When on the table a lot of snacks or treats I want to try everything. But some of the dishes are located nearby, while others have to stretch, or to have conveyed, and this, of course, is not very convenient.

When on the table a lot of snacks or treats I want to try everything. But some of the dishes are located nearby, while others have to stretch, or to have conveyed, and this, of course, is not very convenient.

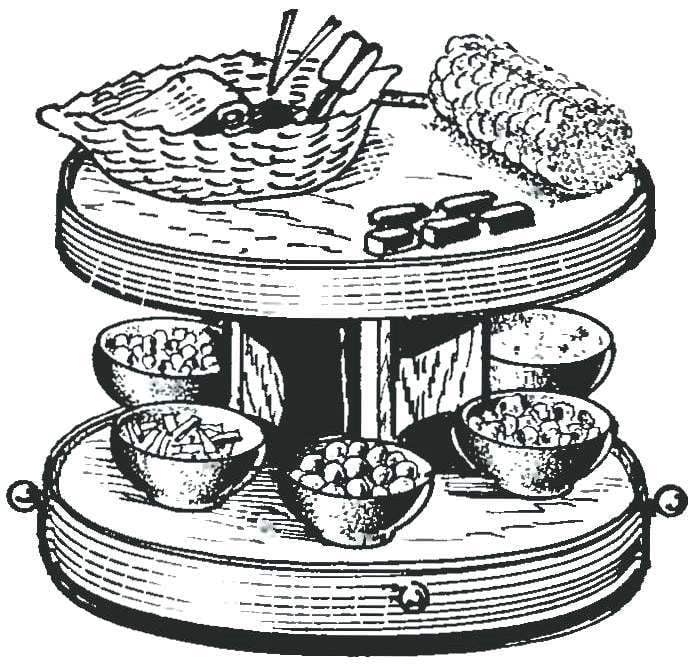

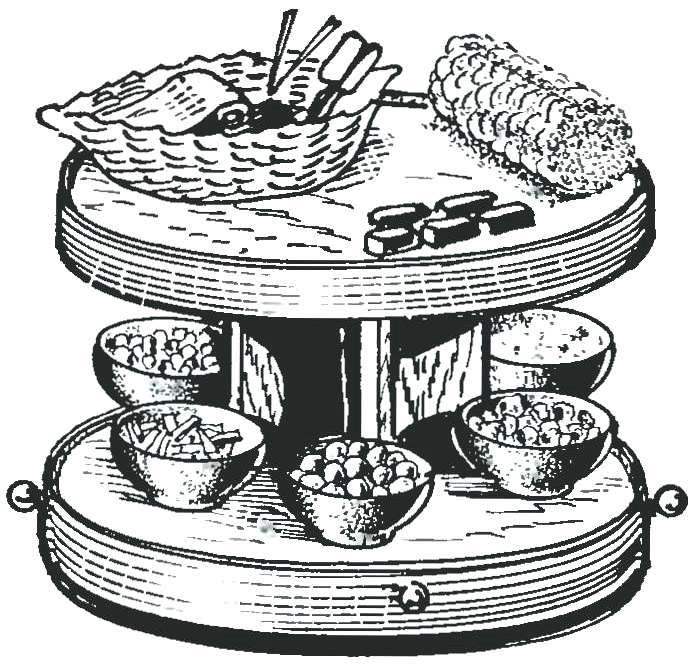

In these cases, would be bailed out the original Board rack-spinner, proposed by the Hungarian magazine “Earmaster”. It is set in the center of the table and with cool shape and ability to turn around its axis and capacity (as dishes or vases are arranged in two levels), allows each of the guests without much concern for the neighbors on the table to use either a food—simply turning the shelf, bringing, thus, need food.

The device shelves are extremely simple, so it is available for self-production. Materials required pieces of Board, plywood and wooden rod to the axis of rotation and handles.

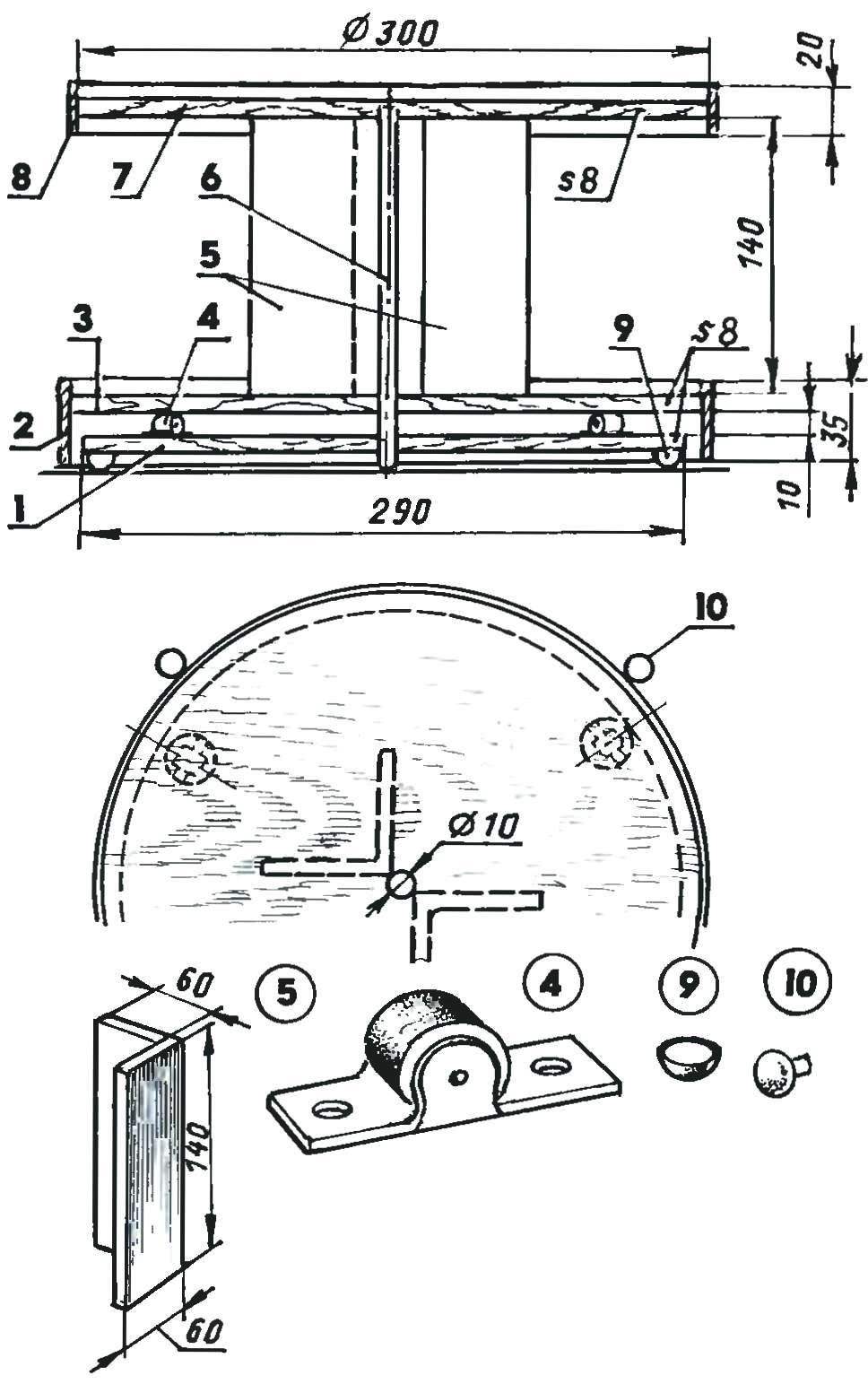

Fig. 1. Table rotating shelf:

1 — base; 2 — fencing of the lower shelves; 3 — bottom shelf; 4 — rollers; 5 — rack; 6 — axis; 7 — the upper shelf; 8 — fence top shelves; 9 — stem; 10 — handle

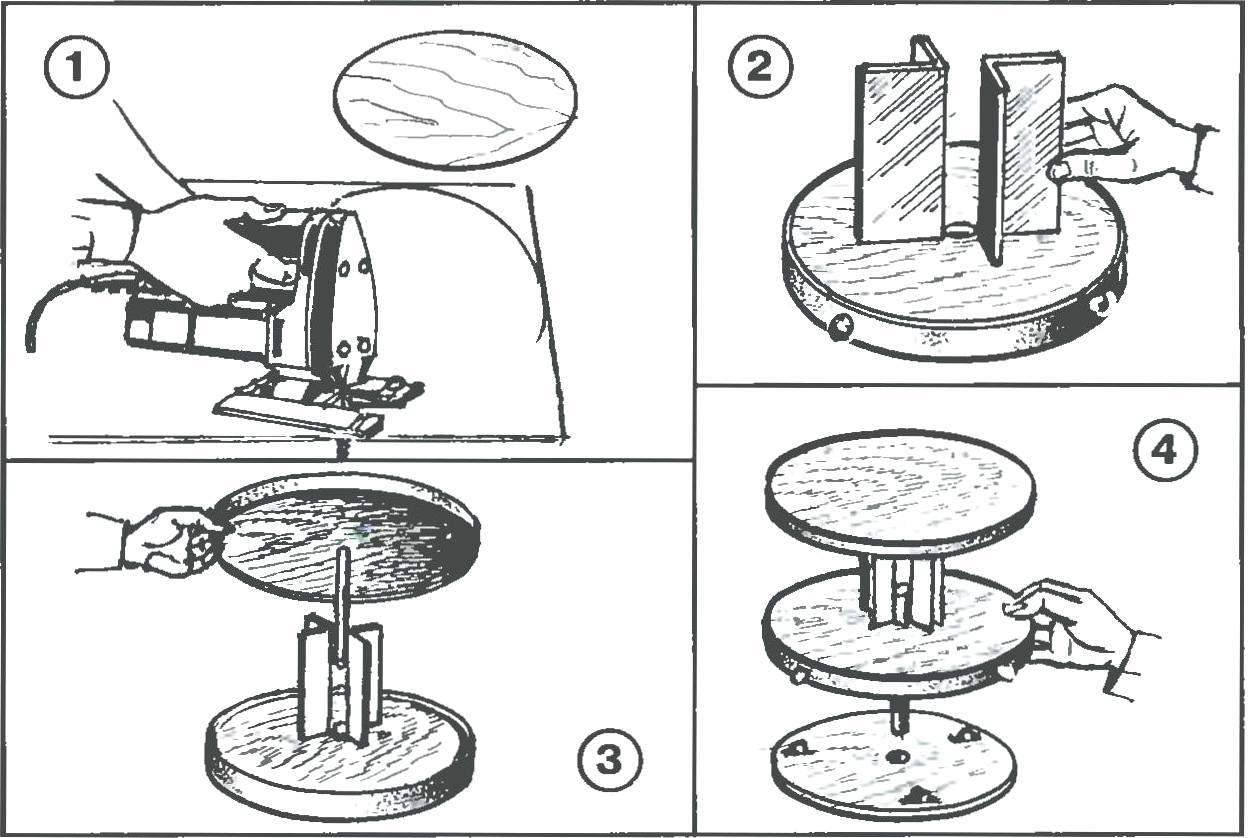

So, out of plywood with a thickness of about 8 mm cut two circles of diameter 300 mm — upper and lower shelves. The first small nails attached thin plywood strip fencing with a width of 20 mm and to the lower Cup of the same plywood strip of shirinoi 35 mm and four handles-“mushrooms” from a wooden rod with a diameter of 20 mm. it is glue (carpentry, casein, PVA) are glued boards of two area-stand 140×60 mm, between which in the centre circle pre-drilled through hole the axis of rotation with a diameter of 10 mm. Is the same, but a blind hole is drilled in the upper circle, which is glued in the end of the axis then the circle with glue connects with the corners already glued to the bottom of a mug. The axis thus passes into the hole of the lower shelves.

It remains to assemble the base, which is a wooden circle with a diameter of 290 mm, with a hole in the center near the axis of rotation. Stick four legs on the bottom of the wooden rod, and the top set of three miniature wheel (for example, used as Cabinet roller latches).

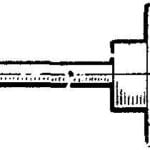

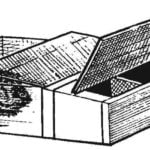

Fig. 2. The sequence of manufacturing shelves:

1 — cutting out circular blanks; 2 — glue stands; 3 — install the top shelf with the axis; 4 — completion

For these videos rests in the final Assembly and then rotates them all so made shelf-spinner.

Because the structure is wooden, its finish fits all traditional operations on sanding, staining or varnishing, are used in the manufacture of furniture.