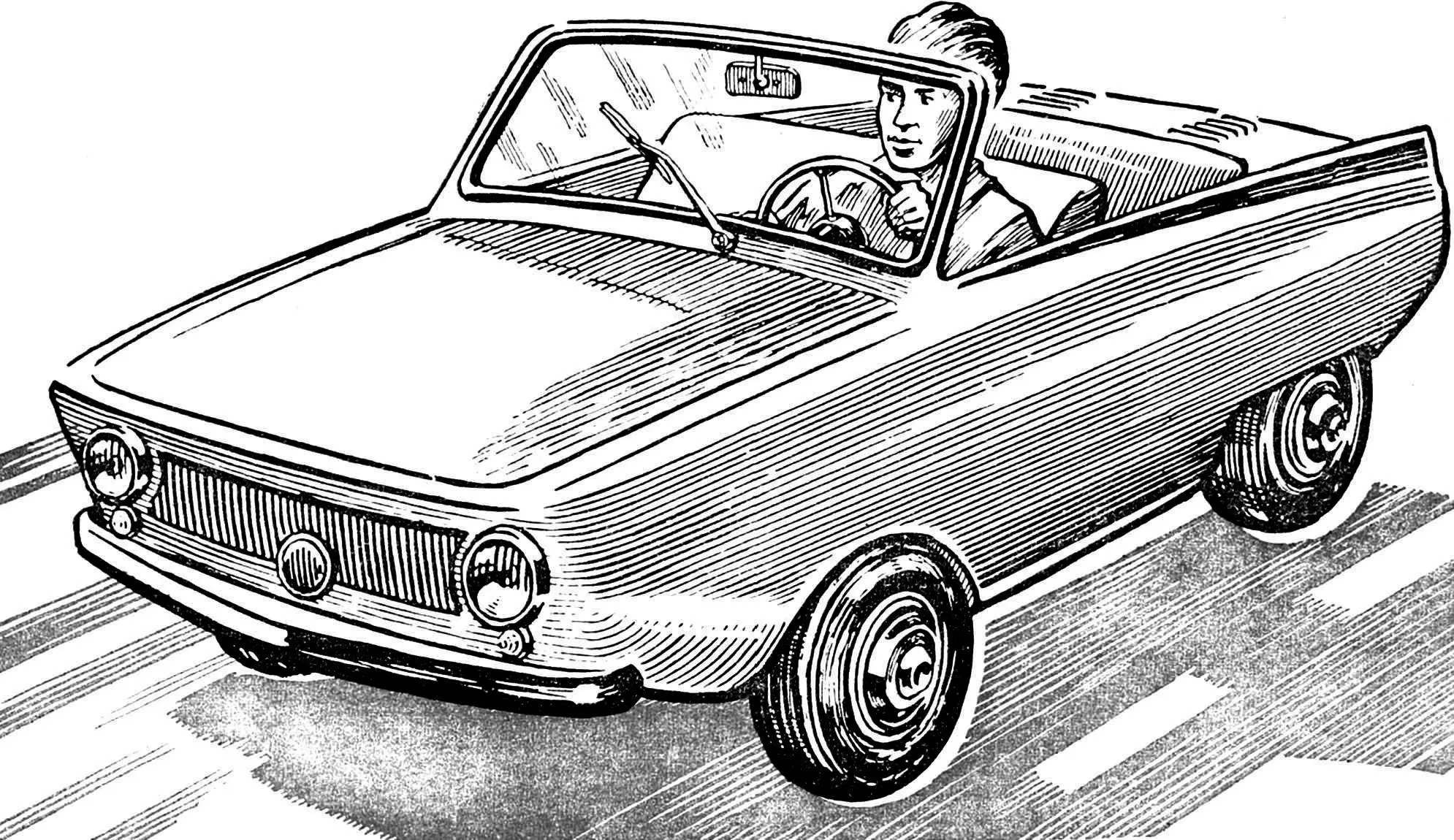

“Many people are now interested in designing and building microcars. We in our automotive design club at School No. 146 in Novosibirsk also tried. The result, in our opinion, is a fairly successful car in terms of design.

The power unit turned out to be very compact, as the “SZA” engine was equipped with a dynastarter DS-1 from the “T-200”, connecting it with an adapter to the engine crankshaft and covering it with a protective housing.

The breaker, naturally, together with the ignition advance mechanism, had to be redesigned for reverse rotation. The ignition and lighting systems are quite satisfactory. The frame also turned out to be strong, bent from Ø 42 mm tubes. We concentrated all controls on the steering column.

The car’s interior is spacious. Thanks to the duralumin body and lightweight frame, it turned out to be light (dry weight 230 kg; the two of us tip it on its side, having previously placed a block underneath, and repair or inspect the bottom).

The car is not inferior in cross-country ability to any motorcycle, and in bad weather, on mud, even significantly surpasses them. All these qualities were revealed after three years of operation of the “Malutka” (Little One).

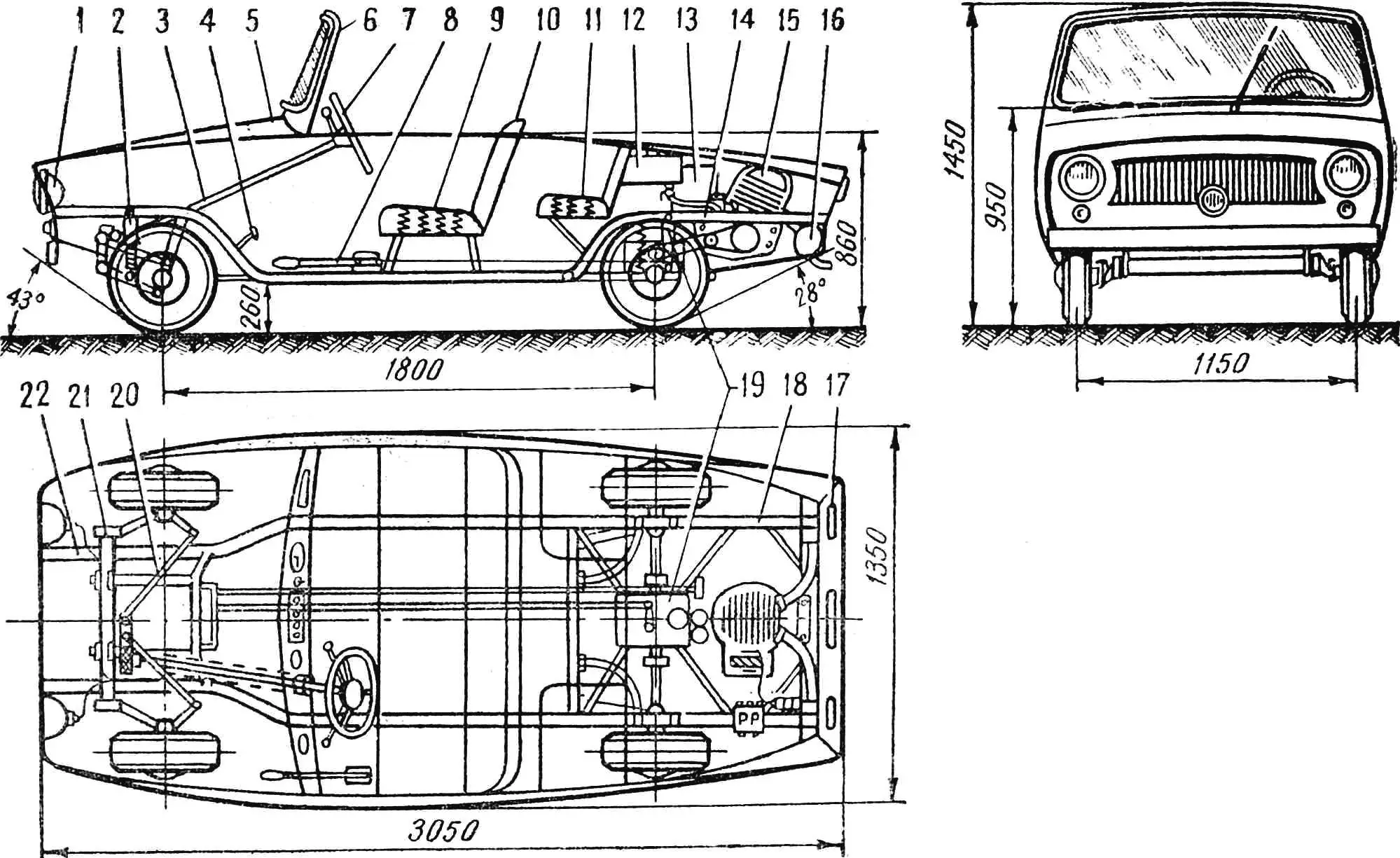

1 — headlight, 2 — front suspension shock absorber, 3 — steering shaft, 4 — clutch pedal, 5 — fairing, 6 — windshield frame, 7 — steering wheel, 8 — engine start handle, 9 — front seat, 10 — front seat back, 11 — rear seat, 12 — fuel tank, 13 — battery, 14 — rear part of frame, 15 — “IZH-56” engine, 16 — muffler, 17 — turn signal and marker light, 18 — longitudinal frame tube, 19 — final drive, 20 — steering rod, 21 — front axle upper beam, 22 — front subframe.

The “Malutka” microcar was designed and built by young automotive designers over two years. The car is designed for 2 adults (front) and 2 children (rear) seats.

The body is of open type; since the height of the side panels is only 860 mm, side doors are absent to avoid complicating the body structure. For convenience when getting in, there is a niche on the right panel at floor level for foot support when entering. The niche is automatically closed with a lid using a spring.

The main load-bearing element is a frame made of Ø 42 mm tubes with inter-frame connections. Side frames made of lightweight 20X20 mm angle and upper longitudinal thin-walled Ø 20 mm tubes are welded to the frame. All this forms a frame that repeats the body silhouette. Aluminum side and end panels 1 mm thick are riveted to the frame. Thus, the frame and body are a single rigid structure that takes all loads.

The windshield from the “Moskvich-407” is equipped with a manual wiper. In front there is a spacious trunk, closed with a lid that folds forward. Inside, the trunk and interior are lined with felt using glue 88 to reduce vibrations, and the interior is also lined with varnished fabric. To reduce vibrations, the interior floor is made of 8 mm thick multi-layer plywood and painted twice with nitro enamel so it doesn’t swell from moisture and rot. The front seat is solid, can move along the interior to adjust the driver’s position, and has a handrail arch on top. The rear seat is split, with a U-shaped niche cut in the middle for young passengers’ legs or for large cargo.

The seats are spring-loaded, covered with leatherette. The body is painted with pentaphthalic enamel in dark cherry color (like the “Java-350” motorcycle).

The engine is from the “SZA” motorized wheelchair, boosted to 17 hp. Gasoline “A-72”. Electrical equipment 12 V, as instead of the “SZA” starter and generator, a DS-1 dynastarter from the “T-200” motor scooter is installed. Cooling by fan from the “SZA” motorized wheelchair. Carburetor K-28G with a main jet of increased capacity (up to 260 cm3/min). The air filter is contact-oil type, homemade. The fuel tank with a capacity of 21 liters is homemade, fuel is supplied by gravity. The battery is from “Moskvich-407” with a capacity of 42A. Engine starting is by starter, from a button, or manual, from a handle in the interior on the left side of the driver. The gearbox is equipped with a homemade gear engagement sensor, and on the instrument panel there is a gear engagement indicator in the form of a light panel, which is very convenient when driving, especially for beginner young drivers.

The front axle is from the “SZA” motorized wheelchair with reinforced shock absorbers (springs from the rear axle of the “T-200” cargo motor scooter are fitted on the outside of the vibration damper).

The rear axle is of our own design, consists of longitudinally swinging arms made of Ø 33 mm tubes, hubs from the “SZA” motorized wheelchair, suspension springs two per side: the first spring is taken from the “SZA” motorized wheelchair (large), the second from the rear axle of the cargo motor scooter, fitted on the vibration damper (as on the front axle). The differential and driveshafts are soft, rubber, from the “SZA” motorized wheelchair. The drive from the engine to the differential is by reinforced chain from the “SK-6” combine, pitch 15.0 mm. The sprocket on the differential is homemade, 19 teeth. Wheel rims and tires 5X10 from the “SZA” motorized wheelchair. All four wheels are equipped with hydraulic brakes. The brake cylinders, master and wheel, are taken from the “Zaporozhets”, Ø 19 mm. Support discs, brake pads and drums from the “SZA” motorized wheelchair. The parking hand brake is taken from “Moskvich-407” and acts on the rear wheels.

The steering is rack-and-pinion type, from the “SZA” motorized wheelchair. Two handles are placed on the steering column: the right one for controlling the engine gearbox, the left one for switching the differential when it is necessary to move forward or backward. Thus, the interior floor is not cluttered with handles and levers, except for automotive-type pedals. The interior is spacious, which is very convenient when getting in and driving.

The instrument panel is equipped with a speedometer, fuel gauge in the tank, ammeter, turn signal toggle, light switch, ignition lock, gear engagement indicator, clock and a homemade radio receiver.

***

The car was manufactured in accordance with the technical requirements for building homemade cars and registered with the traffic police with the issuance of a technical passport and license plates.

During three years of operation, the car has traveled about 17,000 km on city and country roads (we went on hiking trips, for berries and mushrooms). The brakes, axles, frame and body have proven excellent. The car handles the road well, is stable, maximum speed with full load is 64 km/h, and if only one driver, then on asphalt up to 80 km/h. The fuel supply is enough for 250 km of travel or approximately 4—4.5 hours of continuous driving. The car has good maneuverability.

V. TAMBOVTSEV