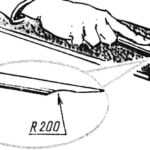

Wall of the cooking compartment is made in the image and likeness of the walls of the living compartment. In one panel cut the window opening in the other door. The cut portion pobednogo used for the manufacture of doors. The door in the usual, hinged, with non-opening window. The window, like all others, is made of Plexiglas in the frame of aluminum profile. Profile, I-beam, which is used principally for the device of false ceilings of akmagra. Its height (25 mm) and determined the thickness of the wall panels, as at the stage of designing a garden, I already planned to turn over the Windows and the door. When you trim unnecessary or disturbing the shelves on the I-beam was removed. At small radii shelves carefully clench (thinning), while the arching profile.

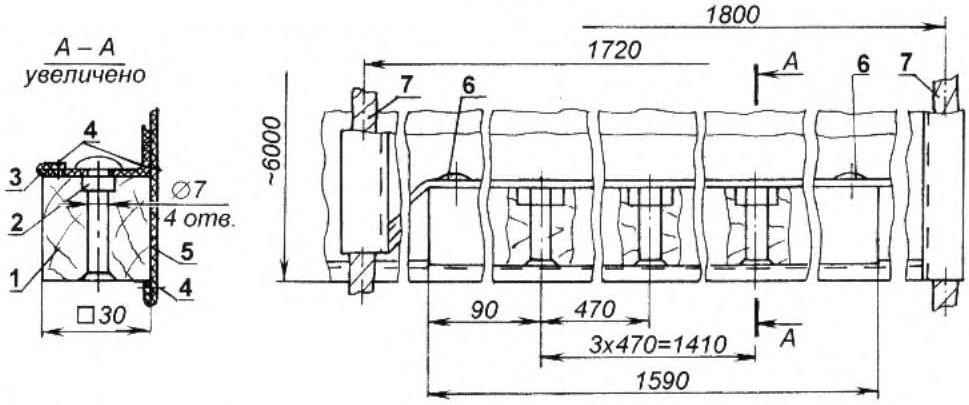

The roof garden is soft. Builders invest in this concept, the coating of rolled materials on mastic. But I it is made of tissues: the bottom layer of the tent, the top from “silverfish”. So this fabric I call just by the color, perhaps its industrial name — percale, but not sure. This “silver” is very suitable in its properties for the roof of garden — waterproof, soft, light, reflects the sun’s rays and even in the heat does not warm up much.

The roof also has features: its start and end parts serve as the end walls of the cottages.

The roof consists of two long fabric widths slightly larger than the villas, and the upper blade (“silver”) overlaps the bottom. On both edges along each leaf is stitched channels-kuliski. They inserted strong cords by which the two canvases are tightened and fixed to the wall panel. On the inner side of the lower cloth secured (nailed with big heads), at equal intervals of 30 jumpers section 20×15 mm of ash (oak and beech, and if of pine, it is necessary to thicker — section 30×20 mm) with hooks on the ends. Jumpers prevent sagging of the canvas and hold the bar at equal distances from each other.

80 mm from the beginning of the two canvases sewn together. The lower end of the cloth wound on top of the mounting strip to the inside and nailed to it, and the upper end of the cloth hangs out and performs the role of Lesnica.

In the nut plate are drilled four holes with a diameter of 7 mm. from the Top they still reamed out in these nests epoxy immured M6 nuts. With their help, the M6 screws with washers bracket (and roof) is attached to the edge of the floor kitchen section.

![Panel"the]()

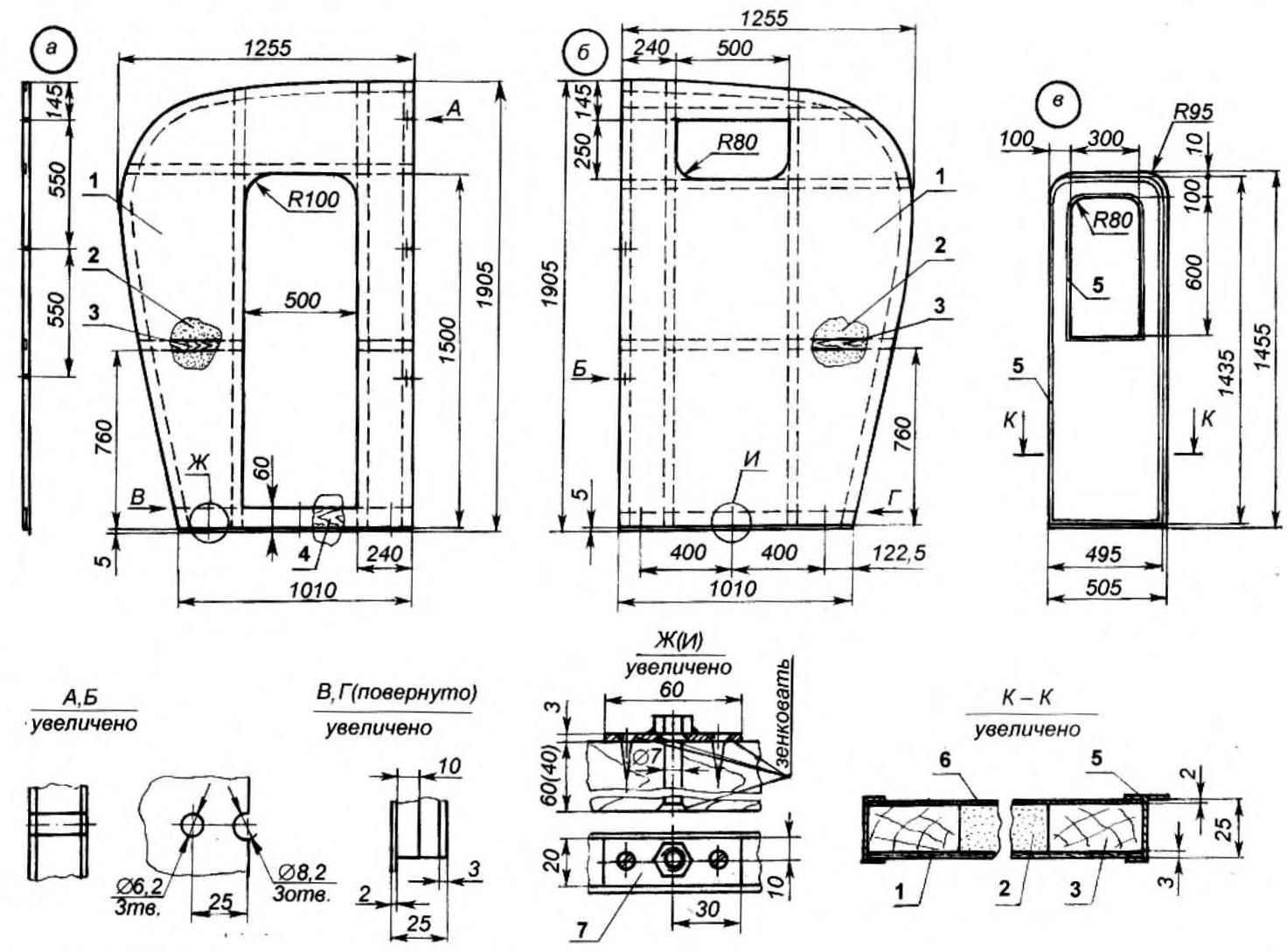

Bar of the living quarters:

1 – interior lining (plywood s); 2 — insulation (construction foam, sheet s20); 3 — frame (bar 40×20); 4 pin (screw d6, out head, 3). 5 — insert with a rounded (Board s20, 2); 6 — external facing (Micarta s2)

Panel, refrigerator compartment (a—door, b — window, in — door):

1 – interior lining (plywood s); 2 — insulation (building 5 – aluminum profile (t 25×20); 6 – outer oblicovka foam, s20); 3 — frame (bar 40×20); 4 – threshold (Board 60×20); (Micarta, sheet s2); 7 – plate with the nut M6 (6 PCs.)

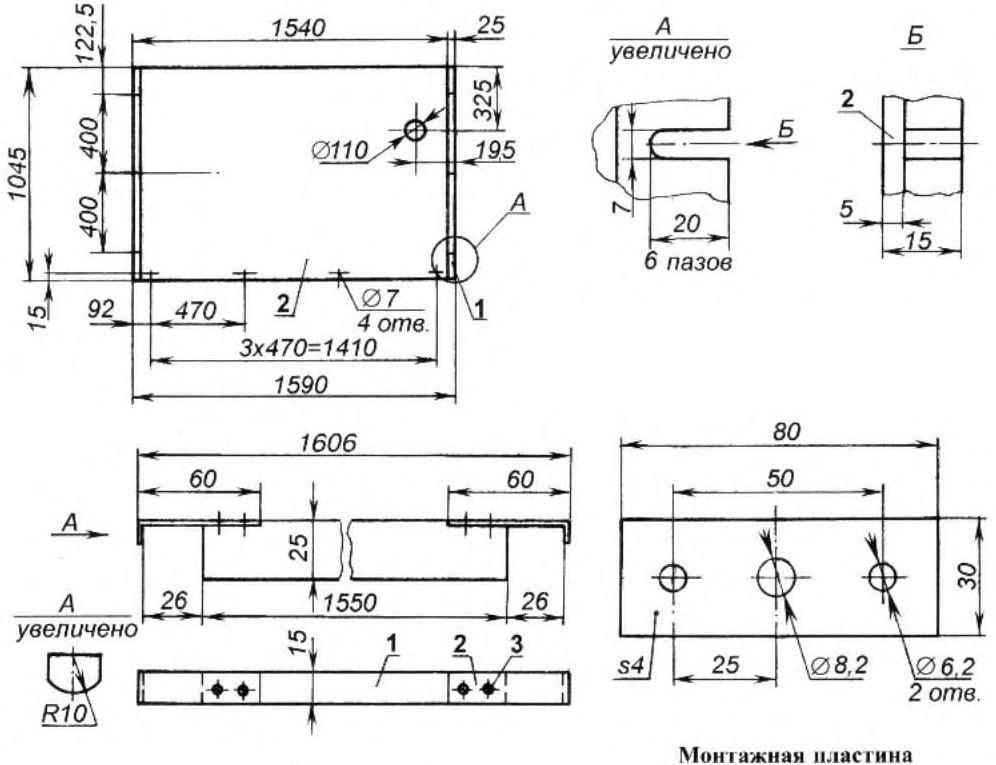

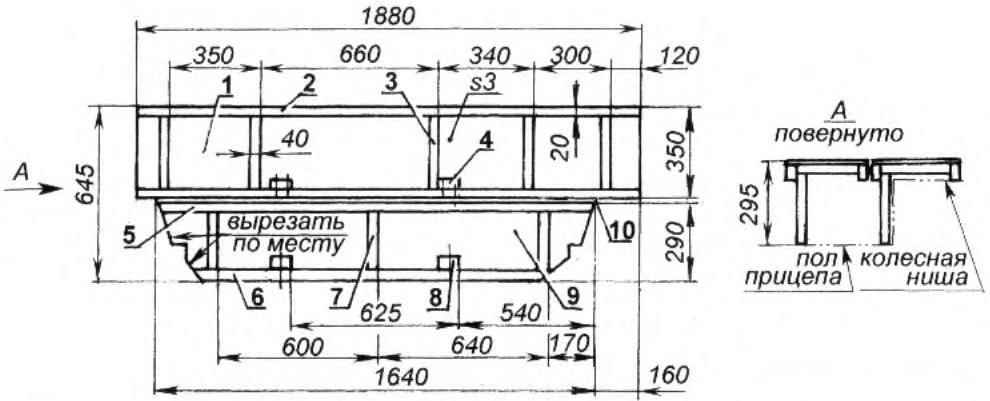

Floor kitchen box:

1 – based (plywood, sheet s10); 2 – flooring(linoleum, for pile basis)

Jumper soft roof:

1 bar (bar 25x 15); 2 — hook – (stainless steel, sheet s2, 2); 3 — screw (4 PCs.)

First installing the main panel — partition, then the side

Installation of a soft roof

Samsika-lounger (bottom view in the unfolded position):

1 — facing seat (plywood s4,5); 2 — longitudinal bars of the seat (2); 3 — cross bar of the seat (5 PCs); 4 stem seat (2 pieces); 5 — the inside longitudinal bar of the lounger; 6 — outer longitudinal bar of the lounger; 7 — transverse bar lounger (3). 8 — foot folding lounger (2 pieces); 9 — facing lounger; 10 — joint for swinging out the sunbed (piano loop).

All parts except POS. 1 and 9, is made of bar 40×20; details 2,5,6 attached to the narrow side wall parts 3,7 — wide party

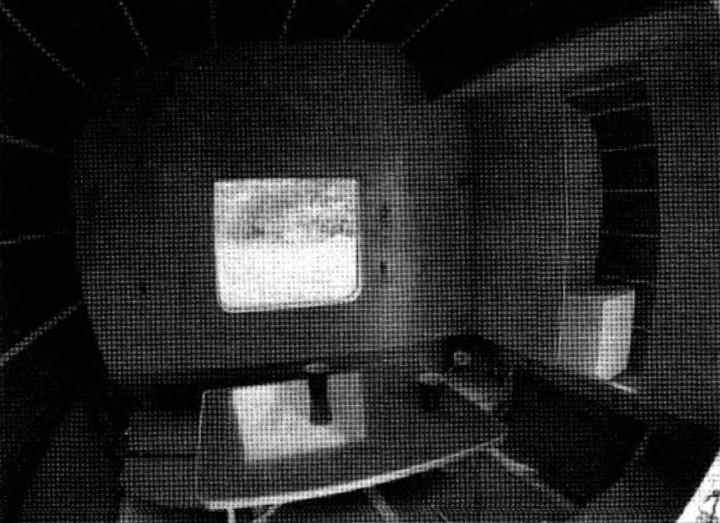

The living chamber (with the table under the window is visible a bench with a hairy rug)

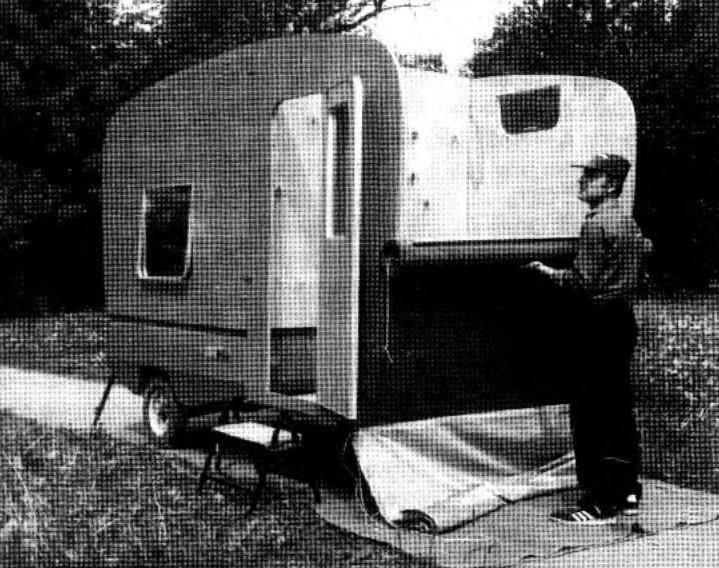

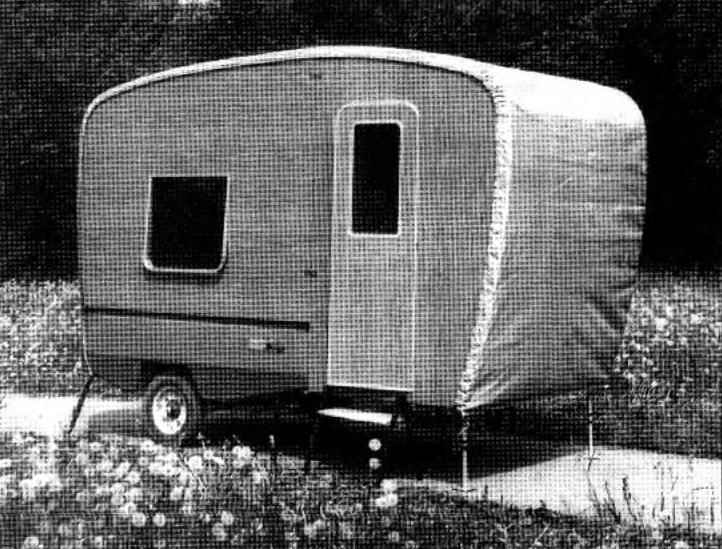

Caravan Assembly

In the country installed three shelves. And sizes they are all the same. Their design is the same as a partition: wooden frame, lined with 3-mm plywood. Only they are thinner, their thickness, like the wall panels, 25 mm. Different shelf mounting. One for the electronic equipment, is mounted on the pins between the panels of the housing compartment above the rear frame of the trailer. The second is fixed on the pins and hung on hooks on the wall above the door of the room. The third is attached to the pins between the kitchen wall panels and “watermelon” (as I call the convexity of the end walls of the villas).

Build garden begins with site selection and unloading of the panels giving from the trailer, which are stacked nearby. First, on the front wall of the trailer is mounted and fixed props partition (main panel) and to it are screwed (nazhivljajut) with bolts M8 for mounting plate. Then on the side of the trailer side wall panels are placed of the living quarters and attached using M6 screws and plates to the bulkhead.

Then on the drawbar mounted floor kitchen section, on its walls. Kitchen wall also with the help of M6 screws through the plate mate the septum and then tightly perevorachivayutsya screw M8, finally pulling the wall panels to the wall. After that, the country is put on and tightened to the roof. And the last one. Puts to the entrance porch, like that of PI on a small stepladder, or on a folding chair. But it is a standard equipment trailer.

To ensure the sustainability of the whole structure in the Parking lot under the corners of the trailer and the floor of the cooking compartment are fed stops. They are telescopic, adjustable in height.

Panels and other parts of the garden for transportation starts with the roof. She rolled into a roll and placed on the bottom of the trailer. After that, the internal flare of the body to fit the bulkhead and floor of the kitchen compartment. Free volumes inside the body in this case can be filled with clothes and utensils, only to fix them there should be “travelling” by excluding their movement and mutual contact.

Further loading of the panels is laying in between soft material, excluding their friction between them. In this panel a little beyond the dimensions of the body, but are held therein due to the draped and covered after laying the awning.

The cottage is equipped with appliances that does not require a power supply (gas refrigerator, gas stove) or powered by an onboard network of the car (radio, television, video); there is also a water tank, shower tray. For waste disposal and discharge of wastewater under the cottage dug a pit, which after the “removal camp” is buried and rekultiviruemye.

To recharge the battery, used wind generator with a capacity of 10 Watt, which is mounted on the pole.

V. WHEELS

Recommend to read

MULTITUBE GIANTS

MULTITUBE GIANTS

Ministerial reshuffle in France in the 90-ies of the XIX century in the absence of common ideas in the creation of the Navy not only politicians, but also among experts has led to what... QUICK SHARPENING

QUICK SHARPENING

When working with wood one of the main tools are chisels or chisels. Their sharpening depends on the quality of the product. As a rule, a similar tool to sharpen the entire surface of...

The idea to make a transportable cottage I have matured more in those years, when the travellers dream on road service was just impossible. So I decided to provide it himself. I must say that you made many years ago, the country successfully is now. After all, the campgrounds and motels are mostly located near busy roads. I bivuachnoe its housing break right at the place of rest, close to nature, almost causing her harm.

The idea to make a transportable cottage I have matured more in those years, when the travellers dream on road service was just impossible. So I decided to provide it himself. I must say that you made many years ago, the country successfully is now. After all, the campgrounds and motels are mostly located near busy roads. I bivuachnoe its housing break right at the place of rest, close to nature, almost causing her harm.