The desire to design and build a mini-truck came and got me. By this time I already had experience of manufacture of snowmobile track (see “modelist-Konstruktor” No. 11 of 1991) and other equipment that I was building pretty quickly. However, this case came what is called thoroughly. Designed it slowly, studying the journals and books the experience of craftsmen and specialists, draw the layout, using large-scale silhouettes (front and side) of a man his height (170 cm) and aggregates available and expected to be used.

For the sample taken seen on TV truck motorickshaws, countless scurrying through the streets and roads in Indochina. As components mainly used decommissioned units and spare parts motorized scooter CPAS and “Ant” as the most affordable at the time, and the cheapest. Blind even large-scale plasticine (dummy) model of this truck. So gradually came to the so-called wagon layout scheme of a double four-wheeled light truck of a vehicle with the front leading and driven wheels.

Production of mini-motomobile started from the body, but rather with restoration of old, from scooter cargo “the Ant”. The body is further reinforced welded steel gussets, setting them in the corners of the dock vertical and horizontal elements of the power set of the frame.

Next steel water pipe outer diameter 32 mm produced two spar frames — cut to size and bent according to the drawing, the heating of the blowtorch. Installing them apart at a distance equal to the width of the gearbox housing (used is also from scooter cargo “the Ant”), the front end was welded to the bumper, and the rear part connected by several cross members and here on the strut uprights secured the body. The front part side members, and front bumper, formed the basis of the frame of the cab, which is made mainly from steel pipe with outer diameter of 20 mm and a wall thickness of 1.5 mm. the Frame consists of frames in the door openings, rear struts, cross members and longitudinal members of the roof. The windshield frame formed of the upper part of the uprights of the door openings, the front cross member of the roof at the top and one cross member, connecting the front door of the rack about in the middle. To the frame of the cab can be attributed to the top element of the bumper, as well as several short stands, connecting it (the element) and the mid crossmember. All together they form the engine compartment, although the engine for the most part located in the cab and is covered by a cover hood. This engine can be attributed to the disadvantages of the design, but it is very compact, and the kickstarter along with the shifter was under my right foot.

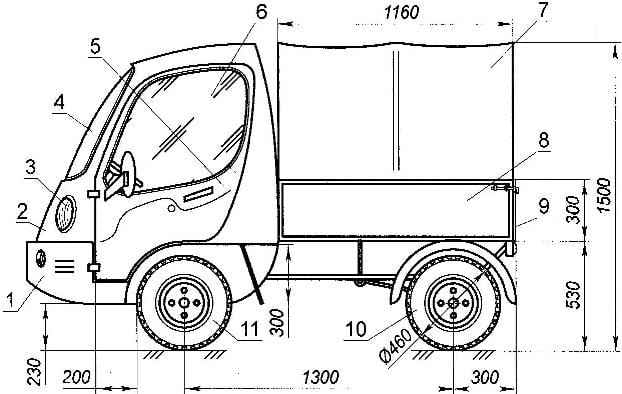

Cargo micromotori:

1 —a bumper; 2—forward facing (steel sheet s1); 3—headlight (from the farm); 4—windshield (of the car “the Zhiguli”); 5—door; 6—window, door (acrylic, 2); 7—tent (fabric Teza); 8—body (cargo scooter “Ant”); 9—rear opening side; 10 is a rear (reference) wheel (2 PCs); 11 —the front (driven, leading) wheel (2); 12—seat (2); 13 — rear observation window (plexiglass); 14—the wheel (from a motor scooter cargo “the Ant”); 15—rear view mirror (purchased product); 16—arch tent (duralumin pipe d14, 3). 17—cockpit (sheet s1); 18 — rear axle (pipe d60)

Two-stroke engine working volume of 500 cm3 and a power of 13 HP with forced air cooling used motorcycle “Tula”.

Rear axle of the truck is not leading, but because it was very simple. It consists of a homemade beam made from steel pipe with outer diameter 60 mm and wheels with hubs from motorized FDD. But the suspension bridge is like a real car. It contains all the necessary elements: there are longitudinal and transverse rods with rubber blocks, coil springs and hydraulic shock absorbers.

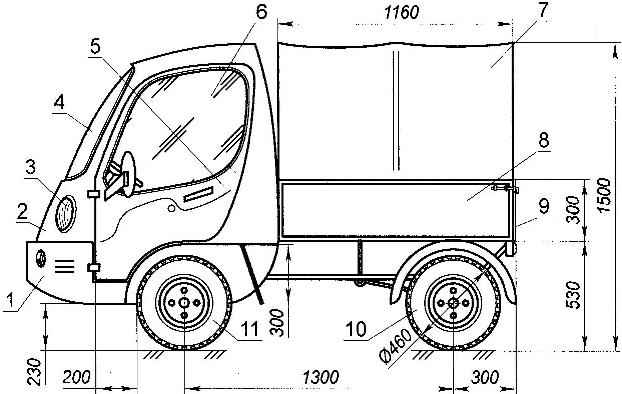

The layout of the truck (parts POS. 6,12 — cargo scooter “Ant”; the details of the poses. 1, 2, 3, 4, 5, 7, 11, 18, 19, 20 made of tube Ø20):

1 — framing of the doorway; 2—crossbar roof; 3 —the longitudinal element of the frame of the roof; 4 front cabin; 5—side grille (extensions of sides) of the body; 6—body; 7—strut front body (2); 8—wheel (sidecar, 4x); 9—longitudinal rod rear axle 2 PCs); 10—frame spar (tube d32, 2); 11 —arc of the wheel housing (2); 12—reducer; 13—the rake of the steering mechanism (motorized); 14 — bumper (tube d32); 15—engine (from a motorcycle “Tula”); 16—steering propeller shaft; 17 — the starter lever and shift lever; 18—rack mounting reducer (4 PCs); 19 — rack frame (4 PCs); 20—front facing (4 PCs); 21 —node front wheel; 22—coil spring suspension-rear axle (2 pieces); 23 —lateral rod; 24 — rear axle beam (tube d60); 25 – rubber (6 PCs.); 26—shock absorber (2 PCs.); 27 — rear opening side of the body

Front axle is a more complex design, since, as mentioned above, he is leading, and manageable. Wheels with hubs and steering blocks used on the sidecar, and as the wheel drive — the propeller shaft from “Ant”. Suspension front axle carried out at spring-hydraulic shock absorbers from some farm equipment.

The steering gear (pinion-rack), bagel taken from the sidecar, but the solid steering shaft had to be replaced with a composite homemade u-joints.

Brakes — mechanical and only on the rear wheels.

Seat — foam, covered with leather, with the reason of duralumin sheet.

Cabin cushions — steel sheet mm thickness. The same sheet is closed and the wheelhouse, it made the cover hood. In the rear of the cab cut out aperture in him, as in a door window inserted plexiglass. The windshield is cut from automotive laminated glass.

Knot front wheel (detail POS. 4, 5,7, 8, from motor scooter cargo “the Ant”):

1 —wheel; 2 — ball joint (from the car “Lada”); 3 —arm; 4 — universal joint; 5 — axis; 6—tie-rod; 7 — spring; 8—damper; 9—the top support of the shock absorber (steel wheel); 10—hub (“Ant); 11—knuckle

Headlights and sidelights tractor, lights are installed in the niches of the front fascia.

The body was made of “blown” (without the front and rear walls) tent made of waterproof fabric.

The truck could carry a load weighing up to 350 kg, while the empty speed is “rolled over” for 50 km/h.

Thereafter it was intended to insulate the cabin from the inside with polyurethane, but this did not have to come true. To ride around the yard on this truck did not make sense, and check it in for state inspection has caused much confusion and in the end the car was disassembled into assemblies and parts used for other designs.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.

Recommend to read INVITED TO THE CASTLE… When I opened this, the most usual door of the model apartment I was not in a normal hallway, and... However, in order. Inside the door was as if hammered together from thick oak, the... GAS LEAKAGE SENSOR Explosions and fires resulting from gas leaks, unfortunately, are not uncommon. Recognizing the work of administrative bodies and emergency services, hams designers can do something...

Scroll back to top

Sketch small motomobile truck, about which speech will go, I found in an old folder during the big tidy-bulkhead in garage archive. They are inspired by memories of the days when the passion for technical creativity: the production of self-made cars, boats, aircraft and various other structures have been possible to say mass.

Sketch small motomobile truck, about which speech will go, I found in an old folder during the big tidy-bulkhead in garage archive. They are inspired by memories of the days when the passion for technical creativity: the production of self-made cars, boats, aircraft and various other structures have been possible to say mass.