk lid are made of sheet duralumin 2 mm thick. An awning can be stretched over the body, for which a special frame is welded from Ø 14 mm pipes, rigidly connected to the windshield frame.

The flat front fenders are made from 3mm plywood, with slats running along their outer edge to add rigidity. The wing is fastened with screws to special longitudinal strips of the body.

1 — pipes Ø 21 mm, 2 — pipes Ø 14 mm, 3 — corners 30Х30Х140 mm, 4 — brackets for fastening to the body, 5 — channel for fastening the windshield.

In the front part of the body, on the triangle for attaching the front spring lugs, there is a bumper cut from a steel sheet.

The clutch and throttle valve of the carburetor are controlled by a cable on the pedal. The service brake (on the rear wheels) is activated in the same way. And the handbrake is only driven by the front wheels.

TECHNICAL SPECIFICATIONS

Body design and type. . full-carrying, phaeton Number of seats (with driver) – 2

Maximum speed with full load, km/h 75 Braking distance with full load at a speed of 30 km/h, m — 6

Minimum turning radius (along the axis of the outer wheel’s track) no more than, m – 2

Ground clearance, mm – 180

Overall dimensions, mm:

length – 2780

width – 1320

height – 1570

Dry weight of the car, kg – 250

Car’s own weight, kg – 450

main gear

Type – chain, chain PR-12.7-1800-2

Chain pitch, mm – 12.7

Number of links – 84

Chassis

Front axle – continuous tube

Front suspension – dependent, on two longitudinal springs

Rear suspension – independent, four coil springs

Brakes

Foot (working) – shoe, for two rear wheels

Manual (parking) – block, on two front wheels

Width of friction linings, mm:

front – 35

rear – 40

A. KRYLOV, Vologda