Any Amateur designer first interested in how much work is to be performed, what parts and components will have to do it yourself to, say, the machine went. Therefore, immediately list: going after strange had been collected or made the following main assemblies — gearbox in unit with the differential actuator of the rear wheels and the body of their suspension, podguzova frame, the brake mechanism. I have used some parts from a motorized С3Б: took her from the engine cooling system, differential, universal joints, springs and friction dampers rear suspension.

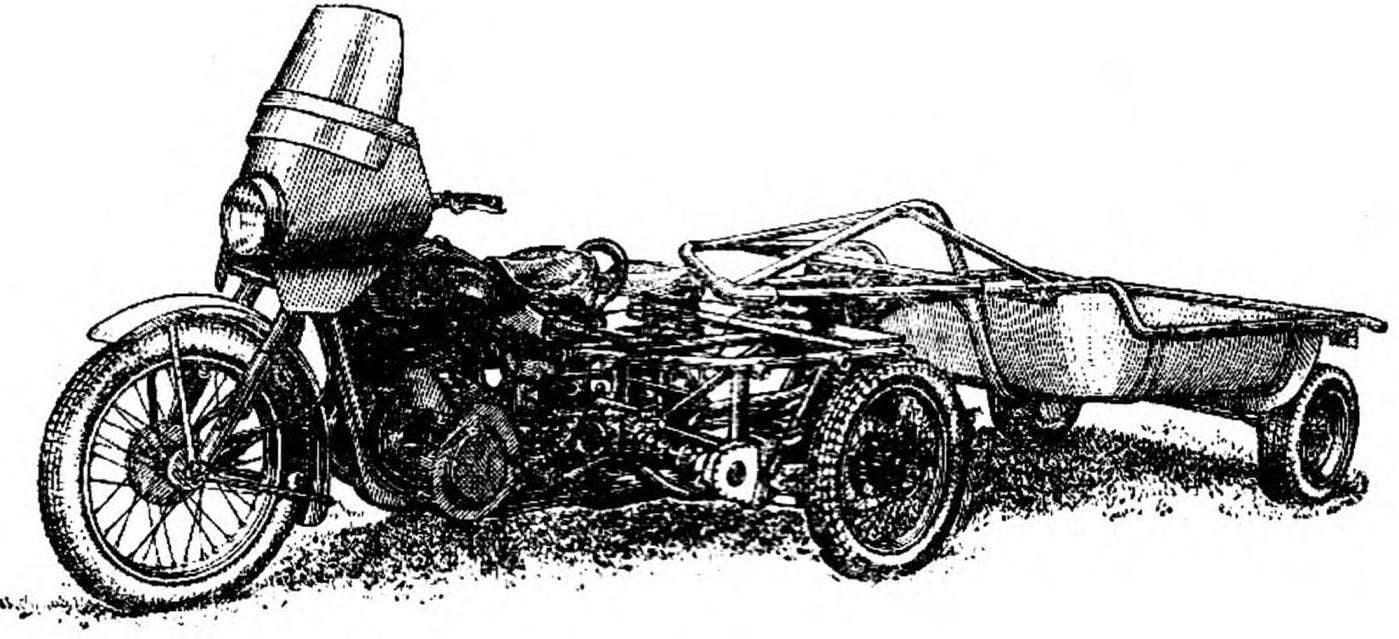

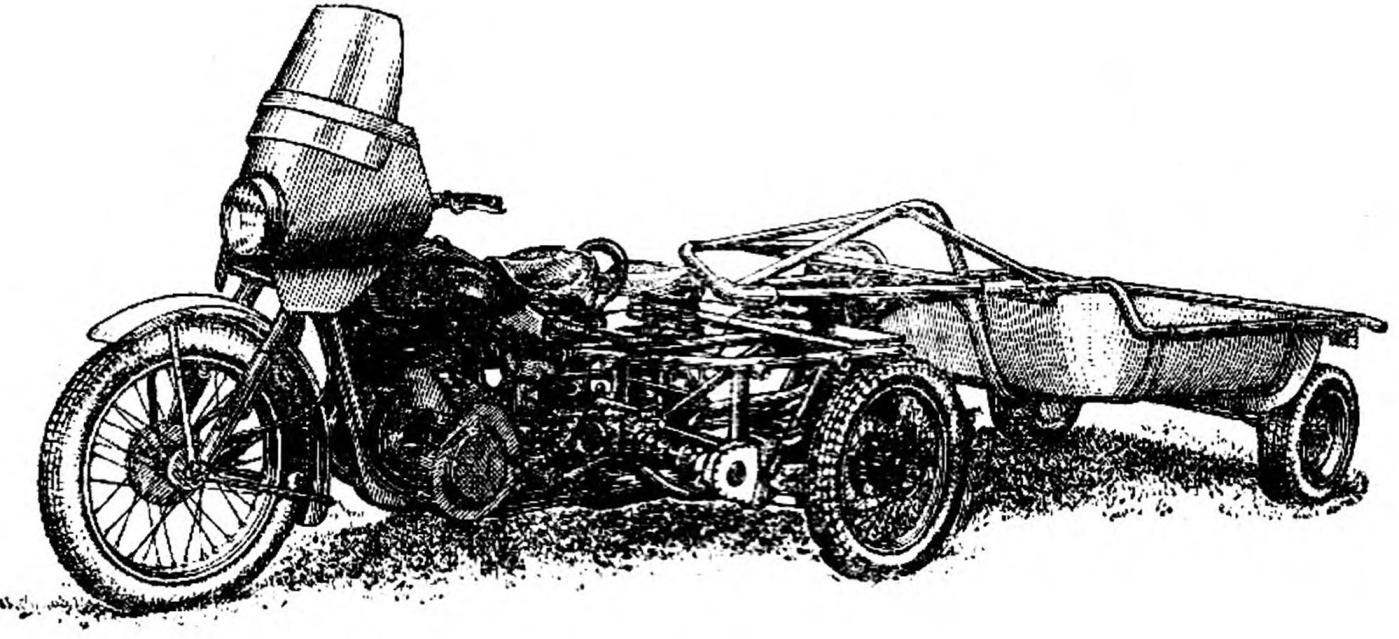

Built the car I would call mini-metamagic because its base 1850 mm gauge of 1100 mm, a basis — the motorbike. The alteration turned out three-wheel design, according to the scheme similar to a motor scooter cargo “the Ant”.

The engine left the staff, but added forced air cooling: left crankcase cover removed and replaced with a fan from С3Б with its casing.

The transmission from the engine to the rear wheels through the block “reducer — differential”.

the housing is made of aluminum for the block was cast a simple casting in the ground. In the manufacture of gear was used, some gear and shafts from the transmission Izha switching mechanism and the differential sidecar. The workers — three gears: two forward gears (two-stage) and one rear (single stage). Gear ratio for increased high-speed transmission of 1.14, for reduced working — 2,55, reverse of 2.41. The motive force from the engine is transmitted by roller chain directly to the output shaft of the gearbox: first gear on the intermediate shaft removed. For the drive circuit used two stars from the output gear 18 teeth gear ratio 1; tractive force from the gearbox to the rear wheels from differential output shafts (propeller nirami from С3Б) via the prop shafts, couplings, shafts intermediate supports and their leading sprocket (18 teeth) roller chain. For safety of operation and protection from contamination of the circuit placed in the casing. Stars are also closed housings and rubber boots. Bearings the intermediate supports are installed in special housings.

Fig. 1. The layout of major components and assemblies of the tractor:

1 — frame, 2 — rear, 3 — axis rear wheels, 4 — case circuit 5 — housing sprocket, 6 — Klondike support, 7 — the bearing of the intermediate shaft 8 to the clutch of the propeller shaft, 9 — eyelet fastening reducer, 10 — unit “gearbox— differential”, 11 — the engine of the motorcycle.

R and S. 2. Kinematics power of transmission:

1 — engine, 2 — roller chain, 3 — unit “gearbox — differential”, 4 — universal joint output shaft, 5 — propeller shaft, 6 — clutch, 7 — intermediate bearing, 8 — intermediate shaft, 9 — sprocket, 10 — sprocket driven rear wheel.

Fig. 3. Rear wheel drive:

1 — shaft nut, 2 — cheque, 3 — the adjusting washer, 4 external disk, 5 — bearing No. 305, 6 — hub 7 — external spacer sleeve, 8 inner spacer, 9 — axle, 10 — bearing No. 206, 11 — rubber bushing, 12 — internal drive, 13 felt oil seal, 14 — sprocket driven, 15 — leather oil seal, 16 — brake pad, 17 — stop screw M8 18 — spring suspension, 19 — spacer, 20 — the case of the suspension, 21 — housing sprocket, 22 — eccentric leash brake, the 23 — screw mount enclosure, 24 — bushing sprocket (bronze).

Mount splined shafts. The rear wheels have the regular driven sprocket with the brake drum: the gear ratio on the sprockets “leading — slave” — 2,33. All roller cap is also a staff — P-4. Clutch finger from the motorcycle M-72. To adjust chain tension provided by the possibility of some movement of the gear unit and intermediate supports.

Soft enough attenuation achieved by the elastic suspension of the rear axle on the springs from motorized with friction dampers and rubber buffers.

Suspension cantilever with triangular “legs” of the tubes. The axis of the bolts pass her in the eyes podgotovkoy frame, and axle mounts in the case and suspension is pressed by the fastening screw of the abutment. The housing consists of a box-shaped parts: a base and a pressure plate, one end welded to the “legs”, and with another — tightened bolt.

Sprocket driven rear wheel is mounted directly on the axis on the bronze bearing and the fingers (like the clutch) are connected to the inner drive wheel hub, which is drilled for that corresponding window. In addition, it as and external drive, there are holes under reinforced spokes Ø 5 mm. the Hub rotates on two bearings; the knot ends of the nut with the key.

Fig. 4. The clutch of the propeller shaft and drive sprocket:

1 — housing cover sprocket, 2 — shaft nut, 3 — the case of the sprocket 4 — body support, 5 — housing cap, 6 — intermediate shaft 7 — clutch 8 — gimbal$l, 9 — key, 10 — felt oil seal, 11 — thrust nut, 12 — ring, 13 — bearing No. 205, 14 — inner spacer 15, and outer spacer sleeve, 16 — bearing No. 2505, 17 — oil seal 18 — star.

Fig. 5. Podguzova frame.

Fig. 6. Suspension axis of the rear wheels:

1 — axle suspension, 2 — bushing (bronze), 3 — the bearing bushing (tube 38X2), 4 — the main attraction (tube 38X2), workpiece length 340 mm, 5 — axle, 6 — base suspension, 7 — clamping strip, 8 — stop, 9 — screw М8Х60, 10 — corner traction.

The frame of the tractor consists of two parts, connected together by pins: front from IZH-49 and rear podgotovkoj — homemade. The latter is a three-dimensional structure of longitudinal and transverse beams and struts. It is welded from pipes; curved side beam is supporting it is installed at the gusset plate support of intermediate shaft power transmission from the drive sprocket. To the frame by means of welded lugs and bracket for mounting of the gear unit, the intermediate axis of the brake rods, suspension rear wheel, muffler, tail light, hinge coupling of the semitrailer, and locks the body.

Front fork of the tractor normally. Drive forward manual brakes; rear wheel having a regular brake drums, — foot rods.

The frame can be installed tipping body with capacity 200 kg. the towing vehicle is able to tow a two-wheeled trailer with a load up to 600 kg. the frame has a special hinge for joining.

D. CHERNYSHEV, g. Kasli, Chelyabinsk region

Recommend to read “KALASKI” FURNITURE If chairs, armchairs and other furniture with metal or thin wooden legs, they can damage floors, especially linoleum. This will help avoid rubber (for example, from a wheelchair cane) or... FOLDABLE, WALL From garden benches from weathering are more likely to suffer seat: on the horizontal plane accumulated snow caps, russiausa in the thaw and rains have had a devastating effect. The...  Recently, in connection with the development of private farms has increased the demand for motor scooter cargo “the Ant”; especially in need of it rural. Only in 1983, will be sold 12 thousand of these machines. For a huge number of our villages is, of course, a little bit. But the motorcycles in the current year is expected to sell nearly half a million. Maybe here lies the reserve of the missing trucks for gardens? Indeed, many Amateur designers rebuild their cars in trucks. Did it D. I. Chernyshev from the city of Kasli of the Chelyabinsk region. He designed from your motorbike tricycle tractor with two rear driving wheels to use on farms, to carry on the truck-semitrailer vegetables and potatoes from the garden.

Recently, in connection with the development of private farms has increased the demand for motor scooter cargo “the Ant”; especially in need of it rural. Only in 1983, will be sold 12 thousand of these machines. For a huge number of our villages is, of course, a little bit. But the motorcycles in the current year is expected to sell nearly half a million. Maybe here lies the reserve of the missing trucks for gardens? Indeed, many Amateur designers rebuild their cars in trucks. Did it D. I. Chernyshev from the city of Kasli of the Chelyabinsk region. He designed from your motorbike tricycle tractor with two rear driving wheels to use on farms, to carry on the truck-semitrailer vegetables and potatoes from the garden.