The velomobile is equipped with soft-spring suspension front and rear axles. The front axle consists of a double beam-pipe, which are fixed lugs swivel axles and pad guides for travel of the beam in the vertical direction on the rod bolts. The springs are selected from the valve mechanisms for engines of passenger cars. To enable the warp beam to the underbody when driving on uneven lower covers have holes for the guide rods with a diameter of 0.7 mm larger than the diameter of the stock.

The tie rod with the adjusting elements of the toe are located in front of the beam. The rotation of the steering wheel is transmitted via the bipod and extra traction length 180 mm on the tie-line through the hinges with nylon bushings. The gear ratio of the steering mechanism 1:2. The maximum steering angle to 30° to accommodate the turning radius of the car is 3.5 meters.

Rear axle consists of a block of stars with number of teeth 11, 14, 17, 20 and 24. It is connected through the makeshift one-way clutch with the shaft of the right rear wheel. The whole mechanism revolves inside the beam rear axle bearings. Brake — cable, on both of the drum from one handle. The left wheel rotates freely on the axis. Depreciation of the rear axle done using three longitudinal levers and two springs from the seat of a motorcycle “Minsk” first releases. Springs attached to the ends of the side levers, and axle offset 100 mm forward from them. This is done to increase suspension stiffness. The Central lever is designed to reduce the deflection of the bridge under the action of a stretched chain.

Coaches face-to-face site — homemade, has two asterisks with the number of teeth respectively 56 and 48. Transfer circuit is a switch from a sports bike.

Gear change transmission driven sprocket fixed to the casing of the unit and consists of two plates of the cheeks, two rollers, axis, return springs,

three brackets and pull cable.

The device is similar to the soup port sport bike. The total number of gear recumbent is 10, so it is possible to choose the most appropriate for any road.

Seat — semi-rigid. The frame is assembled from pipes from the cot and plywood plates laminated foam with a thickness of 30…40 mm. from the Top seat is sheathed with a cover of “loose” fabric.

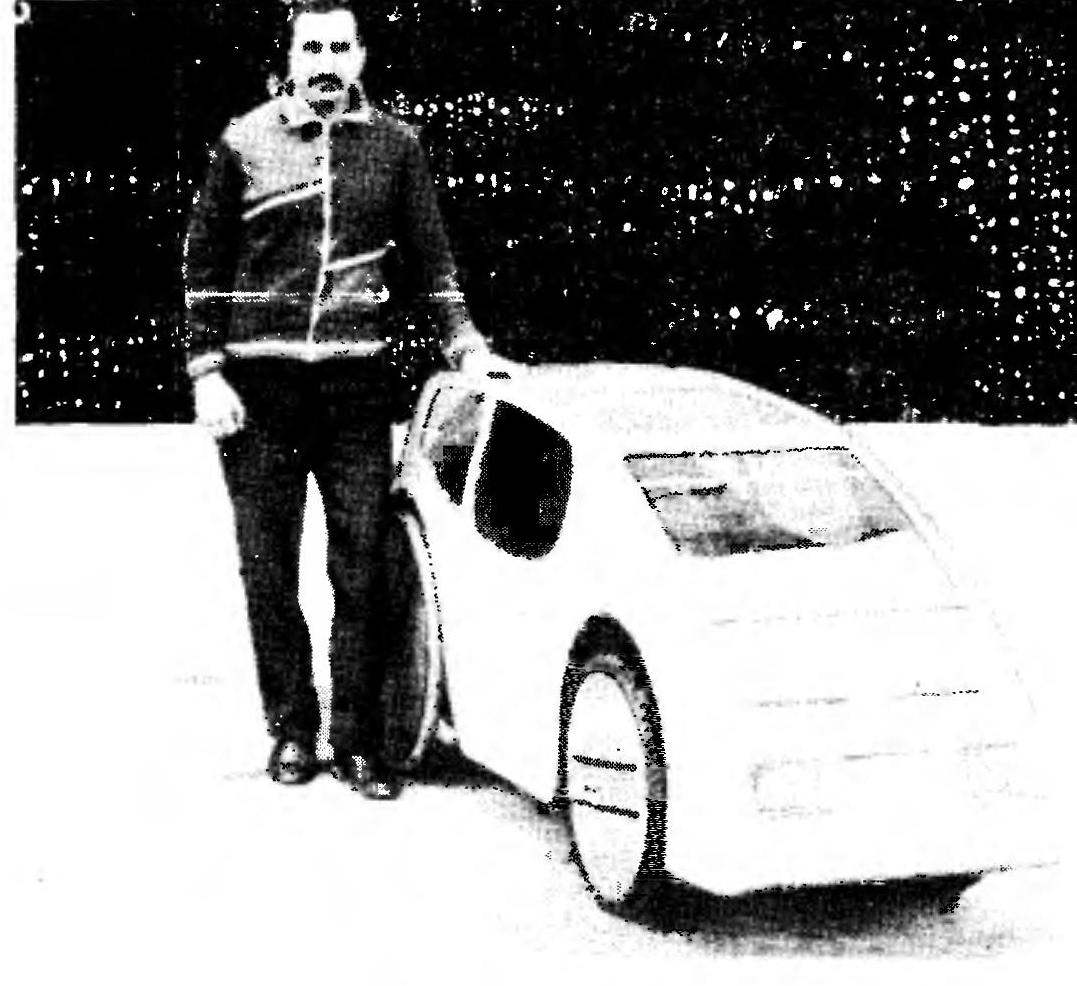

Because the velomobile is moving In the Potts-ke cars, it must be equipped with turn indicators and a system of “vallecrosia”. You must also have a rear view mirror and, preferably, velometer, which can be conveniently mounted on the alcove of one of the front wheels. Security working and bright, conspicuous colour of the body: the “Hope” it’s yellow.

Travel along the body set two large bags to camping accessories and products. First aid kit and repair kit with some located in the forward trunk.

Conditions for velomobiles are closed body, good: whatever the weather glass does not mist, and the air circulation is satisfactory due to directed flow of air from the cracks of the intakes.

If desired, the velomobile can float if sealed front axle beam rubber cuffs seals in wheel wells. To move water or using double bladed paddles, or blades, combs, attached to the rear wheels.

First trip of “Nadezhda” took place in February 1990. He confirmed that the design is convenient, easy, fast, adapted to the many hours of travel.

A few words about yourself. Are velomobiles since 1986. Made the two devices. My firstborn — recumbent “Kokra” — was shown in 198В year at the festival “Golden ring” and was awarded a diploma.

“M-K” can rightfully be considered one of the founders of velomobiles in the country: in its pages appeared in 1976, the description of the first, still largely imperfect muskurahat Vita. Remember! And folding ludikar “Hummingbird”! For 15 pet journal also regularly acquaints its readers with the most interesting diys.

“M-K” can rightfully be considered one of the founders of velomobiles in the country: in its pages appeared in 1976, the description of the first, still largely imperfect muskurahat Vita. Remember! And folding ludikar “Hummingbird”! For 15 pet journal also regularly acquaints its readers with the most interesting diys.