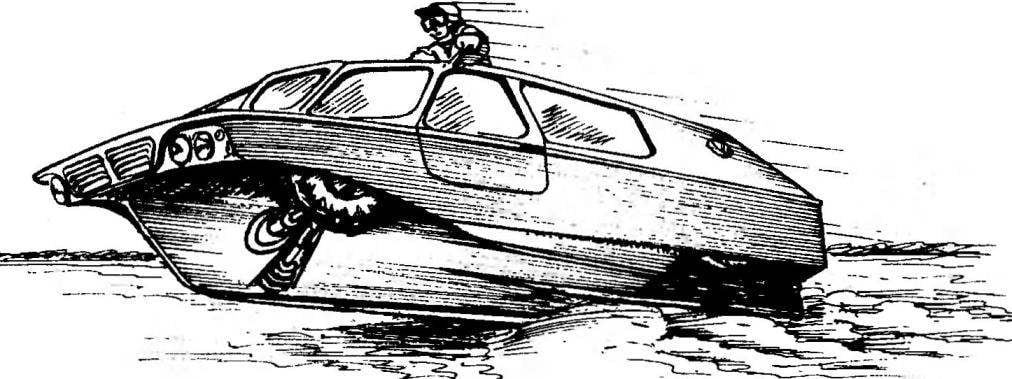

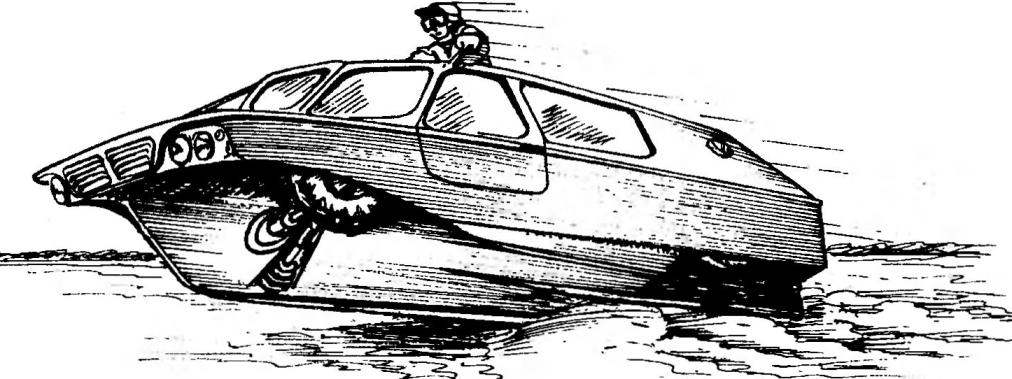

So, what’s new in the “Triton-2”? Externally, the amphibian is not so extravagant. She reduced wheel track (which took some of the stress twisting corps), no wings, wheels with suspensions fit into the dimensions of the enclosure, on the left side “cut” a door for the driver (only used on land).

However, the approaching appearance of the machine to the current automotive standards, paid for by the complication of the design of the tool body. Shields wheel arches and driver’s door ripped side elements for longitudinal stiffness, had the power set to introduce two additional longitudinal — parallel sides at a distance of 300 mm, equal to the depth of the niches. To these spars and rear wheel suspension (“Triton” such burden fell on the side). In the rest of the power set case is similar to the prototype it is based on frames and rails made from oak and pine beams with different cross-sections and paneling, walls, knize carved from Aviaenergy.

“Triton-2”:

1 — body, 2 side door, 3 — manhole cover 4 — mast masthead lights, 5 — window, 6,23 — rails, 7 —damper, 8 — fencing of the water cannon — the top rung of the ladder, 9 — jet 10 —fire chassis, 11 — grille duct input, 12 — door, 13 — front wheel in the “afloat”, 14 — front wheel in the working position, 15 — gear box with differential, 16 — node connection of the telescopic axle with the main transmission gearbox, 17 — redan longitudinal, 18 — Sprayhood, 19 — grille duct output, 20 rear, 21 — fire kakovy, 22— rear door panel bottom 24 —step ladder bottom (flip), 25 — hydrolyze.

The bottom of amphibians (bottom view):

1 — housing 2 — bottom, 3 — hole in the casing under the telescopic drive shaft, 4, 8 — niches of the front and rear wheels (suspension is not shown), 5 —Sprayhood, 6 — hydrolyze, 7 — redan longitudinal, 9 — grate jet intake, 10 —the case of the cannon, 11 — fencing of the cannon.

Layout:

1,9—cylinders suspension wheels, 2,6 — wheel in position “afloat,” a 3.8 — driven, 4 — driver’s seat, 5 — seat passenger, 7 — fold Cabinet, 10 — panel, rear door, 11 — radiator water-cooled engine full-time, 12 — bonnet sound-absorbing, 13, 34 — grille duct output ugodna, 14 —rotor shaft of the jet, 15 — the mechanism of the cannon reversible 16 — the case of the water cannon, 17 — coupler to the intake Cam, 18—engine, 19, 28 is a top plate with shock absorbers of the suspensions of the wheels of 20.29 — wishbone suspension, wheels, 21 — clutch propeller shaft Cam, 22,31 — axis wishbone suspension, wheels, 23 — shaft, 24 — Elan (interior floor), 25, 32—branch duct bottom and bow, 26 — support for propeller shaft intermediate, and 27 frames of the hull force, 30 — gearbox with differential, 33 — radiator water cooling engine optional.

Constructive section of the case:

1, 3 — rails door opening (rake 40×20), 2 — rear door panel bottom 4 — stringers ceiling (rake 20x 15), 5 — glass back, 6 — front wall Cabinet (aviatour s3), 7 — polubes (rack 30×20), 8 — timber fenders (rake 40×30), 9 — timber (the vertical branch of the frame, the rake 50×20), and 10 wall of the wheel housing front (aviatour s4), 11 —sheathing (aviatour s4), 12 — panel, folding table, 13 — hood sound-absorbing (aviatour, foam, leather), 14 — shelf top bottom side rail (rail 20×20), 15 — front additional side rail (rail 40×20), 16 — hinge folding mechanism passenger seats, 17 — bilge stringer (rail 30×30), 18 — stringer bottom (rack 30×25), 19—front bottom side rail (rail 20×20), 20 — Flor (lower branch of the frame, the rake 70×20) and 21 bottom shelf bottom side rail (rail 35×35), a 22 — branch duct lower 23 —gidroliza (aviatour s6), 24 — keel (rake 60×30), 25 —qunicy (aviatour B4), 26 — Elan (aviatour s6), 27 the threshold of the doorway (rake 40×20), 28 —rung domestic ladder, 29 — polyflor (rack 30×20), 30 — transom, 31 — wall of the wheel housing back (aviatour s4), 32 — wall Cabinet rear (aviatour s3).

The suspension of the front wheels (rear view):

1 — steering knuckle 2 — bracket toe upper ball joint, 3 — absorber, 4 — arm, 5,12 — ball joints, upper and lower, 6 — rocker steering drive, 7 — tube telescopic axle spline, 8 — seal printed, 9 — telescopic shaft axle spline, 10 — regular driveshaft shortened, 11 — cover of the hinge of equal angular speeds (shrus).

The connection node of the telescopic axle transaxle differential:

1 — axis, 2 — clamps, 3 — cross u-joint, 4 cover rubber 5 — pressure washers, 6 — hydrolyze, 7 — axis combination, 8 — finger satellite, 9 satellite, 10 — gear axle driven, 11 — case, 12 — bearing 2007913 differential, 13 — bearing axle 206, 14, 15 — bearing, 16 — cover rubber, 17 — Cup screw, 18 — spar hull.

The Cam clutch of the propeller shaft:

1—splined shaft 2 — bearing 206, 3 — fork, 4 — leash 5 — cover of the clutch housing, 6 — clutch housing to engine, 7, 13 stud Carter’s regular (4x), which is attached to the clutch housing, 8 — cover transmission engine front, 9— clutch clutch, 10 — shaft gearbox with leading coupling half primary, 11 — bearing up 203.12 — under-sippin 110,14—clutch housing, 15 — half-coupler led.

The Cam clutch rotor jet:

1 — the shank of the crankshaft of the engine, 2 — flange hub of the crankshaft, 3 — a pulley of the water pump and alternator, 4 — leading-coupling, 5 — 110,6 bearing cover clutch housing, 7 — the leash, the 8 — plug 9 — bearing 206, 10 — spline shaft, 11 is the driven half-coupling, 12 — needle bearing, 13 — right bracket (area 25x25x3) securing the clutch to the engine, 14 — clutch housing.

The lower part of the body, like the old amphibians is a solid sectioned box, the platform of high hardness — “support the bottom”. All of his spacey isolated from each other, since the frames are blocked (except for the lower branches of the duct) plywood bulkheads, equal in height to the bottom longerons.

Side (driver’s) door is a space frame car and a gasket of elastic rubber. It is located in the wide spacey between the frames 3 and 4. The doorway does not affect the power of the elements “the bottom of the carrier” because the bottom edge of it above the water line by 100 mm.

There was another problem with the rear wheel arches. Invading the traditionally untouchable “boat” bilge area, they reduce and distort it a planing surface. All existing in camerascreen rules this can not be done without the risk of reducing the hydrodynamic qualities of amphibians. And yet, if we take into account the results of the experiments conducted in experimental pool Calarossa United States Navy by the famous American expert in the field of hydrodynamics of high-speed vessels E. R. Clement (the magazine “Boats and yachts” № 66, p. 22), rear wheelhouse will be not so malicious.

The Designation “Triton-2”

Amphibian can be used as the vehicle output or a long day of tourism on combined water and land routes. With appropriate equipment it will be used in rescue services, coast guard, expeditions.

Technical data

Curb weight

amphibians; CP…l L..g…………….1100

Total weight

(displacement), kg.. ……………..1450

Engine power, HP, ..,,..,….,,…100 Jet pump: single stage,

diameter/pitch of the rotor, mm……….219/230

Speed on highway, km/h…………..up to 120

Planning speed, km/h to 50

Clement it was found that the body of the glider should have a narrowing in the stern, reaching up to 30…35% of the maximum width at the cheekbone. It is logical to assume that the aft sections of the bottom of the “Triton-2” reserved wheel niches, almost serve the same purpose — reducing in the direction of the stern planing surface of the bottom.

For the approximation of practical to theoretical results (Clement, narrowing in the feed should be smooth, and the “Triton-2” it’s speed) the bottom is complemented by a full gidroliza, two short longitudinal side steps and spray deflectors.

The unusual layout of power plant and transmission new amphibious: engine (GAZ-31029) — in the stern, and the transmission with the differential in the fore part of the body. They are connected to a long well balanced propeller shaft with intermediate support, and an uncoupling device, and a Cam clutch. On the other hand to the engine through another divisive device (like a dog clutch) docked rotor jet. Both clutches have a welded body filled with fluid. Management is focused on the workplace of the driver.

This layout demanded special care in the removal of excess heat from the power plant. Dual system and liquid-air cooling “Triton-2” reinforced with additional radiator of small height, located at the beginning of the duct (before frame 1), extending to the motor through the housing under the trunk and floorboards. Radiator, and a heater connected to a three position valve to the supply hose from the engine, so you can enable or radiator, or in series, the heater and the radiator. For the latest on the rubber seals installed manobrista the transom, controlled from the driver’s seat: when driving in the rain and on the water in breezy weather it can be closed. In this case, the radiator is cooled by natural irrigation.

However, the most important feature of the “Triton-2” is the absence of his transmission of “intermediaries” — reducer and chain wheel actuators. The undoubted advantage: reduced number of components and parts nezapadnogo of manufacture, reduced noise, simplified maintenance, and reduced, finally, the cost of the project.

Let us consider the individual units.

Important place in the construction of a new amphibian belongs to the suspensions of the wheels. They rise out of the water or fall now is not a cable winch, and hydraulic cylinders double-acting with warning lights on the dashboard. Accordingly modified and the mechanical part of the drive. The upper plate spring and damper pivotally connected with the carrier control, set them in working position (in the reference slot on the case), does not require any fixing — kinematics of the suspension is such that when the load the spontaneous movement of the wheels in position “afloat” is excluded.

The multifunctional nature of the work the front suspension requires a strict linking of all the components. In particular, the configuration of the lower extremities of levers, fitted with spherical bearings have been thoroughly proven on the layout, without any hesitation carried out the third function of the front-drive amphibious — free upgrade the wheels to a great height — 600 mm. the Last is taken from the VAZ-2108 with hinges of equal angular speeds (Shrus). With the differential from the ZAZ-968 joints associated homemade a telescopic rod with sliding slots (speed up to 200 mm). This ability to stretch allows the rod to remain linked with the wheels when climbing out of the water. Recall that the performance of the suspensions is ensured and the special kinematics of the steering gear, is entirely borrowed from the “Triton”.

From the differential installed universal joints with the angle of the fracture up to 44°in the position of the wheels afloat. Working the same angle hinges — 2…4°. (They are currently working on installation and Shrews from here “eight”. I think they are more reliable gimbal.)

Pay attention to another very important feature of front drive for amphibians (with niches in the body or without floating or gliding): when lifting the wheels and levers of suspension, and an extendable axles are almost the same characteristic property of the bow of the hull V-shaped, and small holes in the casing for the lower fragments of the semi-axes do not impair driving performance amphibious, as when planing the front of the case is literally flying over the water.

The mechanism of uncoupling of the propeller shaft — homemade Cam clutch (only one detail in its factory design front cover the regular transmission GAZ-31029). It is attached to the free end of the clutch housing of the engine is exactly the same as PPC, or four studs.

Uncoupling mechanism of the water jet partly follows the design of a Cam clutch. It is attached to the front end of the crankshaft via the drive flange of the generator and water pump. Three regular bolts flange added three more — with thread M10x1. Ratchet replaced the bolt with a conventional head.

The clutch housing has two angled bracket that he is using a special adapter made to place the console attached to the engine block (used bolts to timing cover and studs macropodia).

To compensate for movements of the engine relative to the powertrain in the line of transmission shafts and water jet introduced universal joints with sliding spline joints, and to reduce noise and mitigate shock loads — elastic rubber coupling.

Both are operated uncoupling mechanism of the remote cable-drive from the driver’s seat.

Brake system the same as on the prototype: a working — hydraulic, dual circuit, with dry connectors hydraulic drives, acts diagonally on all wheels; Parking — cable — only on the rear wheels.

From the above it can be seen that front-wheel drive layout, implemented on the “Triton-2”, “embedded” in the body quite naturally. It may be the most rational if not the only possible one, because it allows you to get rid of many intermediate nodes in the transmission of amphibians in General, and gliding in the first place.

It seems that inherent in “Triton-2” creative findings will help Amateur designers when creating a planing amphibian.

D. KUDRYAKOV

Recommend to read TO AVOID SPLASHING Usually water from the tap, even if it is slightly unscrewed, flows with turbulence and spray, which is especially frustrating when under a stream of running any job. A kind of handler... KEROSENE INSTEAD OF METHANOL As you know, aeromodelling motor "rainbow-7)" is a typical "Kalinka". But a few additional parts easily turn it into a compression engine with a displacement of 7.0 cm3. Somebody...  Moscow musician D. T. KUDRYAKOV among Amateur designers known as the author of a unique car is amphibious “Triton” — one of a kind vehicle that is registered simultaneously in two state inspections: car (GAI) and for small vessels (GIMS). Our regular readers may recall the publication of “Planing… car” (“modelist-Konstruktor” No. 5 of 1996), containing quite a full description of the construction of the “Triton”. In it the author shared his approach to solving complex technical problems, which allowed him to create a vehicle equal in their performance on land and on water.

Moscow musician D. T. KUDRYAKOV among Amateur designers known as the author of a unique car is amphibious “Triton” — one of a kind vehicle that is registered simultaneously in two state inspections: car (GAI) and for small vessels (GIMS). Our regular readers may recall the publication of “Planing… car” (“modelist-Konstruktor” No. 5 of 1996), containing quite a full description of the construction of the “Triton”. In it the author shared his approach to solving complex technical problems, which allowed him to create a vehicle equal in their performance on land and on water.