At the start of the competition, when all the cars line up in rows in front of the white line, this kart can easily get lost among its counterparts. The same wheels, a seat, and a steering wheel familiar to the eye… The only difference is that its engine does not emit deafening popping sounds but operates with a barely audible hum. This is simply explained—instead of an internal combustion engine, this kart has an electric motor powered by a familiar lead-acid battery…

Yes, before us is the country’s first electric kart (Fig. 1). It was created at the Kharkov Automobile and Highway Institute, where the first sports electric car and the first sports electric motorcycle were built and tested. The “KHADI-electro” family demonstrated itself excellently during tests and sports competitions. For example, in 1973, the KHADI-11E electric car set three all-Union speed records, one of which exceeded the international standard.

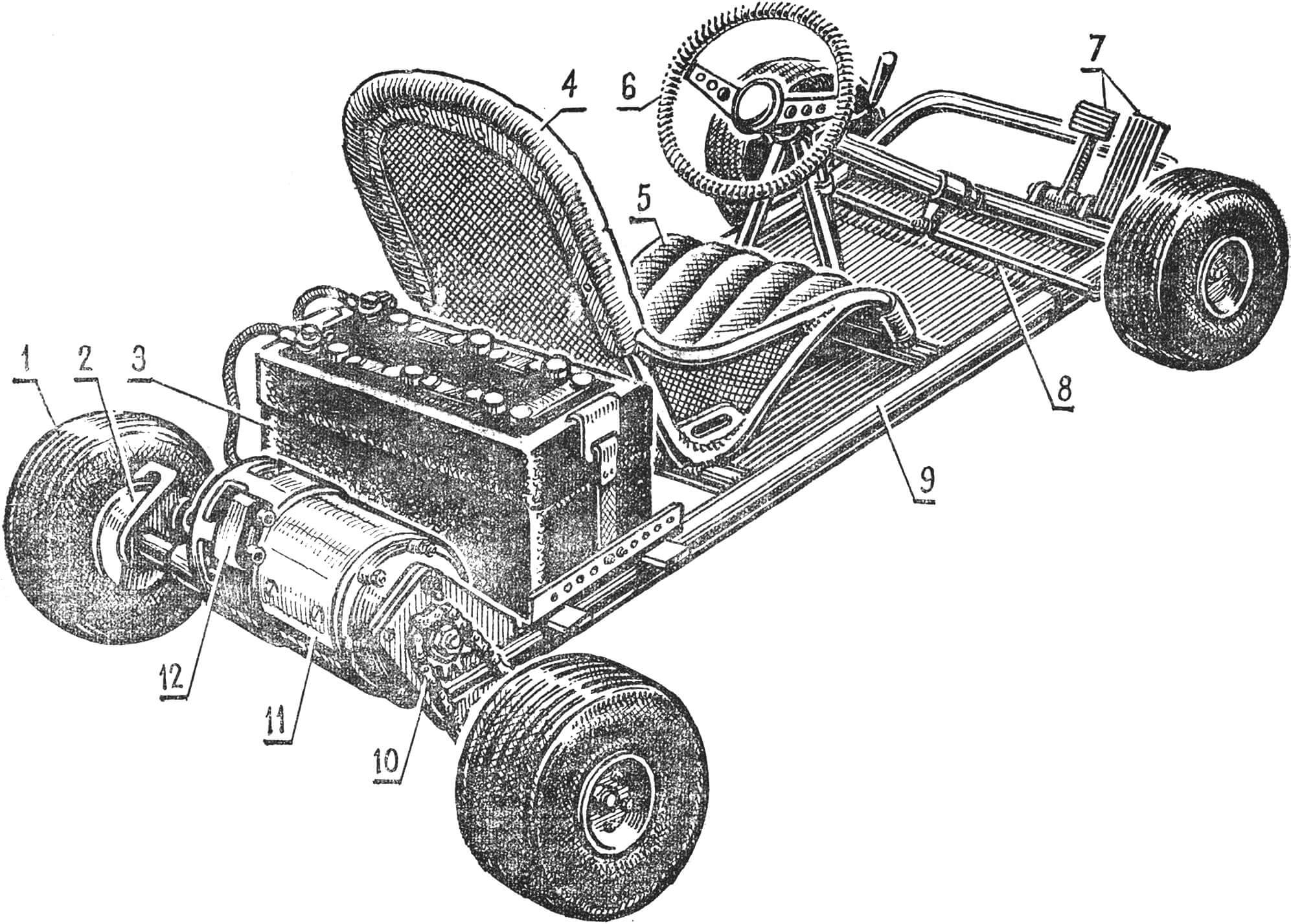

1 — tires, 2 — disc brake, 3 — battery (rear placement option), 4 — roll cage, 5 — ergonomic seat, 6 — steering wheel, 7 — control pedals, 8 — steering linkage, 9 — frame, 10 — chain drive, 11 — electric motor, 12 — contactor.

But let’s get back to the electric kart. During its creation, the Kharkiv designers used an already existing standard kart. The “Modellist-Constructor” magazine has written many times about how to build such a kart. For this purpose, you can use standard “Estonia K-5” or AK-2 karts from the Leningrad sports shipbuilding plant.

The conversion of a regular kart into an electric one is mainly about replacing the engine.

The direct current motor R-2500 (power 2.5 kW, current consumption 40-100 A, voltage 24 V, nominal speed 1800 rpm) is attached to the rear frame tube of the kart with a hinge so that it can be shifted within a range of 50 mm to tension the chain drive.

You can also use a lower-power motor (up to 1 kW) but it must be a direct current motor with series excitation. It is desirable for the chosen electric motor to have reverse, that is, be able to change the direction of rotation.

A small drive sprocket (12 teeth) is put on the motor shaft. The large driven sprocket (27 teeth) is fixed on the driving axle. Both sprockets are connected by a motorcycle chain with a pitch of 12.7 mm.

The methods of attaching the sprocket to the electric motor shaft depend on the construction of the shaft itself. If it is splined, the sprocket is directly mounted on the shaft.

The electric power for the direct current motor is supplied from lead-acid batteries with a nominal voltage of 12 or 24 V. The battery, located behind the seat or on the side of the driver, is secured in a socket made of a steel angle 15X15 mm. The more batteries, the longer the range without recharging. The operating experience of the KHADI electric kart has shown that at a voltage of 12 V, the maximum speed of the kart was 20 km/h, while at 24 V, it reached 50 km/h.

For remote engine activation, the K-600 contactor is used. It works equally well at both 12 V and 24 V. If the contactor is not available, it can be replaced with a powerful homemade switch. In this case, it is necessary to consult with an electrical engineering specialist because it is important not only to correctly select the cross-section of busbars and wires but also to reliably isolate the switch from the metal frame of the kart.

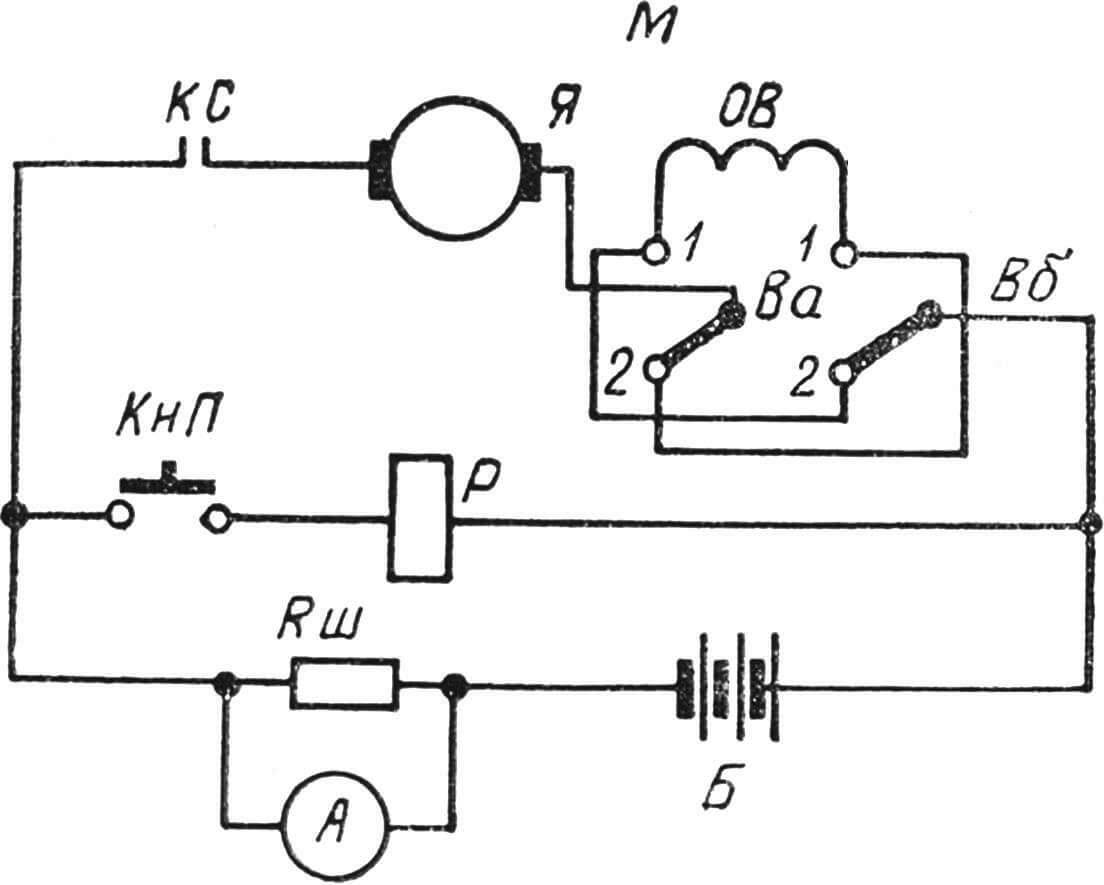

The electrical scheme (fig. 2) of the kart is not very complicated. It has two current circuits.

KS — power contacts, M — electric motor, YA — armature, OV — excitation winding, KNP — start buttons (switch), P — contactor winding, V — reversing switch, Rsh — shunt, B — battery.

The first one is the control circuit: battery B, start button KNP, contactor winding P, and shunt Rsh.

The second circuit is the power circuit, which also includes battery B, power contacts KS, armature (YA) of the electric motor (M), reversing switch (if available), and shunt Rsh.

The reversing switch is used for an electric motor with reverse. Then the electric kart will be able to move forward and backward. In the presented scheme, the first position of the contacts corresponds to forward movement, and the second to reverse.

The electrical circuit is activated by pressing the “gas” pedal, which is connected to the KNP switch. At the same time, the control current (small current) from battery B through shunt Rsh is supplied to the contactor coil P. Passing through its winding, the small current closes the power contacts KS, and the power current (100-200 A) from the battery enters the armature winding YA, the motor winding OV, and the reversing switch V, if any.

The battery discharge level is monitored using an ammeter A, which is connected in parallel to shunt Rsh (the shunt must be designed for a current of 100 A) to reduce the current passing through the control device.

The “forward-backward” reverse lever is installed on the steering column. The speed of the electric kart is automatically regulated depending on the load.

The HADI Electric Kart has one undeniable advantage: silence and the absence of harmful exhaust emissions. This opens up new possibilities for karting, allowing competitions to take place on indoor tracks and in enclosed spaces. Such a direction in the development of karting will undoubtedly contribute to its further popularization and the growth of skills among young karting enthusiasts.

V. ZAKHAROV, Engineer