Many people are now interested in cycling. Kirill Gagloev from Sergiev Posad has been actively riding since childhood; it seems he has tried all possible types of two-wheeled vehicles. Over time, the hobby even grew into a profession: Kirill became a qualified bicycle mechanic. However, this work is seasonal – what to do in winter? It was then that I remembered that there was a bicycle that I had never ridden before, but it would be very interesting to try! But where can I get it? But first things first…

The fact is that the bicycle we are accustomed to – with two wheels of the same diameter and chain drive to the rear wheel – did not immediately acquire. The first such mechanism appeared only in 1885 and was subsequently called the “safe bicycle”. Unlike its predecessor, the “regular” or “tall” bicycle, it was also called the “penny farthing” or “spider”. A distinctive, memorable feature of this bicycle from the century before last is a huge front wheel with direct pedal drive and a rear support wheel several times smaller in diameter. This, by the way, is where the nickname “penny farthing” came from: after the name of the coins in circulation at that time, which varied greatly in size. This bicycle was nicknamed “Spider” either because of the interlacing of spokes on the front wheel, reminiscent of a spider’s web, or because the cyclist, moving his legs on such a machine, slightly resembles a spider.

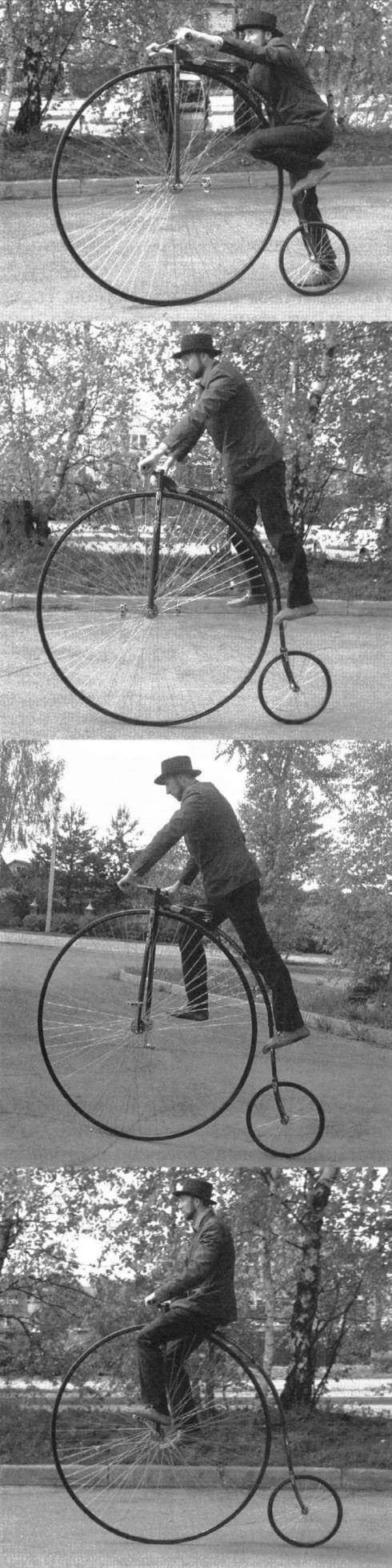

Nowadays, such vehicles can most often be seen live in the circus. And riding them requires acrobatic skills, since the high seating position makes it quite difficult to maintain balance. These are, of course, replicas of those vintage bicycles. The original technique, which has survived to this day, can be found in museums and among collectors. These unusual designs were not produced for long, from about 1870 until the end of the century.

So Kirill got excited about the idea of mastering the “spider”, but to do this, he first had to… make it!

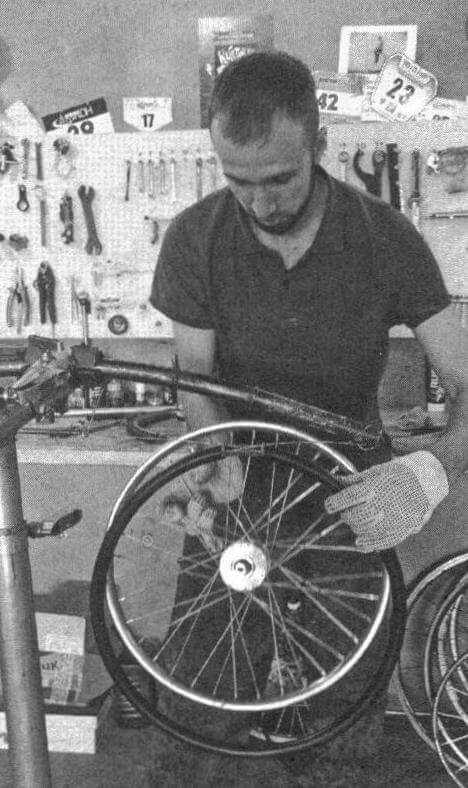

The most important detail of such a bicycle is, as everyone will think, the huge front wheel, and he will not be mistaken. Kirill and his friend assembled the first such wheel by taking two rims from a Soviet Sputnik bicycle. We cut them, carefully straightened them using a press and wooden mandrels, and the resulting sectors were connected by argon welding. The diameter was just right.

The next difficult task is to come up with a tire. It would have been possible to use a thick-walled hose of the appropriate diameter, but I wanted something more technologically advanced and elegant. What if you try to make an inflatable tire! They took two tires from the same Sputnik, pulled out the side wire rings from them, glued two tires together into one large one, restored the sidewalls with a cable, the ends of which were woven towards each other and soldered. The camera was also glued together from two. Overall, it turned out well; such a wheel with a pneumatic tire rolled perfectly, especially on rough terrain, on ice and snow (this was in early spring).

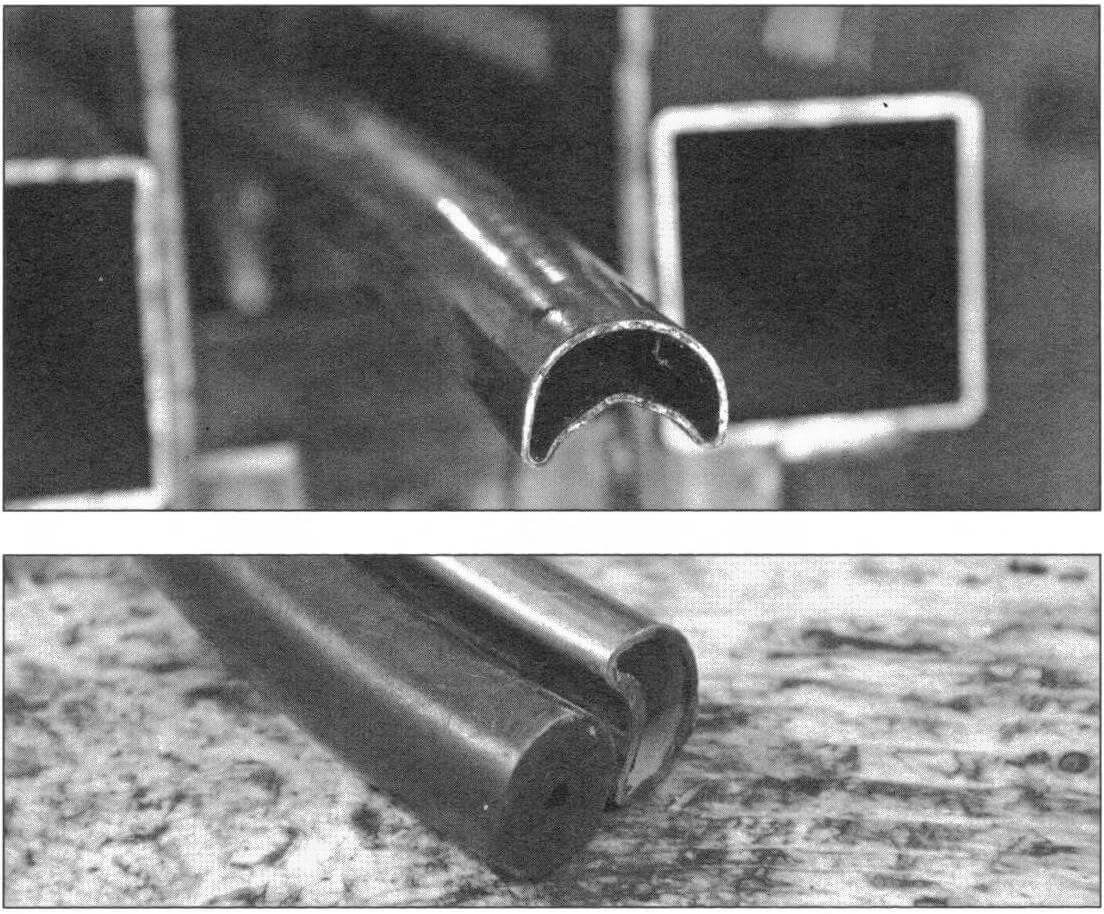

True, the tubes burst quite often, and it was also impossible to select the diameter of the wheel: its size was determined by the tire. This wheel also had one more significant drawback: it had a single rim, and therefore it did not hold the lateral load well. Modern bicycles use stiffer rims that are hollow in cross-section. This means that for the “spider” (having made one, you immediately wanted to build the next one) you need to make one.

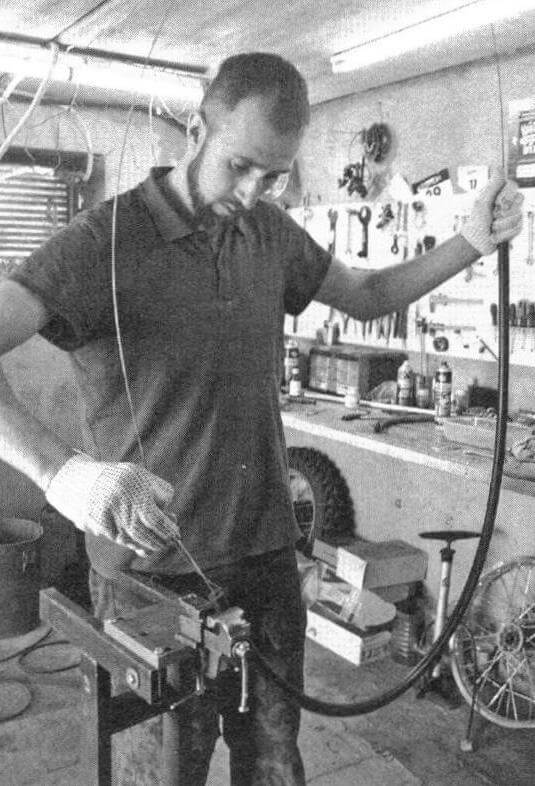

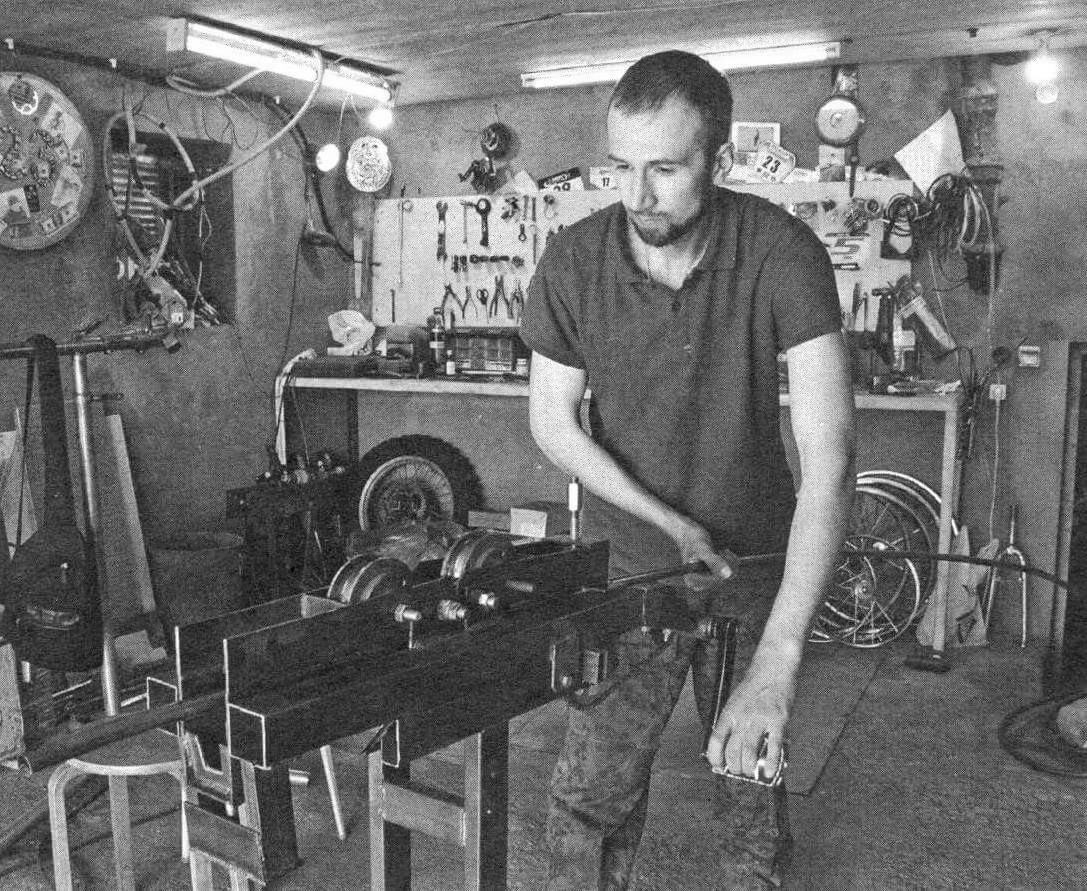

To solve the problem, a special machine was designed and assembled that turns a 22×1 mm stainless steel pipe into a U-shaped profile, and at the base of the “U” there is a cavity. You turn the handle, two chain drives rotate rollers of a certain shape, which flatten the pipe. In several passes the required profile is obtained. Having reconfigured the machine, the profile is bent and rolled into a rim, which can only be welded. Of course, you still need to drill, having calculated the pitch, holes for the spokes that will connect it to the central axis-hub.

Now Kirill makes rims with an accuracy of 5-10 mm in diameter. It is appropriate to note here that each bicycle is individual, made for a specific person. After all, the seat, unlike modern bicycles, is mounted on a frame without the possibility of height adjustment, which means that you need to select the wheel diameter so that it is as comfortable as possible for the cyclist to pedal with the greatest efficiency. For example, the Peugeot company produced penny farthings in three sizes: with a front wheel with a diameter of 48, 50 and 52 inches. In Sergiev Posad, production is strictly individual: Kirill made a “big one” for himself with a drive wheel diameter of 57″, for his wife – 50″, for a friend – 53″.

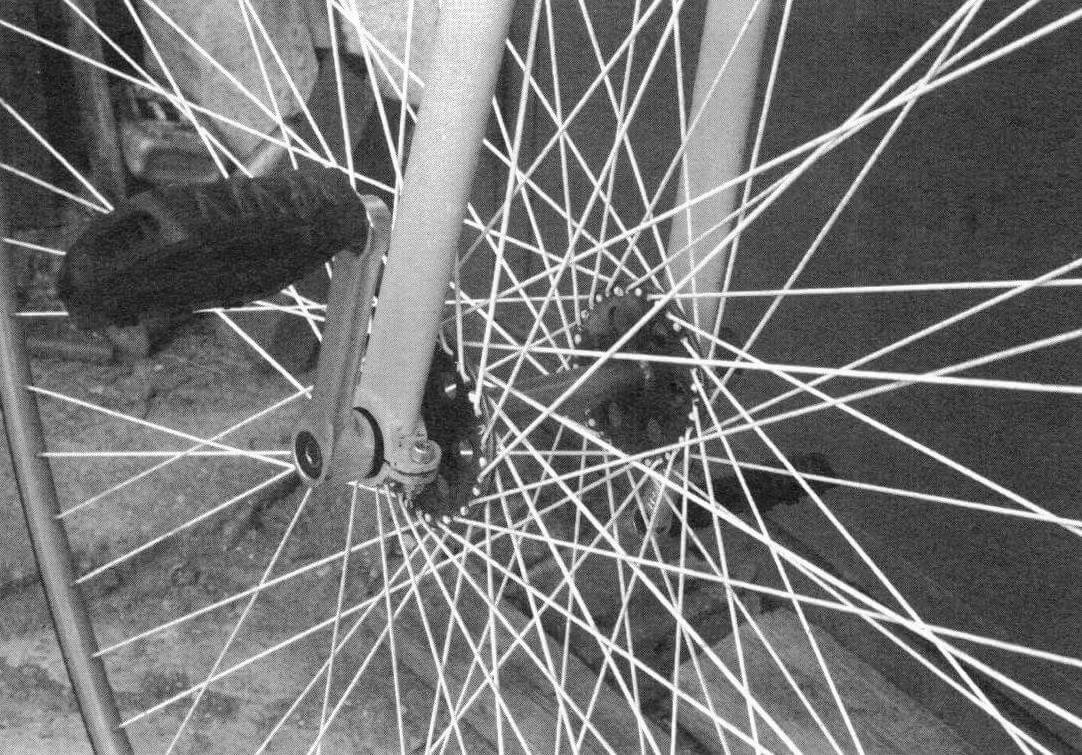

Knitting needles are a simple thing at first glance, but I had to struggle. We experimented for a long time, tried different types of steel, using a tensile testing machine to determine the yield strength. In the end, we selected the appropriate wire. Steel is better than stainless steel, it is more springy, better absorbs impacts on the rim while driving, and retains its length after the load is removed. By the way, each spoke experiences a breaking force of about 100 kg. As a result, welding rods with a diameter of 2 mm were used as blanks for the spokes.

The flanges of the central axis, which hold the curved ends of the spokes, are made on a laser cutting machine. A bushing is welded between them, into which two parts of the pedal carriage shaft from a modern bicycle, sawn in half, are inserted on both sides and welded. Seats for ball bearings are machined along the edges. The connecting rods with pedals are ready-made, from a “fatbike” (an off-road bicycle with fat tires). The size of the connecting rods depends on the terrain where the bike will be used: if there are a lot of climbs on the route, then longer connecting rods are needed to make it easier to pedal uphill.

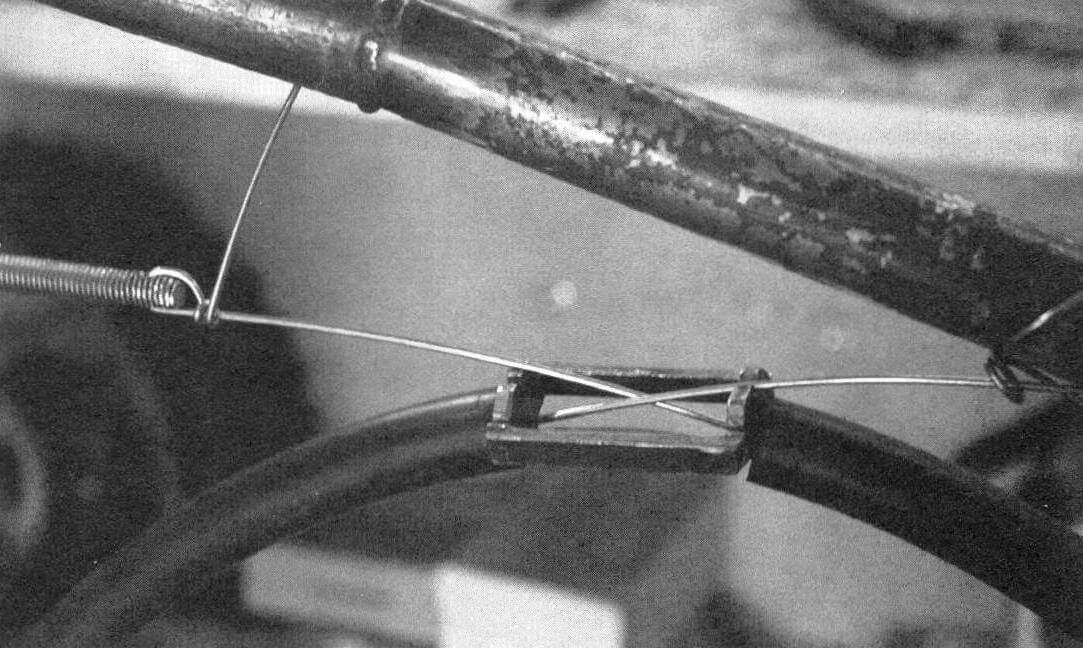

Having installed the spokes and centered the rim relative to the axis, you can begin to tire the wheel. The pneumatic tire is good, but it is too difficult to make, and it is not necessary. On the original “spiders” the tires were solid, and they should be made that way now. First, a thick-walled oxygen hose was used, into which two turns of wire were inserted to hold the tire on the rim. They say that a similar technology was used on “rubber-running” carriages. It is not known for certain how it was inserted inside the tire then. Kirill, while making the first tire, pulled the wire so hard… that he tore the heating radiator in his house off its mountings. Now the matter is moving forward, fortunately a tool has been invented with the help of which the tire is seated on the rim. And an excellent hose of the required cross-section and stiffness, as it turns out, can be ordered, as they say, close by – at the Research Institute of the Rubber Industry (NIIRP), conveniently located just in Sergiev Posad. Note that the difficult technology of fitting a tire to a rim does not exclude the possibility of removing and returning it to its place, for example, to tighten the spokes.

The rear wheel is made in the same way, only it is several times smaller than the front. There is nothing to choose here: all “spiders” have the same rear wheels. On some you can see a disc brake from a modern bicycle. It is installed for ease of riding; the original bicycles did not have brakes at all; they were braked by the engine, as they now say, that is, the cyclist himself resisted the rotation of the drive wheel, holding back the pedals. You could also brake the rear wheel with your foot, although at the risk of being left without a sole on your shoes. Some models were equipped with a spoon brake, which worked on a similar principle. Of course, with a normal modern brake the bike is safer.

The frame here is elementary! Just a curved pipe (steel or aluminum alloy), with a steering column cup welded in the upper part, and a support wheel fork in the lower part. It can be made from suitable pipes or even profiles, or you can take a ready-made one from a small bicycle.

The front fork is more difficult. It is much longer than any bicycle of the usual type, and because of this, when actively pedaling, its feathers experience significant bending moments. Here it is important to choose a pipe of suitable rigidity, but at the same time such that it can be flattened in a press to give it an oval cross-section. On one of the “spiders” they tried to make a spatial front fork from thin pipes. It came out both beautifully and stronger than from a single pipe.

The fork rotates in bearings, the steering wheel itself is a simple cross member. The appearance of the bike is not the most important thing for Kirill. It would have been possible to make wooden handles and leather seats, but I wanted to make a bicycle not for the exotic, but for every day, adapt it to modern materials and components, and work out the manufacturing technology. And in general, all these problems have been successfully solved.

The “Spider” from the 21st century unexpectedly found its buyer, and Kirill was inspired, thinking that it would be great to make these forgotten funny cars to order. Moreover, practically no one produces them in Russia. There are masters in Europe, and the most famous lives in Australia, but if you can get their crafts here, it’s for a lot of money. And the bicycles are more for show, works of art; hardly anyone will ride them often.

By the way, is it difficult to ride a “spider”, in particular, to sit on it? This is not easy for a beginner. There is a small kickstand at the bottom of the frame. Having rolled the bike a little, they put their foot on it, quickly climb into the saddle and begin to pedal. The main thing is to do all this really without delay, otherwise a fall is inevitable. Apparently, this is why the bicycle that replaced the “spider” was called “safe”, because it is easier to master. However, it’s all a matter of habit. Kirill drives wildly, holding the steering wheel with one hand. He manages to do some tricks with his cars, for example, drive a little in reverse, because there is no freewheel mechanism. He says that an untrained person can learn to drive at least a little in about five minutes. By the way, I tried it and experienced a thrill. A professional on such a bike can accelerate to 40 km/h, but this is the lot of truly fearless people!

It is believed that “spiders” are inconvenient and have no advantages over modern bicycles. This is partly true, it’s not just that the latter quickly supplanted the former. But it has a very simple design, a minimum of parts, and there are no problems with tire punctures. It is easier to ride uphill on “spiders”, because the large wheel smooths out dead spots when rotating the pedals, the movement occurs evenly, and not jerkily. By the way, bicycle engineers even attempted to install a flywheel on the wheel in order to get rid of dead spots in the pedal drive. And of course, when you drive this “spider” out onto the street, you can’t avoid surprised, admiring glances. You go and cheer up both yourself and people!

Andrey FAROBIN