From seamless steel pipe Ø190 mm sliced ring height 100 mm (blank). It is machined on its outer diameter and both sides othertown; welded ring flanges. To the body welded two sleeves to connect the gearbox with the rear axle. Exactly in the center, perpendicular to the forming, welded to another bushing for the neck of the housing shaft pinion gear.

A sequence of further works. In the center of the opposite wall electric grab boss 0 70 mm — for installation of the housing and the lathe, face piercing holes, the neck, and then ring-flanges welded to the hull, butt, removing the uncertainty of electric welding. Face piercing holes in the casing at the inner diameter to the wall thickness of 4-5 mm. For tubes of accumulation and drain the oil cut thread М16ХІ.5 and М14Х1.5, respectively.

The leading gear is made with the shaft diameter of 25 ± 0.1 mm. Therefore, the shaft is applied a layer of chrome, and then grind for landing bearings. The first of them back, No. 7205, roller, tapered. It takes the main axial and radial loads. The other two — ball, No. 205, for radial loads. Front and second rear bearings are fixed in the glass retaining ring. The gap is adjustable race rear mounting flange of the propeller shaft.

To install side clearance gear are two adjustment nuts, which are fixed stoppers and pressed a flange with a rubber protective cover the axle shaft. Side clearance between the teeth leading and driven gears must be within 0.08—0.22 mm. the bearing Housings of the differential adjusting nuts taken ready-made, are attached to the housing cover bolts. Details application prefabrication simplifies the manufacture of the gearbox and, most importantly, increases its reliability and durability.

The body of duralumin panels 1.5 mm thick. the Basis of it serves as a frame to which is attached by bolts M8 frame, riveted corners of duralumin 45X45 mm. For the relief of the frame in the corners of the welded holes Ø 18 mm.

The bracket of the gearbox.

The suspension arm.

Rear axle.

The jointing of panels is reinforced with overlays. The nose and tail rounded frame is enhanced with a scarf sheet of aluminum with a thickness of 4 mm. the surface of the body is thoroughly cleaned, irregularities embedded putty on epoxy resin.

Taken from the windshield of the car “Moskvich-412”. For curved glass frame from dural area with panels in the corners in the form of glass strips with a thickness of 1.5 mm of aluminum and duralumin in two layers! Frame covered with fiberglass epoxy resin. The design of it was hard.

The profile of the front part is made also by pasting strips of aluminium with a thickness of 1 mm and of glass epoxy resin.

Seat foam rubber and foam rubber. To reduce the noise level in the car inside, glued felt, the engine hood is lined with foam on the inside and outside.

The variant of the car and hard top, but the preferred installation is easily removable awning as made on the “Microse”.

Fans, who will undertake the construction of similar micro-car, only, I suggest to replace the steering knuckles (hub) of the front axle. Installation of fists with ball joint (front axle ZAZ-966) the great difficulty. Another option is to make a new bridge using the same details. Ball joints are sealed and are more durable, much stronger compared to the same host bridge motorized С3А. They will improve ride quality inputs to directly affect reliability.

A. STREMOUSOV, locksmith, Orenburg

Recommend to read

“MNOGOTSVETIE” CUSHION

“MNOGOTSVETIE” CUSHION

For painting walls, fences and other large surfaces are often used paint rollers. However, if you use several different paint colors, it is necessary to acquire a set of rollers or spend... BOTH A PATHWAY AND DRAINAGE

BOTH A PATHWAY AND DRAINAGE

Our magazine has already dedicated several articles to the topic of making good use of such a seemingly useless material as various bottles. And today, we are once again returning to this...

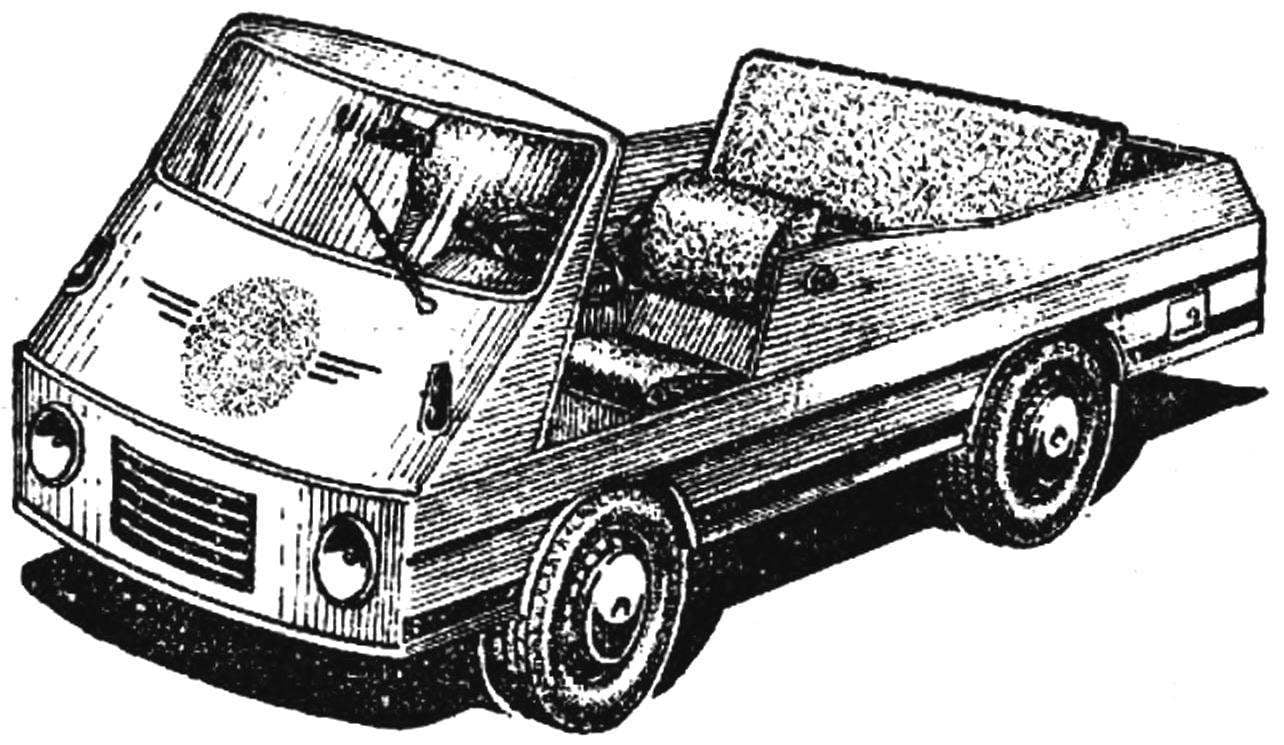

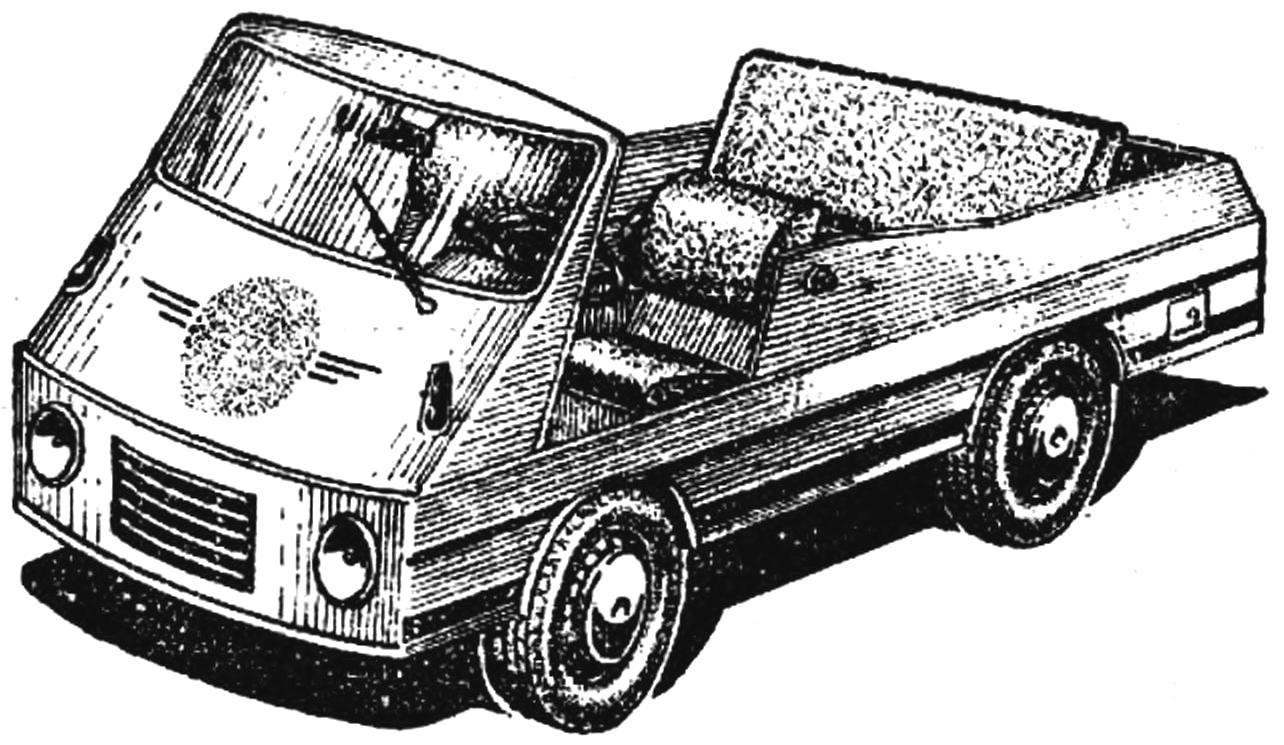

Practice Amateur autocostruzione, including my personal, shows that wagon layout with the use of wheels with tyre size 5X10 (motorized С3А) provides a very convenient and rational design of little micro-car. That is my “Mikrus”. It is stable, holds the road well, speeds up to 90 km/h the engine under the driver seat and the passenger increases the useful volume, makes the body more succinct. The interior is spacious, seats are arranged, which is convenient for overnight stay and rest. One cannot underestimate the capacious trunk: there is, for example, you can install a baby carriage, not looking. In the right corner of the trunk easy to install the battery, and in the bottom of the fuel tank from the car ZAZ-966. Made for the base, they both increase the load on the rear axle, which improves traction of the drive wheels. And convenient access to the engine: the hood folds with the seat, driver and passenger; repairing and explore without leaving the salon. For transportation of bulky goods — TV, washing machine, fridge — enough to move the back seat forward and fold the seatback or delete it. Get a small truck.

Practice Amateur autocostruzione, including my personal, shows that wagon layout with the use of wheels with tyre size 5X10 (motorized С3А) provides a very convenient and rational design of little micro-car. That is my “Mikrus”. It is stable, holds the road well, speeds up to 90 km/h the engine under the driver seat and the passenger increases the useful volume, makes the body more succinct. The interior is spacious, seats are arranged, which is convenient for overnight stay and rest. One cannot underestimate the capacious trunk: there is, for example, you can install a baby carriage, not looking. In the right corner of the trunk easy to install the battery, and in the bottom of the fuel tank from the car ZAZ-966. Made for the base, they both increase the load on the rear axle, which improves traction of the drive wheels. And convenient access to the engine: the hood folds with the seat, driver and passenger; repairing and explore without leaving the salon. For transportation of bulky goods — TV, washing machine, fridge — enough to move the back seat forward and fold the seatback or delete it. Get a small truck.