In the practice of homebrew somehow less common device is a bending machine. I don’t think this is due to the rarity can be accomplished with it operations, rather — the lack of information about how to do it. For example, I haven’t seen in magazines or technical literature his descriptions. But this simple tool is very useful: it allows even unskilled wizard efficiently curving blanks from sheet material. This ensures the absence of deformation at the bent portion of the sheet, making it impossible to achieve using the traditional mallet and mandrel. Experienced in the production of our NII bending machine proved to be indispensable in the manufacture of chassis of radio equipment, various housings, casings and connection sheets in the fold.

In the practice of homebrew somehow less common device is a bending machine. I don’t think this is due to the rarity can be accomplished with it operations, rather — the lack of information about how to do it. For example, I haven’t seen in magazines or technical literature his descriptions. But this simple tool is very useful: it allows even unskilled wizard efficiently curving blanks from sheet material. This ensures the absence of deformation at the bent portion of the sheet, making it impossible to achieve using the traditional mallet and mandrel. Experienced in the production of our NII bending machine proved to be indispensable in the manufacture of chassis of radio equipment, various housings, casings and connection sheets in the fold.

NO HAMMER AND DOLLY

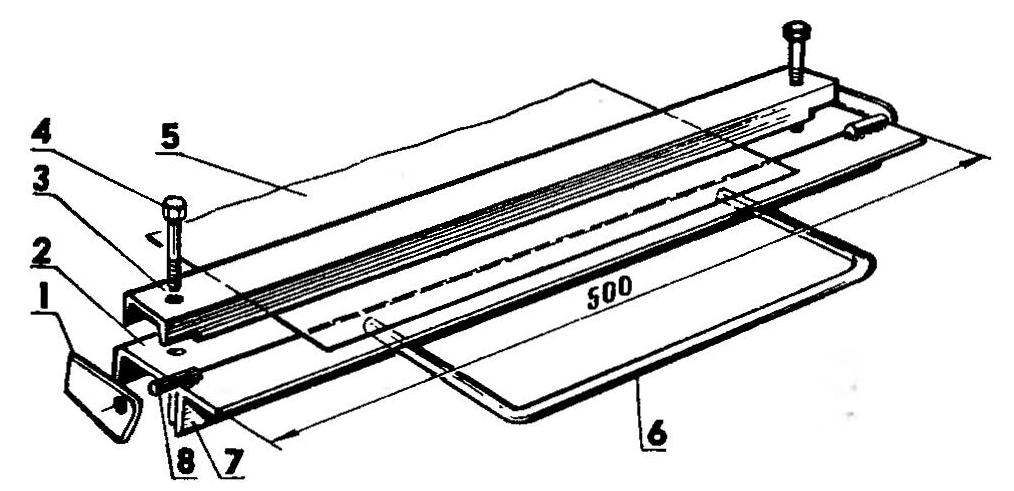

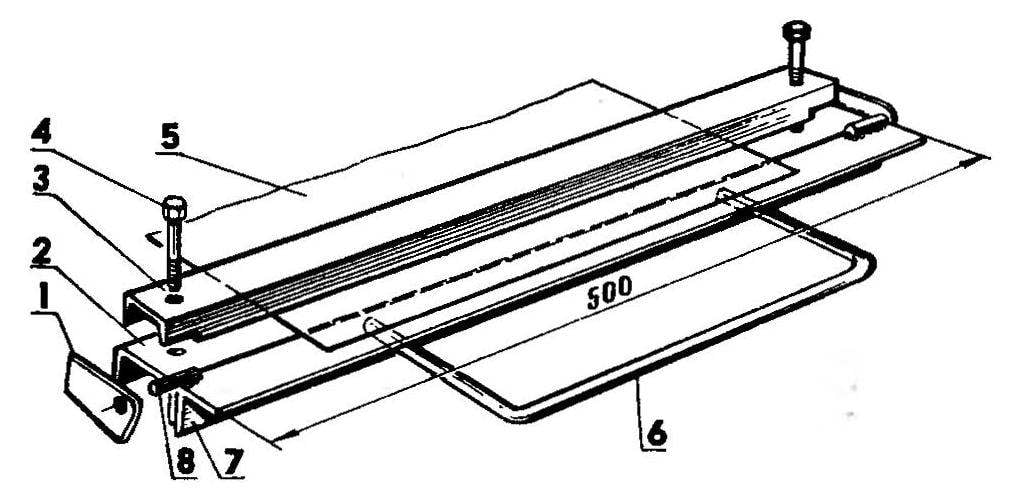

In the presence of welding to fabricate this device is not too difficult. It is only necessary to have segments of channels and corners with straight edges.

The bending machine consists of base, clamp and crimp the plug with the handle lever. The base is made of cut steel channel No. 6,5 (No. 8) length up to 500 mm. the Clamp and punch are made shorter than him by about 5 mm. Pressure from channel number 5. Strictly along the axis of the profile drilled two holes 8.5 mm diameter at a distance of 30 mm from the ends. Crimping punch is made from area No. 5, it is desirable to choose a profile with a thicker wall. The handle lever is curved in the form of clamps of rods of reinforcing steel with a minimum diameter of 15 mm and welded to the corner. From scraps of sheet steel with a thickness of 5 mm are produced cheeks.