An important element of the power set — box-shaped keel, located ka the bottom of the boat along the axis of symmetry. The keel is formed by two shelves (upper and lower), connected by walls made of plywood with a thickness of 2 mm. flange Width: 20 mm, thickness — variable: bow shelves, it is equal to 12 mm, in the area of Rodan — 20 mm. throughout the length of its keel plywood walls supported by struts.

The housing is encased aircraft plywood with different thickness in the nose — two mm, then the thickness gradually increases and the area of redan is 7 mm. the expediency of such gain we have seen after a collision with a floating snag. Less” durable plating would not survive.

Ha boards — plywood with a thickness of 2 mm, the fairing is 1 mm. the Outside of the entire boat covered with a layer of fiberglass stamps of ASTT(b)With epoxy resin. To keep the boat’ kicking the water and had a clean smooth surface, which is important for its wrapping, sheathing stripped, treated by epoxy putty and painted with synthetic enamel and then covered with a layer of parquet lacquer.

Bolshej of the equipment and devices Kranolta placed and the bow of the boat: tow hook, PA — Pitot TP-156 (for measuring speed and altitude), an antenna pole of radio battery.

In the middle of the boat cockpit. In it one behind the other aircraft has two seats with seatbelts and niches for parachutes. The rear seat is located near the center of gravity Kranolta to alignment machines less dependent on the passenger. The floor in the cabin is made of polyethylene sheet, placed him under transaction control the ailerons, elevators and turning. To the left of the pilot’s seat on the panel there is a handle engine control (Gaza strip) and the block electrotumbao. In the cockpit, on the bulkhead No. 4, mounted instrument panel with indicators of speed, altitude, turn and slip, as well as a variometer, compass, artificial horizon, tachometer, ammeter, voltmeter, and temperature of the cylinder heads of the engine. The cockpit is transparent canopy. The front part is fixedly mounted on the fuselage, rear — removable. Castles of the flashlight make it easy to access the cockpit. In an emergency you can ecranele bistro to leave, dropping the lantern.

To the frame number 10 on a special cradle suspended fuel tank. He is drawn to the lodgement metal strips, lined with felt. The points of fastening of the keel and auxiliary wing spars are mounted not frame № 15.

For ease of transportation and repair Kranolta his wing is made up of two consoles, connected to the boat with bolts M10. Front and rear docking units — mounts made of steel 30KHGSA. They are connected with the flanges of the side members with M5 bolts and are designed as the same wing, ka fourfold overload with a safety factor of 1.5, i.e. total margin of safety equal to 6. This supply is sufficient for normal operation of the apparatus.

The console is odnaleziono design with rear auxiliary wall, stringers, four to nine ribs.

Fig. 6. Dependence have thrust and aerodynamic drag from the speed of flight:

A — the aerodynamic drag, G is the flow resistance, C — total, T is the available thrust, And excess thrust; and — navigation mode, b — plane, in — overcoming “hump” of resistance, g is the separation from water, d — flight.

Fig. 7. The polar ESKA-1 at different heights.

Fig. 8. The pressure distribution on the airfoil.

The main spar consists of two shelves, walls and diaphragms. Top shelf has a thickness 34 mm at the root and 18 mm at the end of the spar, the lower — respectively 25 and 18 mm flange Width 38 mm across the span. Glued shelves from a set of pine slats with epoxy resin in a special clamping bench. The walls of the spar on the plywood VS-1 with a thickness of 1.5 mm. And for the strength of the fibers of the outer layers of plywood are oriented at an angle of 45° to the axis of the spar. The diaphragm is made of pine planks 34X8 mm cross section, glued to the shelves with the corners of Linden. The construction height of the spar along the span is determined by the thickness of the airfoil.

Rib number 1, 2, 3, 4, and 5 – truss and truss-beam construction, pine shelves and diagonals, tied together with plywood gussets. Rib No. 1 — power, continuous, it is located on the attachment points of the wing. Rib No. 6, 7, 8 and 9 — beam construction, with shelves made of pine and the walls out of plywood with a thickness of 1.5 mm.

An auxiliary rear spar similar to’ core. His troops — a constant width of 32 mm. the thickness of the upper shelves to the root of the spar 20 mm, on the end is 12 mm; the thickness of the lower — respectively 15 and 10 mm. on both sides of the spar sheathed mm aircraft plywood.

SUNGLASSES perched on the end of the console at an angle thereto. Under the plywood sheathing there are two spar, bow stringer and six ribs. The front longitudinal box section with shelves 25 X 12 mm and a wall made of plywood with a thickness of 1 mm. of the Rear spar-channel with the same shelves and the wall.

Aileron plane type consists of a spar, front, rear stringers and five girder ribs. Spar-channel shelves 15X10 mm and the plywood wall of thickness of 1 mm To the spar glued pine boss to install the hardpoints of the Aileron.

The internal cavity of the wing is double-coated with linseed oil. Wing SUNGLASSES and ailerons on the outside covered with cloth AST-100 covered with four layers of lacquer NC-551 and painted with white alkyd paint.

Resistance to water ekranolyot attach the floats from foam PVC 1. Omi covered with a layer of fiberglass of astg(b), and attached with M5 bolts to the wing not four ears of steel 30KHGSA.

Tail — keel with rudder and a water rudder and stabilizer with rudder heights. Keel sheathed millimeter plywood and is a conventional design of the two side members, eight ribs and a sock. The rear spar-channel with pine shelves 28X14 mm and the wall of the ka of plywood with a thickness of 1.5 mm. the Front spar of the same type as the rear, only the shelf of his less — 14X34 mm. To reduce malkivka socks keel broken ribs and form with the front edge of the keel is almost straight angle.

The rudder consists of plywood covered with a sock, spar, stringer and tail thirteen ribs. The steering wheel with a cloth AST-100, and suspended to the keel at two points.

Stabilizer in plan trapezoidal profile symmetrical NASA-0009, uGod installation plus 5° from horizontal Kranolta. The frame of the stabilizer is assembled from longitudinal support walls of the front stringer and 13 ribs. The stabilizer is bolted on four ears of the keel. The nose of the stabilizer is sewn plywood BS-1 with a thickness of 1 mm.

Stabilizer spar box section on pine wolves 20X12 mm and walls of mm plywood. On the spar there are two eyelets for fastening the struts from aluminum tubing teardrop-shaped cross-section. Pipe stiffen the combination of “Kiel — stabilizer”.

The Elevator is the same the wheel turns; attached to the stabilizer at three points. The rudder and stabilizer covered with a cloth AST-100, covered with paint and dope.

Rotor installation includes a two-cylinder four-stroke carburetor motorcycle engine M-63 output of 32 HP, special step-down gear reducer with a gear ratio of 1 : 2,3, hardwood SDV propeller-2 fixed pitch, Ø1,6 m and motor frame made of steel tubes Ø 26 mm.

The engine is attached to Motorama the M8 bolts through the rubber dampers and is mounted behind the cockpit on the nodes of the power frames No. 9 and 12. The maximum power the engine develops 4700 rpm gear propeller gets 1900-2100 rpm This corresponds to 95-100 kgf thrust.

The launch of the propeller installation is performed by the starter ST-4. It is installed on the engine through the gears and it rotates the camshaft. The power source of the electric starter is the battery ITSELF-28 with a voltage of 12 V. To ignition system worked reliably, the engine is equipped with magnetos “KATEK” driven by the camshaft via an intermediate shaft extension.

Standard carburetors did not satisfy us with its inconsistent, especially when sudden changes in engine operating conditions. We replaced it with a single carb “Weber-32 JEM”.

As you can see, the design of the ESKA-1, in principle, simple. Dominated by wood, plywood, fabric. The metal parts are kept to a minimum, and their production are not scarce steel grades and alloys. Externally ecranele is also quite simple, complex, curved surfaces little. Therefore, we believe ESKA-1 is easy to reproduce for those who intend to build ecranele on the basis of just such a wooden structure.

TECHNICAL DATA KRANOLTA ESKA-1

Scale, m……………6,9

Length, m……………7,8

Height, …………….2,2

Root chord of wing, meters……..4,11

Lines length, m………..1,0

The narrowing of the wing …………4,11

Elongation …………..1,996

The average aerodynamic chord (SAKH), m . 2,873

Wing area, m2……….13,15

Total bearing area, m2……13,39

The area of the horizontal tail, m?. . . 3,0

The area of the vertical stabilizer, m; . . . . 3,6

Mass of structure, kg …….234

Full flight weight, kg……..450

Wing loading, kg/m2………39,5

Engine power, HP……….32

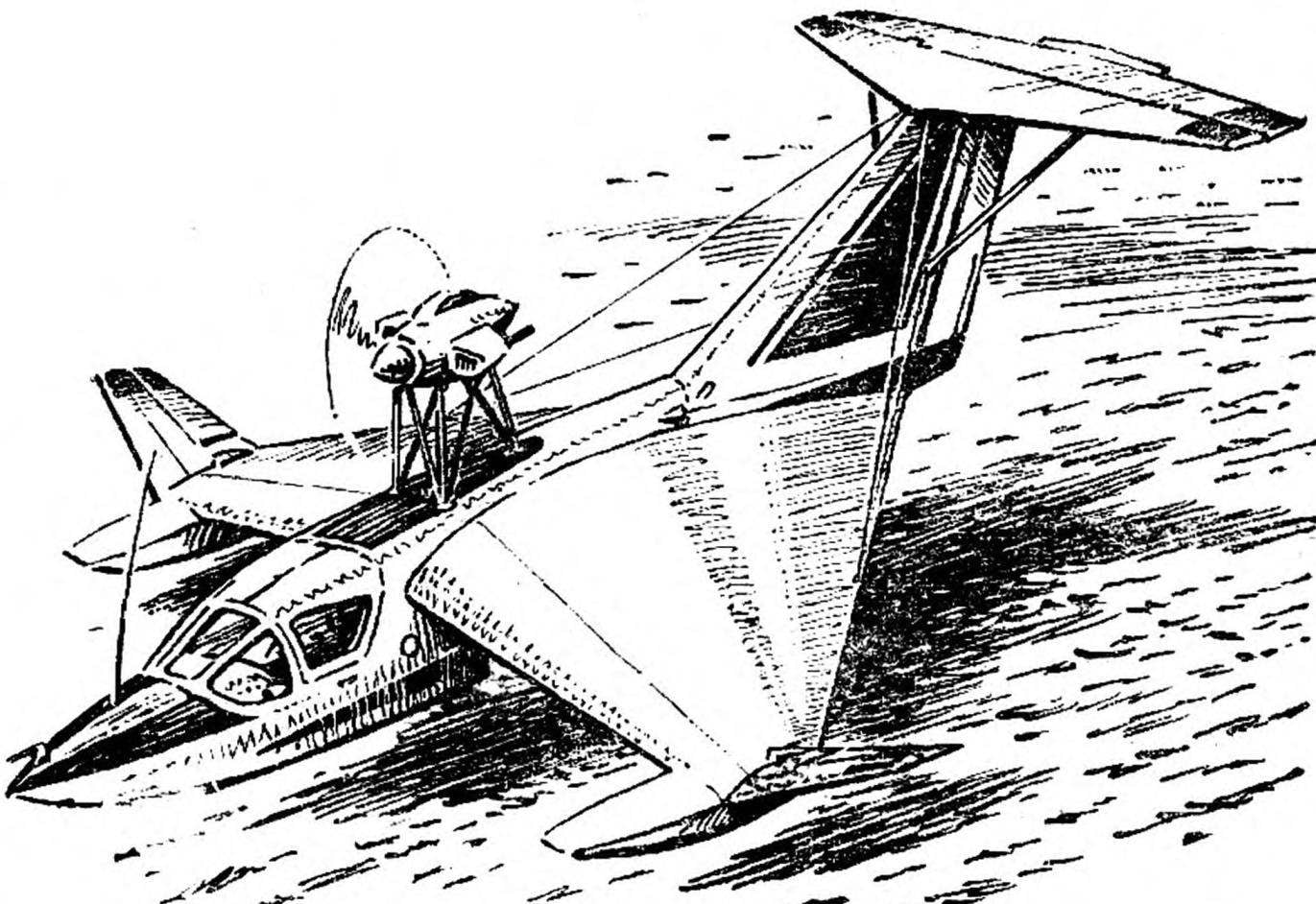

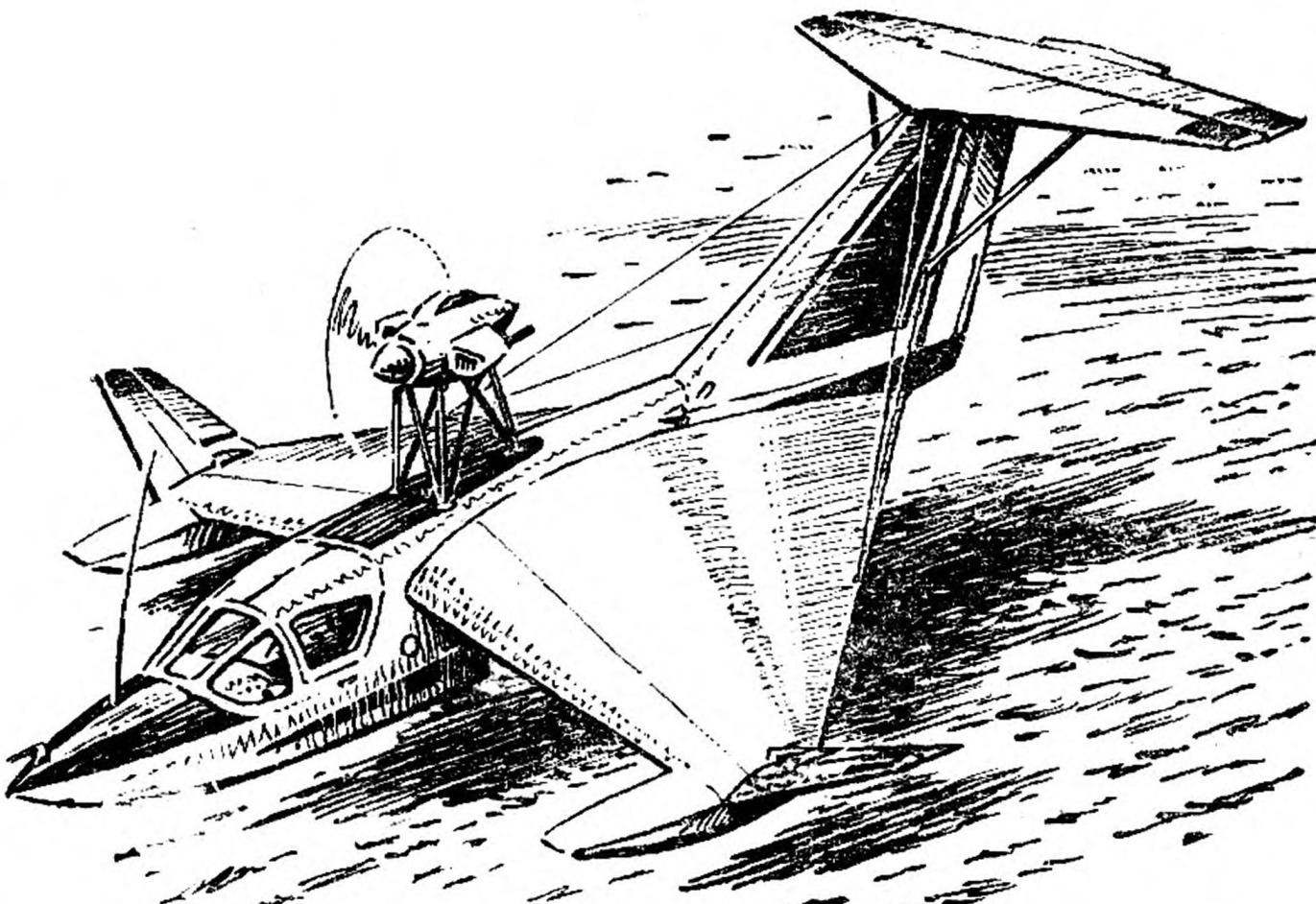

In the Soviet and foreign scientific and popular journals have repeatedly reported Nicoleta apparatus-ekranoplan, including the Soviet pilot the rescue boat amphibious ESKA-1. This car is Amateur-built successfully last cycle of flight tests, designed by Moscow engineers Gramatzki A., E. Grunin, S. Chernyavskaya, Y. Gorbenko and N. Ivanov. Flight tests were conducted by an engineer A. Gramatzki, and then the pilot Baluev A.. ESKA-1 was exhibited on one of the Central exhibitions NTTM was awarded a bronze medal VDNH USSR, and its creators — signs of the winners of the NTTM.

In the Soviet and foreign scientific and popular journals have repeatedly reported Nicoleta apparatus-ekranoplan, including the Soviet pilot the rescue boat amphibious ESKA-1. This car is Amateur-built successfully last cycle of flight tests, designed by Moscow engineers Gramatzki A., E. Grunin, S. Chernyavskaya, Y. Gorbenko and N. Ivanov. Flight tests were conducted by an engineer A. Gramatzki, and then the pilot Baluev A.. ESKA-1 was exhibited on one of the Central exhibitions NTTM was awarded a bronze medal VDNH USSR, and its creators — signs of the winners of the NTTM.