…A young driver sits on a miniature, elegantly designed scooter and starts moving. There’s no familiar crackling sound, no annoying smoke.

What’s the matter? Looking more closely, we discover that this scooter has an electric motor installed instead of the usual internal combustion engine. The scooter is electric!

We admit that such machines are not yet available for sale. The electric scooter exists in a single copy and was built not in a factory, but at the Alma-Ata Regional Station of Young Technicians under the guidance of teacher V. A. Yegorov. This scooter is now being demonstrated in the “Young Naturalists and Technicians” pavilion of the Exhibition of Achievements of the National Economy, invariably arousing interest and surprise among both children and adult visitors. And no wonder! After all, such a machine opens up the widest prospects for training young drivers regardless of the season and weather conditions, in closed premises, in children’s parks, on sports grounds. The refueling problem is solved simply: for this, it’s enough to connect to the city electrical network for a couple of hours — and the discharged battery will be ready for work again. The electric scooter can be stored in a residential apartment, since it’s safe in terms of fire and takes up very little space. What can we say — the new machine has many advantages compared to its gasoline “relatives”. Of course, it would be premature to rejoice that an electric scooter has been created. There are still no — neither here nor abroad — sufficiently capacious and light batteries. To create the exhibit in question, we had to use conventional batteries — heavy, not very capacious, but the guys couldn’t outpace the many scientific teams working on electric cars and motorcycles. Their task was different — to get acquainted with the most complex and most relevant problem of today’s technology, to prepare themselves for further research in this direction.

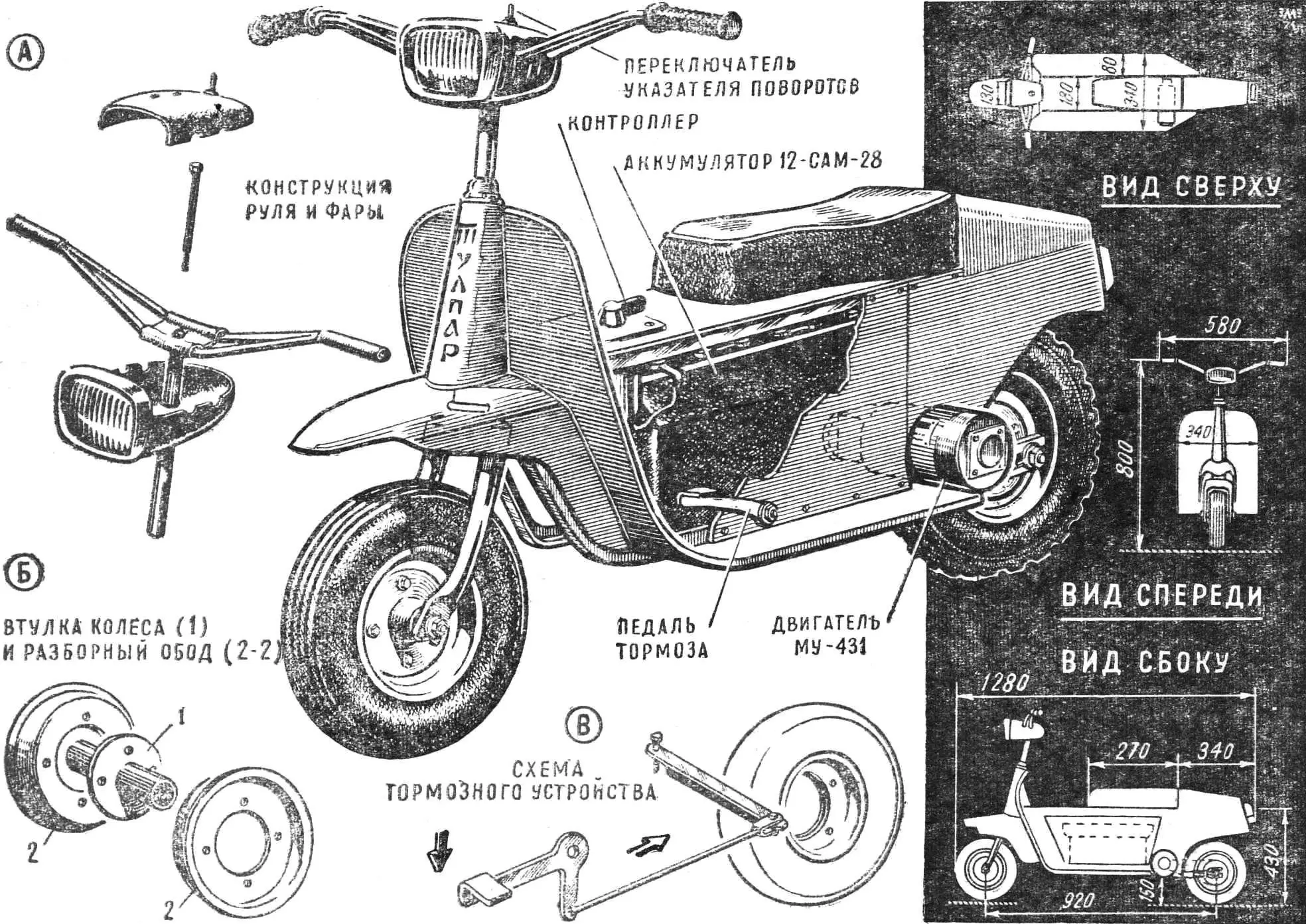

The electric scooter we started our story about is called “Tulpar”. Its general view with partially exposed internals is shown in the figure — a diagram in three projections.

Since “Tulpar” is intended primarily for educational work in closed premises with a flat floor, its chassis does not have suspension. This significantly simplifies construction and allows the structure to be lightened, which is very important for compensating for the large weight of the battery pack.

The frame is of truss type, rectangular in cross-section, welded from thin-walled steel tubes and angles. The frame can also be assembled with bolts, using gussets (“knits”). But such an option will be less strong and heavier. You can also use a children’s scooter frame, welding the missing load-bearing elements and parts for battery mounting to it.

The wheels of “Tulpar” are aircraft-type pneumatic tires. It’s better to use tires with a diameter from 225 to 300 mm or those used by karting enthusiasts. They’re easier to obtain through local DOSAAF organizations. However, the tread pattern of these tires, designed specifically for microcars — karts, has a wide and flat running surface. Therefore, they should be turned on a lathe, making them more rounded — to improve the scooter’s maneuverability.

Wheel discs (see figure) depending on the tire type can also be manufactured on a lathe, either turned from a blank, or pressed (rolled) from sheet metal, as karting enthusiasts usually do. The wheel hubs shown in the drawing are designed for tires used by karting enthusiasts; if tires of another type are available, they will have to be changed accordingly so that the tire together with the disc can be easily disassembled if necessary for repair or replacement. As experience in operating microcars-karts, as well as scooters, has shown, the best wheel design should be considered a system of two discs (“plates”), fastened around the perimeter with bolts. Dismantling and repair of wheels of this type does not present difficulties even for elementary school students, while mounting tires on motorcycle-type rims requires skills and physical strength.

The “Tulpar” electric scooter is equipped with an MU-431 motor with a reduction gearbox. This unit is factory-made, compact and reliable in operation. (MU-431 motors are widely used by young technicians on various self-propelled models.) If such a motor cannot be obtained, the reduction gear will have to be made independently, using available gear mechanisms (for example, a gearbox from a hand drill, a bench grinder, etc.). Knowing the number of revolutions of the motor shaft and the tire diameter, it’s not difficult to calculate what gear ratio needs to be obtained from the gearbox so that the machine’s speed does not exceed 35 — 40 km/h.

The transmission from the gearbox to the drive wheel is carried out by a bicycle or moped roller chain. The gear ratio is about 1 : 2 (the drive sprocket on the gearbox shaft has 10 teeth, the driven one on the rear wheel — 23). These gears are selected from available bicycle or moped parts. The drive chain tension is carried out in the usual way — using eye bolts mounted on the rear axle.

The engine operating mode (and therefore the machine’s speed) is controlled by a controller mounted in the upper panel of the body housing, in front of the driver’s seat. The controller has three lever positions: “off”, “low speed” and “full speed”. Instead of a controller, a rheostat of appropriate current capacity can be used. The speed control of the electric scooter will be smoother in this case. Next to the controller handle on the panel are toggle switches for controlling lighting devices.

The braking device of the “Tulpar” electric scooter consists of a crossbar pressed by a foot pedal against the tread of the rear wheel. For better grip, the crossbar has a friction material pad. The headlight and handlebar are homemade! They are made in accordance with the requirements of today’s industrial aesthetics and give the machine an elegant, modern appearance.

In the opinion of the editorial board, a useful improvement to “Tulpar” would be the installation of a rectifier for charging the battery directly on the machine. This would free “Tulpar” from the need to recharge in one specific place and expand the possibilities of its use.

«M-K» 12’71, G. STEPANOV