The family of tricycles has been joined by another interesting machine — the “combi”, which was invariably popular with visitors to the NTTM-76 exhibition. It was created at the Kharkiv Bicycle Plant under the direction of designer Mykola Oleksiyovych Makohonenko. That is why we are returning to the “bicycle theme” again — and readers should not be surprised: the improvement of bicycles, on the one hand, and the ways and possibilities of their use — on the other, have turned from a purely technical matter into a serious socio-public problem. Life has shown that internal combustion engines are increasingly turning from man’s friends into his enemies. By burning huge amounts of oxygen so necessary to sustain life on earth, they simultaneously pollute the air with exhaust gases and water with waste lubricants.

This is why the “invention of bicycles” is now so actively continuing. There are already multi-seat and multi-wheel bicycles, velocars and velomobiles. Even bicycle planes! With a bicycle drive on a propeller, it has been repeatedly possible to take off in light aircraft (though purely experimental and still very imperfect).

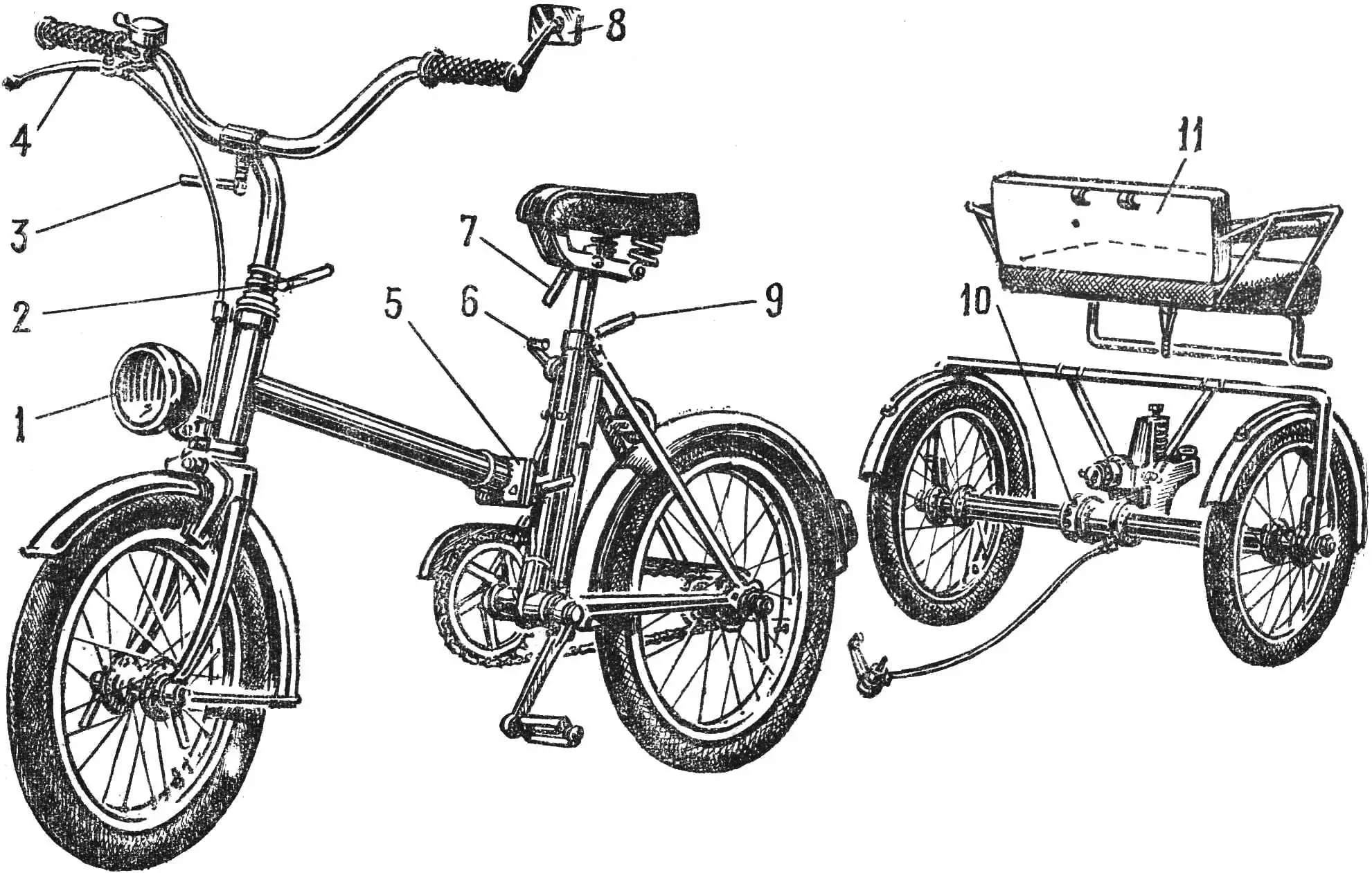

1 — headlight, 2 — handlebar height adjustment lever, 3 — handlebar tilt adjustment lever, 4 — hand brake lever, 5 — frame disconnect unit, 6 — rear axle stop lever, 7 — saddle tilt adjustment lever, 8 — rearview mirror, 9 — saddle height adjustment lever, 10 — rear axle assembly, 11 — child seat.

Our magazine has repeatedly introduced readers to new bicycle designs and their individual components. But all these materials mainly concerned single-track, or, as they are usually called, two-wheeled machines. Meanwhile, in recent times, designers have become interested in tricycles. There are many unresolved issues here. This is precisely why the tricycle did not gain wide distribution and was intended mainly for young children, although after some design improvements it could become an excellent means of transportation, including in rural areas.

A major, if not the main, disadvantage of a tricycle with a front steering wheel was poor stability on turns. The machine easily overturned and was unsafe to operate. Let us recall: the stability of two-wheeled machines on turns is ensured by internal lean. The Kharkiv tricycle “combi” is so interesting precisely because its design provides for the possibility of creating lean on turns, and therefore increasing stability, ensuring safe riding at any operational speeds. But that’s not all: the “combi” can be converted into a regular two-wheeled bicycle in a few minutes, which folds in half for transport and storage, similar to the “Desna” bicycle already produced by the Zhukovsky plant and widely recognized. The design and dimensions of the front part of the “Desna” and “combi” are completely identical, as are the wheels (20″ size).

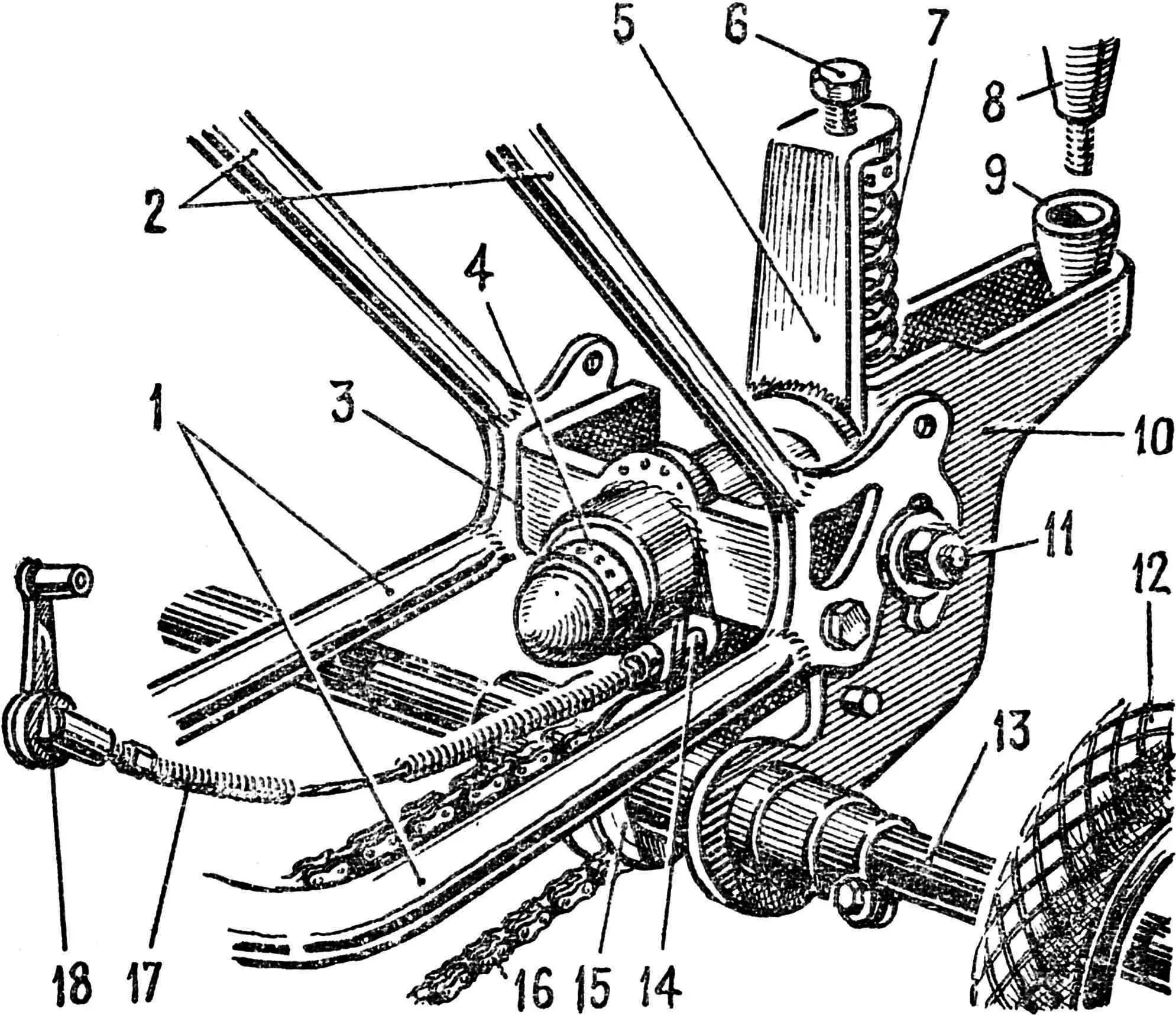

The general view of the “combi” bicycle is shown in Figure 1. To convert it from two-wheeled to three-wheeled, the following operations must be performed: remove the rear wheel by disconnecting the chain; place the rear wheel on the rear axle, install the rear axle on the rear fork stays, close the chain and adjust its tension. A single conical bolt can be used to mount on the rear axle: a luggage basket measuring 600X400 mm, a luggage box 600X600X400 mm, or a soft seat for carrying a child, equipped with safety belts. The mechanism that allows the bicycle to lean when turning is of greatest interest. It is arranged as follows: the front part of the rear axle has a bracket rotating around the longitudinal axis (a bicycle hub is used here); the rotation of the frame is limited by stops and a vertically standing spiral spring; its tension is adjusted by a bolt. The frame can be locked by a pin controlled by a lever, with which the pin is connected by a flexible cable. When the frame is locked, the rider cannot lean the bicycle; by unlocking the frame, they get the opportunity to create the necessary lean, the maximum value of which is softly regulated by the spring. Tests of the bicycle showed that such a system works very reliably and there is no need to “retrain” to ride it. To prevent the chain from falling off while riding, the rear axle is equipped with protective cheeks at the driven sprocket.

1 — lower rear fork stays, 2 — upper stays, 3 — rear axle bracket, 4 — adjustment sleeve, 5 — spring post, 6 — adjustment bolt, 7 — spring, 8 — luggage basket mounting cone, 9 — conical socket, 10 — rear axle housing, 11 — rear fork to bracket mounting bolt, 12 — wheel, 13 — rear axle, 14 — stop, 15 — drive chain sprocket cheek, 16 — drive chain, 17 — stop cable, 18 — stop lever (located under the saddle).

The “combi” bicycle is planned to be produced in series, and soon it can be seen in stores. But we think that enthusiasts of technical creativity are capable of creating similar attachments for any industrial bicycles. At the same time, it is not at all necessary to completely copy the Kharkiv design.

“In Moscow at the USSR Exhibition of Economic Achievements, the NTTM-76 exhibition was successfully held. I saw a lot of interesting things there, but I especially liked the tricycle for elderly people.

It was created in Kharkiv, and as far as I know, it exists in a single copy so far.

Therefore, I would like to learn more about the technical features and innovations applied in its design.”

S. UTKOV